Steel pipe assembly-welding device and rapid installation and movement method thereof

A technology of steel pipe groups and steel pipes, applied in auxiliary devices, welding equipment, tubular objects, etc., can solve the problems of low economic value of the project, small design section, inconvenient installation, etc., and achieve the goals of reducing preparation time, increasing added value, and optimizing design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

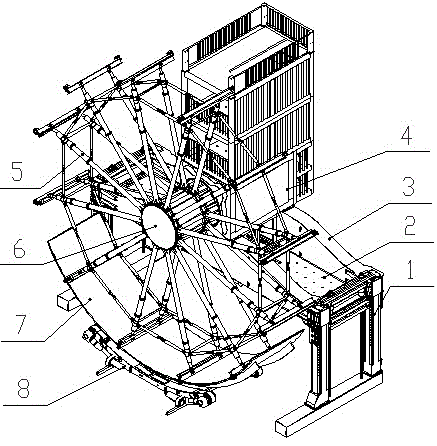

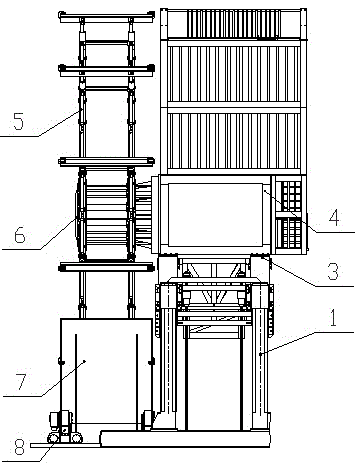

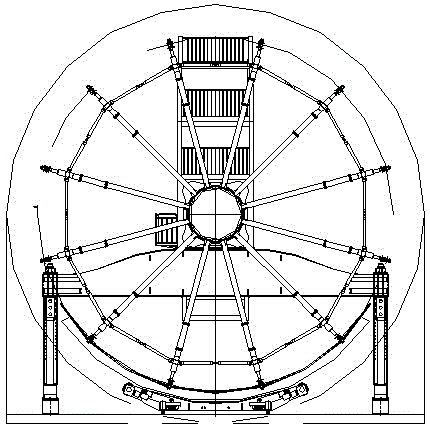

[0028] Such as Figure 1 to Figure 4 As shown, a steel pipe assembly welding device includes a column 1, a beam 2 and a main body 4, the two ends of the beam 2 are connected to the column 1, the main body shaft 6 is connected with a rotary support frame 5, and the main body 4. Set above the crossbeam 2, the connection between the crossbeam 2 and the column 1 has a positioning clamping and lifting device, and the bottom of the beam 2 or the column 1 is provided with a walking device 9; The structure can reduce the height of the whole device, greatly reduce the overall volume of the device, and facilitate transportation and transfer.

[0029] Such as Figure 1 to Figure 4 As shown, the lower part of the main body 4 is connected with a horizontal turning device, and the horizontal turning device is installed on the supporting plate 3 of the main body above the beam; the horizontal turning of the main body reduces the transport width of the entire assembly welding device.

[003...

Embodiment 2

[0039] In this embodiment, the steel pipe assembly and welding device is applied to on-site assembly and welding of large steel pipes in a certain tunnel.

[0040] Such as Figure 1 to Figure 4 As shown, a steel pipe assembly welding device includes a column 1, a beam 2 and a main body 4, the two ends of the beam 2 are connected to the column 1, the main body shaft 6 is connected with a rotary support frame 5, and the main body 4. Set above the crossbeam 2, the connection between the crossbeam 2 and the column 1 has a positioning clamping and lifting device, and the bottom of the beam 2 or the column 1 is provided with a walking device 9; The structure can reduce the height of the whole device, greatly reduce the overall volume of the device, and facilitate transportation and transfer.

[0041] Such as Figure 1 to Figure 4 As shown, the lower part of the main body 4 is connected with a horizontal turning device, and the horizontal turning device is installed on the supporting...

Embodiment 3

[0050] In this embodiment, the main difference from Embodiment 1 and Embodiment 2 is that the rotating device under the main body is changed to a translation device, and the traveling device adopts a track-type seam welding trolley.

[0051] Such as Figure 1 to Figure 4 As shown, a steel pipe assembly welding device includes a column 1, a beam 2 and a main body 4, the two ends of the beam 2 are connected to the column 1, the main body shaft 6 is connected with a rotary support frame 5, and the main body 4 is arranged above the beam 2, the lower part of the main body 4 is connected with a translation device, the connection between the beam 2 and the column 1 has positioning clamping and lifting settings, and the device is also equipped with a walking device 9.

[0052] In this embodiment, the moving direction of the translation device is perpendicular to the crossbeam, so that the main body can move towards the middle of the whole device, reducing the width of the entire assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com