Novel arch-breaking device

An arch breaker and a new type of technology, applied in the field of storage, can solve the problems of affecting the arch breaking effect, prolonging the air discharge time, and the arch breaking effect is not good, so as to achieve outstanding substantive features, improve the arch breaking effect, and shorten the deflation time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

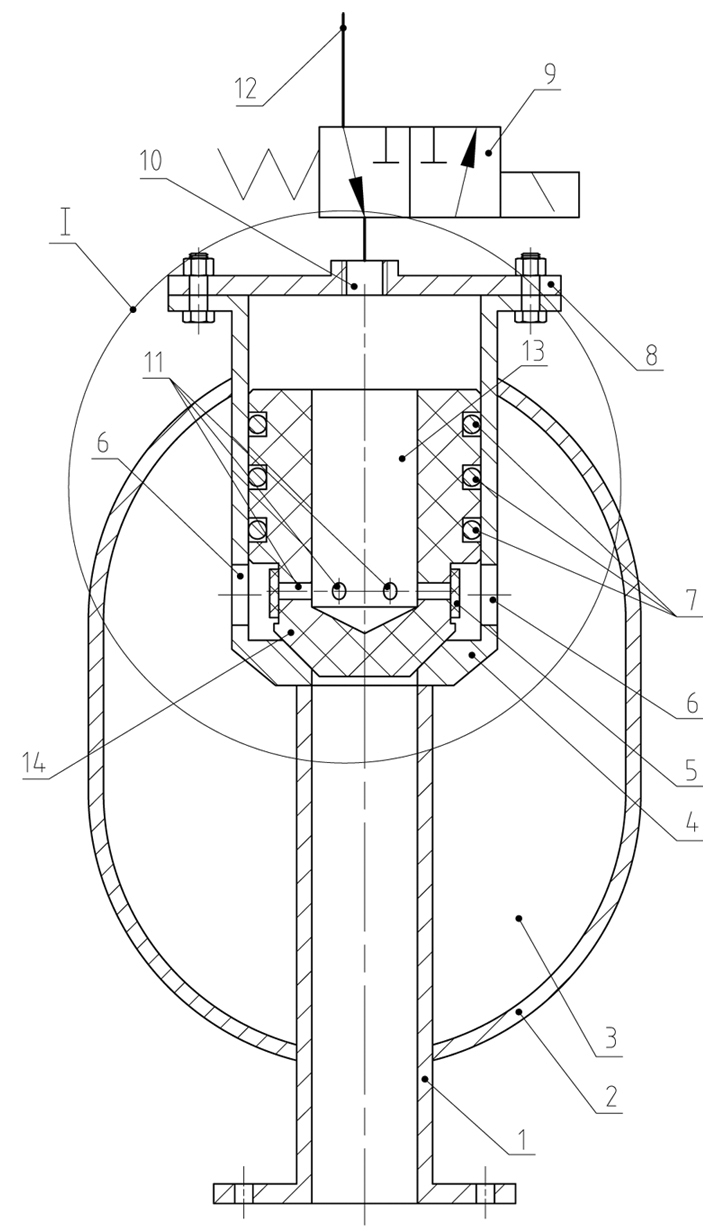

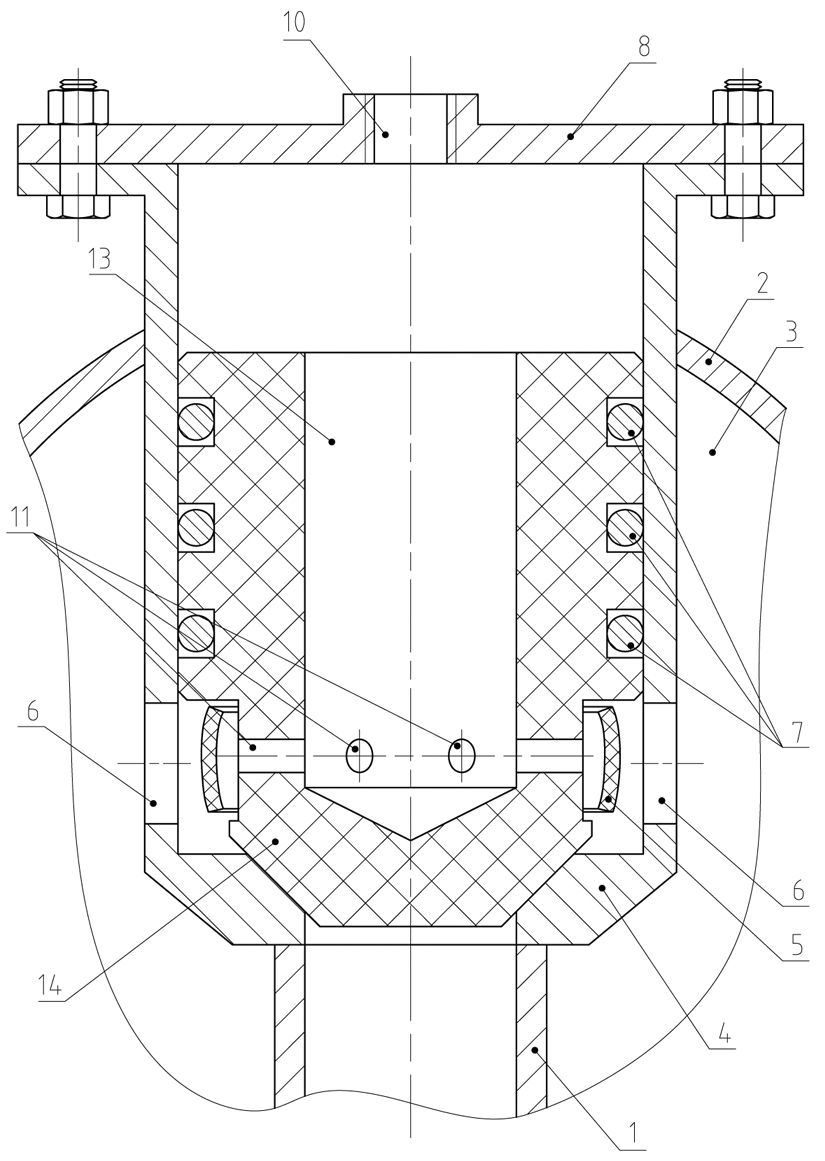

[0035] Example 1. Such as figure 1 , figure 2 and image 3 As shown, the novel arch breaker is composed of a housing 2, an exhaust pipe 1, a cylinder liner 4, a piston 14, an elastic sleeve 5, a sealing plate 8 and a two-position three-way solenoid valve 9.

[0036] The cylinder liner 4 has a cylindrical inner hole, and is fixed on one end of the housing 2, and one end of the cylinder liner 4 is in the housing 2, and the other end is outside. There is a tapered hole at one end thereof, and an air hole 6 is arranged at the end near the tapered hole on the side wall of the cylindrical hole.

[0037]A piston 14 is installed in the cylinder liner 4, and the outer cylindrical surface of the piston 14 cooperates with the inner cylindrical surface of the cylinder liner 4, and can slide