Patents

Literature

40results about How to "Moderate resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

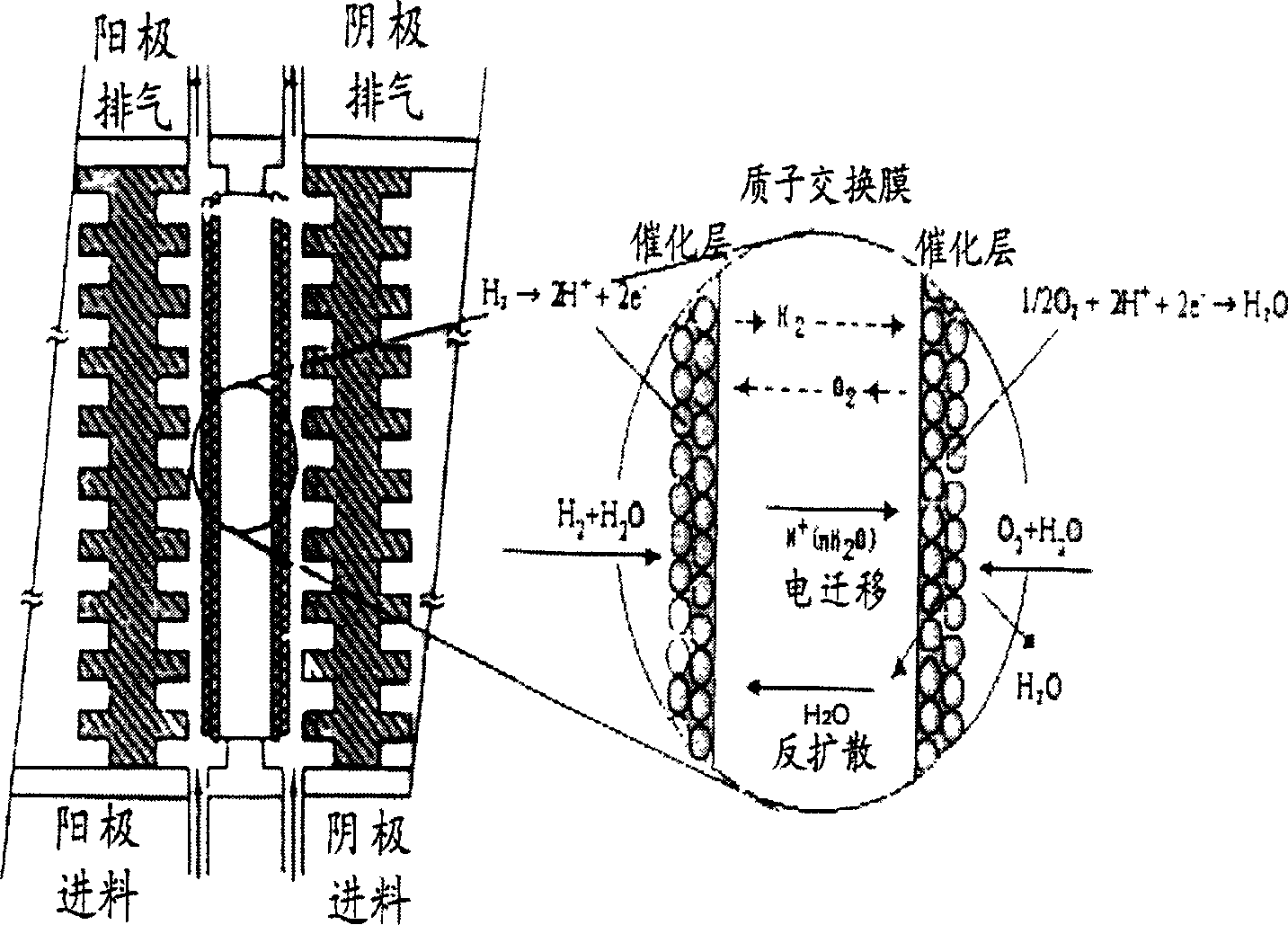

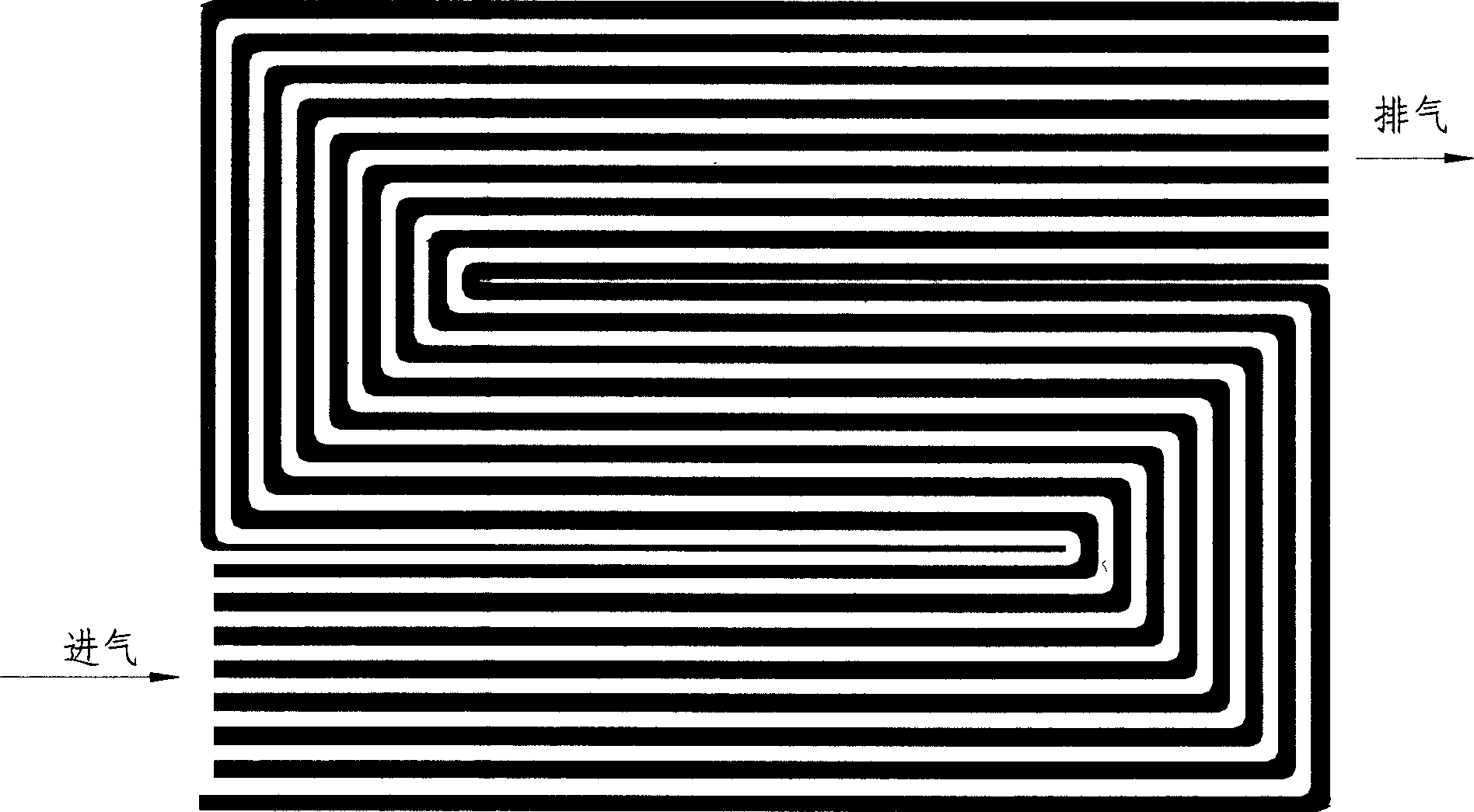

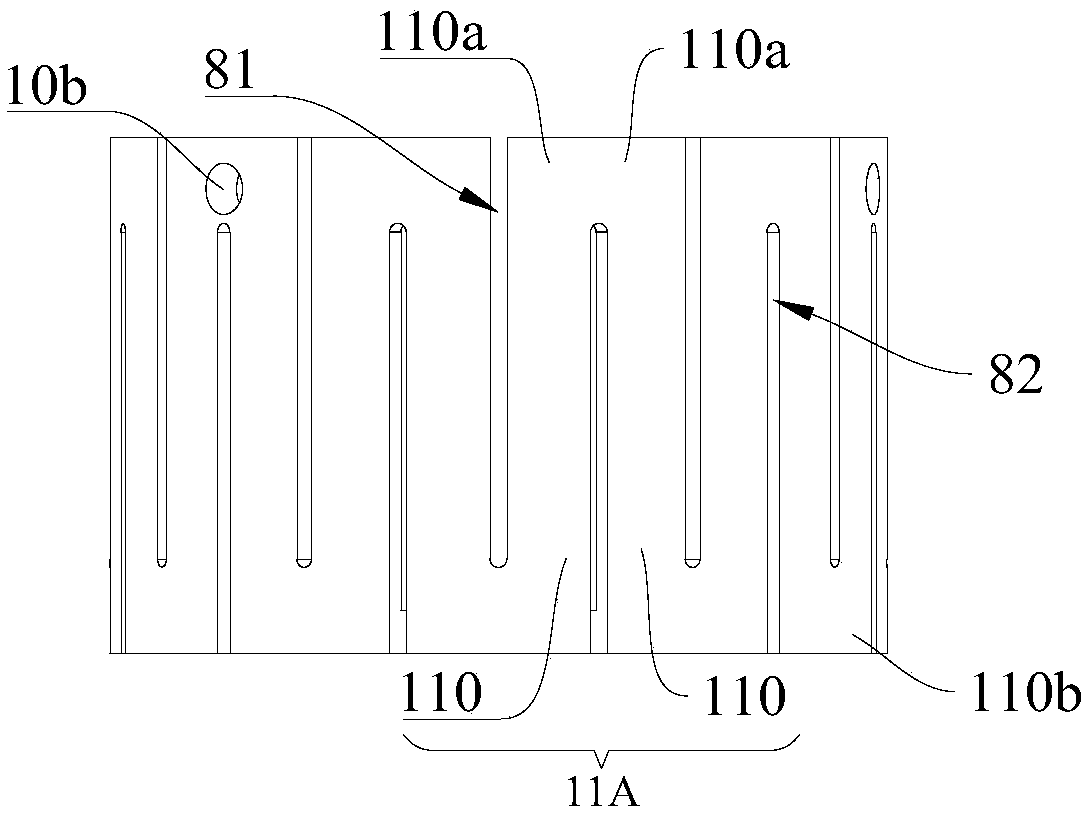

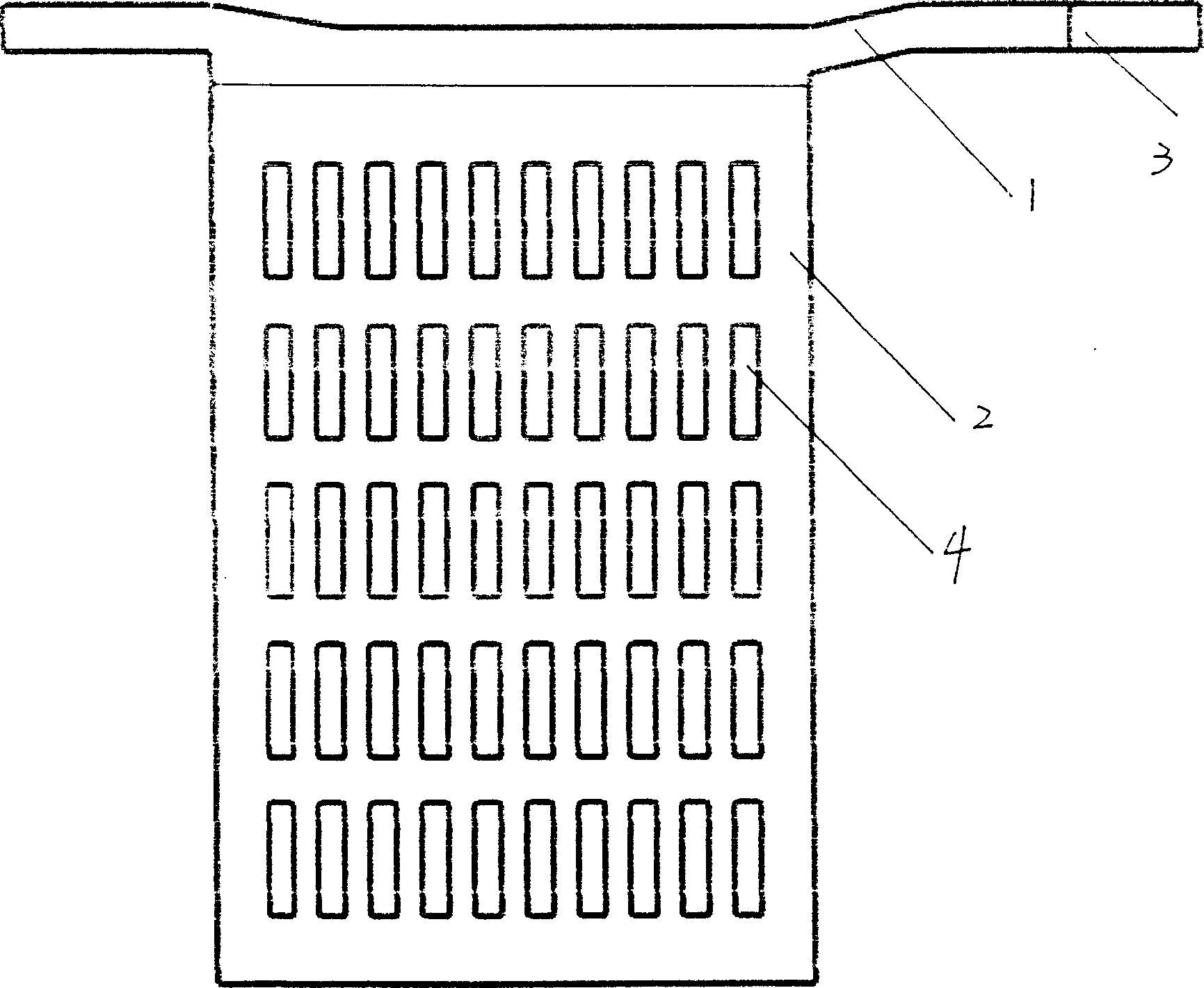

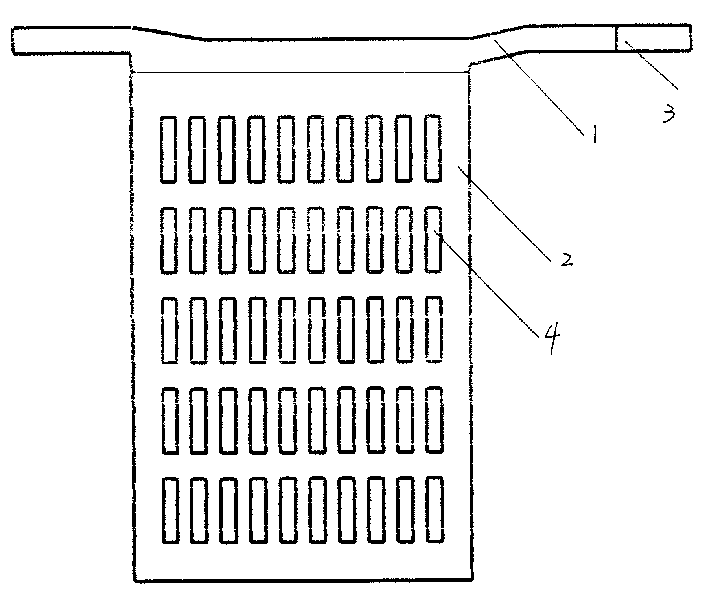

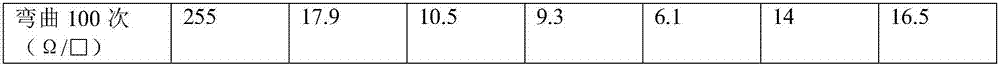

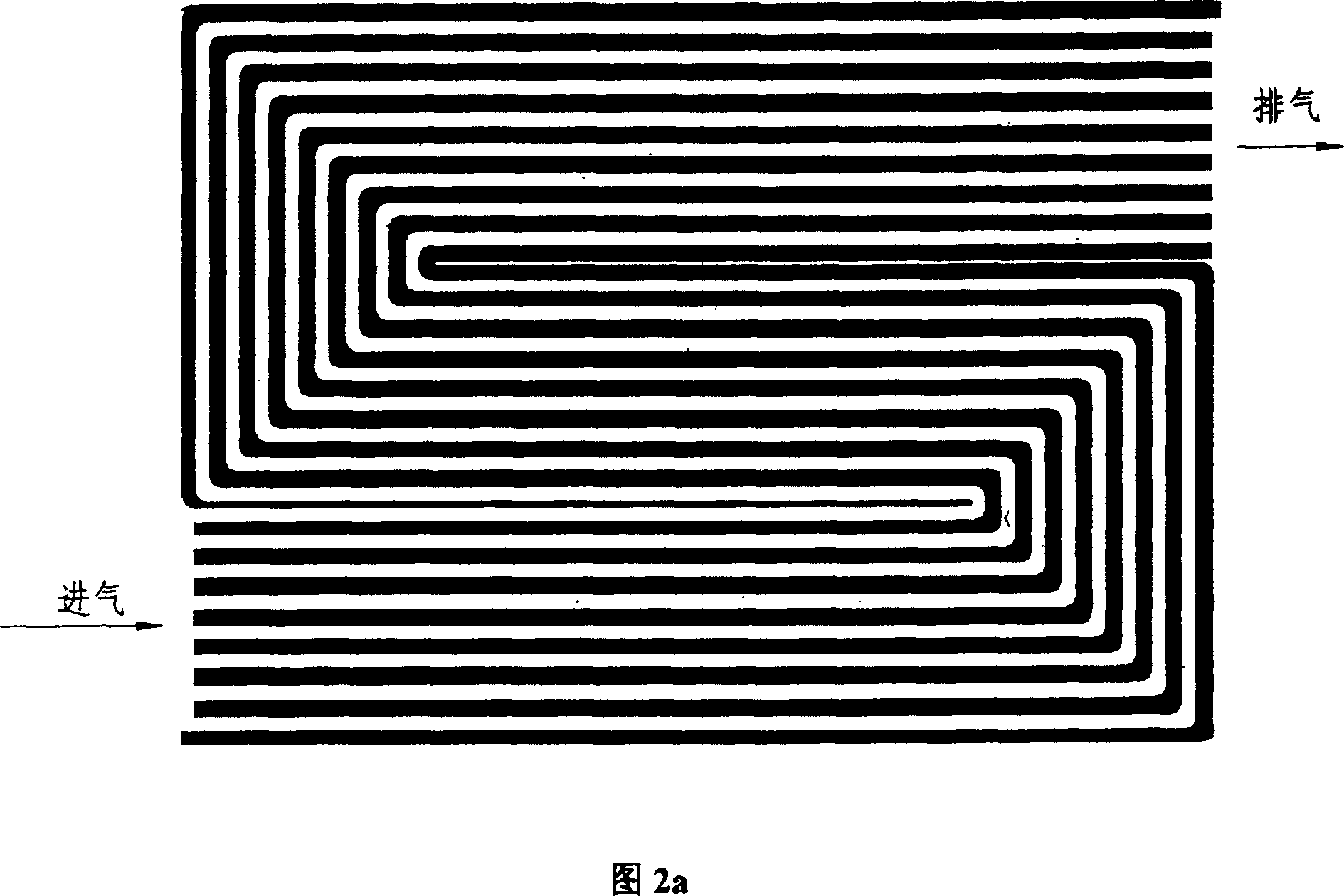

Proton exchange film fuel cell flow field structure

ActiveCN1622377AEasy to excludePromote accumulationCell electrodesSolid electrolyte fuel cellsProtonEngineering

The present invention relates to proton exchange membrane fuel cell. The flow field structure of proton exchange membrane fuel cell consists of netted flow field and deflecting stripes. The deflecting stripes are set inside the netted flow field and parallel to one group of sealing side walls, and have width equal to the height of the netted flow field. Each of the deflecting stripes has one end connected perpendicularly to the side wall and the other end constituting the gas channel. The gas channel has width not smaller than that of the gas inlet. The present invention has the advantages of high pole area utilization, being favorable to the exhaust of water produced in the electrochemical reaction and the elimination of inertial component, no dead arean of gas flow, and stable operation of the cell under low pressure and normal pressure.

