Anode plate for electrolyzing metal manganese

A technology of electrolytic manganese metal and anode plate, applied in the direction of electrodes, electrolytic process, electrolytic components, etc., can solve the problems of poor corrosion resistance of materials, affecting the output of electrolytic manganese, poor electrical conductivity, etc., and achieve good corrosion resistance and hardness Moderate, non-deformable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

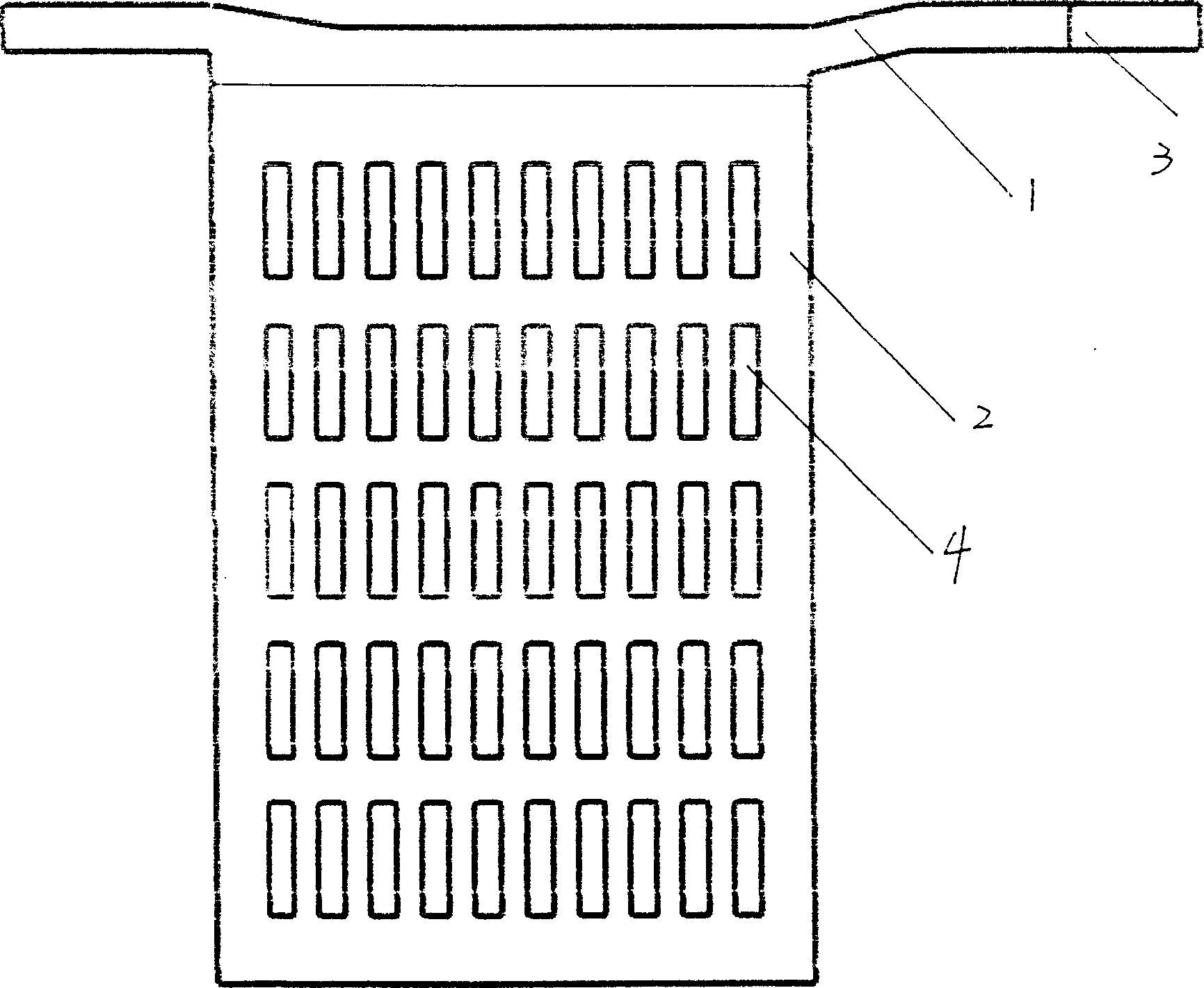

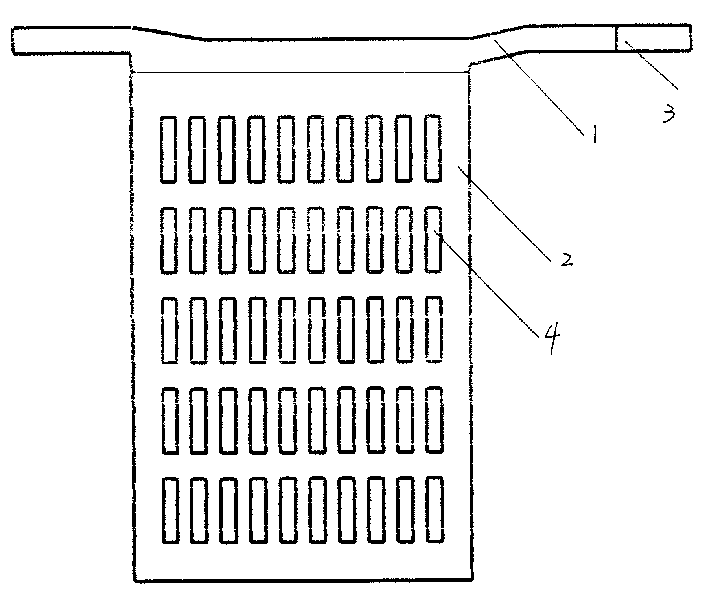

[0008] The manufacturing method of the anode plate for electrolytic manganese of the present invention is as follows: first put 400Kg lead, 32Kg tin, 1.2Kg silver and 0.8Kg antimony into the airtight iron pot, add 20Kg aluminum-arsenic alloy after heating up to 560 ℃, fully Stir, pour into the mold and cast to form a plate, and then roll, cut, and punch to form an insert 2 with holes 4 on the surface, and finally weld it with a conductive rod 1 with a copper strip 3 cast inside to form an anode board, structured as figure 1 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com