Arch breaking unit and stock bin

A technology for breaking arches and silos, which is applied in the field of silos equipped with the arch breaking unit, which can solve the problems of increasing operating costs, heavy maintenance workload, and reducing the discharge efficiency of silos, so as to increase the service life of equipment , Prevent rigid breakage and enhance the effect of arch breaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

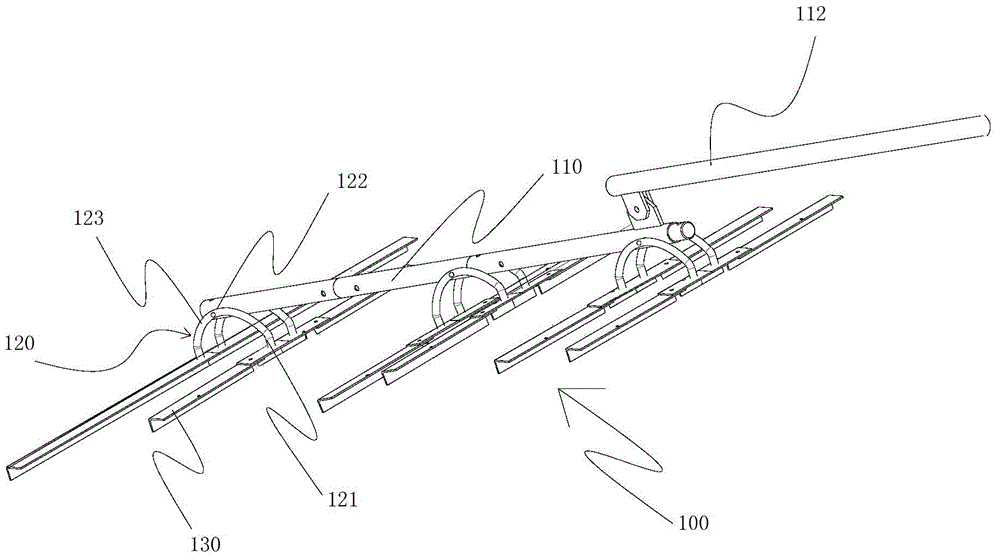

[0063] figure 1 It shows a schematic structural diagram of an embodiment of the arch breaking unit of the present invention;

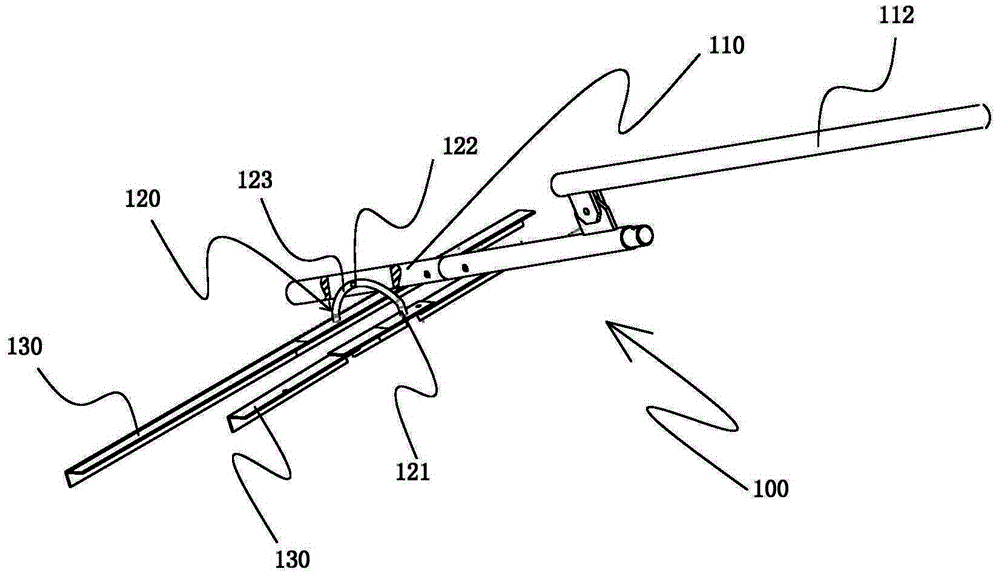

[0064] Such as figure 1 As shown, the arch breaking unit 100 of the present invention includes a connecting rod 110; the connecting rod 110 is pivotally connected with one or more connecting pieces 120 in the axial direction, and at least one cantilever end 121 of the connecting piece 120 is connected with a dial The material arm 130; the material arm 130 is set at an angle with the connecting rod 110; when the connecting rod 110 moves in the axial direction, under the action of arching resistance, the cantilever end 121 of the connecting piece 120 is relative to the connecting piece 120 and the connecting rod 120. The pivot point 122 of the rod 110 is angularly displaced to adjust the arch-breaking resistance of the shifting arm 130 .