Owner:SUNRISE POWER CO LTD

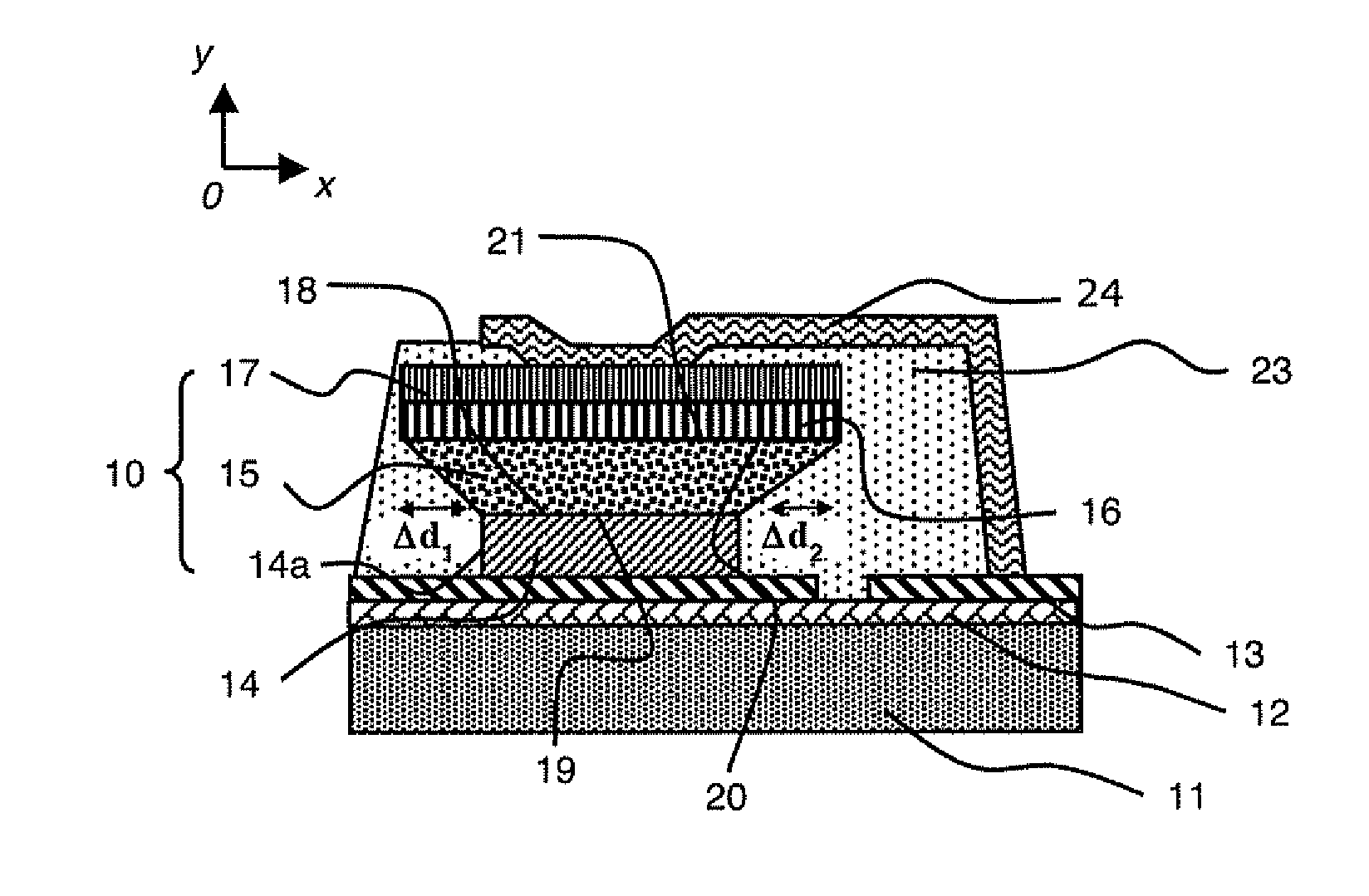

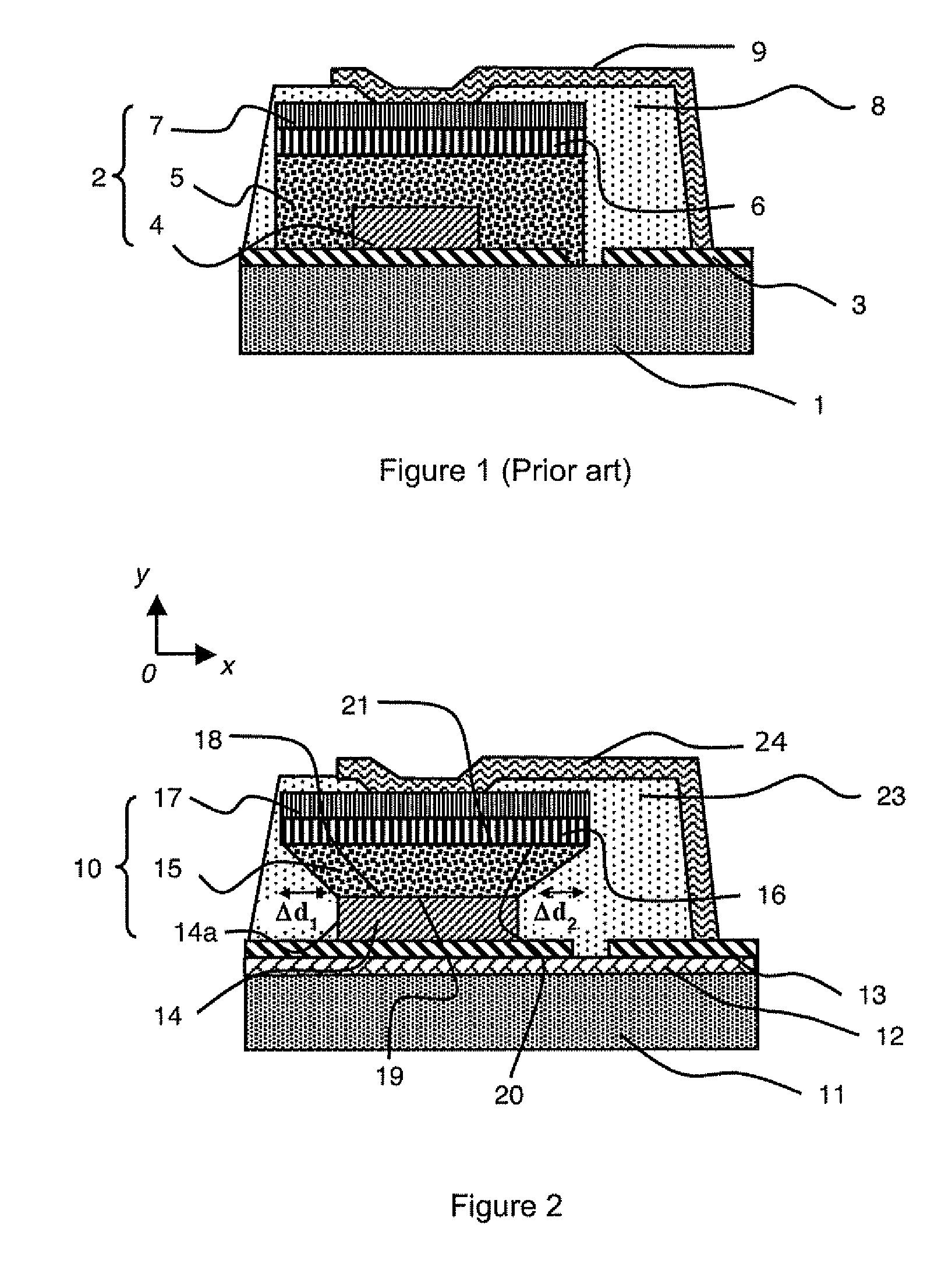

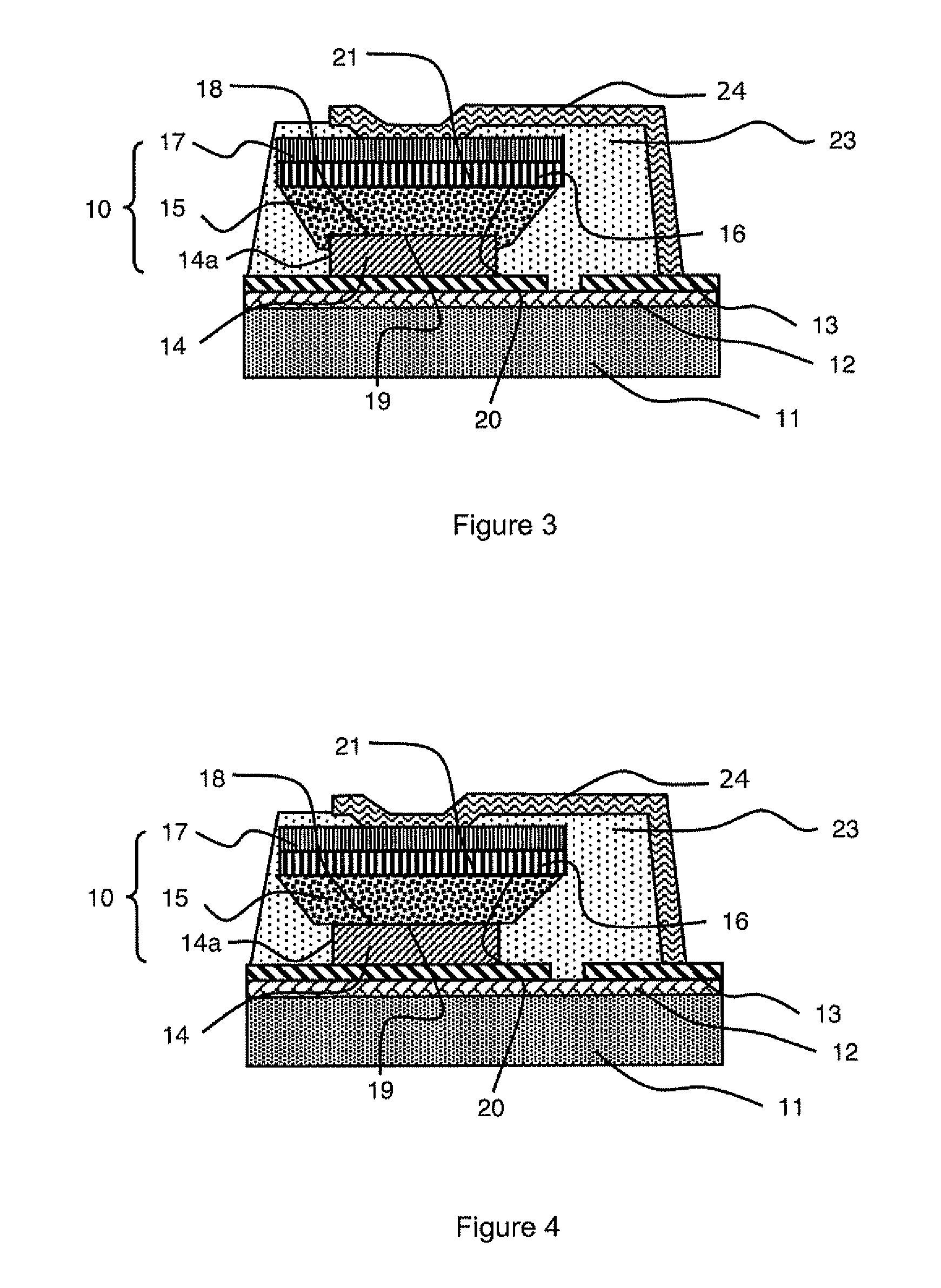

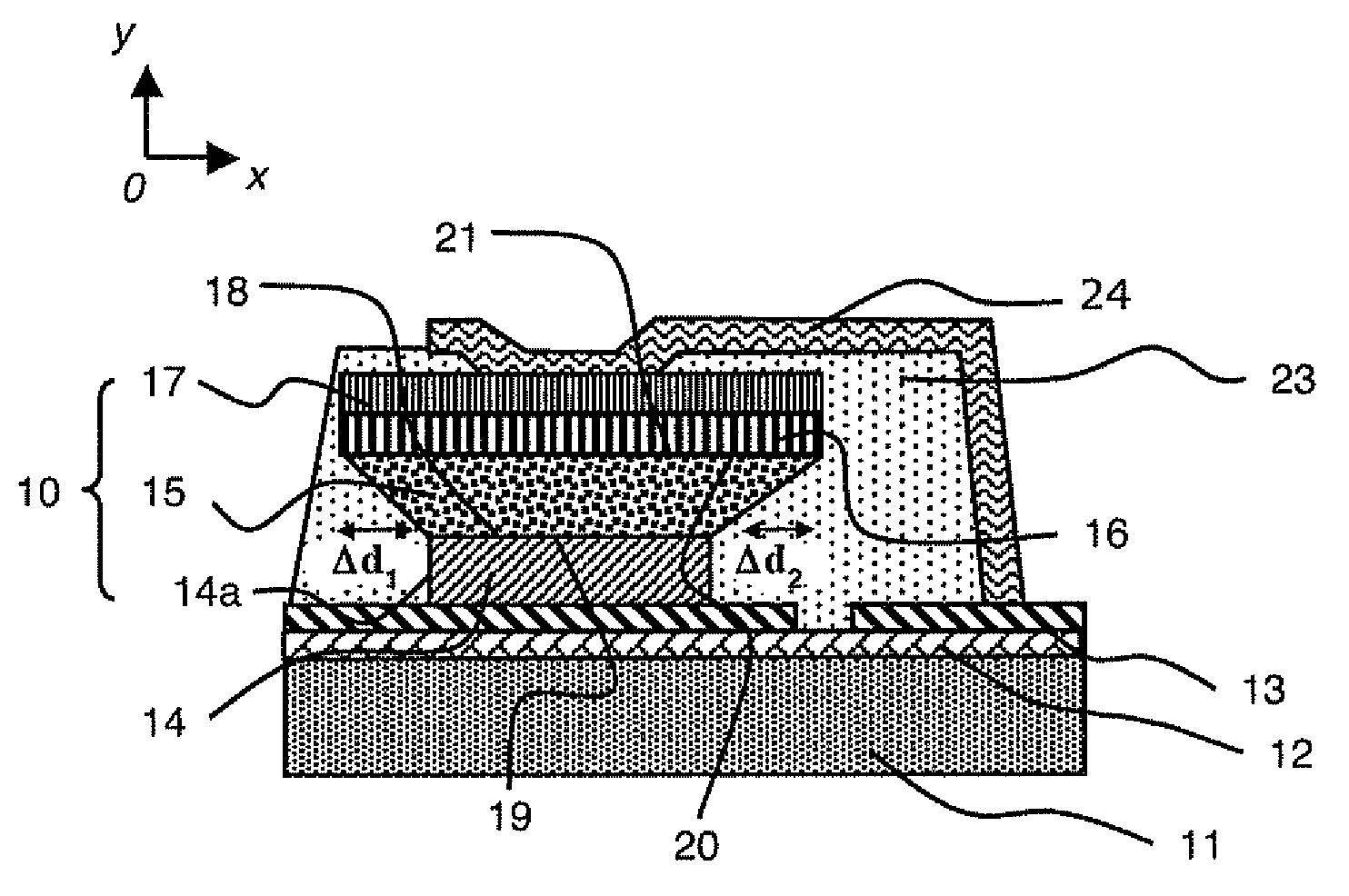

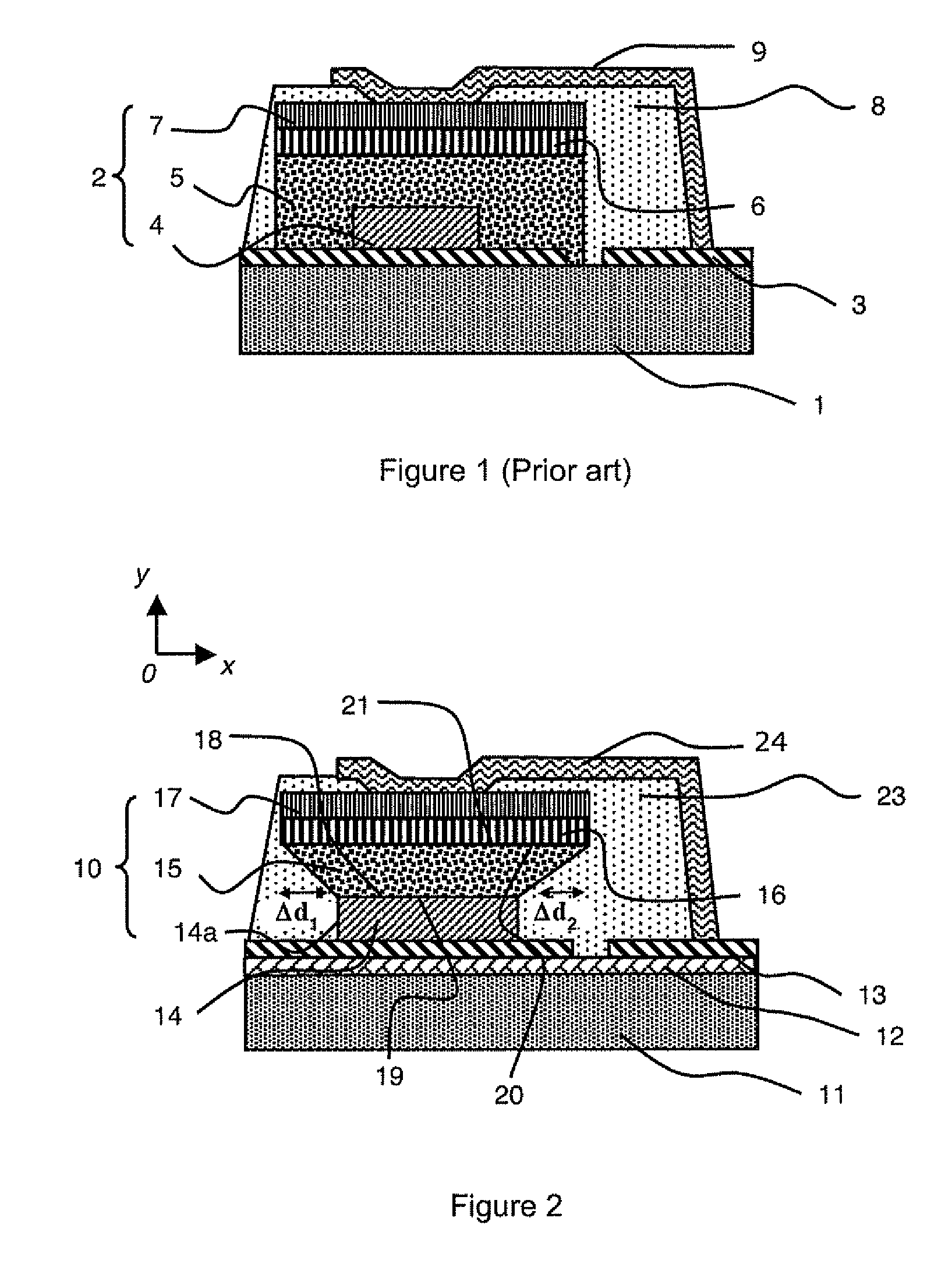

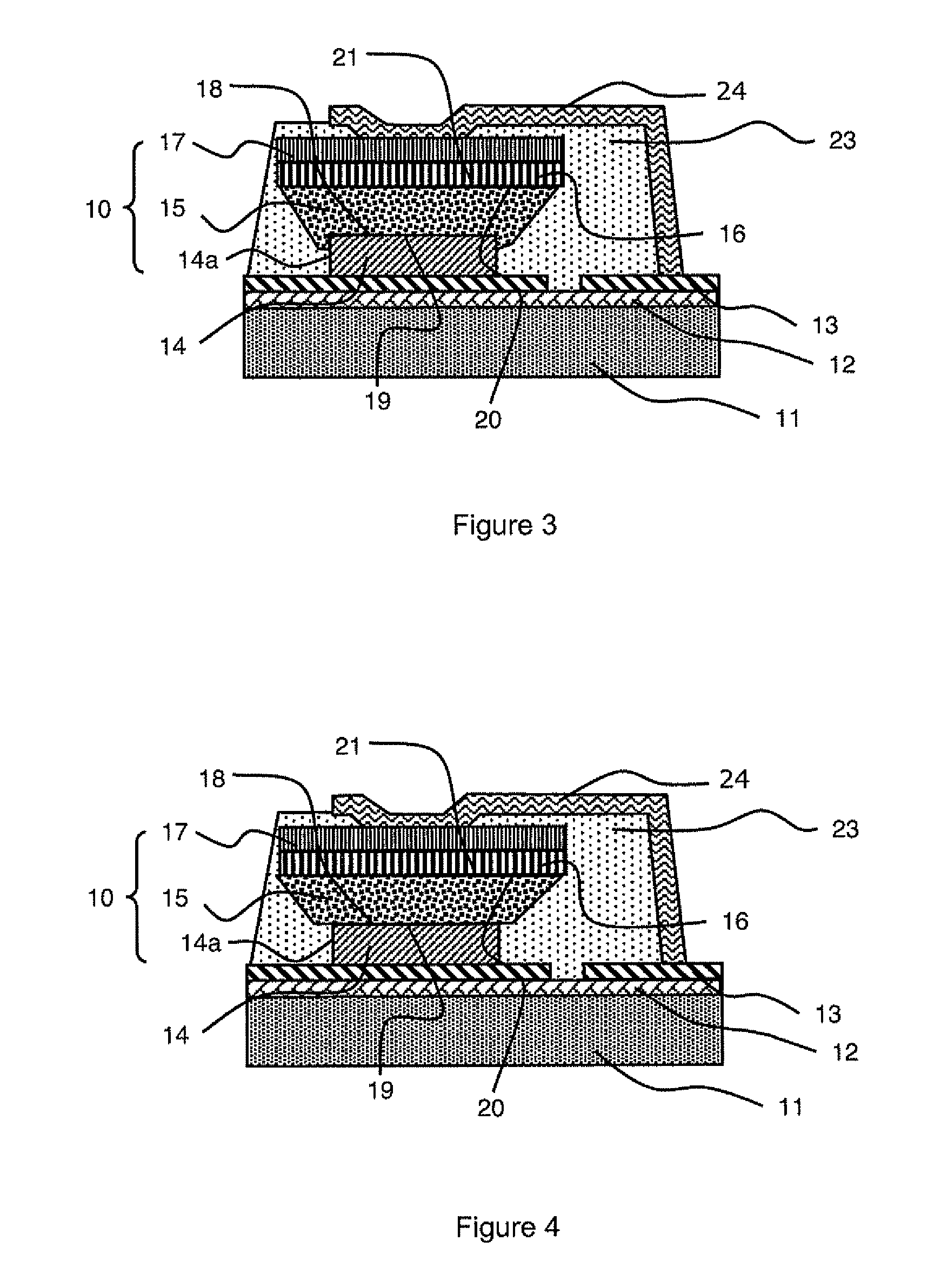

Lithium microbattery and fabrication method thereof

ActiveUS20110311883A1Improve energy storage efficiencyModerate electric resistanceSolid electrolytesFinal product manufactureThin layerCurrent collector

The microbattery is formed by a stack of solid thin layers on a substrate which, starting from the substrate, successively comprises a first electrode, a solid electrolyte and a second electrode / current collector assembly. A first surface and a second surface of the electrolyte are respectively in contact with a main surface of the first electrode and a main surface of the second electrode / current collector assembly. The dimensions of the main surface of the first electrode are smaller than the dimensions of the main surface of said assembly, and the dimensions of the first surface of the solid electrolyte are smaller than the dimensions of the second surface of the solid electrolyte. The solid electrolyte is furthermore not in contact with the substrate.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Soybean cultivar BA947474

InactiveUS7220898B1High yield potentialModerate resistanceOther foreign material introduction processesFermentationRoot-knot nematodeSoybean cyst nematode

A soybean cultivar designated BA947474 with high yield potential, tolerance to Roundup™ herbicide, MG VIII maturity, resistance to race 3 of soybean cyst nematode (Heterodera glycines), and moderate resistance to southern root knot nematode and southern stem canker, further including the plants and seeds of the cultivar BA947474, methods for producing a soybean plant by crossing the cultivar BA947474 with itself or another soybean plant. The invention also relates to soybean cultivar BA947474 further comprising one or more single gene traits, and to methods of producing a soybean having such traits by introgression, transformation or mutagenesis. The invention also includes using the soybean cultivar BA947474 to produce other soybean cultivars, breeding lines, and progeny.

Owner:SYNGENTA PARTICIPATIONS AG

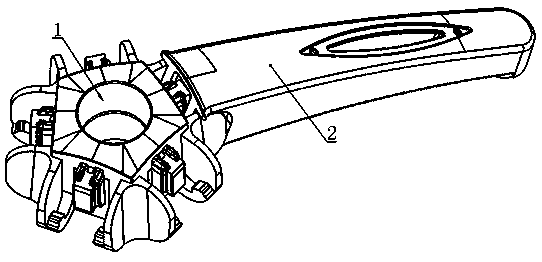

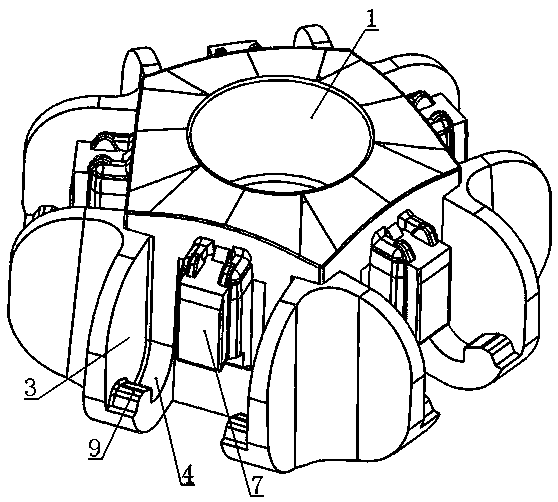

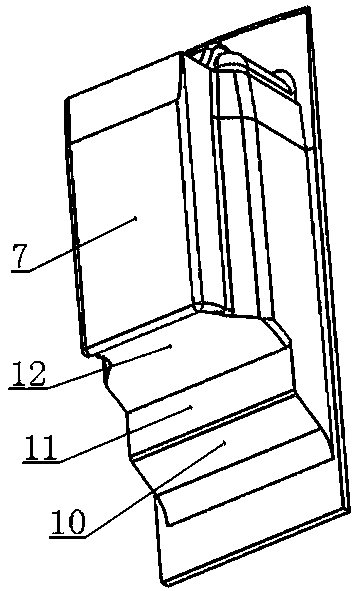

High-strength five-star base with dismounting and mounting functions

The invention belongs to the technical field of support structures and particularly relates to a high-strength five-star base with dismounting and mounting functions. By arranging clamping plates, arctrough plates and support blocks on a central block and arranging connecting grooves, arc connecting plates and ejection blocks on support legs, the five-star base can be effectively dismounted and mounted for use. The five-star base has the advantages that a five-star base split dismounting and mounting structure is reasonable and effective, the support legs are easy to clamp and position beforedismounting and mounting, resistance is moderate and operation is convenient during dismounting and mounting, support strength is high after mounting, the friction fixing effect between the support legs and the central block is good when the five-star base is lifted from the ground, the support legs cannot fall off easily, the dismounting and mounting split structure has good use effects, and single support leg is convenient to replace.

Owner:ANJI JINTAI FASTENER CO LTD

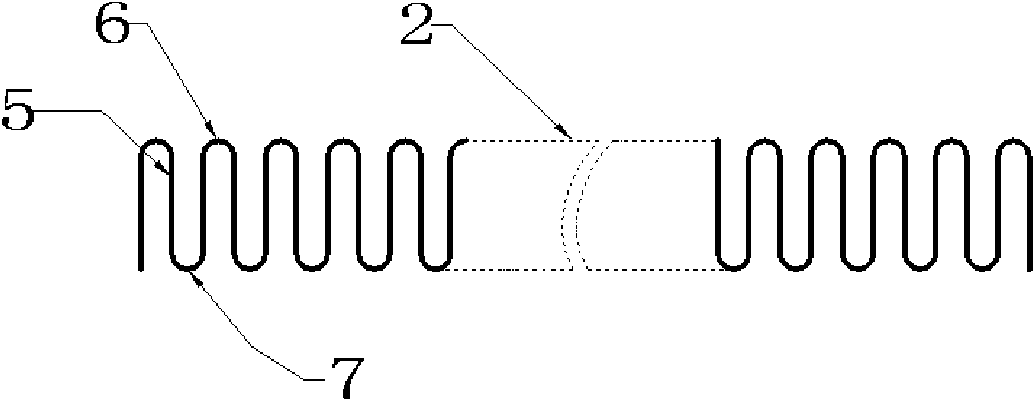

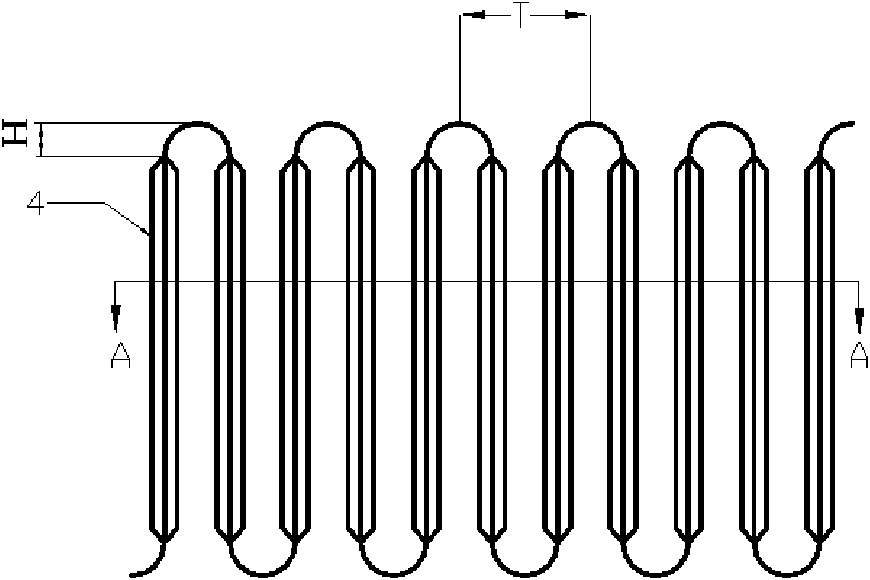

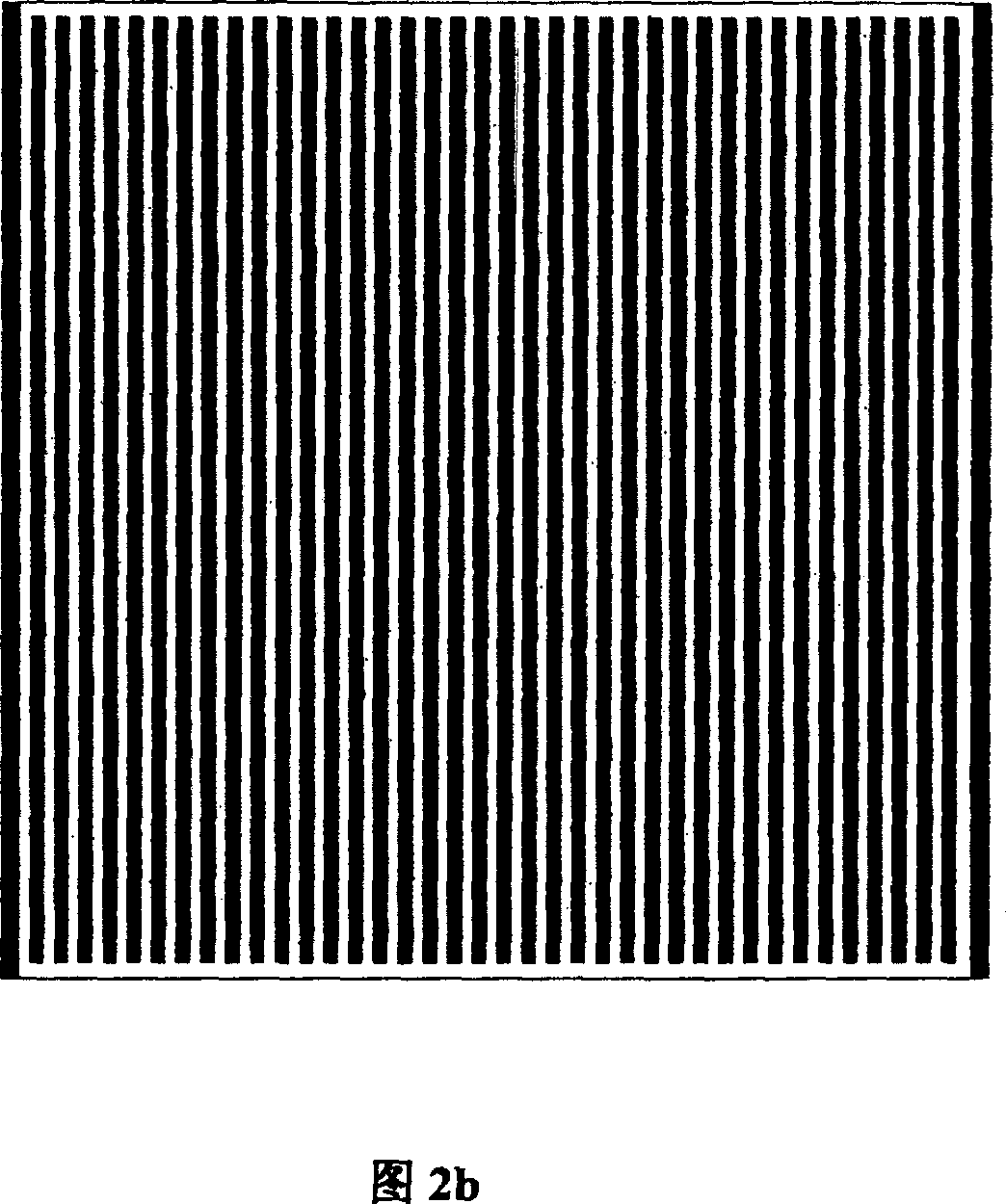

Fin of microchannel parallel-flow heat exchanger

InactiveCN101614501AModerate resistanceReasonable structural designLaminated elementsPlate heat exchangerEngineering

The invention relates to the technical field of heat exchangers, in particular to a fin of a microchannel parallel-flow heat exchanger. The fin of a microchannel parallel-flow heat exchanger comprises a fin and a substrate, and is characterized in that: the substrate extends and distributes in a sine wave; each side wall of the sine wave of the substrate is provided with two sets of shutters consisting of a plurality of strips; each set of shutter raises along the surfaces on two sides of the substrate to form included angles with the surfaces of the side wall; included angles formed between the two sets of shutters on the same side wall and the surfaces of the substrate are mutually symmetric; after being folded in the extension direction of the sine wave, the shutters of adjacent side walls are coincide; and the flow direction of an air flow is perpendicular to the extension direction of the substrate. The fin of the microchannel parallel-flow heat exchanger has the advantages of ensuring proper resistance to air flow flowing in the fin, achieving optimal air flow, effective heat exchange area and heat exchange efficiency, along with easy manufacture, low cost and excellent mechanical performance.