inside. When the holes are close together, a pair of sealing surfaces can be formed. The other end of the piston 14 has an axial ventilation main hole 13, which is a blind hole. Ventilation smal...

Embodiment 2

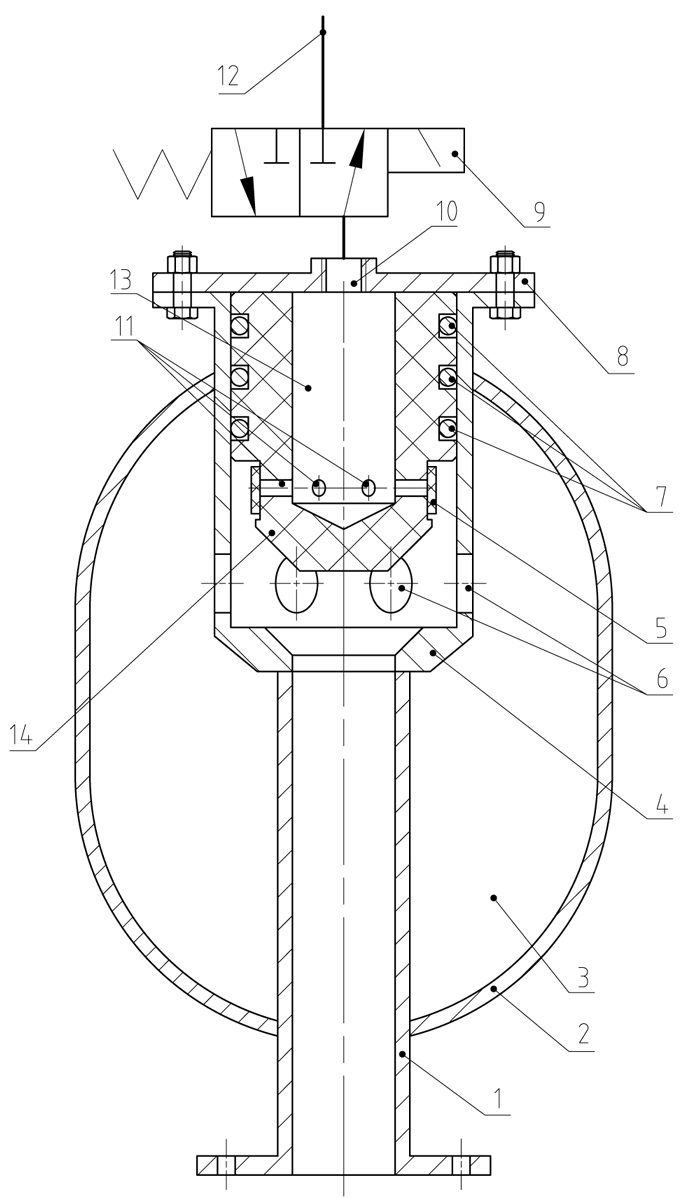

[0049] Example 2. Such as Figure 4 As shown, the novel arch breaker is composed of a housing 2, an exhaust pipe 1, a cylinder liner 4, a piston 14, an elastic sleeve 5, a sealing plate 8 and a two-position three-way manual valve 15.

[0050] The cylinder liner 4 is fixed on one side of the cylindrical section of the housing 2, and the exhaust pipe 1 is fixed on the side opposite to the housing 2. The exhaust pipe 1 protrudes out of the housing 2 and is threaded so that it can be connected with other pipelines. Connect and lead to the silo.

[0051] The cylinder liner 4 is threaded towards the outer end of the housing 2, and is connected with the sealing plate 8, and the junction is well sealed and airtight. There is an air port 10 on the sealing plate 8, and the air port 10 is connected to a two-position three-way manual valve 15 through an external pipeline, and the two-position three-way manual valve 15 is connected to an air source 12.

[0052] Under normal conditions, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com