[0065] The working principle of the present invention is that during the arch breaking process of the arch breakin...

Embodiment approach 2

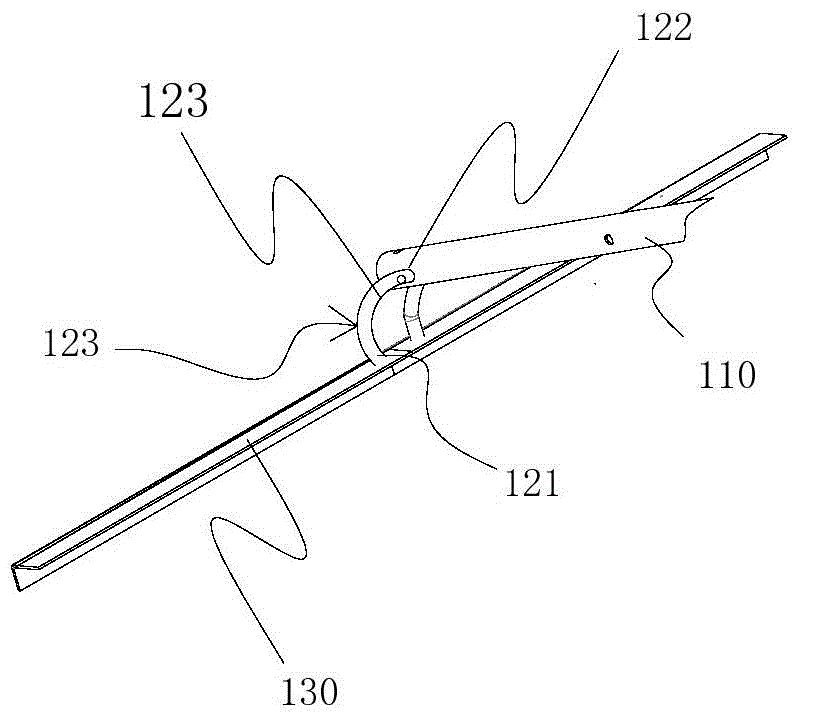

[0075] Such as image 3 As shown, the second embodiment of the present invention is basically the same as the previous embodiment, the only difference being that the shifting arm 130 and the connecting member 120 are pivotally connected within the movement plane of the shifting arm 130, and the shifting arm The other end of 130 forms a free end 131 that can rotate around the pivot point 137 , and the free end 131 constitutes the rotational degrees of freedom of the shifting arm 130 in different planes. When the arching state of the material in the silo is serious, and the material shifting arm 130 encounters a relatively large arching resistance, the free end 131 of the material shifting arm 130 rotates around the pivot point 137 to avoid the arching bridge. A rotation degree of freedom is added to the shifting arm 130, fundamentally preventing the rigidity of the shifting arm 130 from being damaged. Simultaneously, the free end 131 of the driving arm 130 effectively disturbs...

Embodiment approach

[0087] The present invention also proposes a silo 300, which includes a discharge port and is formed at the bottom of the silo 300; it is characterized in that: the bottom of the silo 300 is provided with one or more arch breaking units 100, and the arch breaking units The connecting rod 110 of 100 is arranged along the inner wall surface of the bottom of the silo, and is driven to reciprocate by the driving mechanism 112. The material shifting arm 130 reciprocates with the connecting rod 110, and the material in the silo 300 is moved along the bottom of the silo. The inner surface of the inner wall is dialed to the discharge port of the feed bin 300.

[0088] The present invention utilizes the above-mentioned arch-breaking unit to perform arch-breaking and exporting functions on the materials stored in the silo 300 during discharge, thereby ensuring the smooth discharge of the silo 300 . Moreover, by effectively reducing the breakage rate of the arch breaking unit 100, the br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com