Owner:ZHEJIANG KANGSHENG CO LTD

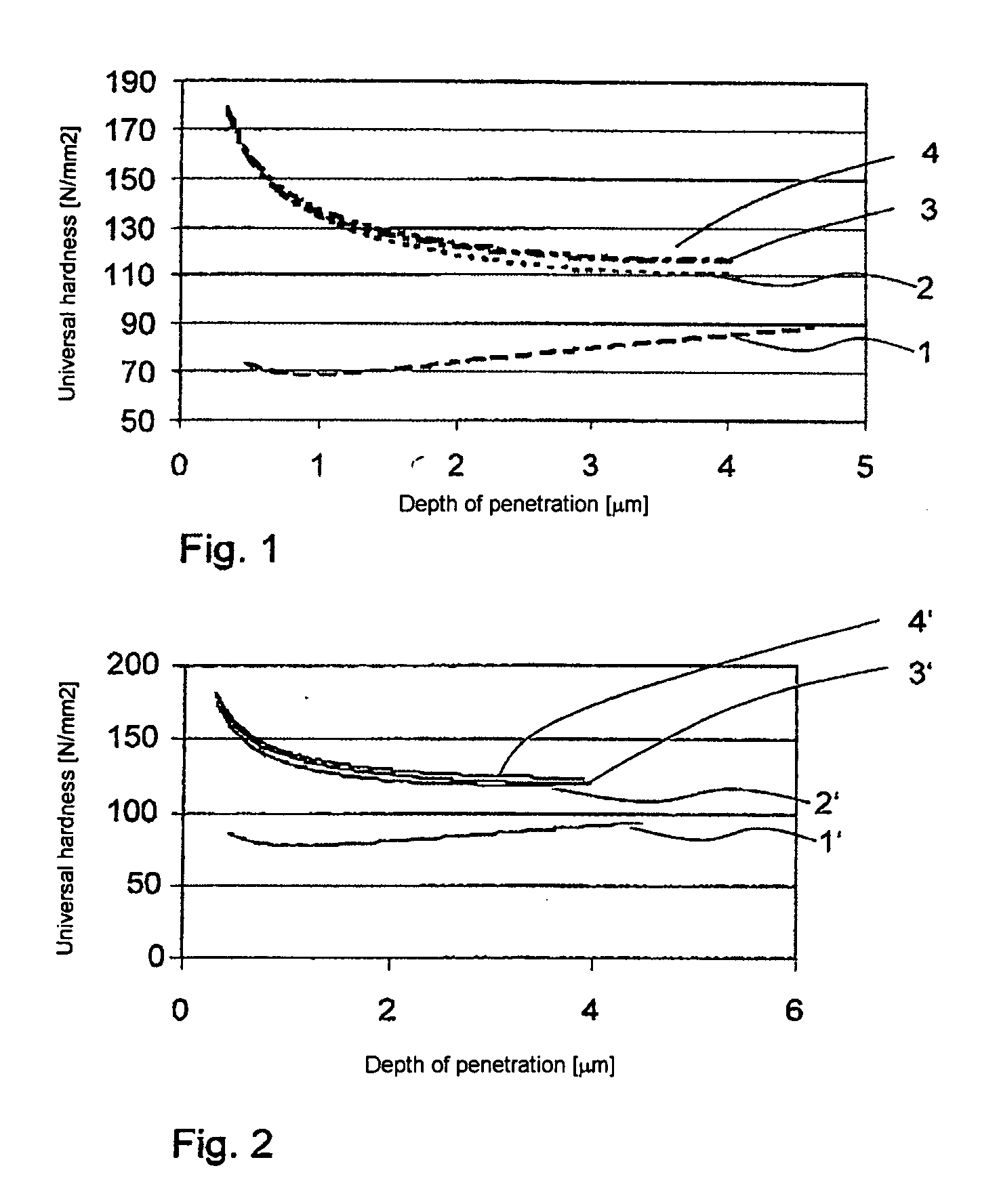

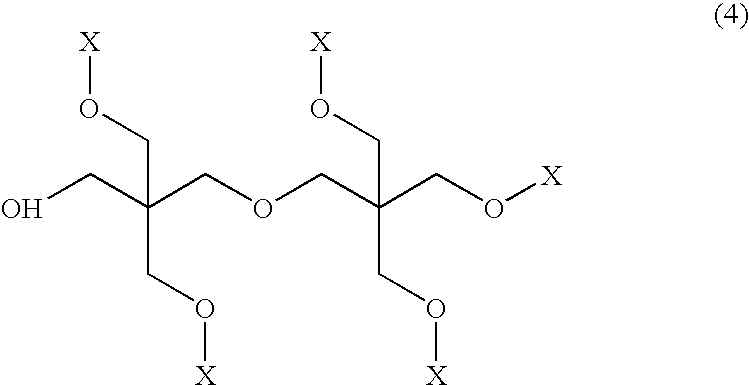

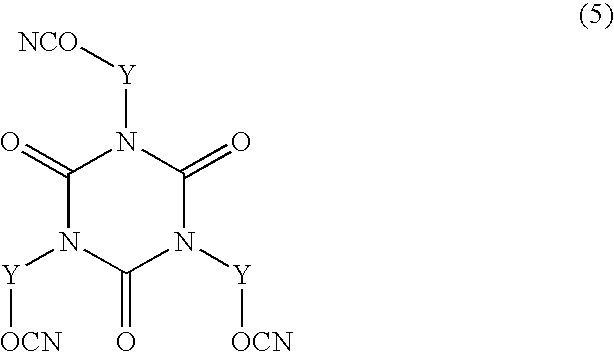

Process for curing paint

InactiveUS20060003109A1High hardnessImprove scratch resistancePretreated surfacesCoatingsHardnessIrradiation

Method of producing coating films from coating formulations which are free-radically polymerizable under thermal initiation, characterized in that it comprises at least the following steps: a) coating of the substrate with the coating formulation b) thermally initiated curing of the coating formulation c) elimination of quality deficiencies in the cured coating material d) curing of the coating material to completion by UV exposure, and also to a coating formulation suitable for this method, comprising monomers containing ethylenically unsaturated groups and thermal free-radical initiators, the coating formulation being substantially free from UV initiators and the hardness of the coating material after thermal curing and subsequent UV irradiation being higher by at least 15% than after thermal curing without UV irradiation.

Owner:DAIMLER AG

Lithium microbattery and fabrication method thereof

ActiveUS8475963B2Improve efficiencyModerate resistanceSolid electrolytesFinal product manufactureLithiumThin layer

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

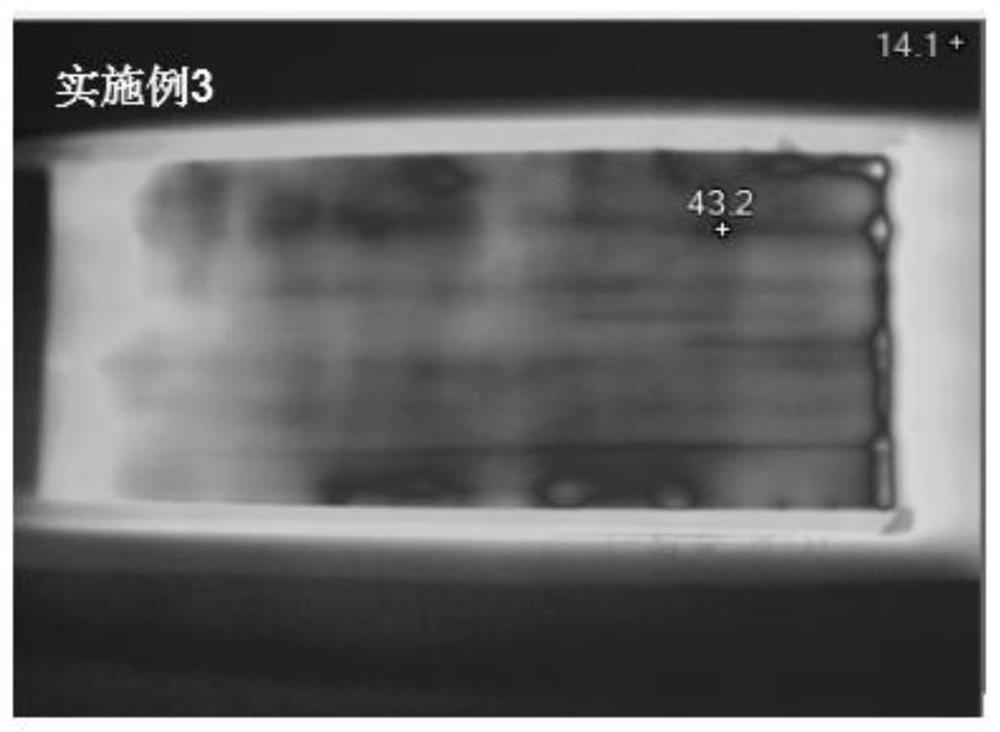

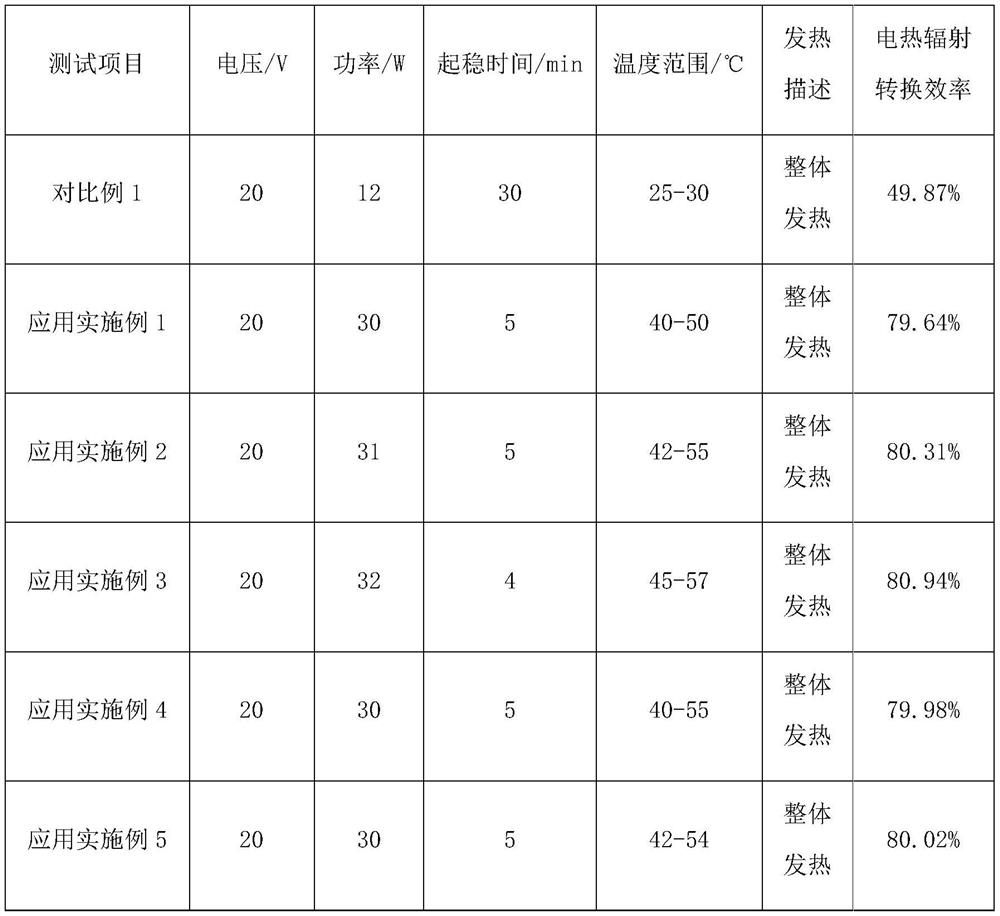

Water-based slurry for graphene far infrared planar heating element

InactiveCN109688644AImprove performanceImprove conductivityHeating element materialsWater basedSlurry

The invention discloses a water-based slurry for a graphene far infrared planar heating element. The water-based slurry for the graphene far infrared planar heating element is prepared from the raw materials in parts by weight: 40-60 parts of water-soluable resin, 40-60 parts of graphene, 20-30 parts of graphite, 20-30 parts of conductive carbon powder, 10-16 parts of nano ATO water-based dispersing agents, 10-16 parts of metal mixture, 3-5 parts of water-based thickening agents, 5-9 parts of water-based crosslinking coupling agents, 3-5 parts of anti-sinking agents, 3-5 parts of deforaming agents, 1-3 parts of flatting agents, 1-3 parts of adhesion promoters and 10-20 parts of deionized water. The water-based slurry for the graphene far infrared planar heating element can enable the comprehensive performance of the water-based heating slurry to be good, further can enable a planar heating element coating to have the advantages of good film formation effect, high bonding force, elasticity, difficult fracturing of the coating and the like, the resistance is moderate, the heating power is large, and the conductive performance of the heating slurry further can be effectively enhanced.

Owner:中山市君泽科技有限公司

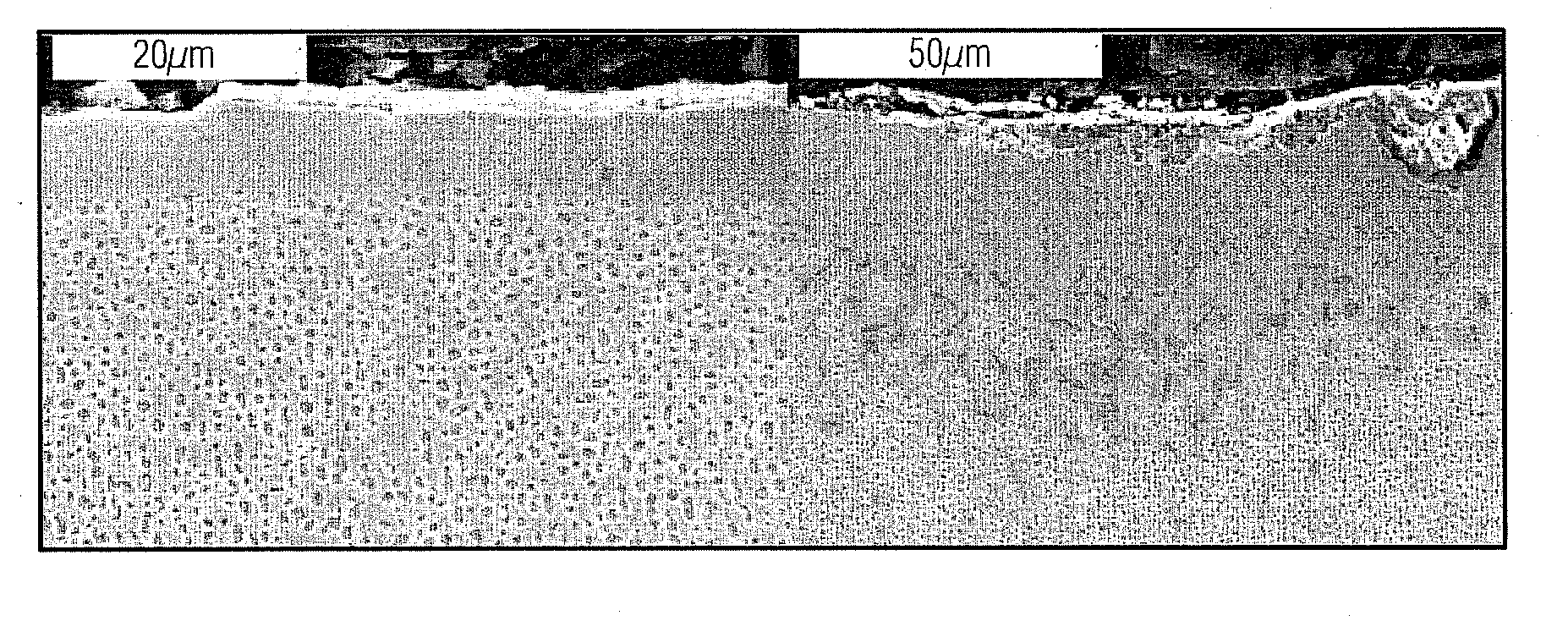

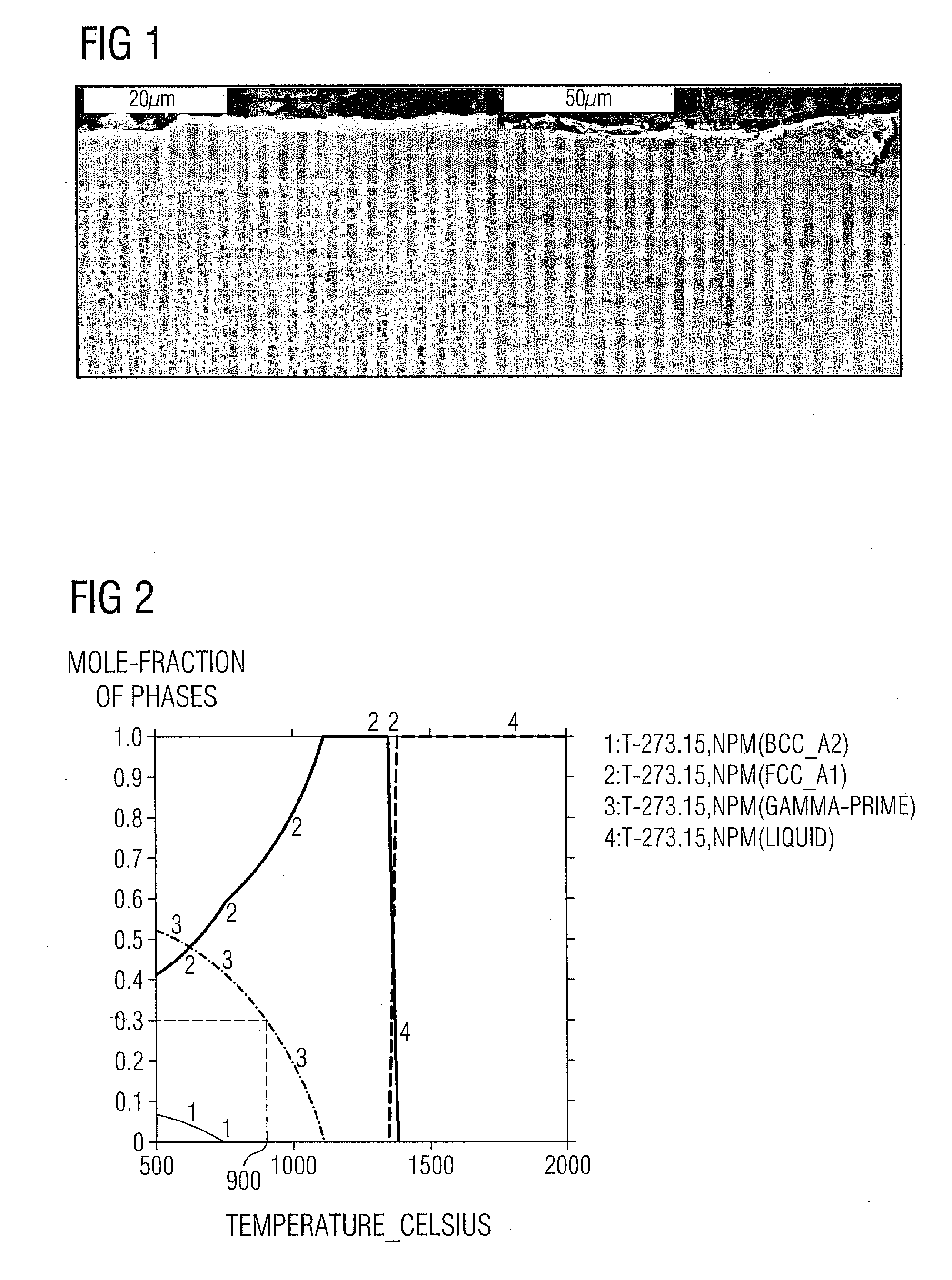

Nickel base gamma prime strengthened superalloy

InactiveUS20110142712A1Improve cycle lifeLonger residual lifeBlade accessoriesMachines/enginesLanthanideRare earth

A nickel base gamma prime strengthened superalloy with a unique blend of high hot corrosion resistance, high oxidation resistance, high coating compatibility, good weldability, high phase stability and at least moderate creep resistance is disclosed. The composite includes: Up to 20 wt % Co, between 17 and 21 wt % Cr, between 2 and 5 wt % of Mo+W+Re, at most 2 wt % Mo, between 4 and 4.7 wt % AL, between 3 and 7 wt % Ta, 0.01 and 0.2 wt % Ta, between 0.01 and 0.3 wt % of C+Zr+B between 0.05 and 1 wt % Hf, between 0.05 and 1 wt % Si, and between 0.01 and 0.2 wt % of the sum of rare earths such as SC, Y, the actinides and the lanthanides. The composition is intended for use as base alloy for moderately stressed hot components and as filler alloy for cladding and weld repair in moderately stressed parts of hot components.

Owner:SIEMENS AG

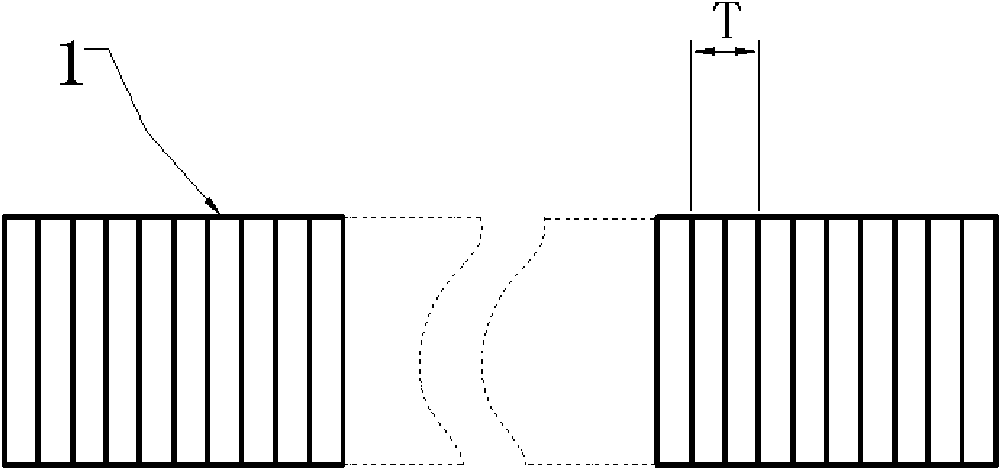

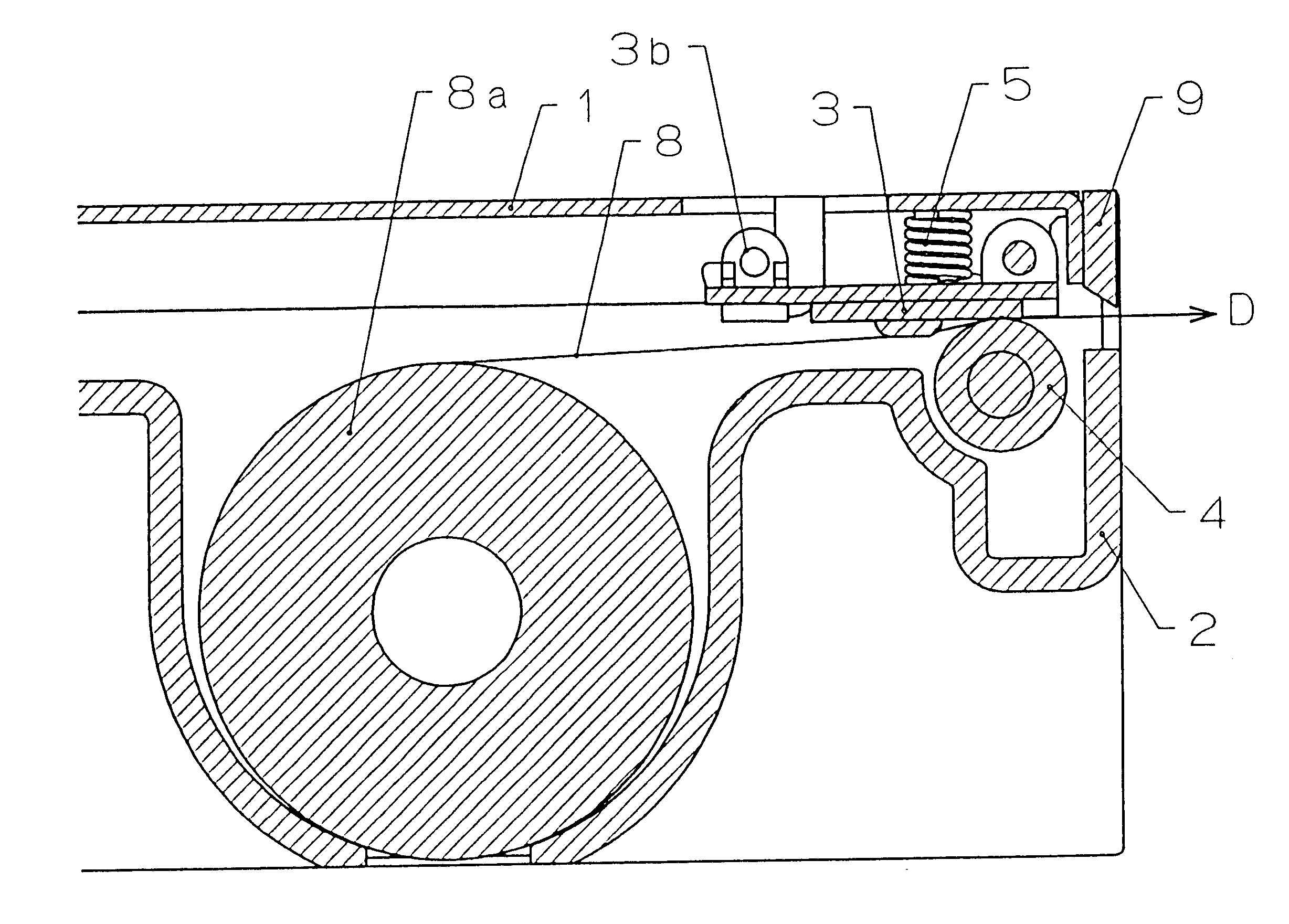

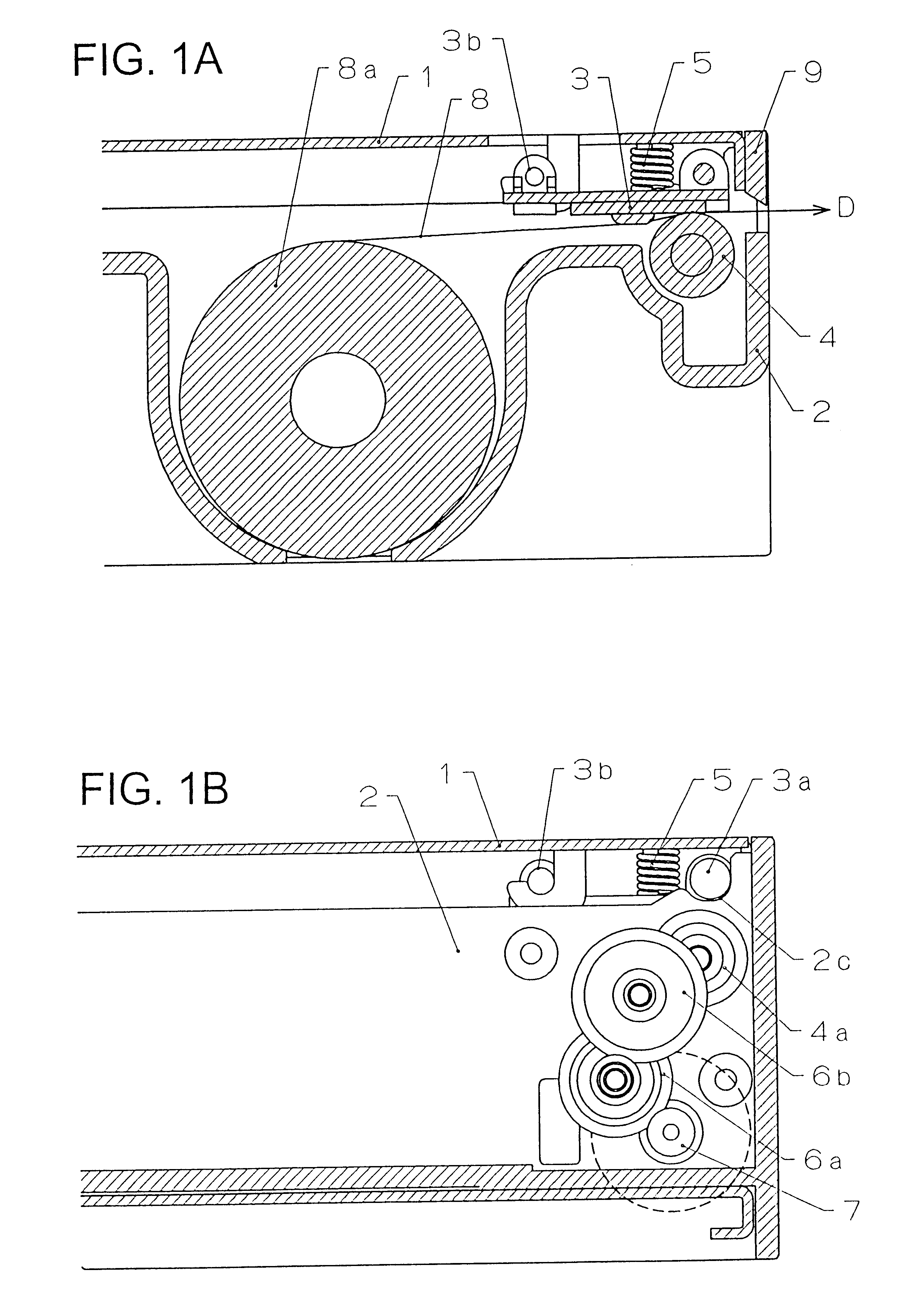

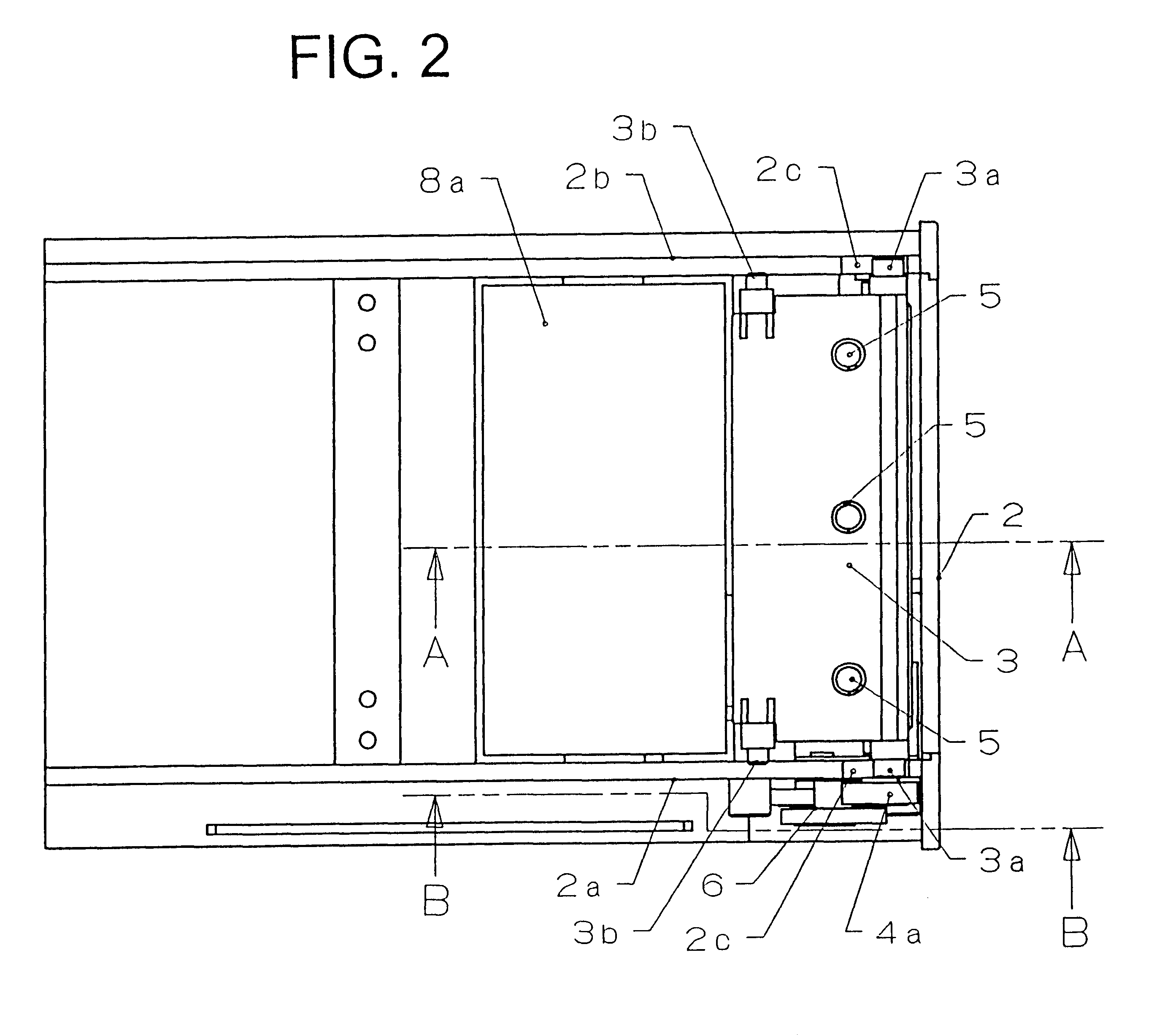

Drawer-type line thermal printer

InactiveUS6469726B2High precisionModerate resistancePrinting mechanismsRecording apparatusRolling paperComputer printing

In a thermal printer with a drawer-type paper holder, a means is provided, which facilitates the loading of recording paper, reduces the number of parts, and improves the precision in positioning a thermal head and a platen roller, a thermal printer is composed of a first frame 1 by which the thermal head 3 is rotatably supported so that recording paper 8 is brought into pressure contact with a platen roller 4 by a biasing member 5 and a second frame 2 that pivotably supports the platen roller 4, is opened and closed in parallel to the first frame 1, and contains a recording rolled paper 8a. The thermal printer has a configuration in which a first cam 3a provided in the thermal head 3 is guided by a second cam 2c formed in the second frame 2 while being biased by the biasing member 5 and thus the platen roller 4 pivotably supported to the second frame 2 is positioned with respect to the thermal head 3.

