Rotary jet grouting bar inserting type mini pile construction method

A construction method and technology of micropile, applied in the direction of sheet pile wall, foundation structure engineering, construction, etc., can solve the problems of affecting the stability of the foundation, inapplicability, and increasing the time consumption of construction

Inactive Publication Date: 2017-03-22

浙江省岩土基础有限公司

View PDF7 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

During the construction of the micropile, two hole cleaning operations are required, which will increase the time consumption of the construction. During the hole cleaning process, the foundation around the drill hole will be scoured, which will affect the stability of the foundation. Therefore, it is not suitable for the built Piling operations in buildings or factory areas

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

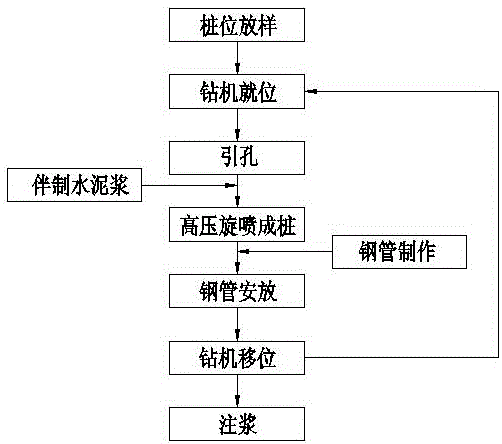

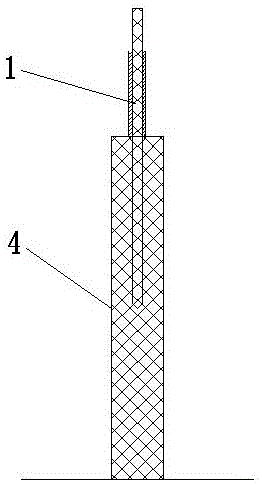

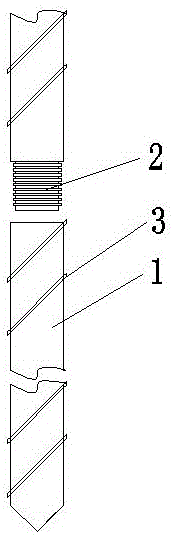

The invention discloses a rotary jet grouting bar inserting type mini pile construction method. The rotary jet grouting bar inserting type mini pile construction method comprises the first step of pile position lofting, the second step of taking drilling machine into place, the third step of hole leading, the fourth step of cement paste mixing, the fifth step of high-pressure rotary jet grouting pile forming, the sixth step of steel pipe manufacturing, the seventh step of steel pipe placing, the eighth step of drilling machine translocating and the ninth step of grouting. The rotary jet grouting bar inserting type mini pile construction method has the beneficial effects that the working face is small, the requirement for the place height is low, the construction place is tidy and clean, the construction process is safe, accident potentials are low, the pile forming quality is good, the bearing force is relatively high, and the method is suitable for construction carried out on places like chemical plants where pipelines are complex, the place limiting conditions are high and the construction process safety requirements are strict. According to the construction method, high-pressure rotary jet grouting piles are adopted, steel pipes are embedded into pile holes, the outer wall of a pipe body of each steel pipe is spirally wound by round steel so that the frictional resistance of the side wall can be increased, and therefore the bearing force of a mini pile is improved. Symmetrical bevel connectors are formed in the bottom of a bottom pipe and are beneficial to sinking of the steel pipes, and the construction efficiency is improved.

Description

technical field [0001] The invention relates to the technical field of pile foundation construction in construction engineering, in particular to a construction method of a micropile with rotary spraying and inserting ribs. Background technique [0002] Pile foundation is a deep foundation composed of piles and pile caps (referred to as caps) connected to the top of the piles or a single pile foundation connected by columns and pile foundations; pile foundations directly affect the bearing capacity of buildings built on pile foundations force. There are various types of foundation piles, and correspondingly, the construction methods of different foundation piles are also different. [0003] When the foundation of existing buildings (structures) is reinforced or the functional area is transformed (especially in the factory area), the surrounding buildings (structures) are still in production and use during the construction period, so the construction safety and the protectio...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): E02D5/46

CPCE02D5/46

Inventor 虞利军王进明汪拾金蒋建良陈敏军吴辉陆舟超苏华吴越琛徐祖佳丁旭亭

Owner 浙江省岩土基础有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com