Nickel base gamma prime strengthened superalloy

a superalloy and gamma prime technology, applied in the direction of machines/engines, manufacturing tools, solventing apparatus, etc., can solve problems such as oxidation damage, and achieve the effects of improving the resistance to thermal barrier coating spallation, cyclic life, and long residual li

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

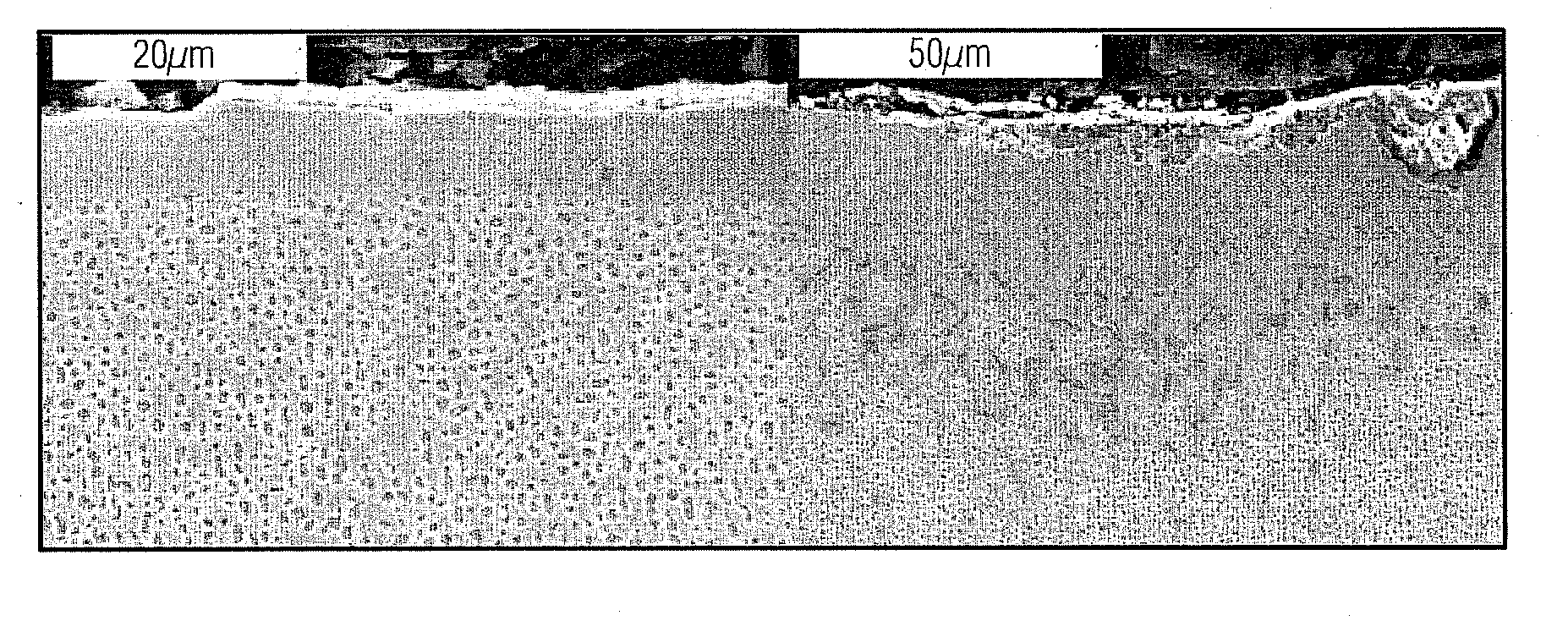

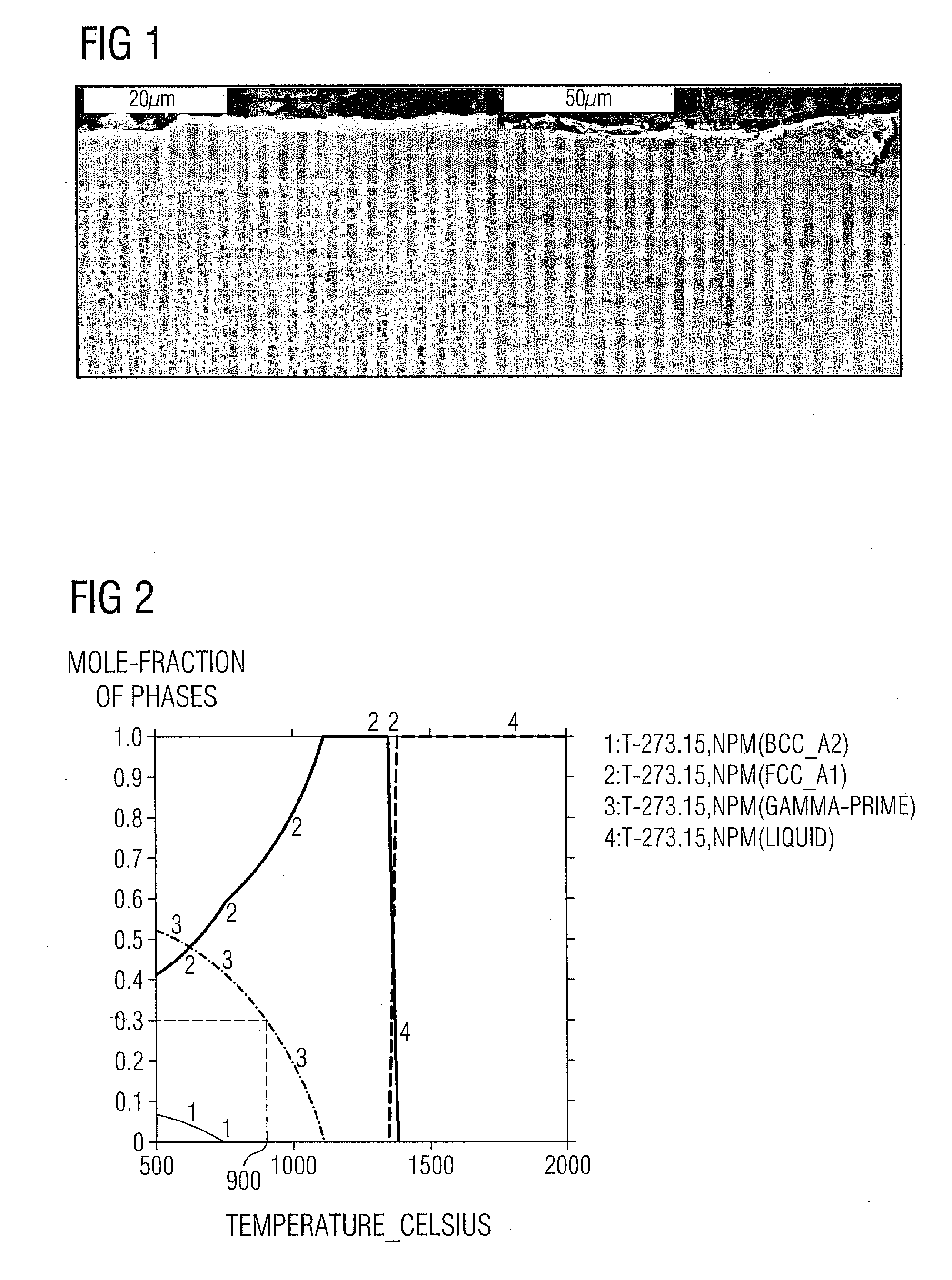

Image

Examples

Embodiment Construction

[0050]According to one embodiment of the invention the alloy may include, measured in wt %, up to 20 wt % Co, between 17 and 21 wt % Cr, between 2 and 5 wt % of Mo+W+Re, at most 2 wt % Mo, between 4 and 4.7 wt % Al, between 3 and 7 wt % Ta, between 0.01 and 0.3 wt % of C+Zr+B, between 0.05 and 1 wt % Hf, between 0.05 and 1 wt % Si, and between 0.01 and 0.2 wt % of the sum of rare earths such as Sc, Y, the actinides and the lanthanides.

[0051]Additionally, the alloy may include, measured in wt %, between 2 and 12 wt % Co, between 17 and 21 wt % Cr, up to 1 wt % Mo, between 1 and 4 wt % W, between 4 and 4.7 wt % Al, between 3 and 7 wt % Ta, between 0.01 and 0.1 wt % C, between 0.01 and 0.15 wt % Zr, between 0.002 and 0.02 wt % B, between 0.05 and 1 wt % Hf, between 0.05 and 1 wt % Si, and between 0.01 and 0.2 wt % of Ce+La+Y+Dy.

[0052]Additionally, the alloy may include between 3 and 7 wt % Co, between 17 and 19 wt % Cr, between 0.5 and 1 wt % Mo, between 2 and 3 wt % W, between 4.2 and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Electrical resistance | aaaaa | aaaaa |

| Stability | aaaaa | aaaaa |

| Weldability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com