Owner:SEIKO INSTR INC

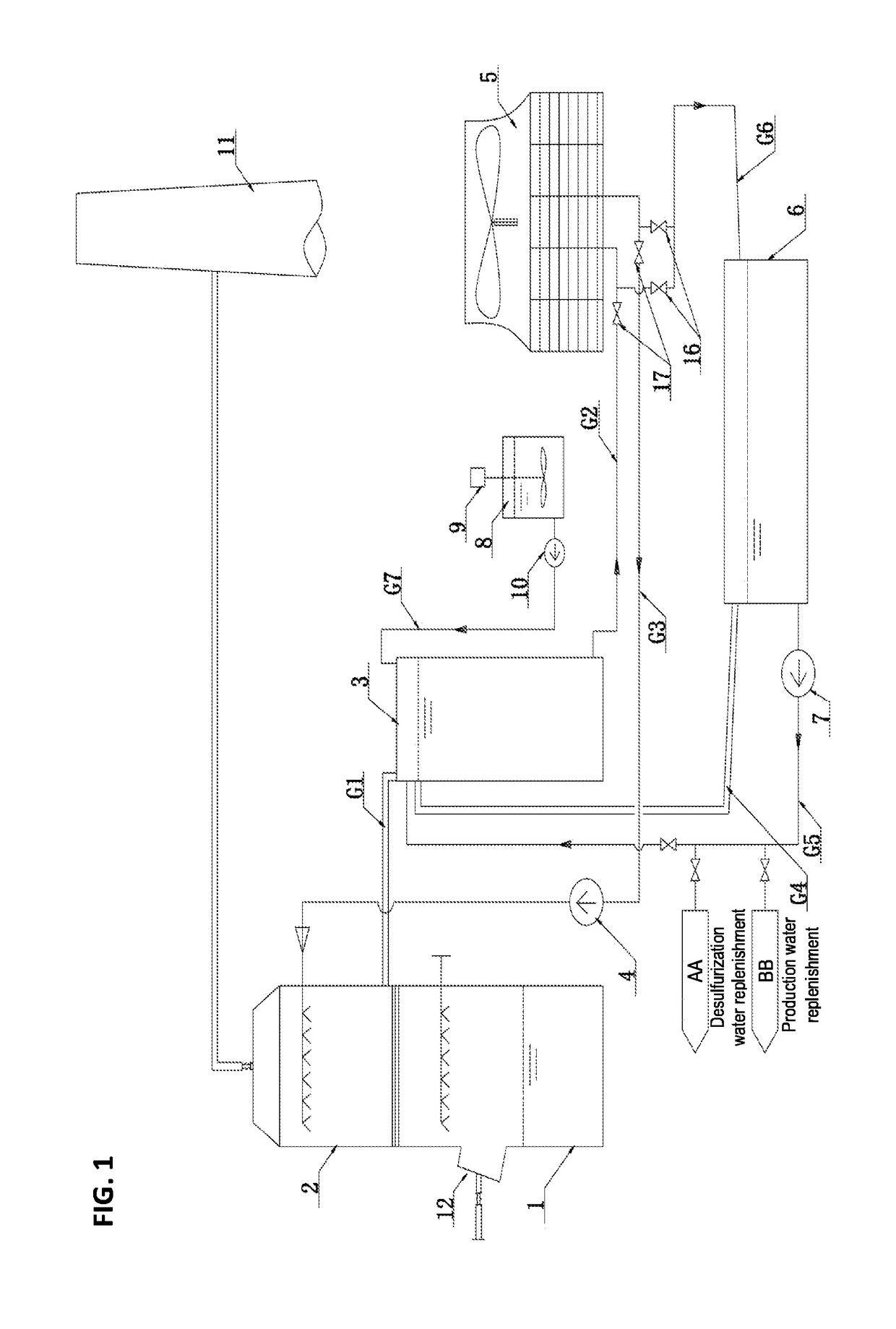

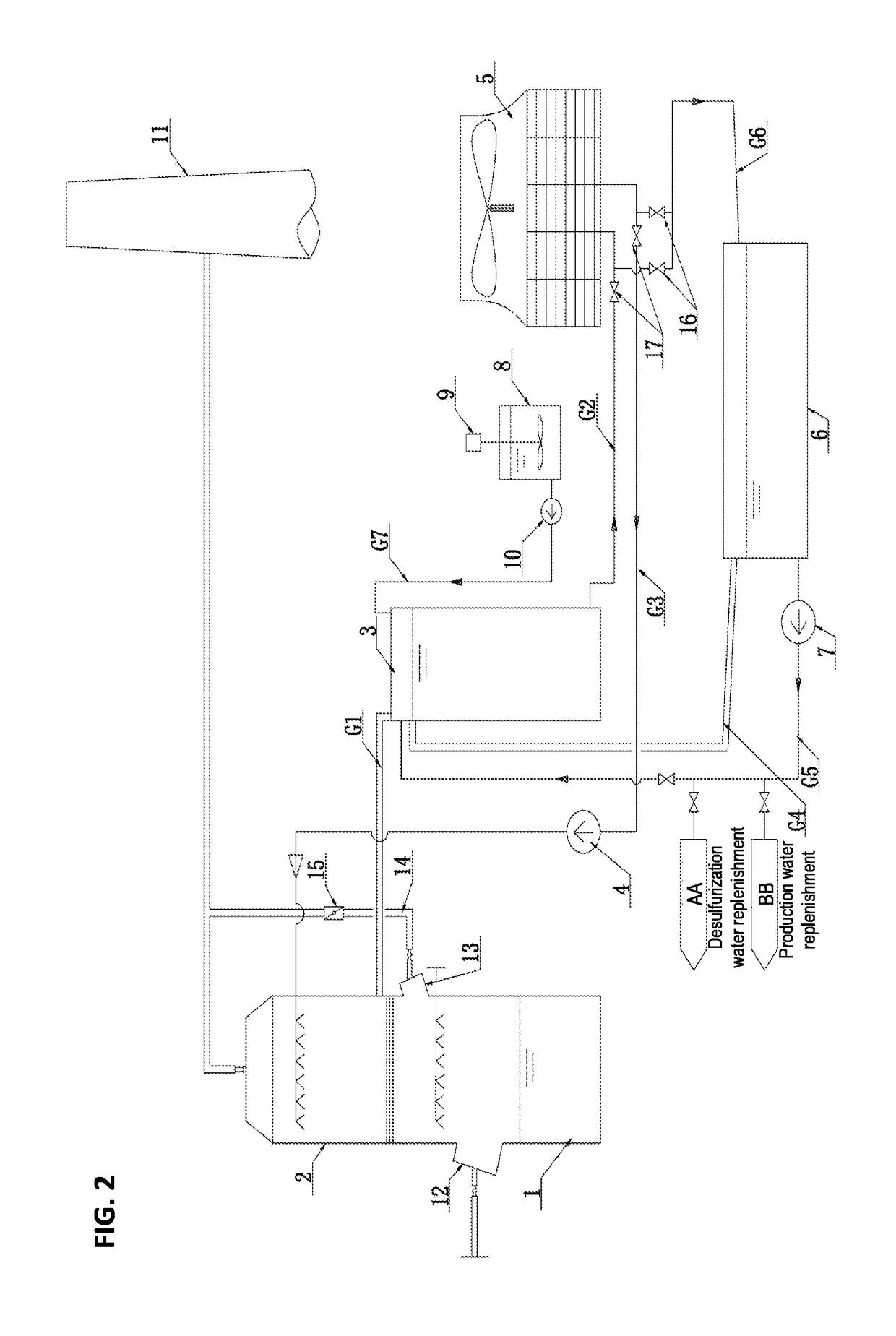

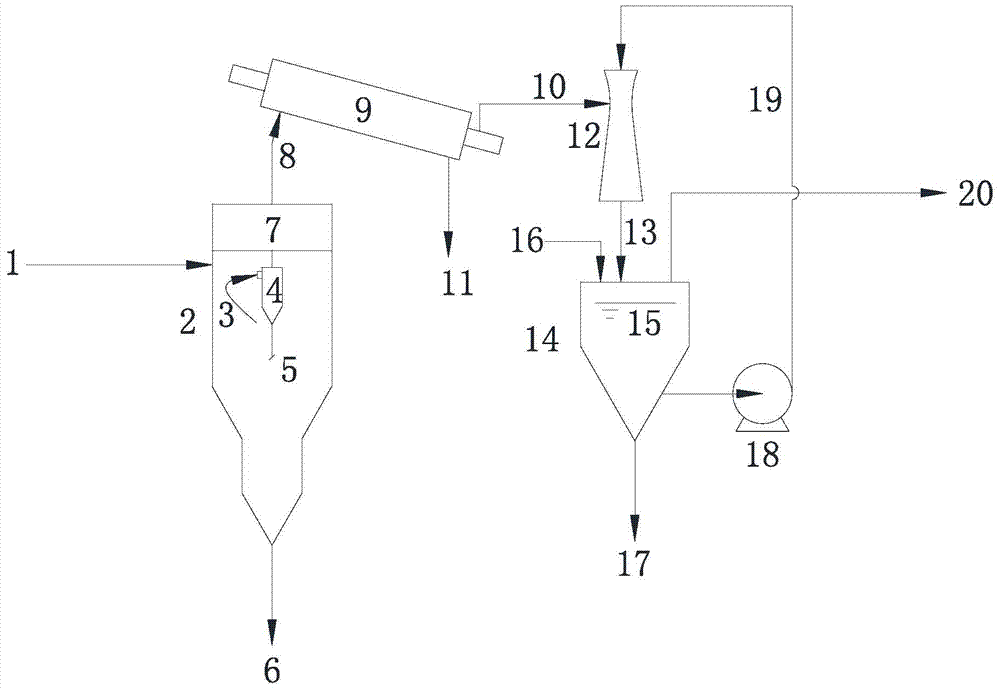

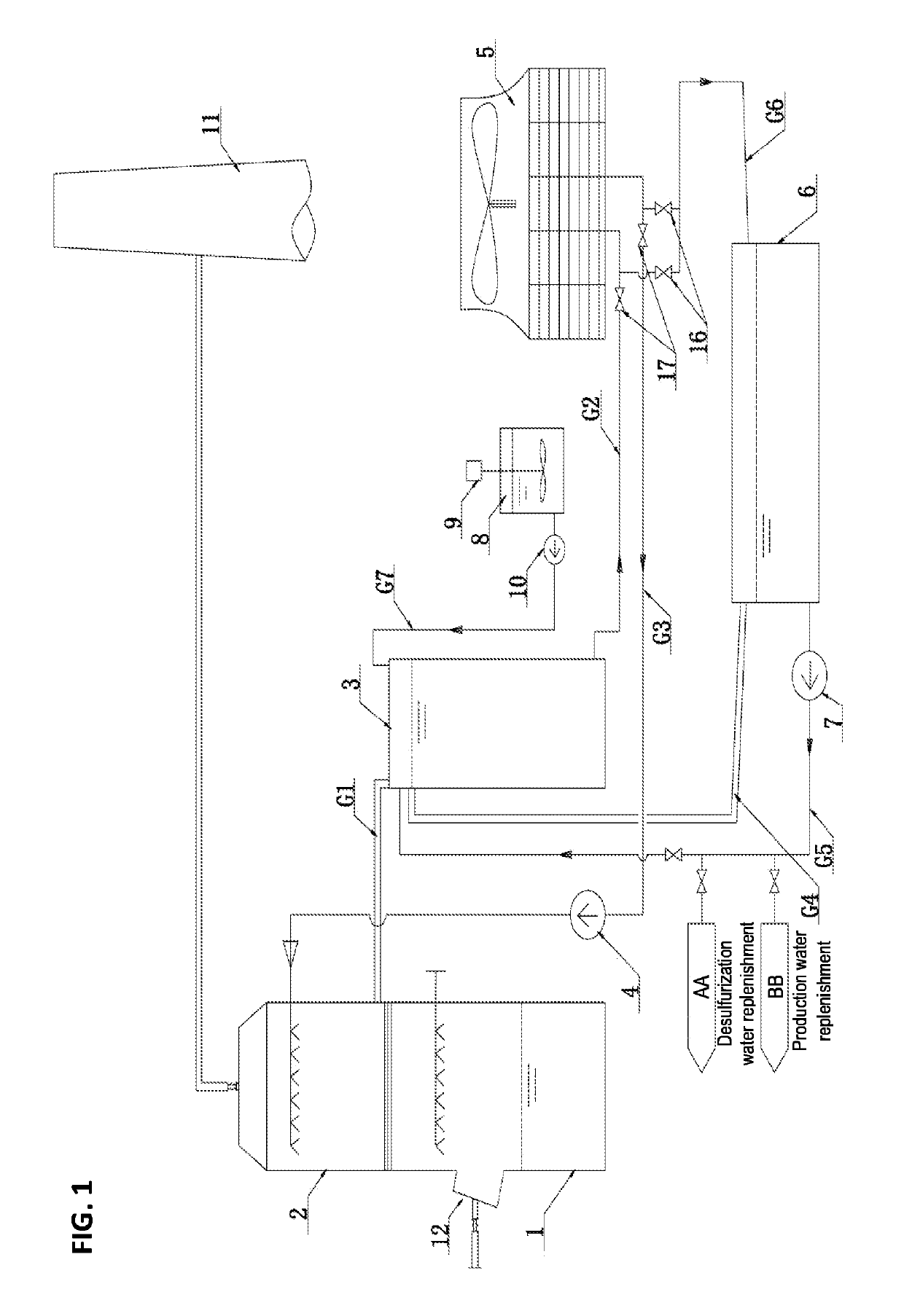

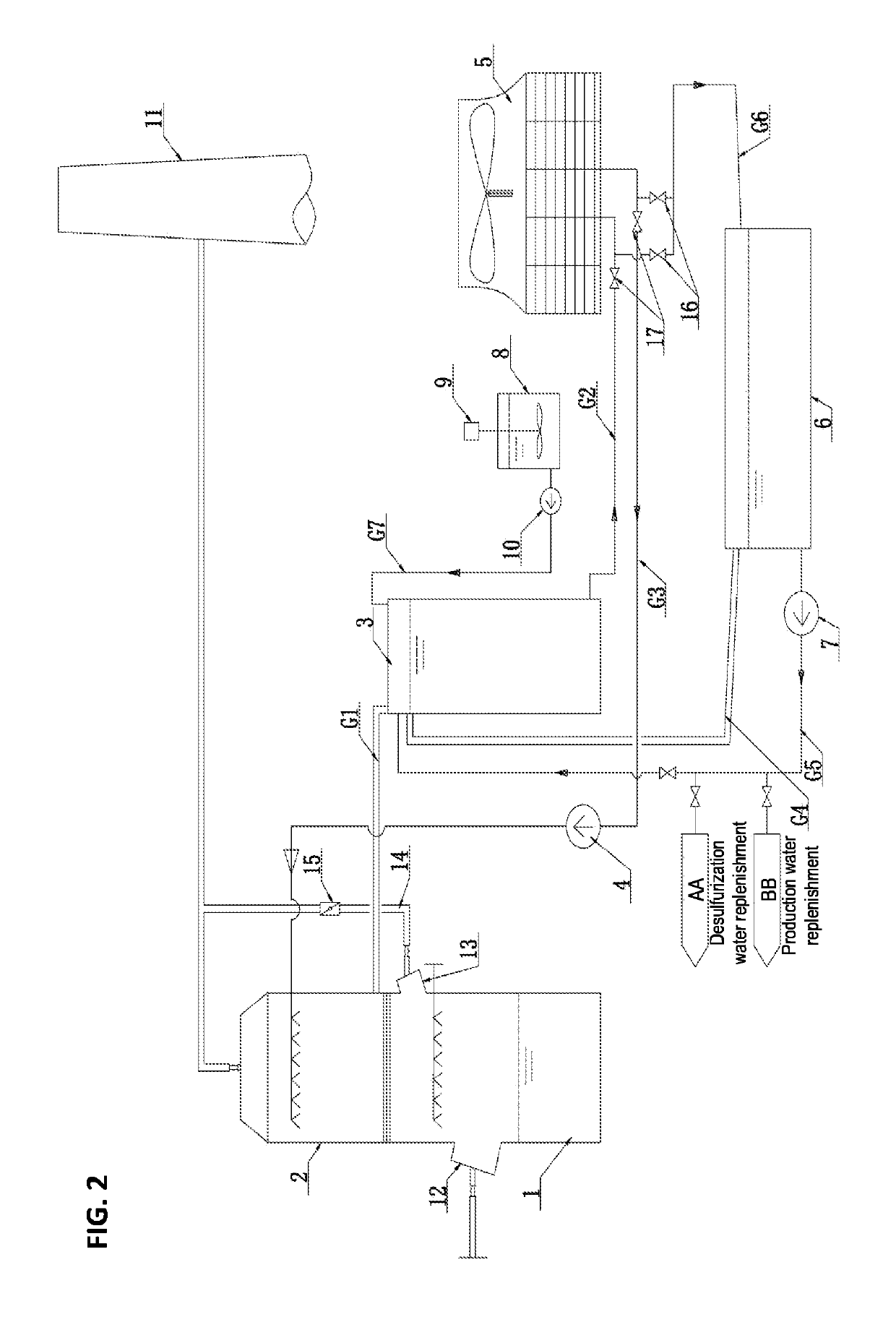

Flue gas condensation water extraction system

ActiveUS20190083900A1Improve reliabilityLong-term stabilityGas treatmentEmission preventionCooling towerFlue gas

A flue gas condensation water extraction system includes a flue gas condensation-end system and a flue gas refrigeration source-end system. The flue gas condensation-end system includes a desulfurization absorption tower, a flue gas purification and condensation tower, and a condensed water storage tank. The flue gas purification and condensation tower is arranged above the desulfurization absorption tower. A flue gas outlet, a water inlet, and a water outlet are provided on the flue gas purification and condensation tower. The flue gas refrigeration source-end system includes a cooling tower. The water outlet is connected to the condensed water storage tank via a condensed water downcomer. The water inlet is connected to the cooling tower via a circulating water supply pipe. A condensation circulation water pump is provided on the circulating water supply pipe. The cooling tower is connected to the condensed water storage tank via a circulating water return pipe.

Owner:LIU CHUNXIAO

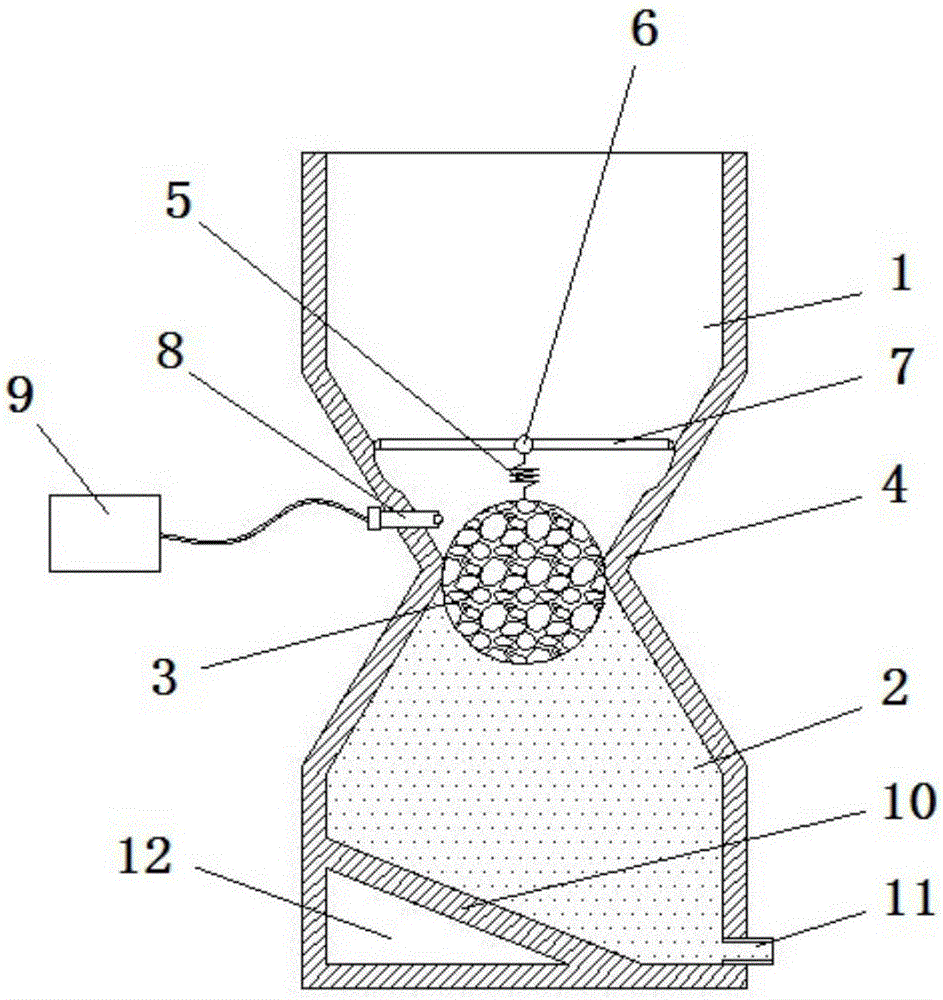

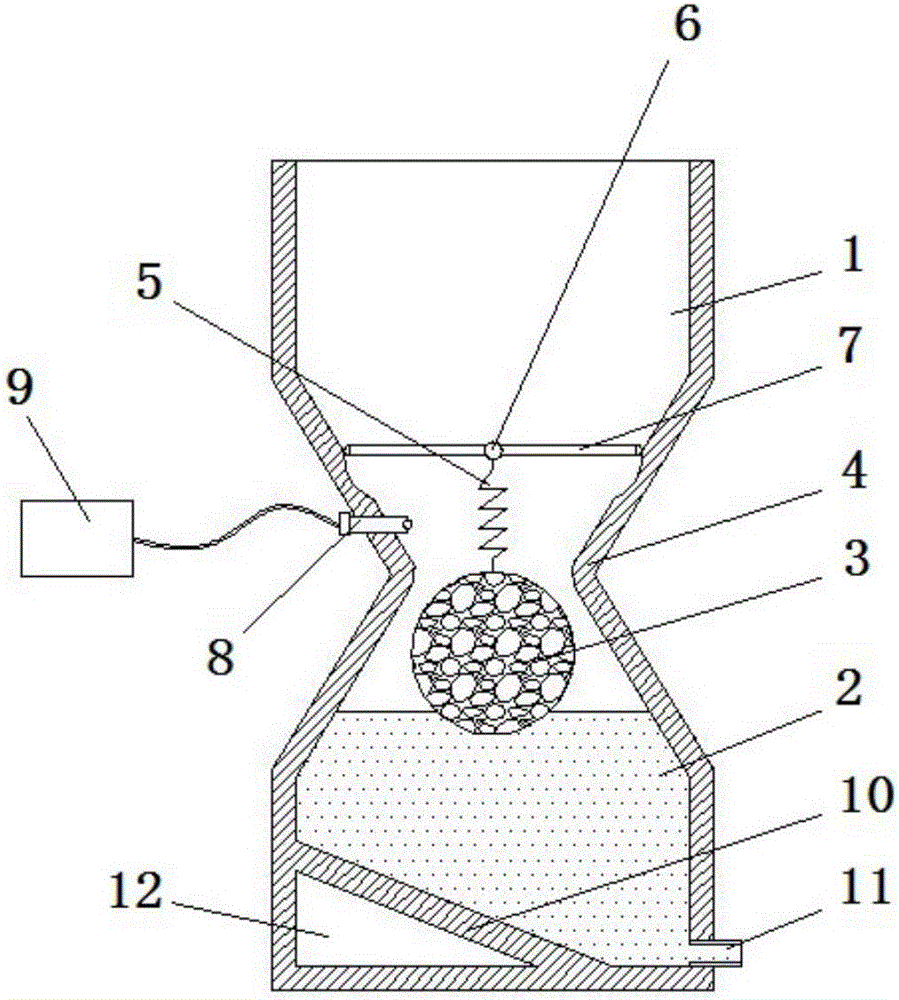

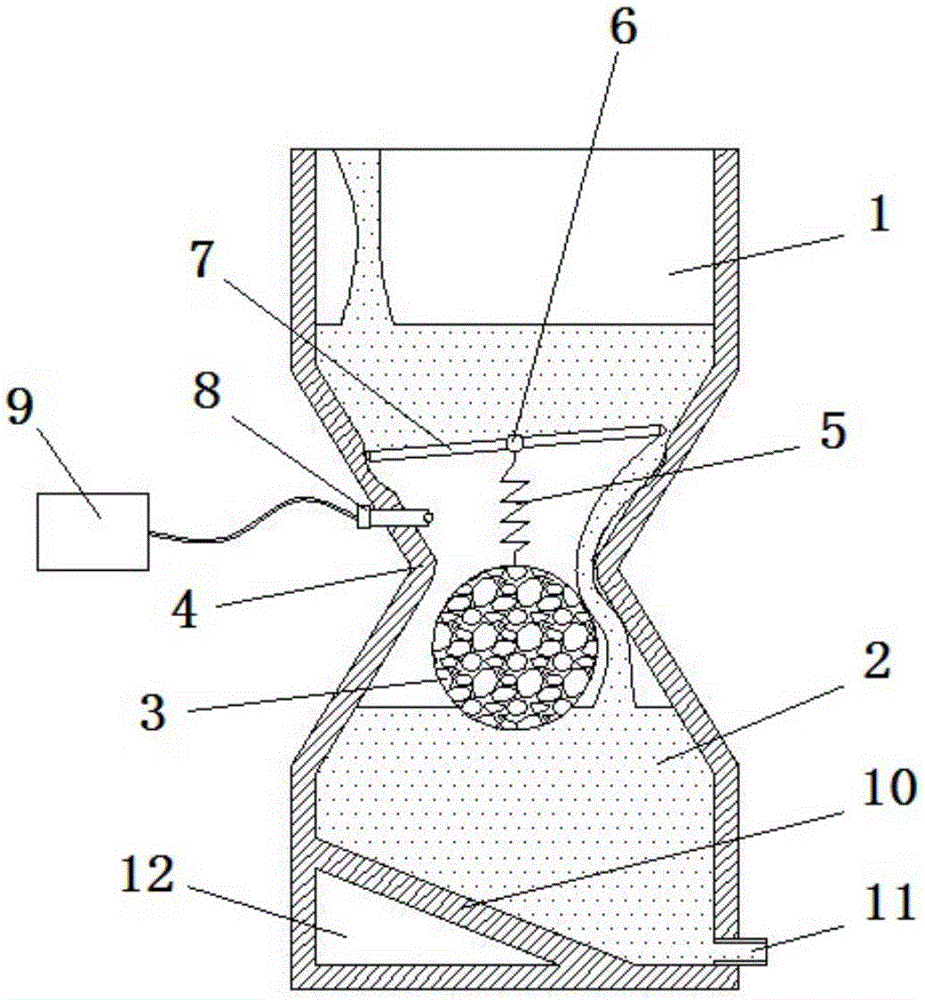

Automatic printing machine ink adding mechanism based on floating ball seal

ActiveCN106827802AModerate resistanceExtend your lifePrinting press partsMachine partsPrinting press

The invention discloses an automatic printing machine ink adding mechanism based on floating ball seal. The automatic printing machine ink adding mechanism comprises an ink box, wherein the ink box is divided into a charging chamber and a safety ink measuring chamber, a neck for limiting a floating ball is arranged between the charging chamber and the safety ink measuring chamber, the floating ball is located in the safety ink measuring chamber and is fixed to a rotary shaft in the charging chamber through a pull rope, the rotary shaft limits a rotary plate, and a position sensor is arranged at the position, close to the neck, of the inner wall of the charging chamber in a penetrating mode. The ink box is provided with the safety ink measuring chamber. When the ink amount is insufficient, the floating ball moves down with the ink liquid level, the position sensor gives out an alarm signal, further ink is added in time, and the service life of printing machine parts are guaranteed.

