Multi-tower series-connected circulating amine solution regenerating device

A technology of circulating amine liquid and regeneration device, which is applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of unfavorable miniaturization, rapid operation, undeveloped natural gas, and uneconomical production scale, etc. The effect of thorough analysis, less equipment, and reduced height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

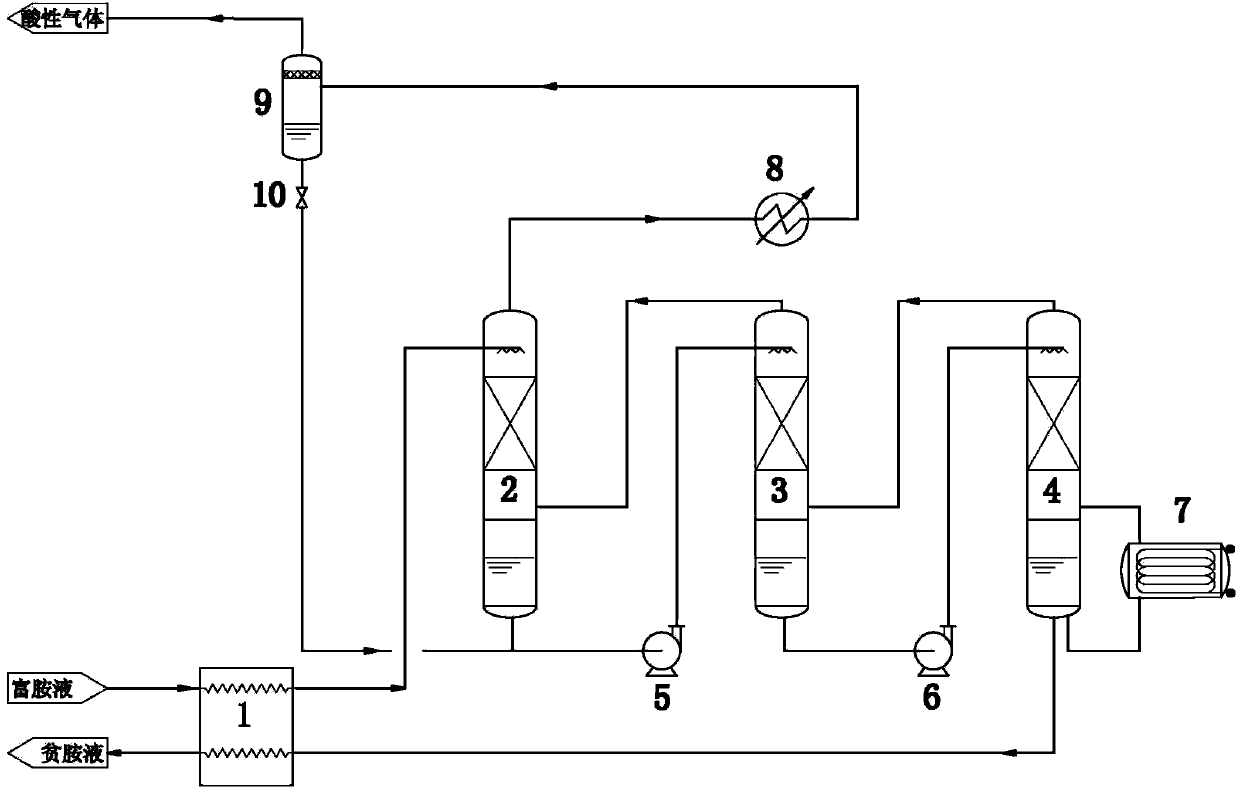

[0017] In this example, three towers in series are taken as an example for illustration.

[0018] attached figure 1 It is a structural schematic diagram of the present invention, such as figure 1 As shown, compared with the existing technology, the main difference is that the height of the regeneration tower used is directly lowered by connecting in series, so that the tower that had to be installed at the production site before has been directly skid-mounted, ready-to-use, Save the steps and troubles of installation. In addition, there are the following key points: the poor-rich liquid heat exchanger 1 uses the heat given by the lean liquid to preheat the rich liquid, and at the same time cools itself, which is more energy-saving; the cooler 8 and the exhaust gas-liquid separator 9 make the The steam is condensed and recovered, which reduces the replenishment of amine liquid and saves raw materials.

[0019] Through the above device, the regeneration and recycling of amine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com