Connecting device for burying pile casing and construction method

A technology for connecting devices and casings, which is applied in basic structure engineering, construction, sheet pile walls, etc., can solve problems such as insufficient precision, potential safety hazards, and damaged casings, so as to improve accuracy, reduce hidden dangers of casing damage, and reduce The effect of the work surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

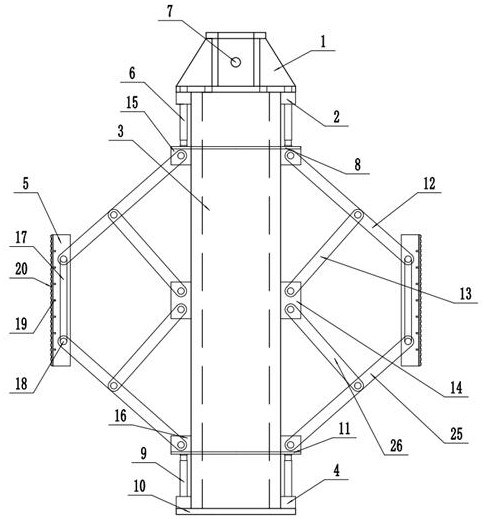

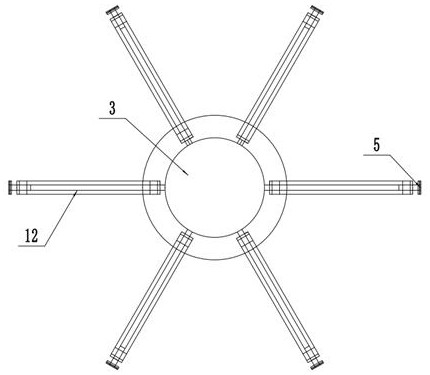

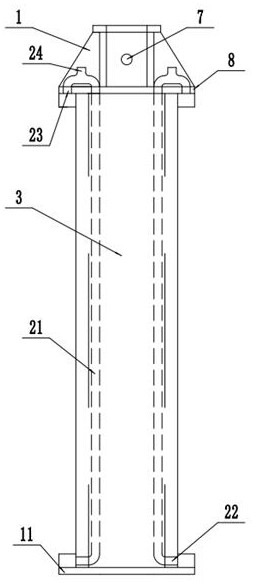

[0032] The invention will be described herein in conjunction with the accompanying drawings and examples.

[0033] This embodiment: see Figure 1 - Figure 4, A connection device and a construction method of a burying cartridge include a connecting head 1 coupled to the rotary drill, and the connecting head 1 is connected to the oil pump cartridge 3 in the inside of the cartridge, and the oil pump cartridge 3 is different. The first hydraulic oil pump 2 and the second hydraulic oil pump 4 are provided, and the first hydraulic oil pump 2 is provided with a first tray 8 axially movable along the oil pump cartridge 3, and the second hydraulic oil pump 4 is provided with axial movement along the oil pump cartridge 3. The second tray 11, the first tray 8 and the second tray 11 are provided with a plurality of robotic arms that are radially disposed along the oil pump cartridge 3, and the end of the robotic arm is facing the end of the oil pump cartridge 3. The strut 5, the robot arm can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com