Owner:HANGZHOU WEICHENG PRINTING

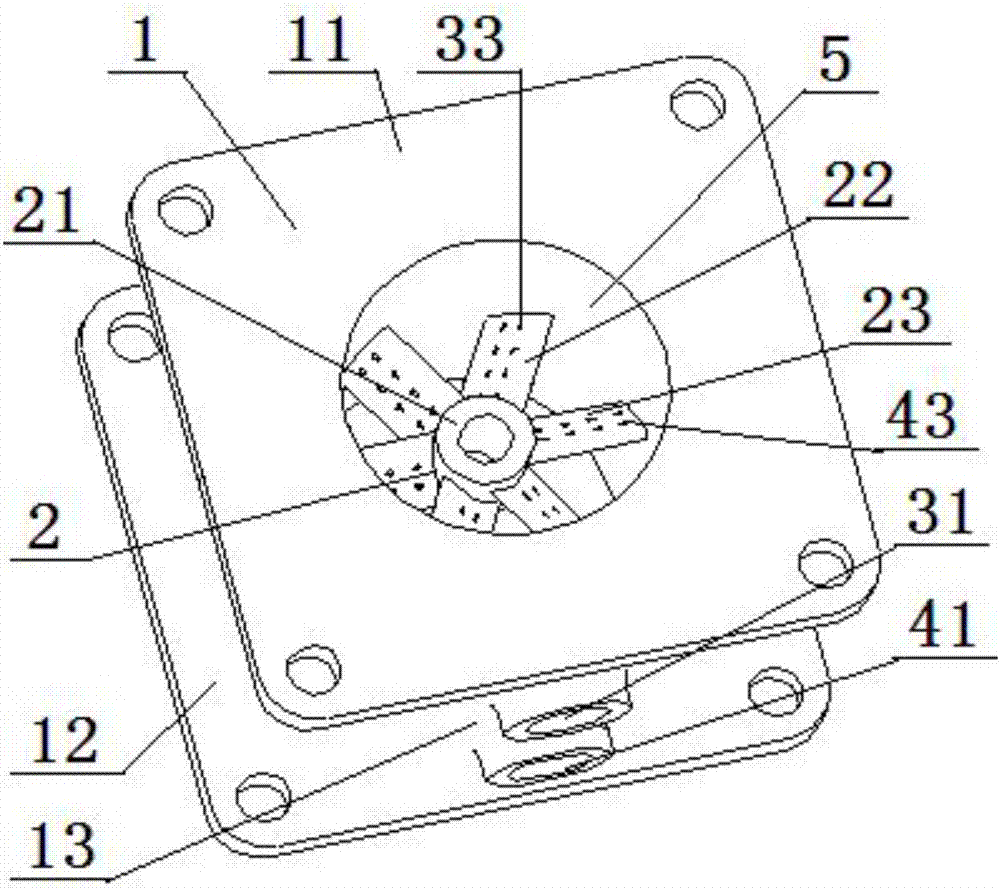

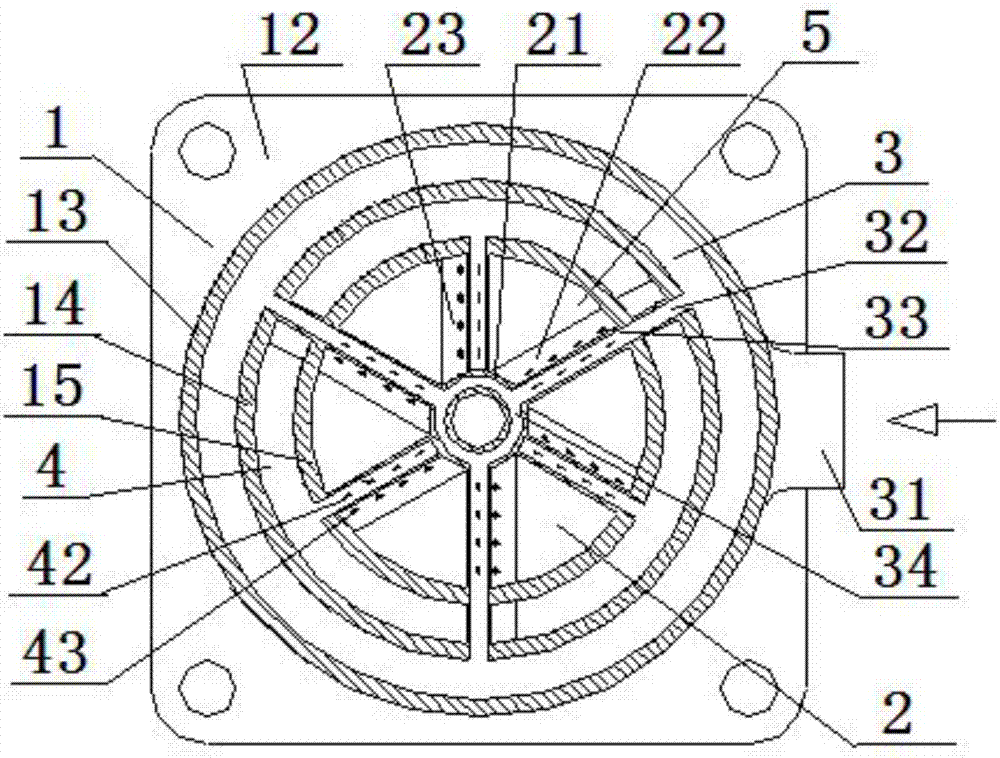

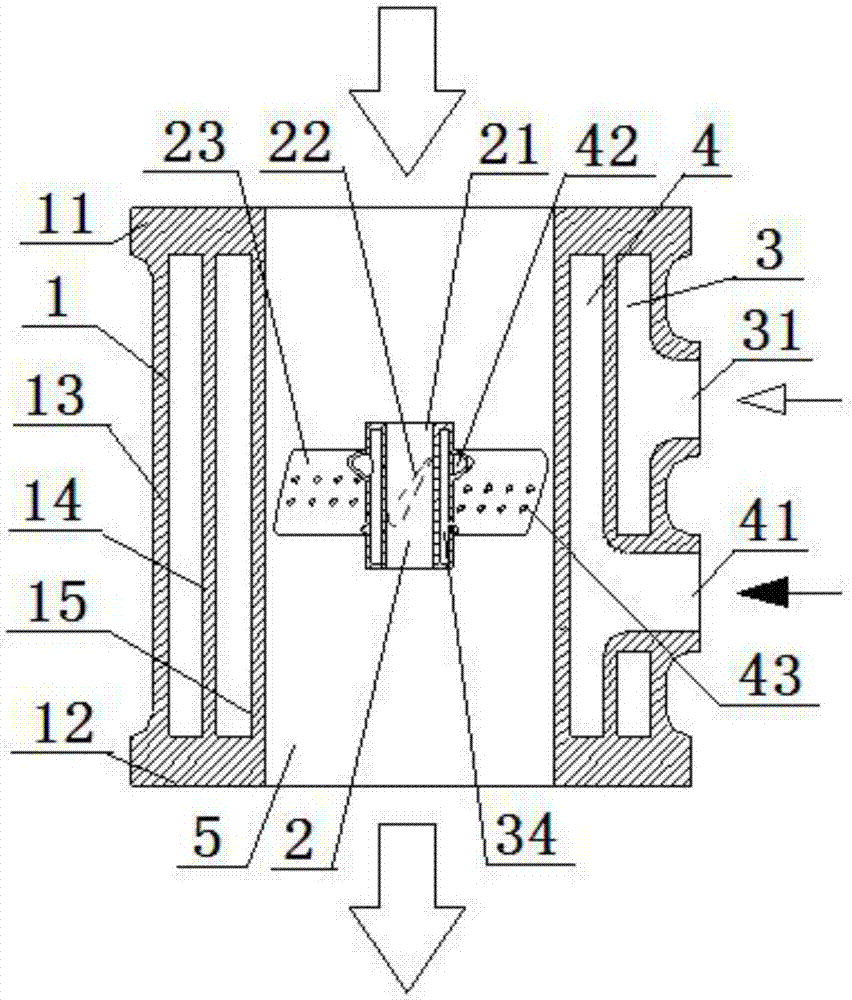

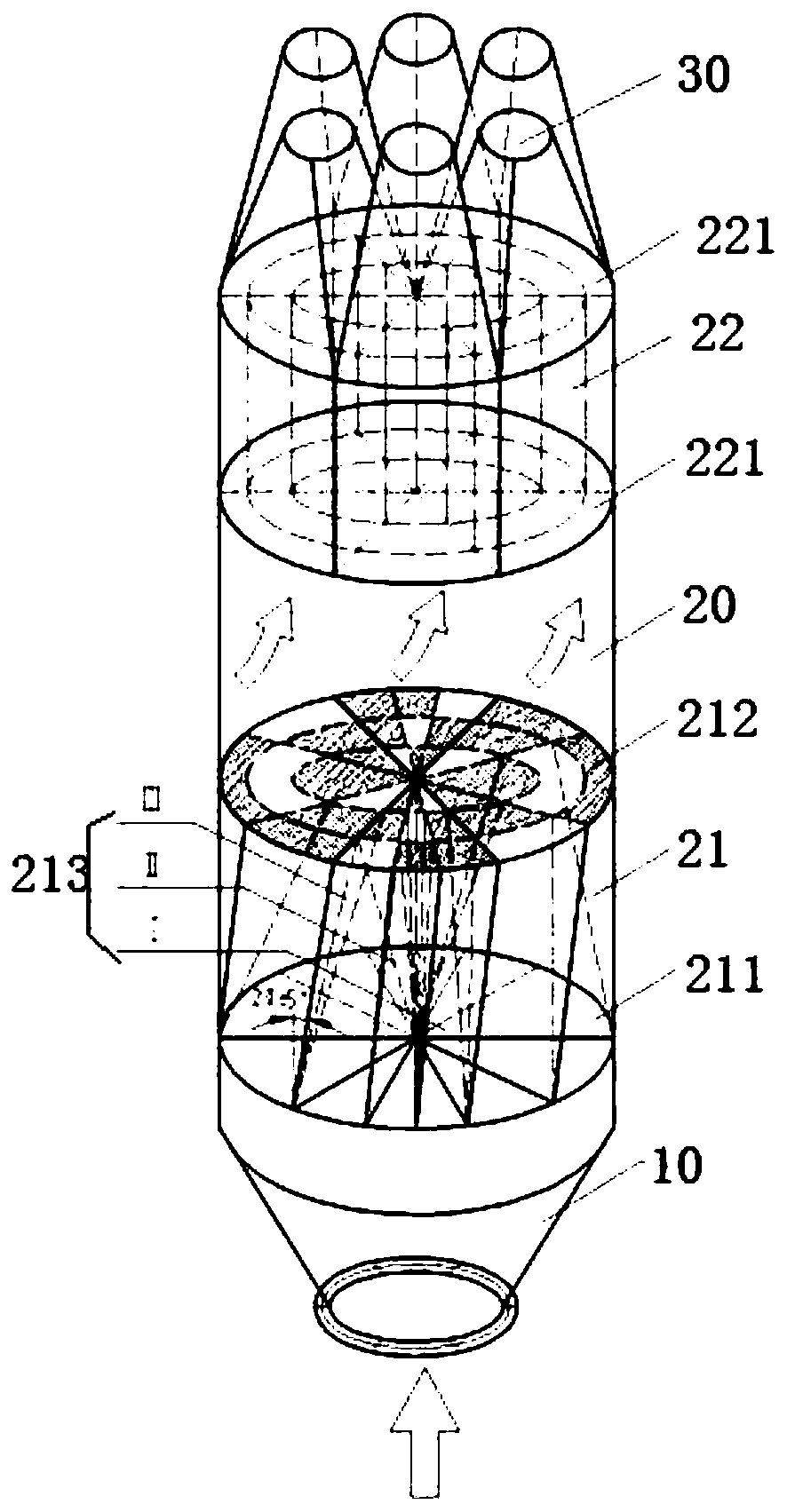

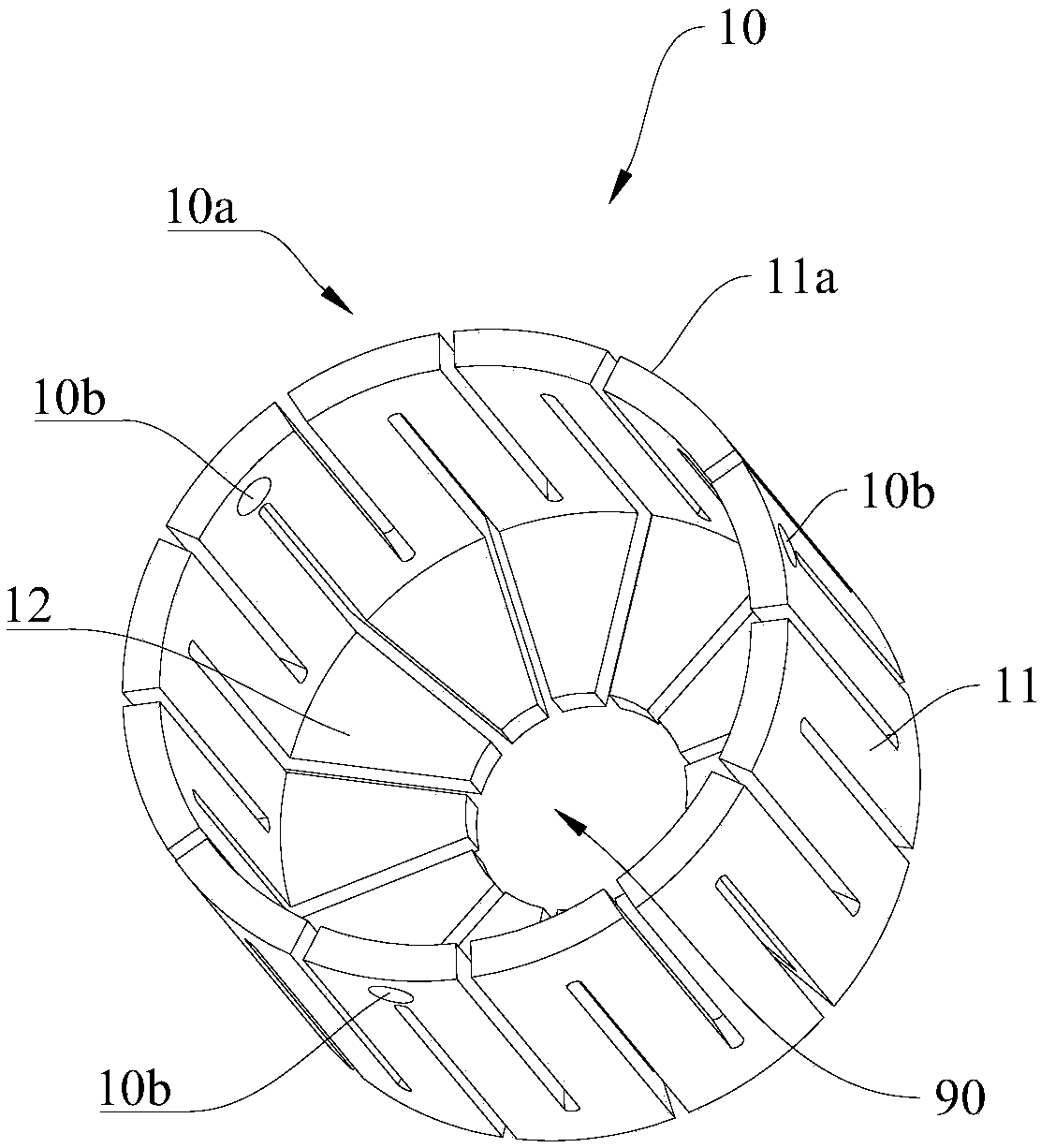

Multi-fluid mixer

ActiveCN107131080ACompact structureHighly integratedExhaust gas recirculationMachines/enginesEngineeringCavity wall

The invention relates to a multi-fluid mixer which comprises a gas mixing base and a mixing core. The mixing core is arranged inside the gas mixing base; the gas mixing base comprises a top plate and a bottom plate, an outer cavity wall, a middle cavity wall and an inner cavity wall are coaxially arranged between the top plate and the bottom plate, a first fluid cavity is formed between the outer cavity wall and the middle cavity wall, a second fluid cavity is formed between the middle cavity wall and the inner cavity wall, and a gas mixing cavity is formed inside the inner cavity wall; and the mixing core comprises a middle support, a first fluid gas mixing blade and a second fluid gas mixing blade, one end of the first fluid gas mixing blade is fixedly connected with the outer wall of the middle support, the other end of the first fluid gas mixing blade (22) penetrates the inner cavity wall to be fixedly connected with the middle cavity wall, one end of the second fluid gas mixing blade is fixedly connected with the outer wall of the middle support, and the other end of the second fluid gas mixing blade is fixedly connected with the inner cavity wall. By means of the design, mixing of three kinds of fluid can be achieved, and the uniform mixing integration level is high.

Owner:DONGFENG COMML VEHICLE CO LTD

High-conductivity self-adhesive graphene low-voltage heating slurry and preparation method and application thereof

InactiveCN111808453AReduce the number of layersReduce defectsGrapheneElectrically-conductive paintsLow voltageGraphite

The invention discloses high-conductivity self-adhesive graphene low-voltage heating slurry and a preparation method and application thereof, and belongs to the technical field of heating materials. The high-conductivity self-adhesive graphene low-voltage heating slurry is prepared from the following raw materials in parts by mass: 20-40 parts of graphene, 30-50 parts of heating carbon slurry, 1-5parts of resin, 5-15 parts of a solvent A, 10-20 parts of a dispersing agent, 5-10 parts of a water-based crosslinking coupling agent, 2-6 parts of a defoaming agent and 3-5 parts of an anti-settlingagent, wherein the graphene is prepared by utilizing a shearing stripping method. According to the method, the graphite raw material is directly subjected to high-speed shearing treatment by adoptinga shearing stripping method so that the graphite sheet layers are stripped and fall off to form graphene, and the prepared graphene is relatively low in layer number and few in defects. Besides, thegraphene low-voltage heating slurry prepared by the method only needs a low voltage of less than 36v, and is higher in low-voltage safety, good in heating stability, high in thermal conversion efficiency, longer in service life, safer and more environment-friendly.

