Storage bin with arch breaking device

A technology for breaking arches and silos, which is applied in the field of silos, which can solve the problems of high noise, difficulty in thorough cleaning, and complex structure of the wind-powered arch breaking method, and achieve the effect of improving the service life of equipment, not easy to malfunction, and simple in motion principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

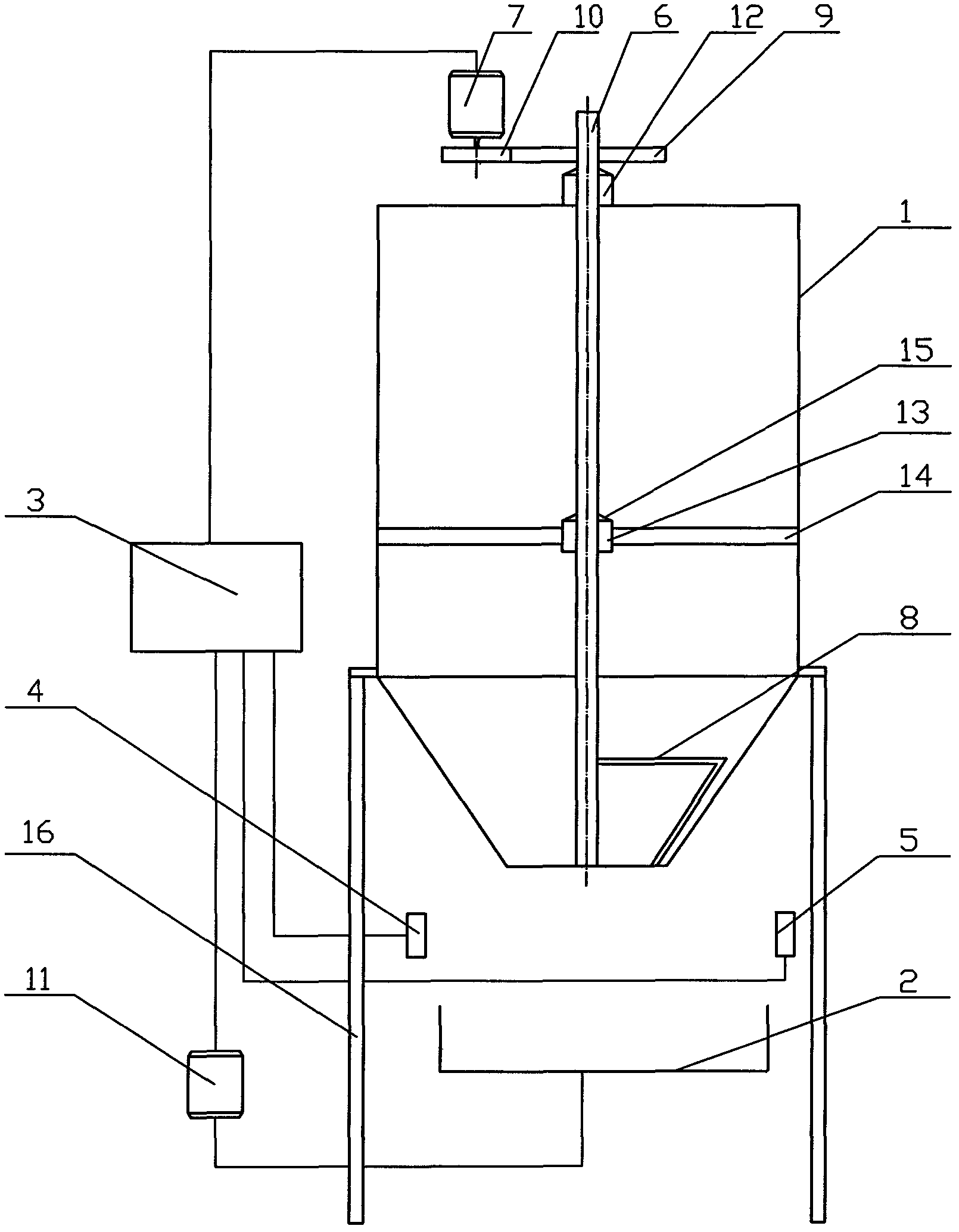

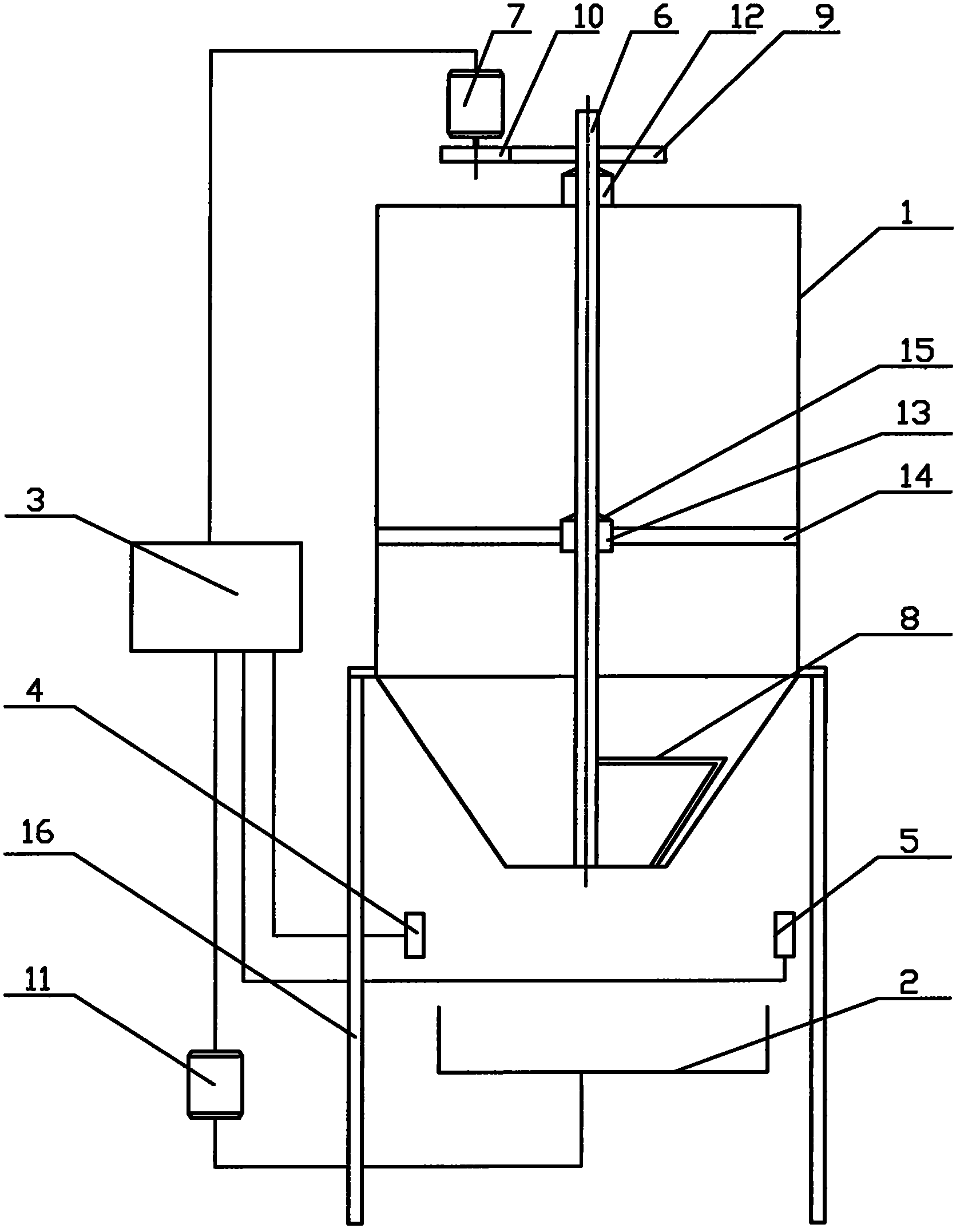

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0016] Such as figure 1 As shown, the silo with the arch breaking device of the present invention includes a silo body 1 and a material conveying mechanism 2, the upper part of the silo body 1 is cylindrical, and the lower part is conical funnel-shaped, and the material conveying Mechanism 2 is located at the bottom of feed bin body 1, and described feed bin body 1 is provided with broken arch device; The described feed bin with broken arch device also includes controller 3 and infrared sensor, and infrared sensor and The controller 3 is electrically connected, and the infrared sensor includes an infrared emitter 4 and an infrared receiver 5, and the infrared emitter 4 and the infrared receiver 5 are respectively installed between the silo body 1 and the material conveying mechanism 2 and distributed among the material Both sides of the outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com