Owner:武汉联维新材料科技有限公司

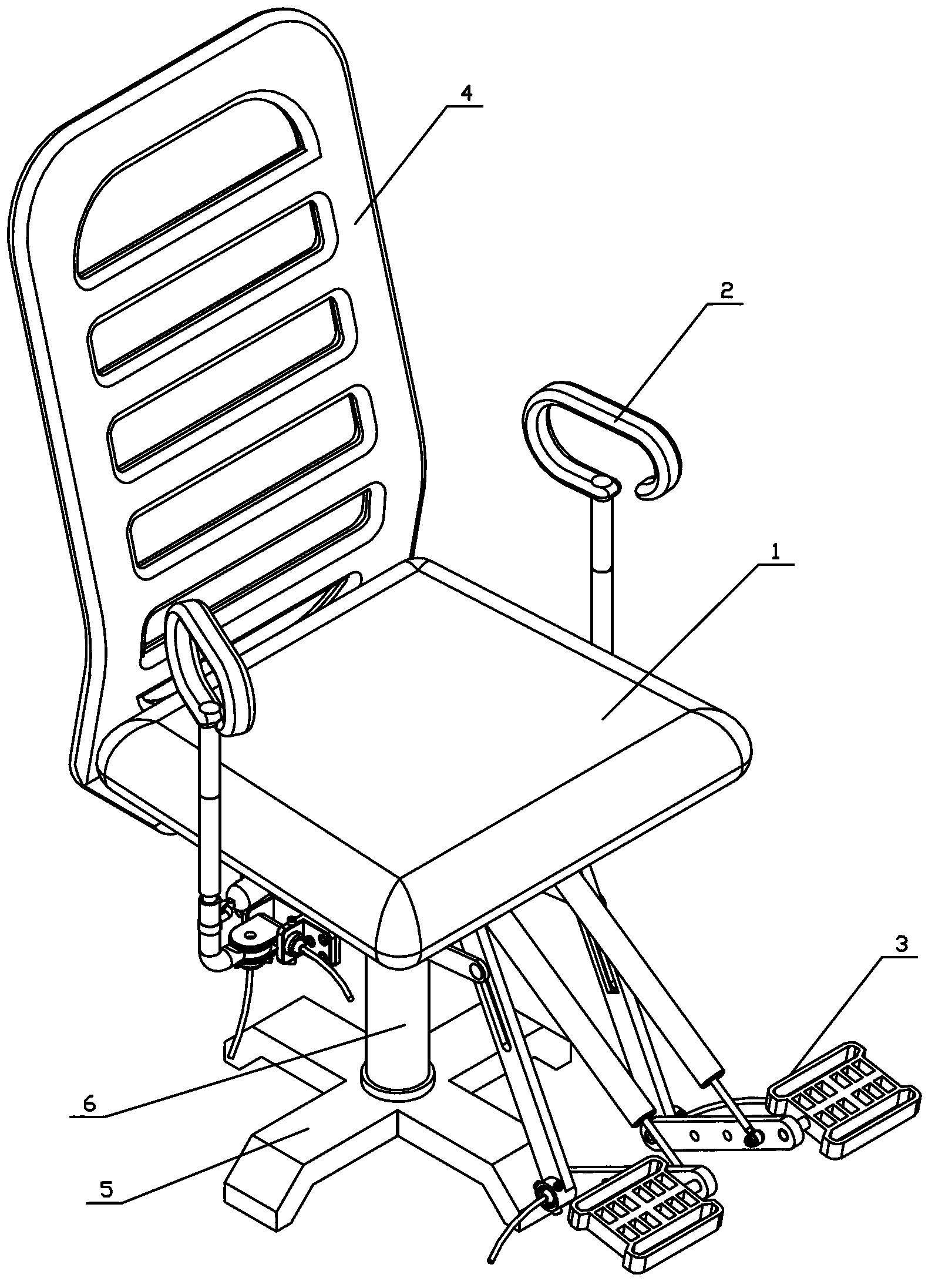

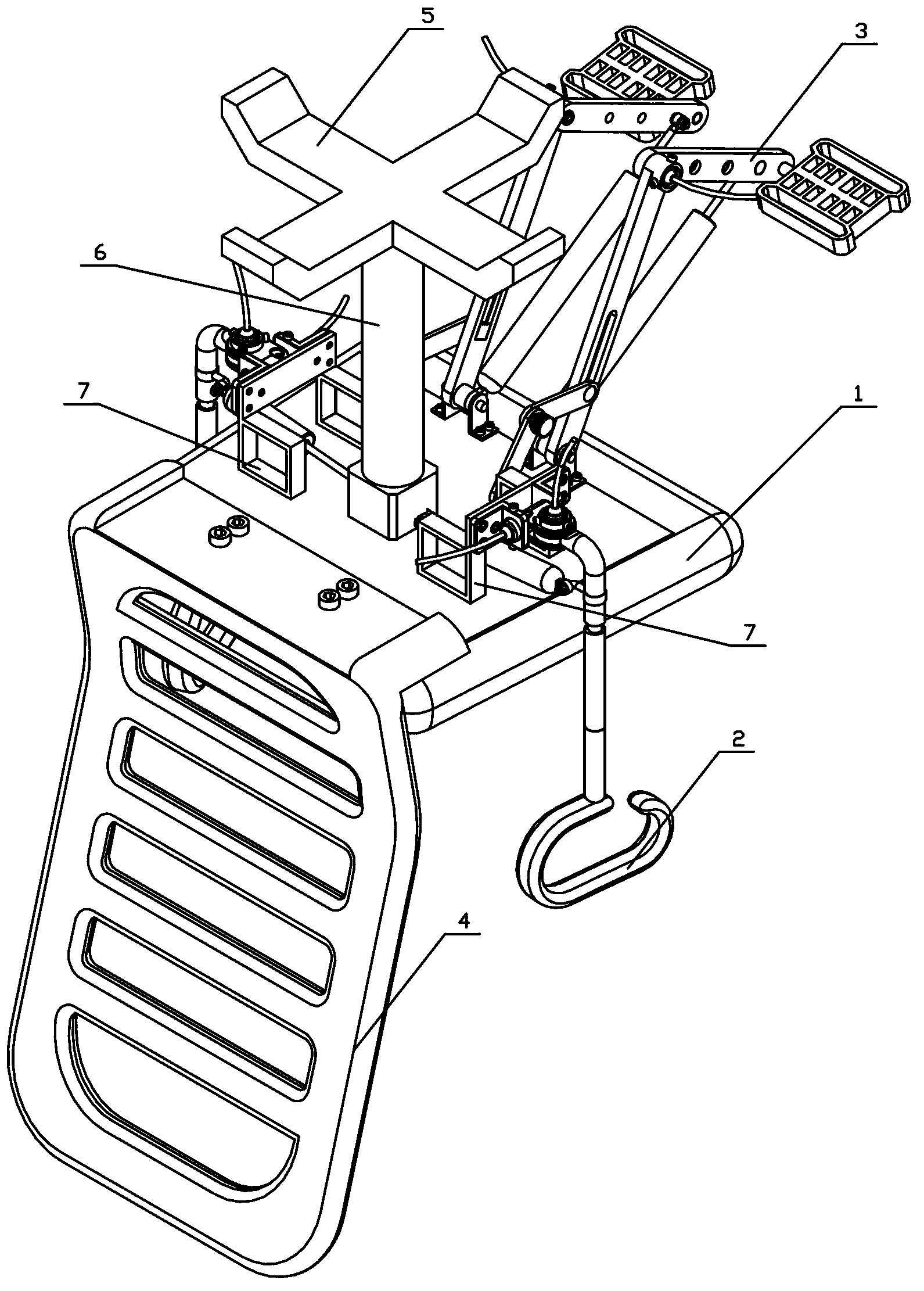

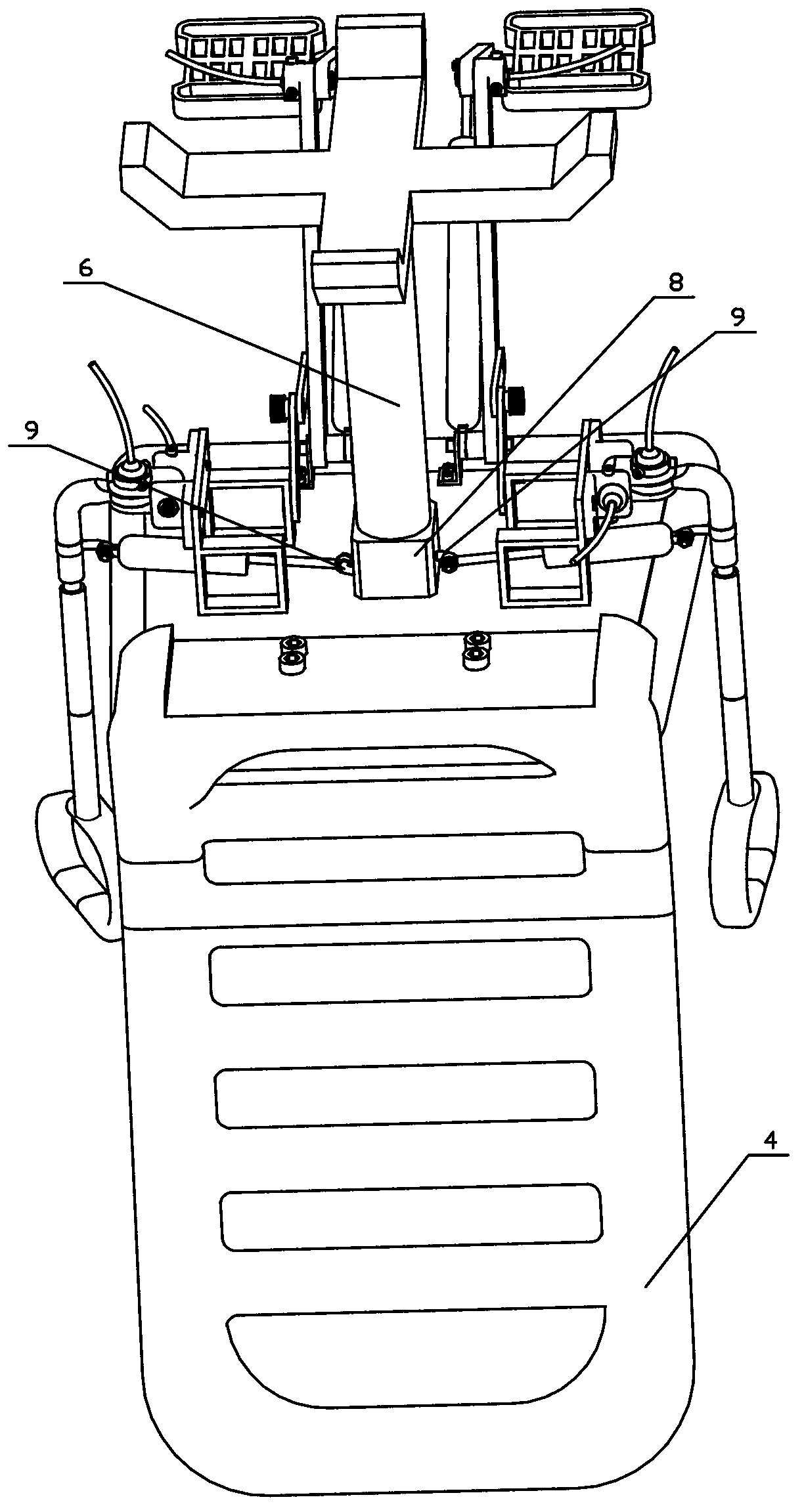

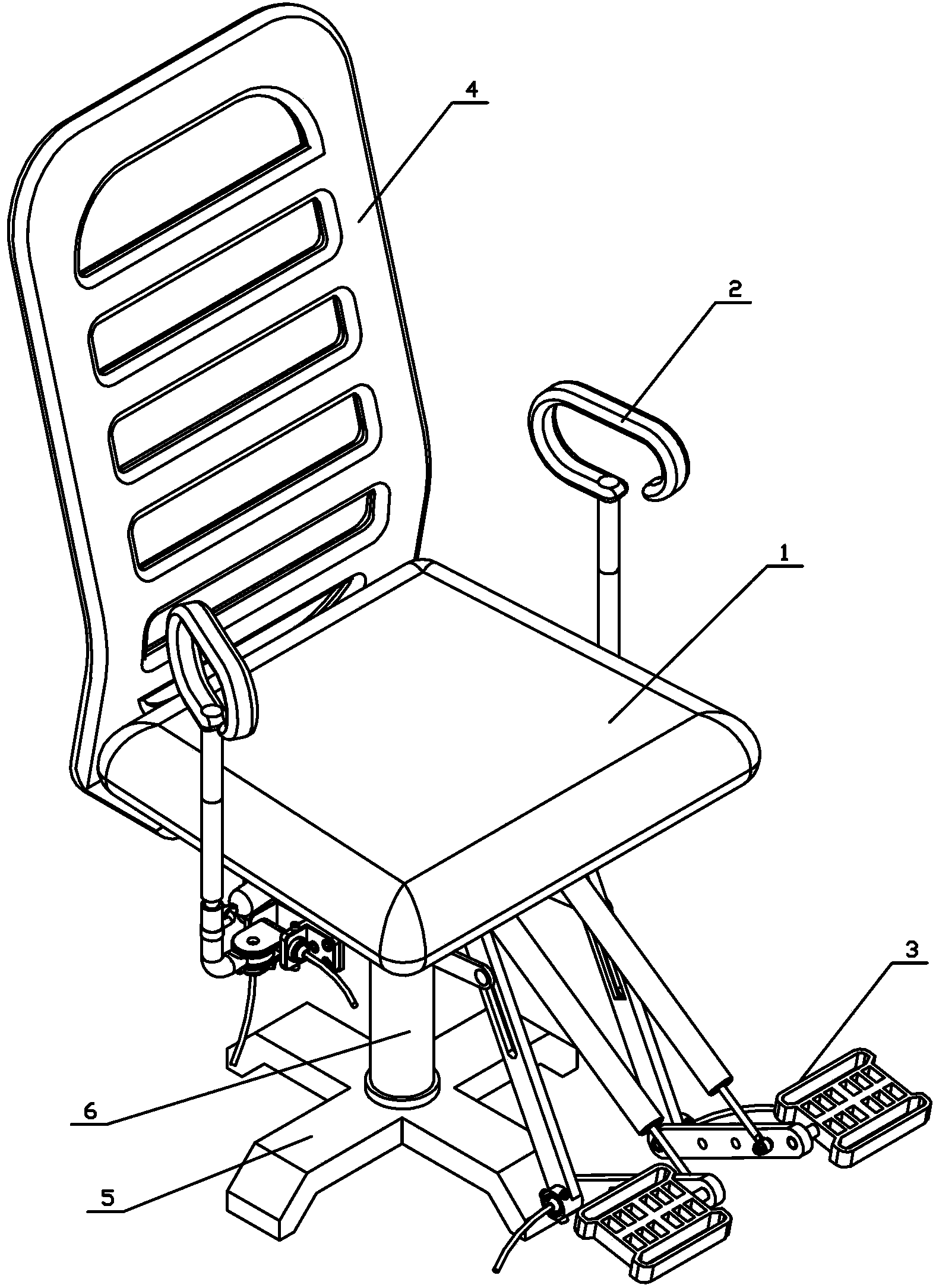

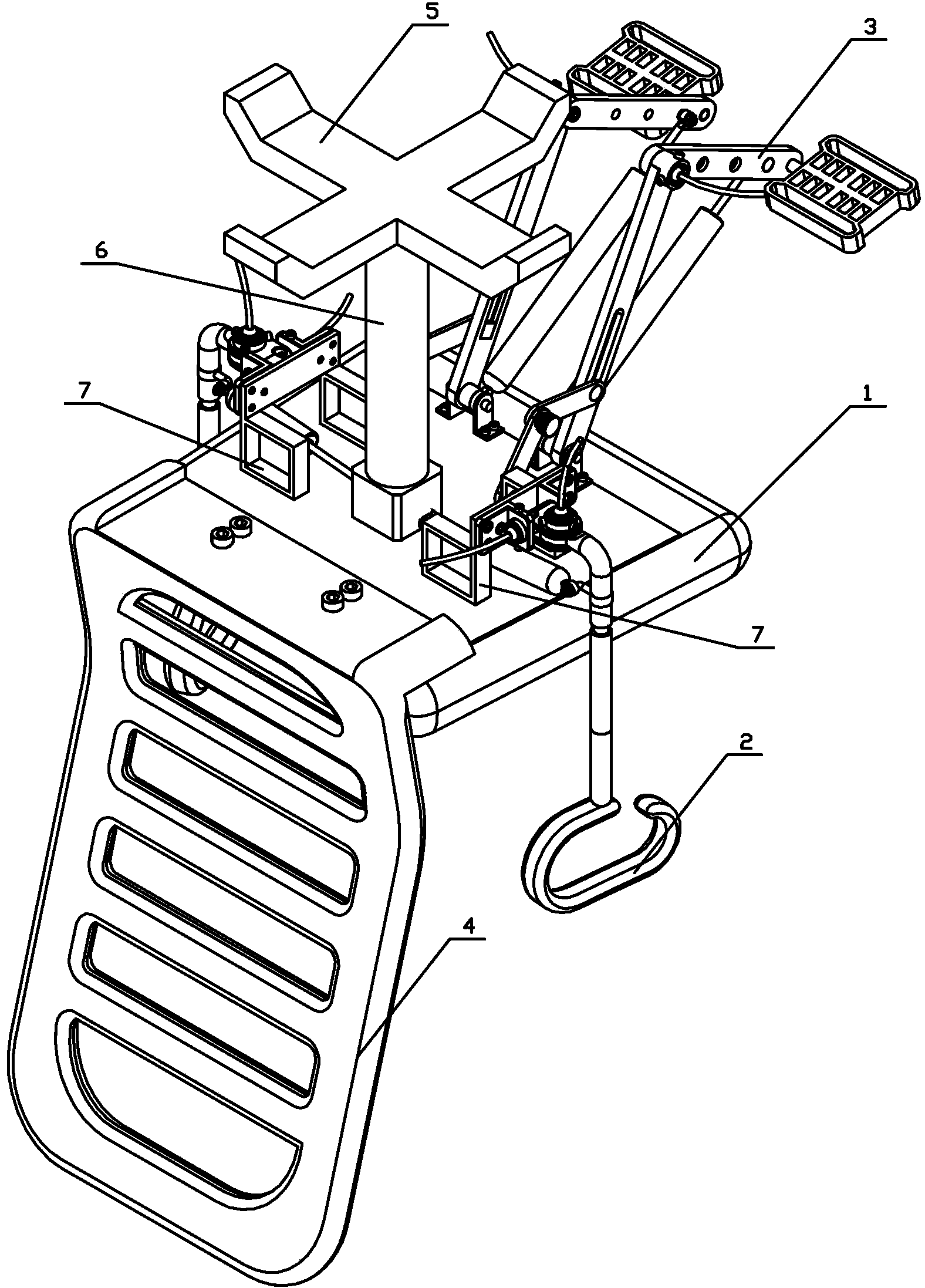

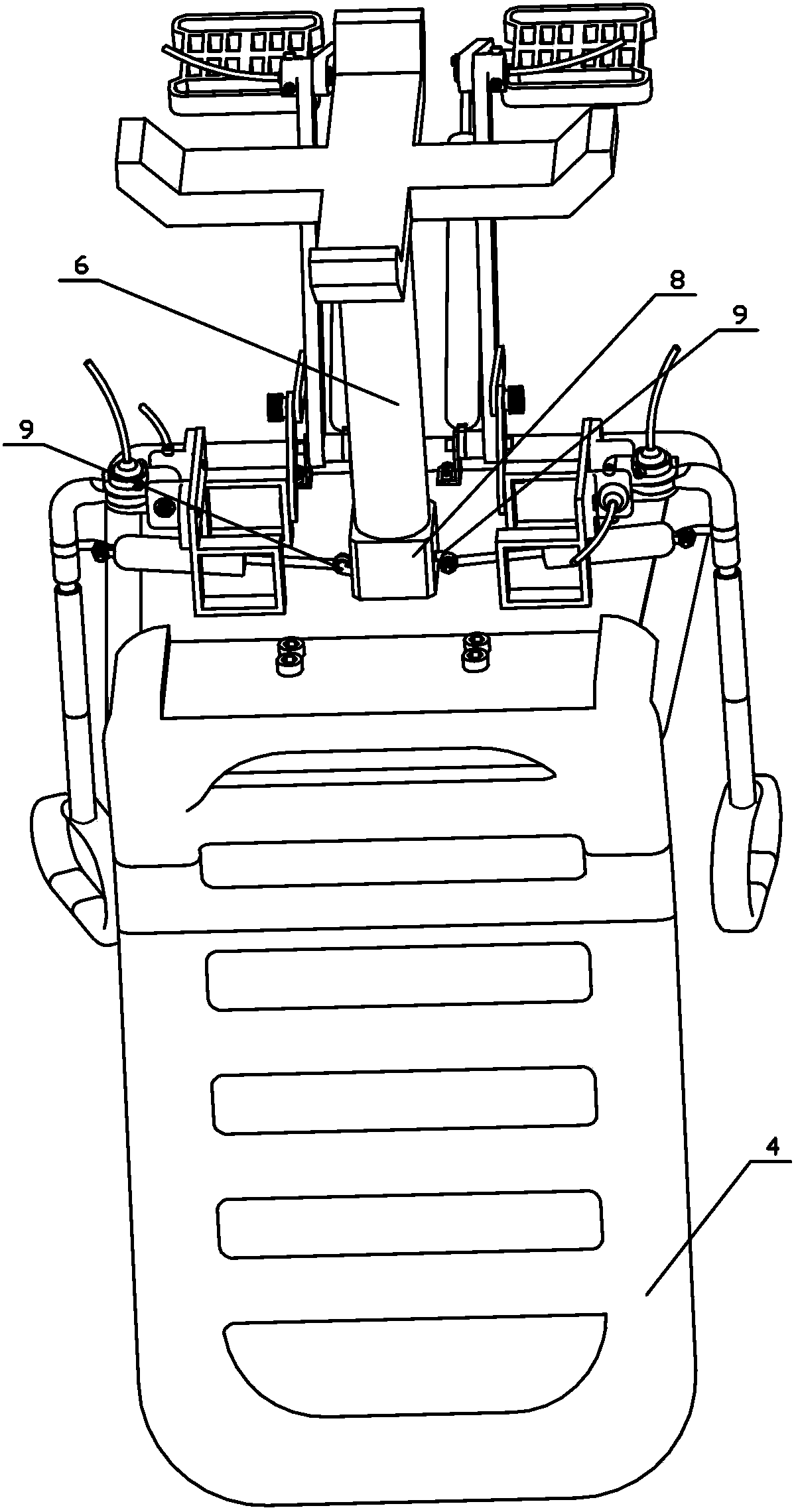

Fitness chair with digital output

ActiveCN103263755ATight locationSimple structureResilient force resistorsStoolsEngineeringMechanical engineering

The invention provides a fitness chair with digital output, which has a simple structure and is provided with a sensor for outputting a digital signal conveniently. The fitness chair comprises a seat panel (1), handle components (2), a pedal component (3), a backrest (4), a base (5) and a hydraulic supporting rod (6) and is characterized in that each handle component (2) comprises an integrated two-stage rotation structure and a potentiometer structure which is conveniently installed; and the pedal component (3) and a rotary shaft form a structure which can be folded backwards below the chair seat panel by virtue of a supporting sheet.

Owner:SHANDONG BODY STRONG FITNESS

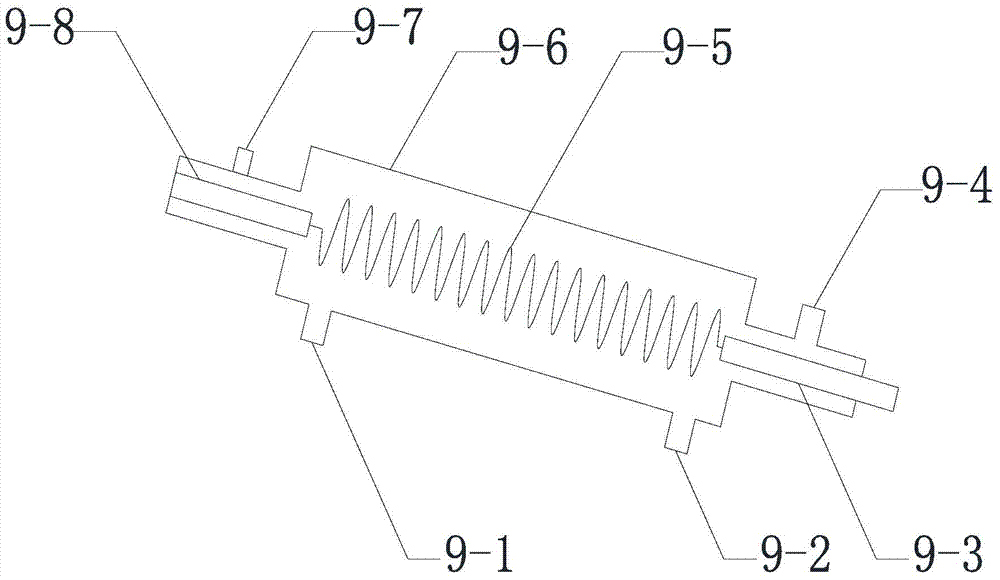

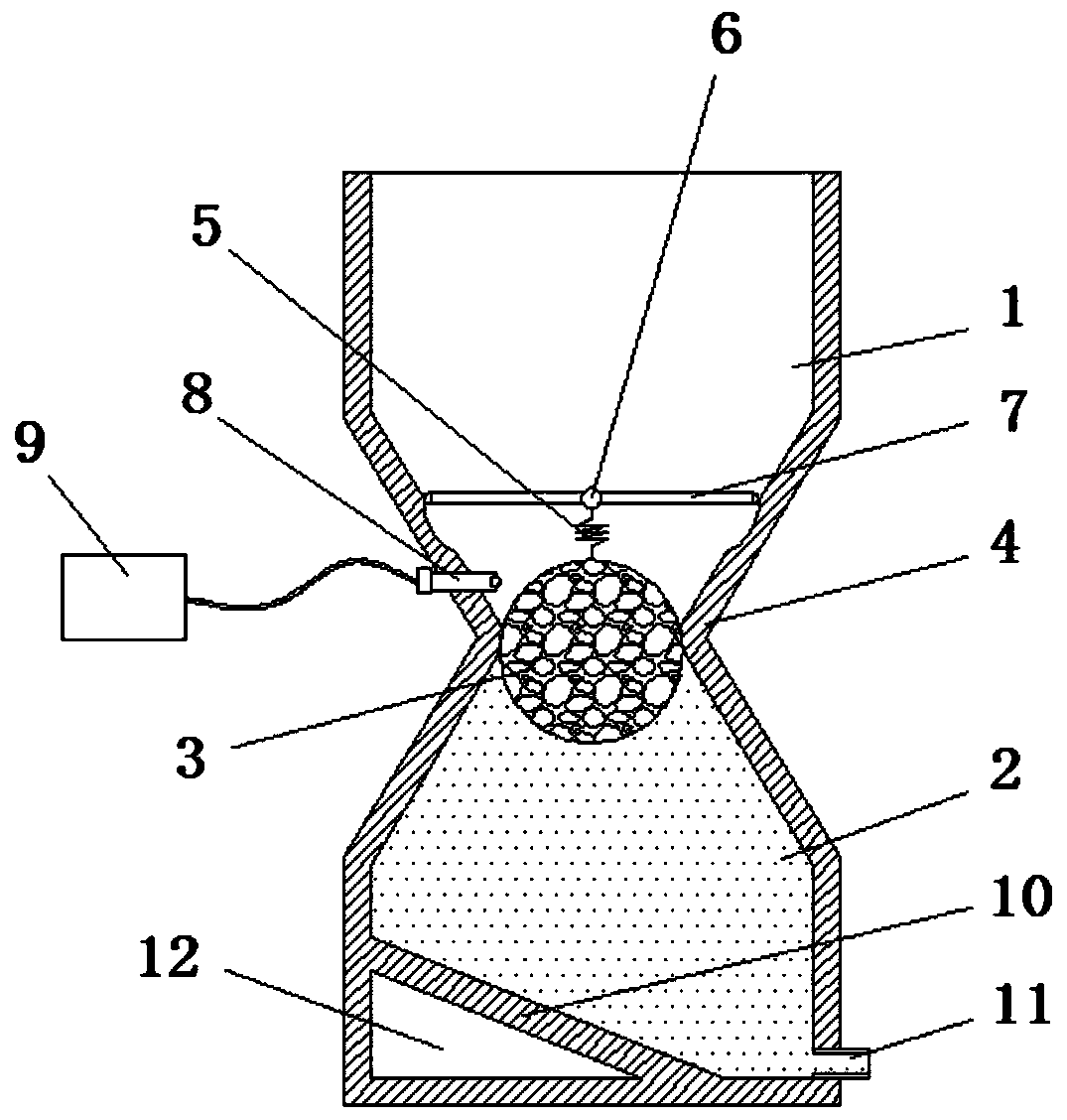

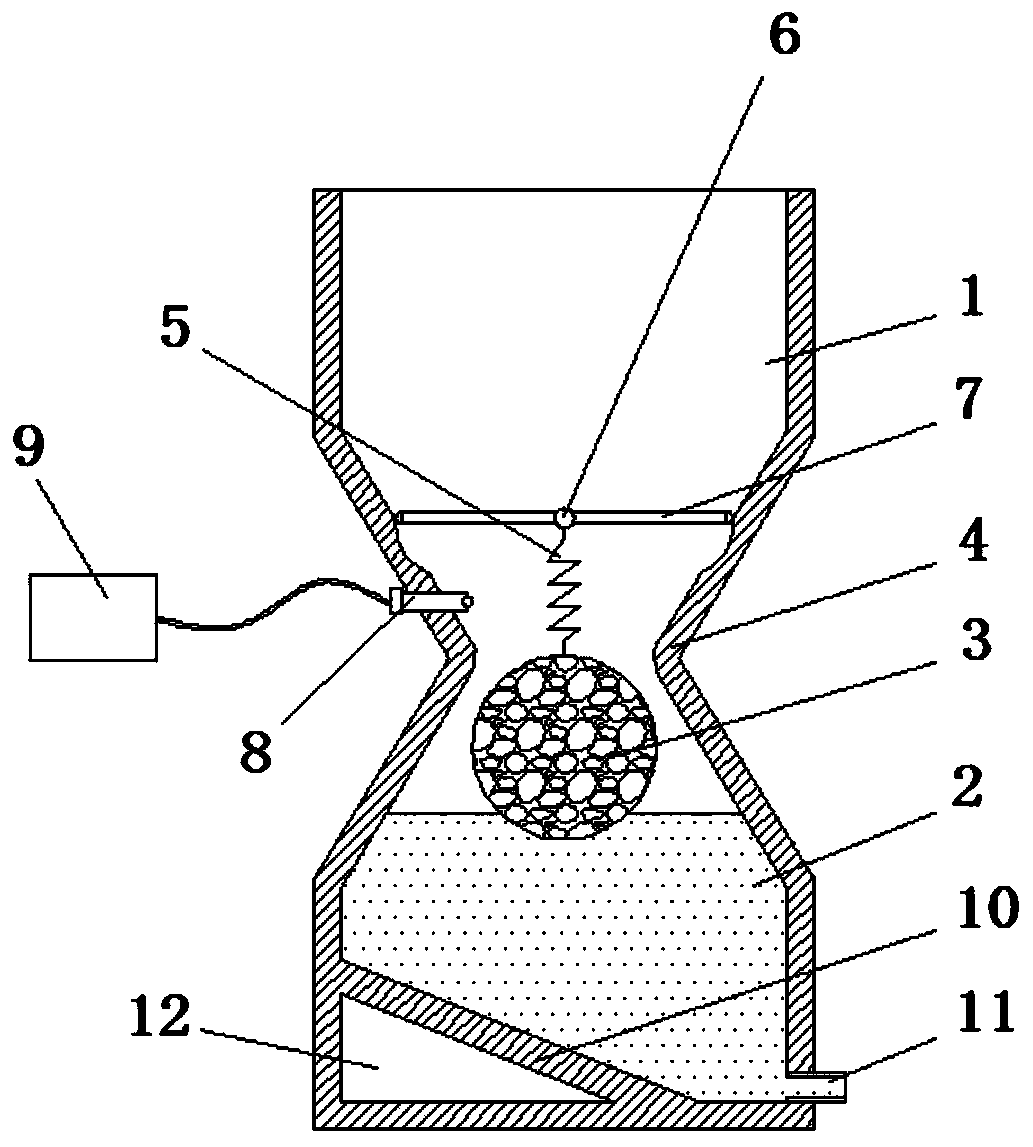

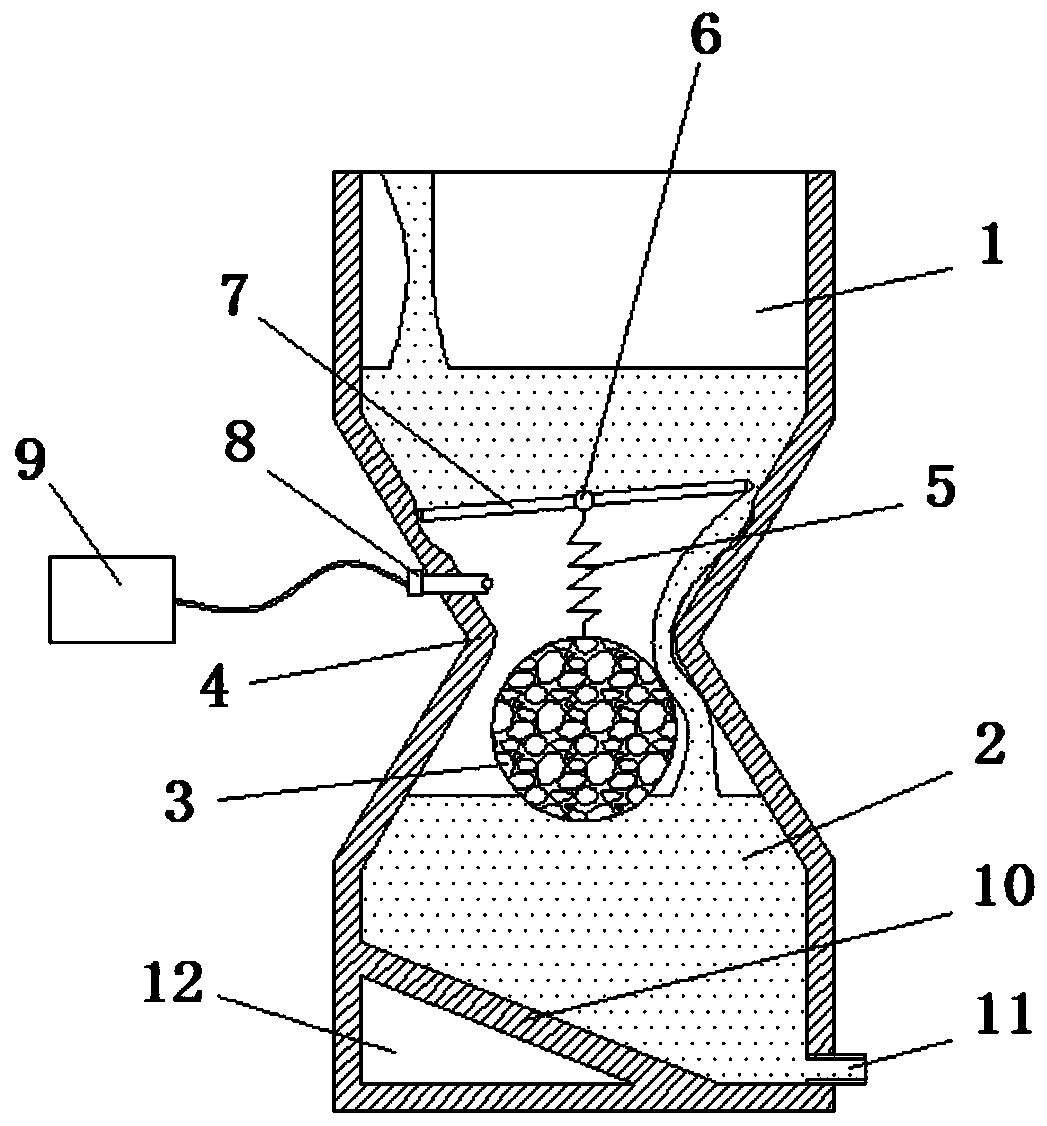

Process unit for removing dust and recovering oil from pyrolysis high-temperature oil gas

InactiveCN104722167ASolve heat and remove dustSolve the difficult problem of tar recoveryCombination devicesCycloneElectricity

The invention discloses a process unit for removing dust and recovering oil from pyrolysis high-temperature oil gas. The process unit comprises a spiral electric dust collector, a secondary-primary cyclone dust collection device which is provided with a high-temperature pyrolysis gas inlet and a Venturi dust collection device which is provided with a gas phase hole, a wash oil inlet and a purified pyrolysis gas outlet for discharging purified pyrolysis gas, wherein the spiral electric dust collector comprises insulating porcelains, an inclined cylinder and a spiral spring-shaped spiral barbed wire; a heat preservation and insulation layer, a spiral electric dust collector inlet and an electric dust collector collected dust outlet are arranged on the outer wall of the cylinder; the insulating porcelains are mounted at both the front and rear ends of the cylinder; the spiral barbed wire is arranged between the insulating porcelain; a purge gas inlet and an electric dust collection purified gas outlet are respectively formed in insulating porcelain mounting cavities at the front and rear ends; the spiral electric dust collector inlet is connected with a plurality of secondary cyclone purified as outlets of the secondary-primary cyclone dust collection device; and the electric dust collection purified gas outlet is communicated with the gas phase hole of the Venturi dust collection device. According to the process unit, the dust collection rate of the pyrolysis oil gas is up to 99.98% and the solid content of the recovered coal tar is less than 0.4%.

Owner:SHAANXI MEISILIN ENERGY SCI & TECH RES INST

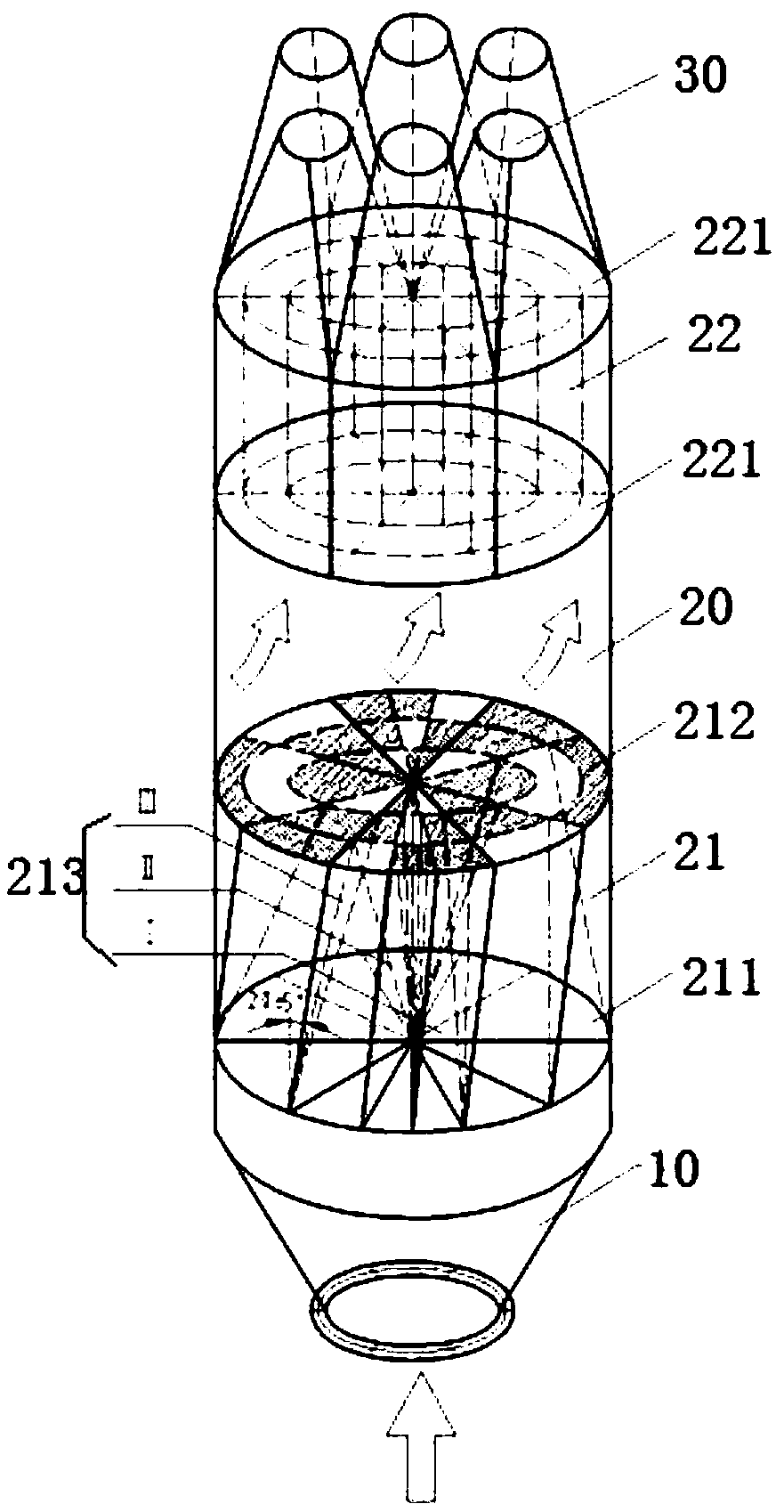

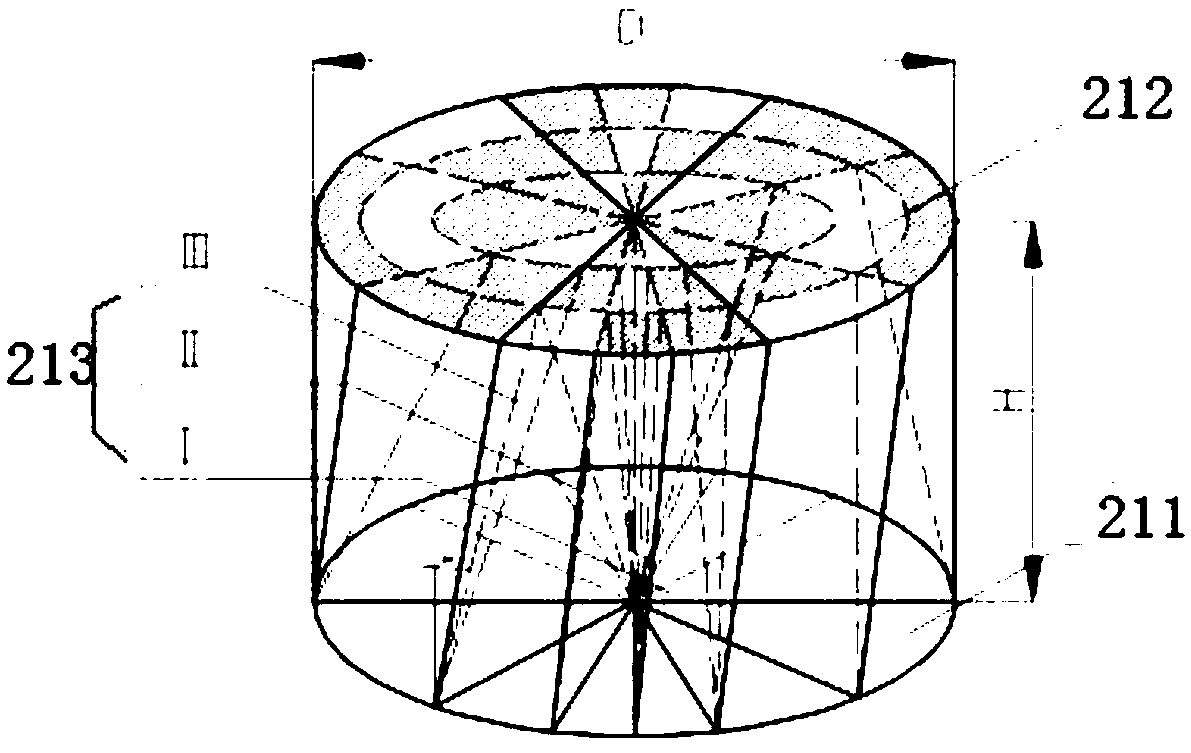

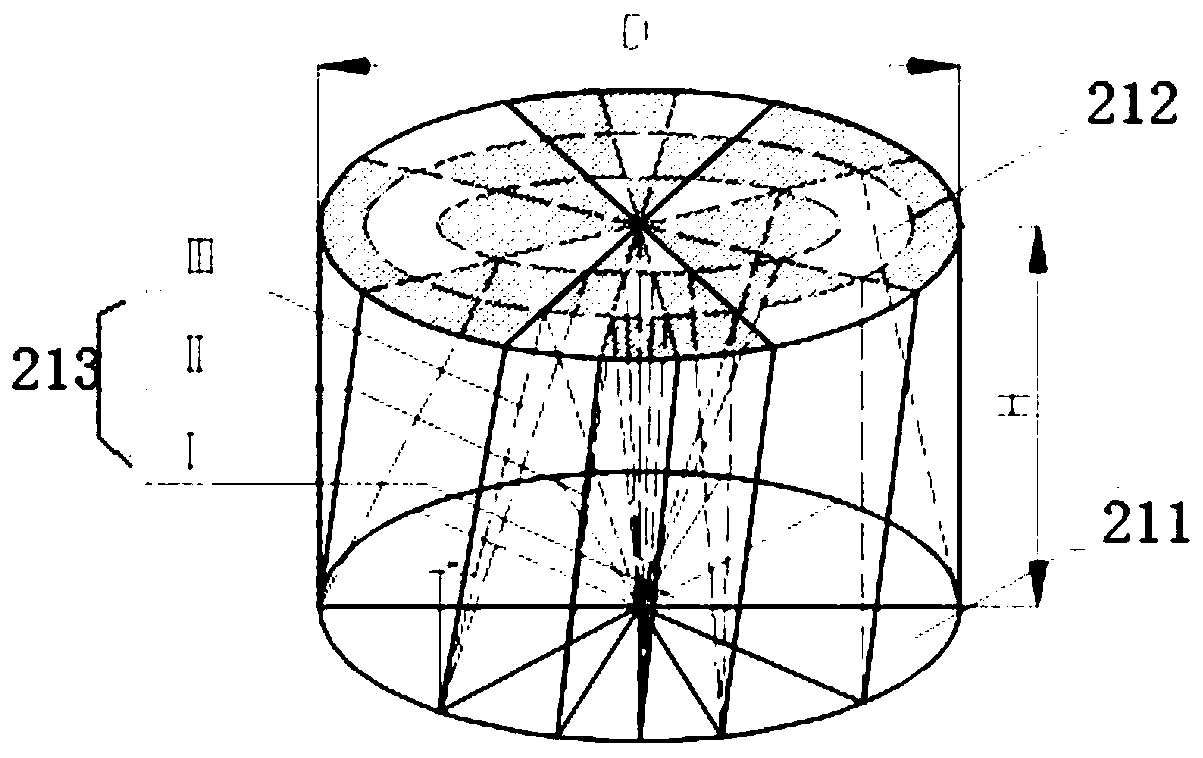

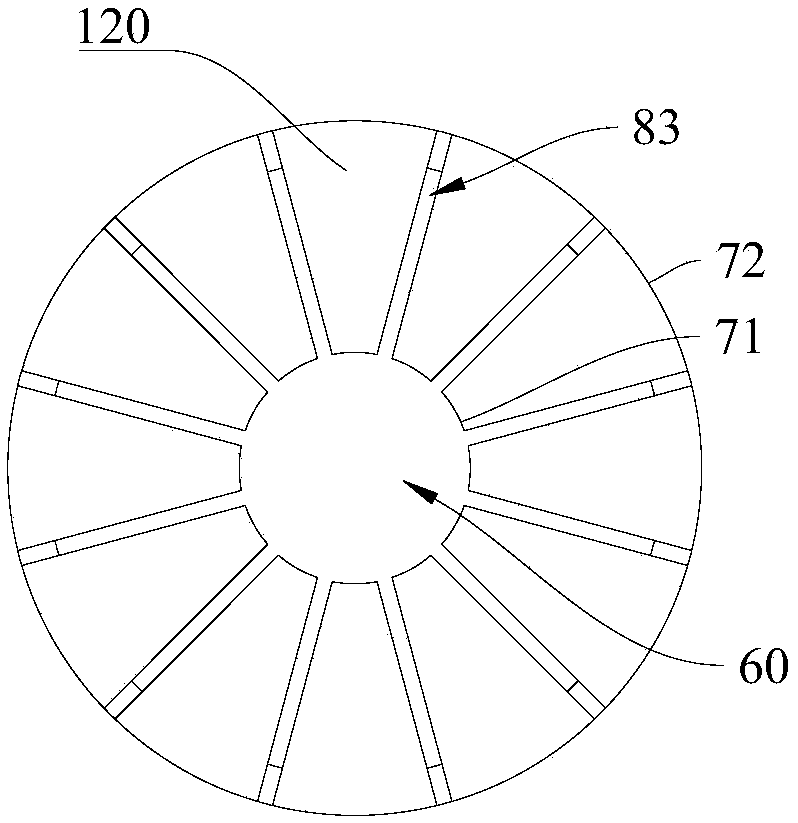

Coal powder uniform distributing device and coal milling machine

ActiveCN108758680AImprove uniformityUniform air velocityLump/pulverulent fuel feeder/distributionGratingCombustor

The invention provides a coal powder uniform distributing device and a coal milling machine. The coal powder uniform distributing device comprises a diffusion speed reduction section, a cylinder bodystraight section and an outlet connecting section which are connected sequentially. An equal-ring-face uniform distributor and a flow arranging grating are installed in the cylinder body straight section. According to the coal powder uniform distributing device, coal powder airflow is dispersed at the initial stage, the speed is reduced, flow uniformizing is achieved in advance, the flow is distributed equally many times and mixed in a rotating manner in the cylinder body straight section, after the flow is arranged uniformly at the later period, the flow enters all coal powder pipes, the speed and the concentration of the coal powder airflow entering all combustors can be distributed more uniformly, and resistance is moderate.

Owner:CHINA SHENHUA ENERGY CO LTD +1

Pulverized coal divider and coal mill

ActiveCN108758680BImprove uniformityUniform air velocityLump/pulverulent fuel feeder/distributionGratingCombustor

The invention provides a coal powder uniform distributing device and a coal milling machine. The coal powder uniform distributing device comprises a diffusion speed reduction section, a cylinder bodystraight section and an outlet connecting section which are connected sequentially. An equal-ring-face uniform distributor and a flow arranging grating are installed in the cylinder body straight section. According to the coal powder uniform distributing device, coal powder airflow is dispersed at the initial stage, the speed is reduced, flow uniformizing is achieved in advance, the flow is distributed equally many times and mixed in a rotating manner in the cylinder body straight section, after the flow is arranged uniformly at the later period, the flow enters all coal powder pipes, the speed and the concentration of the coal powder airflow entering all combustors can be distributed more uniformly, and resistance is moderate.

Owner:CHINA SHENHUA ENERGY CO LTD +1

A kind of preparation method of activated carbon shaped filter element with bactericidal function

ActiveCN104192936BAdsorption recoverySpecial production processBiocideAnimal repellantsPotassium hydroxideCrystal cell

Owner:TAIYUAN YINXIYUAN TECH CO LTD

Graphite heating body and crystal growth furnace

The invention discloses a graphite heating body and a crystal growth furnace. The graphite heating body comprises a graphite body and at least two electrode portions, and the graphite body comprises aheating bottom wall and a heating side wall; the heating side wall comprises at least four heating side plates, and every two heating side plates form a side wall heating portion; the heating bottomwall comprises at least two heating base plates, the heating base plates are spaced from each other, and the second ends of every two adjacent side wall heating portions are connected by the corresponding heating base plate; the electrode portions are respectively arranged on the different side wall heating portions. The graphite heating body and the crystal growth furnace can be applied to solvethe problem of high cost of the KY crystal growth process.

Owner:通辽精工蓝宝石有限公司

Manual Inking Mechanism of Printing Machine Based on Float Seal

The invention discloses an automatic printing machine ink adding mechanism based on floating ball seal. The automatic printing machine ink adding mechanism comprises an ink box, wherein the ink box is divided into a charging chamber and a safety ink measuring chamber, a neck for limiting a floating ball is arranged between the charging chamber and the safety ink measuring chamber, the floating ball is located in the safety ink measuring chamber and is fixed to a rotary shaft in the charging chamber through a pull rope, the rotary shaft limits a rotary plate, and a position sensor is arranged at the position, close to the neck, of the inner wall of the charging chamber in a penetrating mode. The ink box is provided with the safety ink measuring chamber. When the ink amount is insufficient, the floating ball moves down with the ink liquid level, the position sensor gives out an alarm signal, further ink is added in time, and the service life of printing machine parts are guaranteed.

Owner:HANGZHOU WEICHENG PRINTING

Flue gas condensation water extraction system

ActiveUS10456705B2Improve reliabilityLong-term stabilityGas treatmentEmission preventionCooling towerEngineering

A flue gas condensation water extraction system includes a flue gas condensation-end system and a flue gas refrigeration source-end system. The flue gas condensation-end system includes a desulfurization absorption tower, a flue gas purification and condensation tower, and a condensed water storage tank. The flue gas purification and condensation tower is arranged above the desulfurization absorption tower. A flue gas outlet, a water inlet, and a water outlet are provided on the flue gas purification and condensation tower. The flue gas refrigeration source-end system includes a cooling tower. The water outlet is connected to the condensed water storage tank via a condensed water downcomer. The water inlet is connected to the cooling tower via a circulating water supply pipe. A condensation circulation water pump is provided on the circulating water supply pipe. The cooling tower is connected to the condensed water storage tank via a circulating water return pipe.

Owner:LIU CHUNXIAO

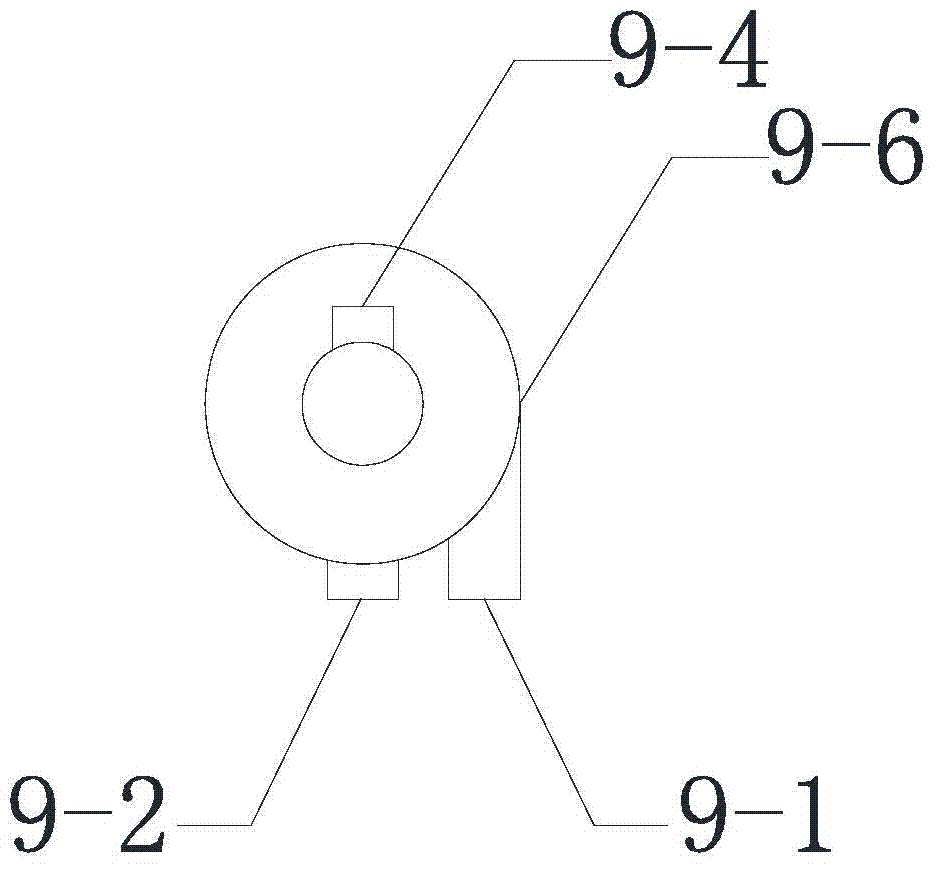

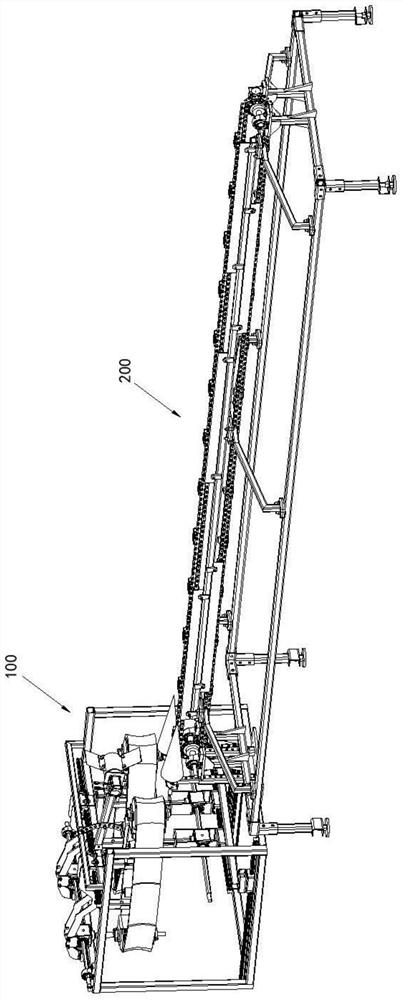

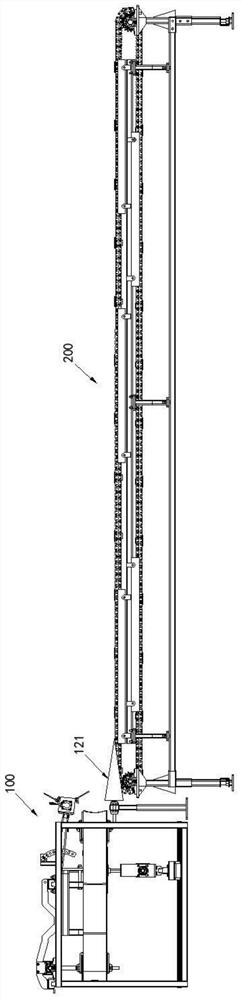

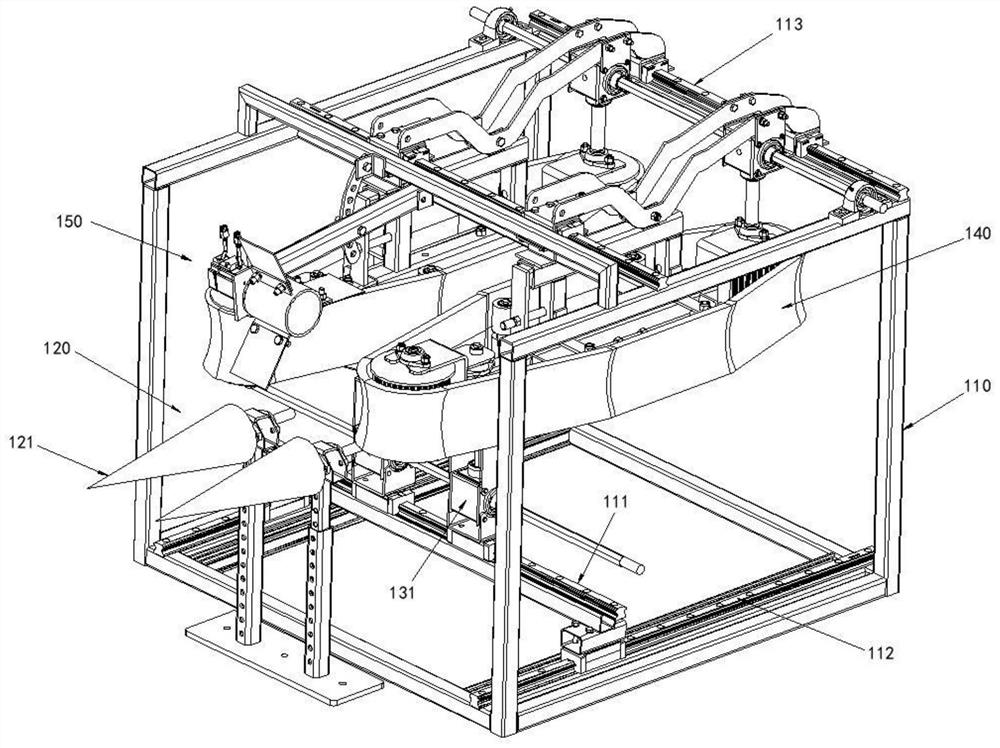

Low-loss conveying test platform for heading vegetables

PendingCN113567161AModerate resistanceThe real stress situation is close toStructural/machines measurementStructural engineeringMechanical engineering

The invention discloses a low-loss conveying test platform for heading vegetables. The low-loss conveying test platform comprises a test model machine, a conveying platform, a connector and a fixer, wherein the conveying platform is located in front of the test model machine, the connector is installed on the conveying platform, the fixer is installed on the connector, and comprises an outer cylinder, a root fixing pipe, a middle cylinder, an inner cylinder, a middle shaft, a pin shaft, a first spring and a second spring, the root fixing pipe is connected with the top of the inner cylinder, the inner cylinder is inserted into the middle cylinder, the middle cylinder is inserted into the outer cylinder, the first spring is located below the middle cylinder, and the two ends of the first spring are fixedly connected with the bottom of the middle cylinder and the bottom of the outer cylinder respectively. According to the invention, the first spring is used for simulating the resistance when cabbage is pulled out, the resistance can be controlled by researchers, the fixer is automatically separated from the cabbage after the cabbage is pulled out by a certain distance, and the situation is almost the same as the real condition that the cabbage is pulled out, so that the researchers can conduct a cabbage harvesting test without entering the field.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

Anode plate for electrolyzing metal manganese

InactiveCN1141419CCompact structureModerate resistancePhotography auxillary processesElectrodesElectrolysisManganese

The anode plate used in manganese producing electrolyser includes one conducting rod with built-in copper strip and one lower inserted plate made of Pb as main component, Ag, Sn, Sb and Al-As alloy. It has the advantages of high conductivity, easy maintenance, high electrolytic manganese output and long service life.

Owner:刘志刚

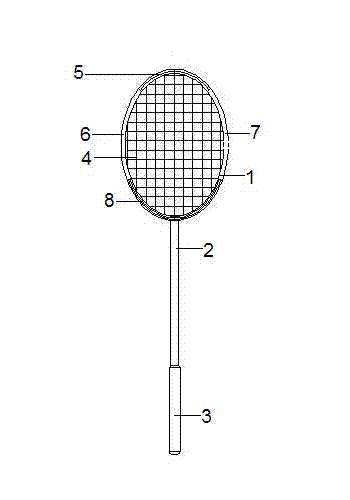

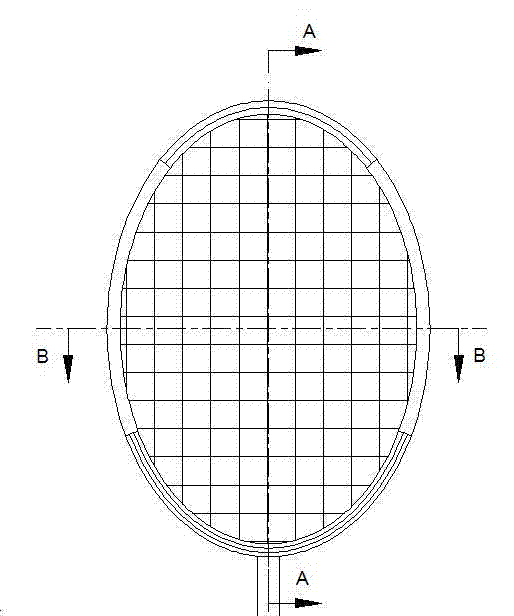

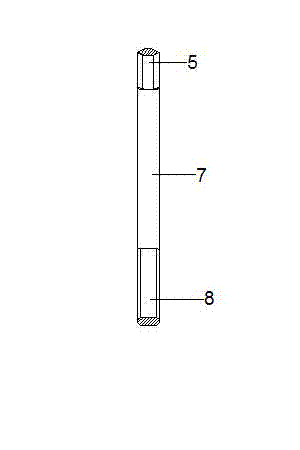

Badminton racket capable of realizing effects of increasing swing speed and stably and accurately controlling shuttle

The invention discloses a badminton racket capable of realizing effects of increasing the swing speed and stably and accurately controlling a shuttle. The badminton racket comprises a head, a shaft and a handle; the shaft is connected with the head; the head comprises a racket frame and racket face lines arranged on the racket frame; the racket frame comprises an upper frame, a left frame, a right frame and a lower frame, the upper frame is positioned close to a 12-o'clock position of the racket frame, the left frame and the right frame are respectively positioned close to a 3-o'clock position and a 9-o'clock position of the racket frame, the lower frame is positioned close to a 6-o'clock position of the racket frame, and the right frame is a structure symmetrical with the left frame; wind resistance of the frames is gradually increased from the upper frame to the left frame to the lower frame; and the adjacent frames are in smooth transition. The badminton racket has the advantages that the swing speed can be increased, and the shuttle can be stably and accurately controlled.

Owner:TONGXIANG BONNY SCI & TECH COMPOSITE

Fitness chair with digital output

ActiveCN103263755BTight locationSimple structureResilient force resistorsStoolsEngineeringMechanical engineering

The invention provides a fitness chair with digital output, which has a simple structure and is provided with a sensor for outputting a digital signal conveniently. The fitness chair comprises a seat panel (1), handle components (2), a pedal component (3), a backrest (4), a base (5) and a hydraulic supporting rod (6) and is characterized in that each handle component (2) comprises an integrated two-stage rotation structure and a potentiometer structure which is conveniently installed; and the pedal component (3) and a rotary shaft form a structure which can be folded backwards below the chair seat panel by virtue of a supporting sheet.

Owner:SHANDONG BODY STRONG FITNESS

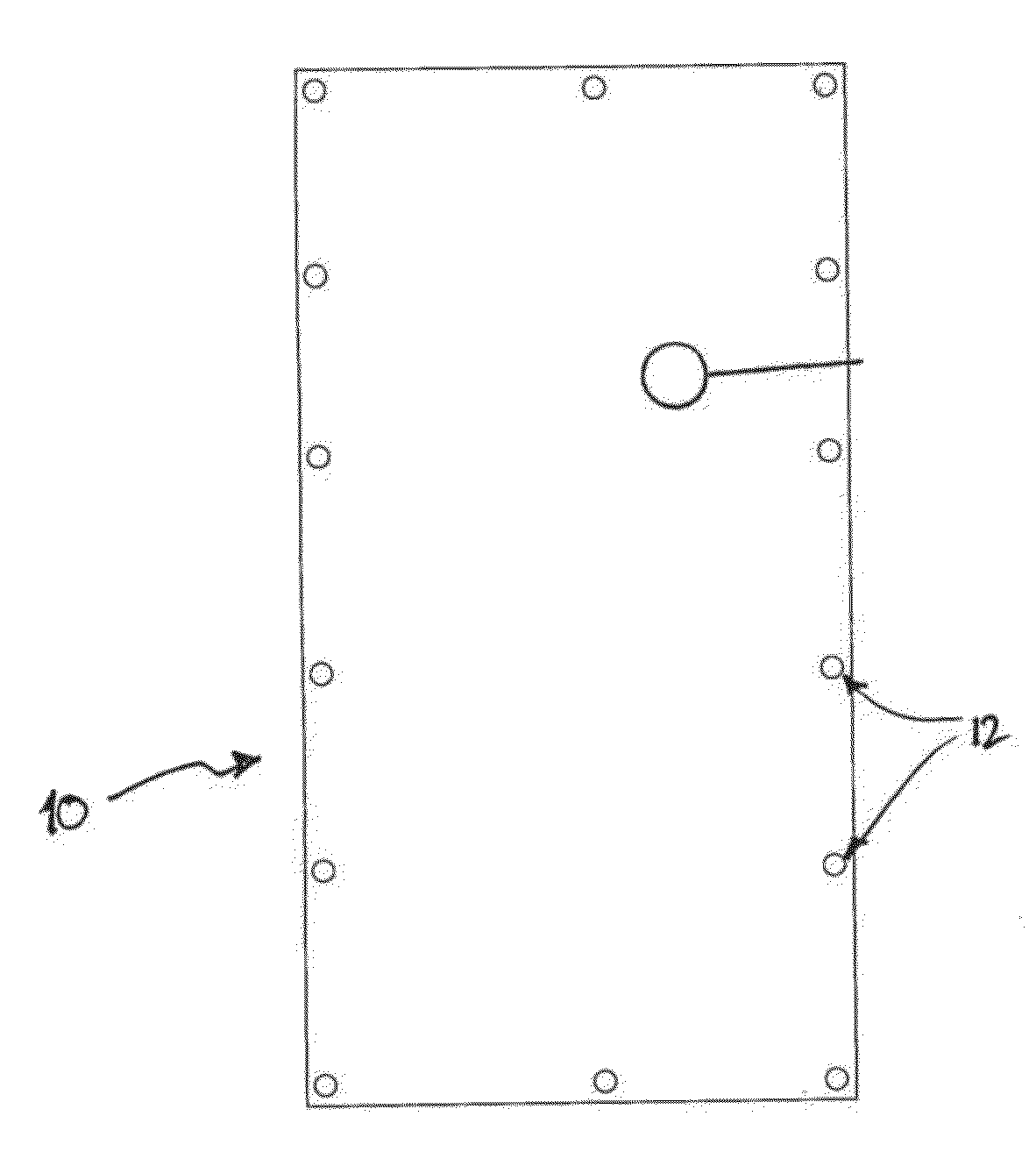

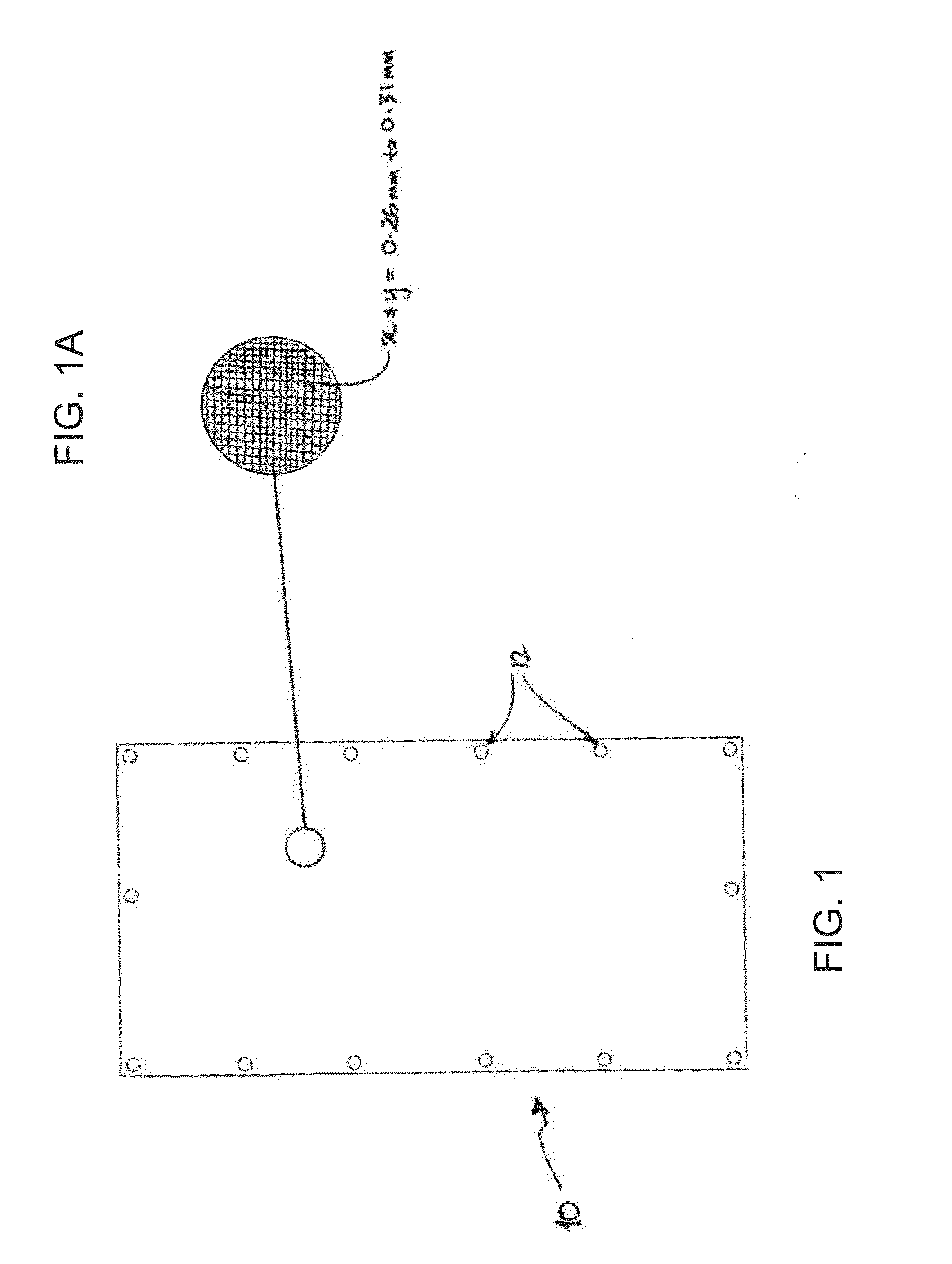

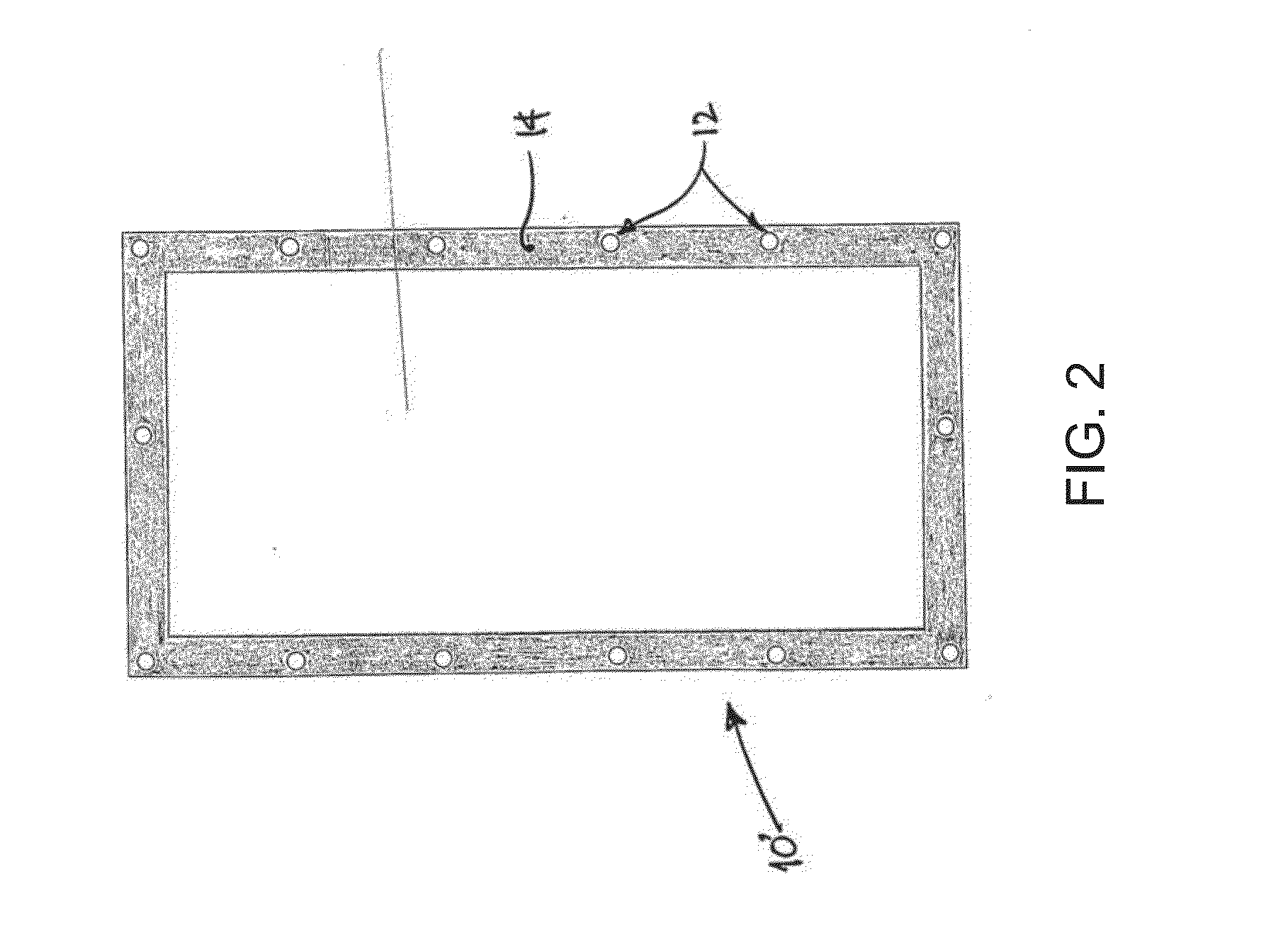

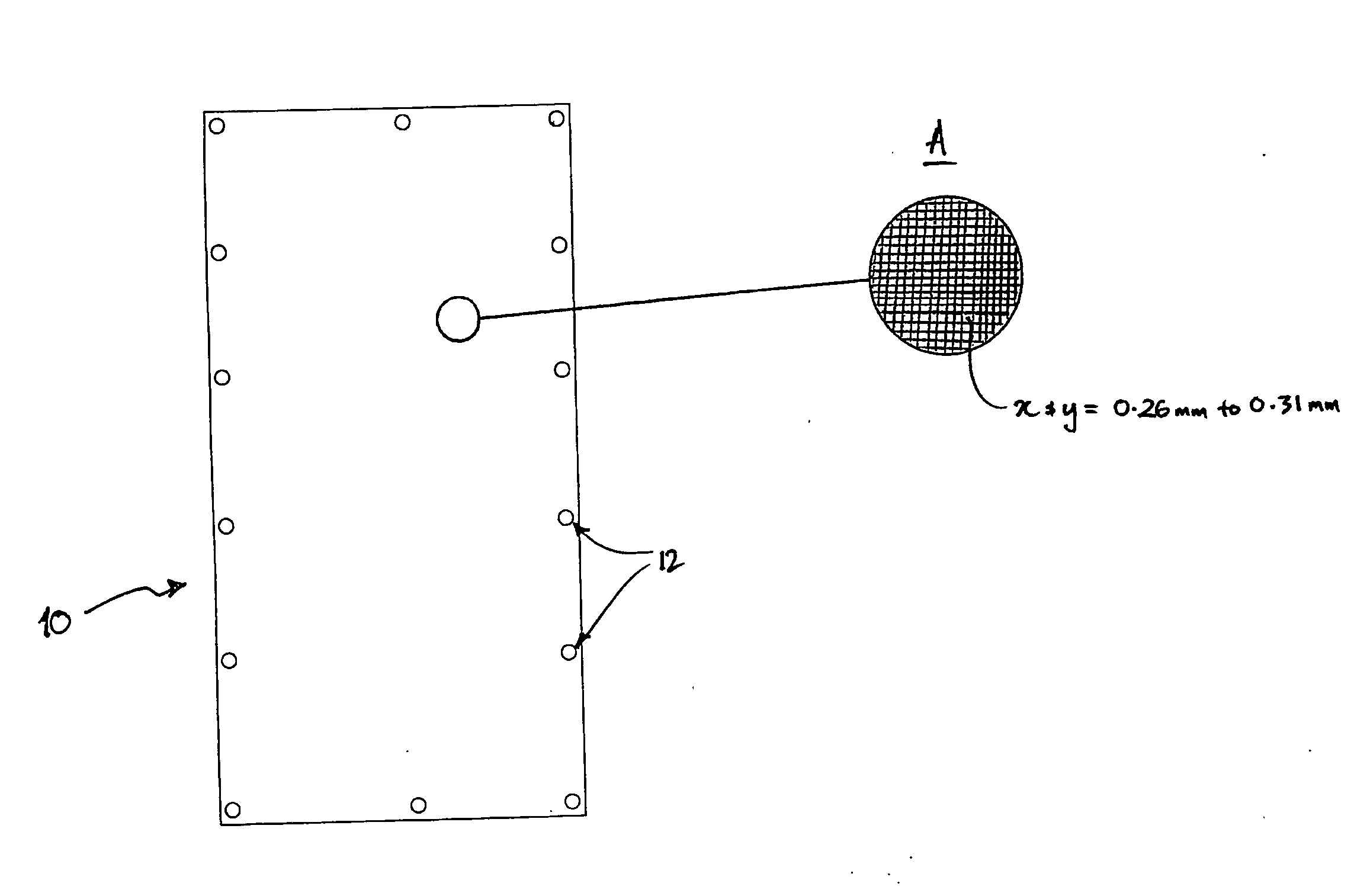

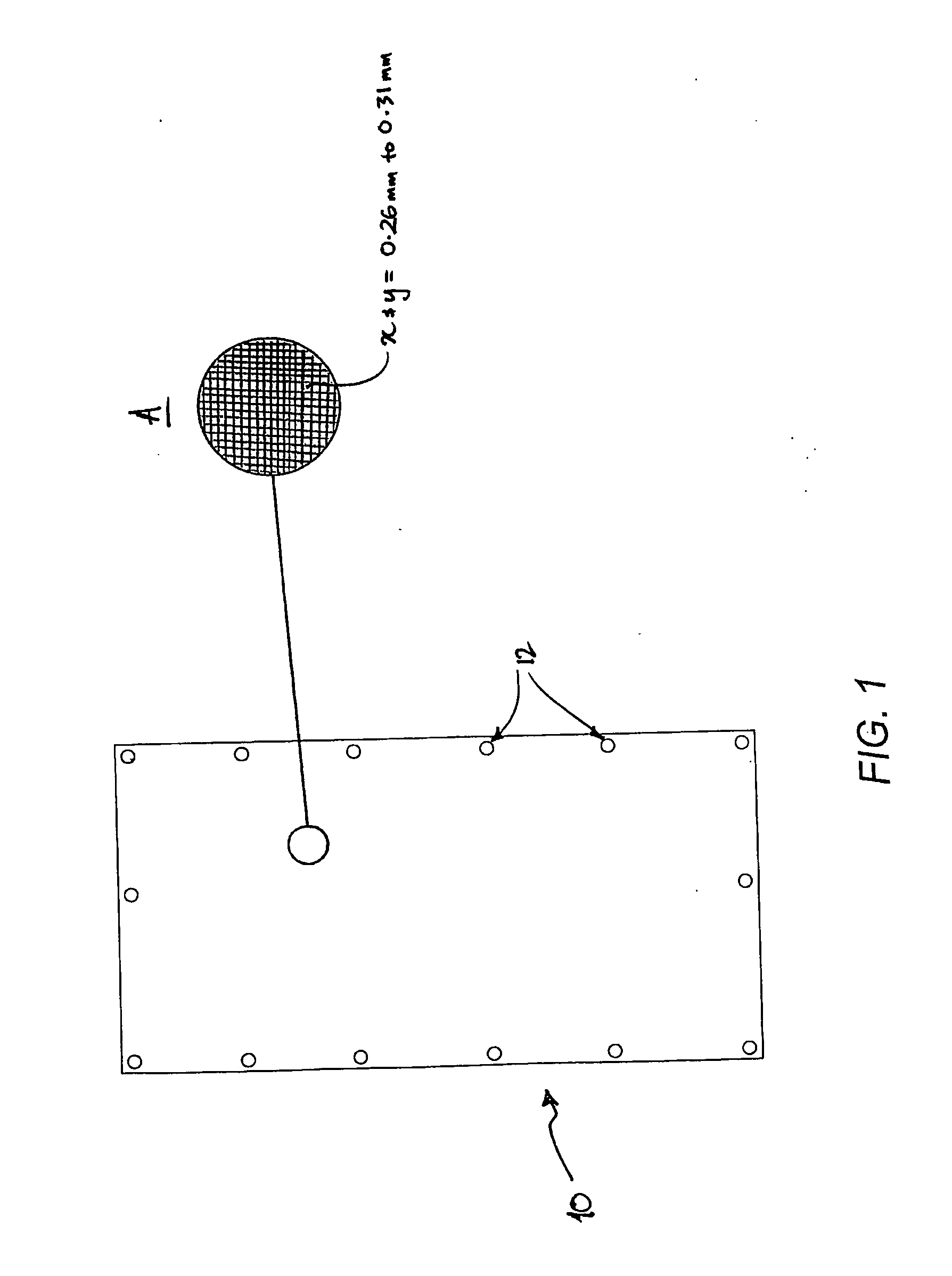

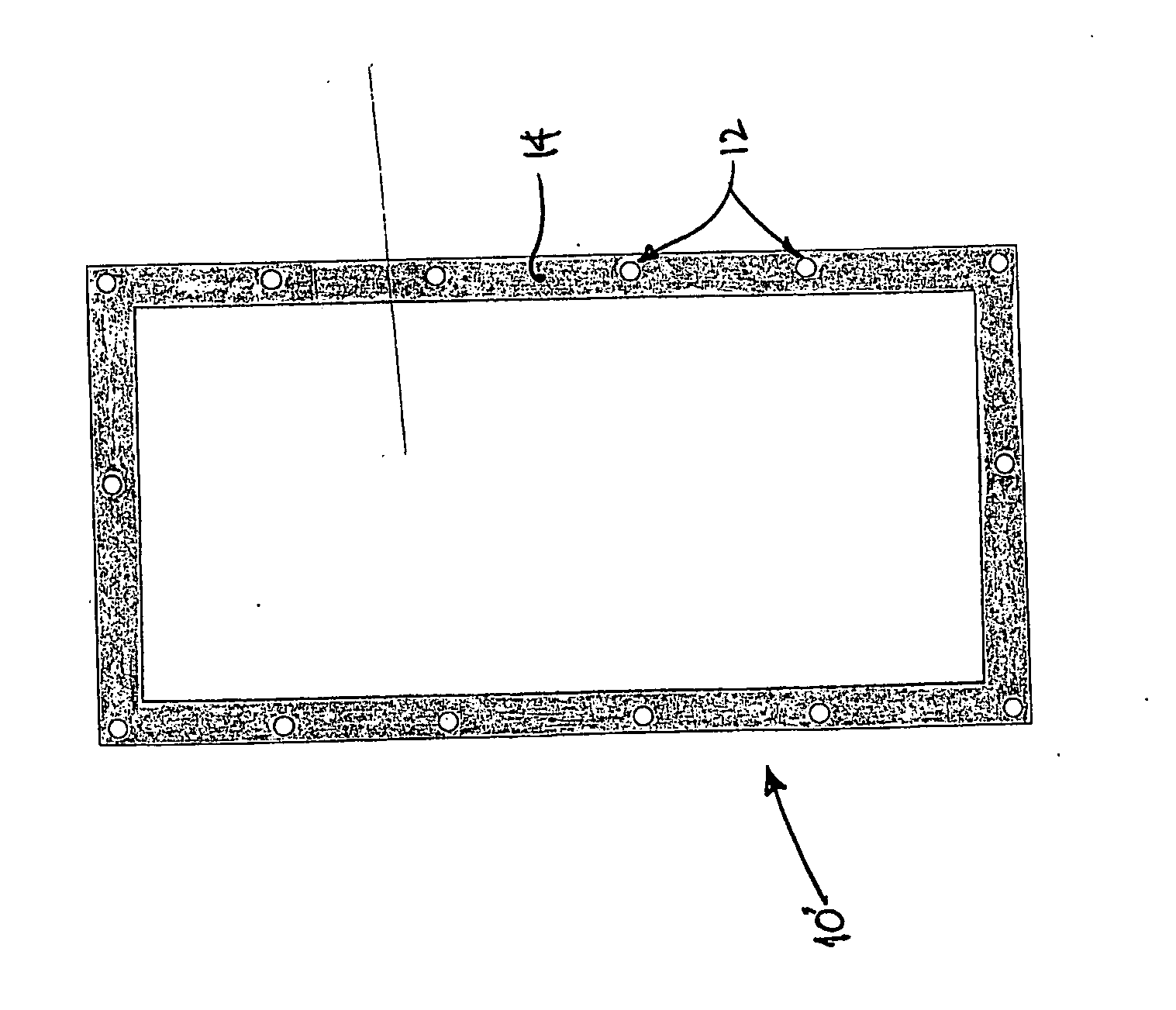

Mesh for Screening a User from Direct Impact of a High Pressure Fluid by Diffusing the Fluid Stream

InactiveUS20160265719A1Easily brokenDeath from pinhole fluid injection into a user can be eliminatedEngineering safety devicesThin material handlingEngineeringHigh pressure

A mesh for use in screening a user from direct impact of a high pressure fluid J is adapted for receiving and diffusing S the high pressure fluid therethrough when positioned in relation to a location P from which the high pressure fluid issues. The mesh can form part of a screening apparatus that comprises a frame for supporting the mesh in a spaced relationship to the location P from which the high pressure fluid issues. The mesh and apparatus can be employed in a method in which the high pressure fluid is diffused at a first location that is spaced with respect to a second location from which the high pressure fluid issues.

Owner:PIGGOTT ANDREW

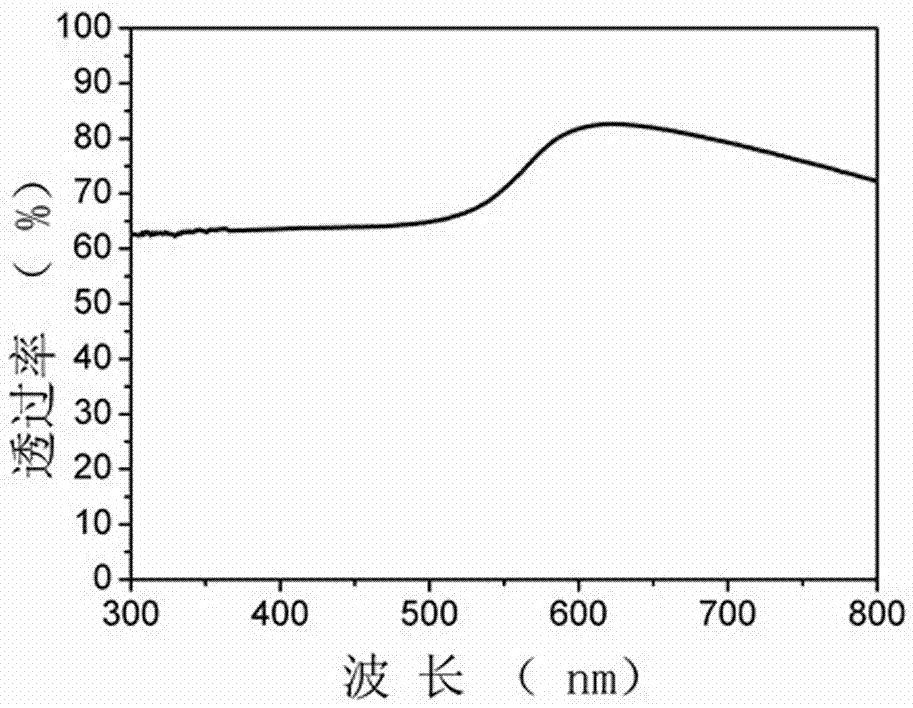

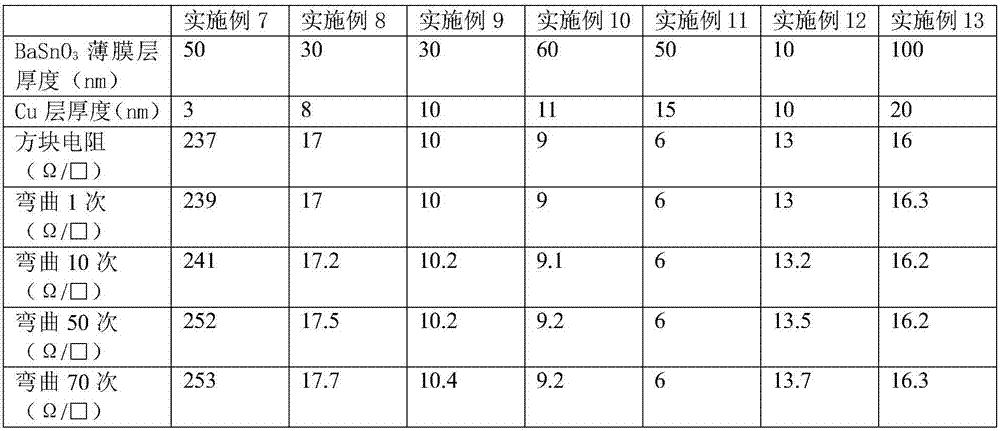

A kind of flexible transparent electrode and preparation method thereof

ActiveCN105741916BImprove transmittanceHigh optical transmittanceConductive layers on insulating-supportsVacuum evaporation coatingOptical transmittanceOptoelectronics

The invention discloses a flexible transparent electrode and a fabrication method thereof. The flexible transparent electrode is deposited on a flexible transparent substrate, is of a BaSnO3 / Cu / BaSnO-3 composite layered structure and is formed by sandwiching a Cu layer between two BaSnO3 thin film layers. The fabrication method of the flexible transparent electrode comprises the steps of BaSnO3 thin film layer deposition, Cu layer deposition and secondary deposition of the BaSnO3 thin film layer. The flexible transparent electrode and the fabrication method thereof have the characteristics of high optical transmittance, appropriate resistance, high stability and wide application prospect.

Owner:徐州鹏盛铸造有限公司

Proton exchange film fuel cell flow field structure

ActiveCN1305158CEasy to excludePromote accumulationCell electrodesSolid electrolyte fuel cellsProtonEngineering

The present invention relates to proton exchange membrane fuel cell. The flow field structure of proton exchange membrane fuel cell consists of netted flow field and deflecting stripes. The deflecting stripes are set inside the netted flow field and parallel to one group of sealing side walls, and have width equal to the height of the netted flow field. Each of the deflecting stripes has one end connected perpendicularly to the side wall and the other end constituting the gas channel. The gas channel has width not smaller than that of the gas inlet. The present invention has the advantages of high pole area utilization, being favorable to the exhaust of water produced in the electrochemical reaction and the elimination of inertial component, no dead arean of gas flow, and stable operation of the cell under low pressure and normal pressure.

Owner:SUNRISE POWER CO LTD

Mesh for Screening a User from Direct Impact of a High Pressure Fluid by Diffusing the Fluid Stream

InactiveUS20120145259A1Sufficient supportModerate ozoneEngineering safety devicesPipeline systemsEngineeringHigh pressure

A mesh (10) for use in screening a user from direct impact of a high pressure fluid J is adapted for receiving and diffusing S the high pressure fluid therethrough when positioned in relation to a location P from which the high pressure fluid issues. The mesh (10) can form part of a screening apparatus that comprises a frame (72) for supporting the mesh in a spaced relationship to the location P from which the high pressure fluid issues. The mesh and apparatus can be employed in a method in which the high pressure fluid is diffused at a first location that is spaced with respect to a second location from which the high pressure fluid issues.

Owner:PIGGOTT ANDREW

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com