Multi-fluid mixer

A mixer and multi-fluid technology, applied in the direction of machines/engines, engine components, exhaust gas recirculation, etc., can solve the problems of poor mixing effect and low integration, and achieve improved mixing effect, high integration, and high mixing uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

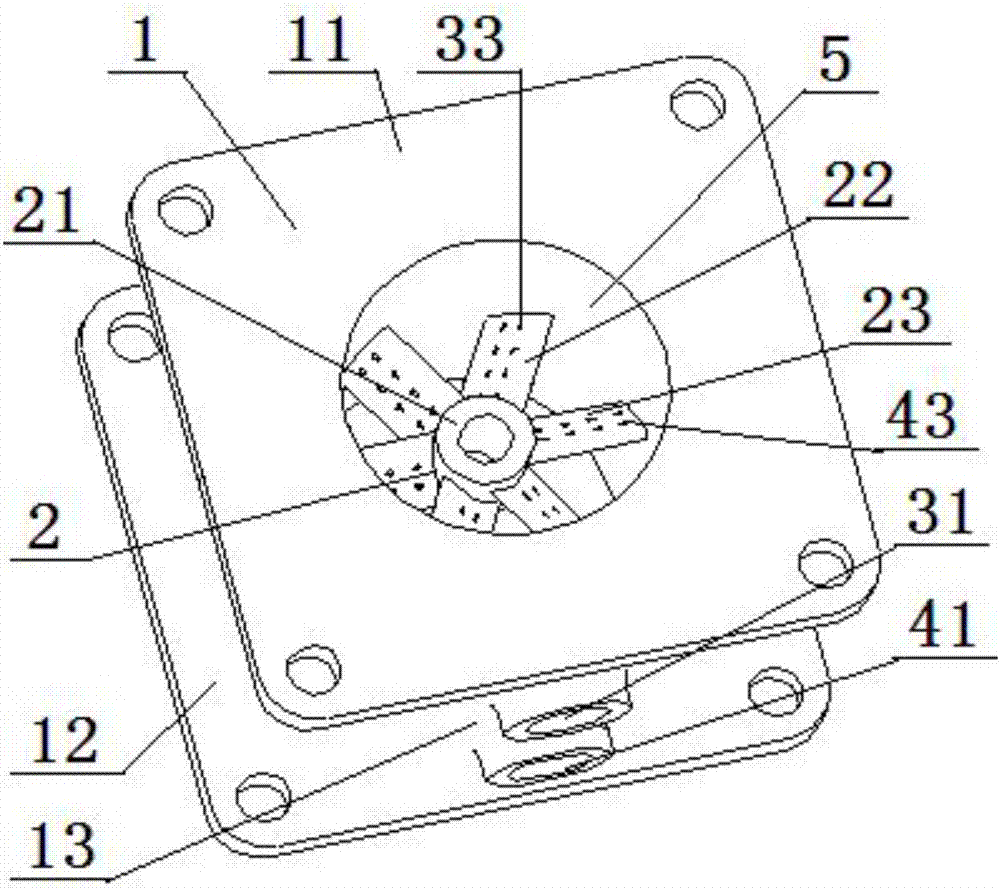

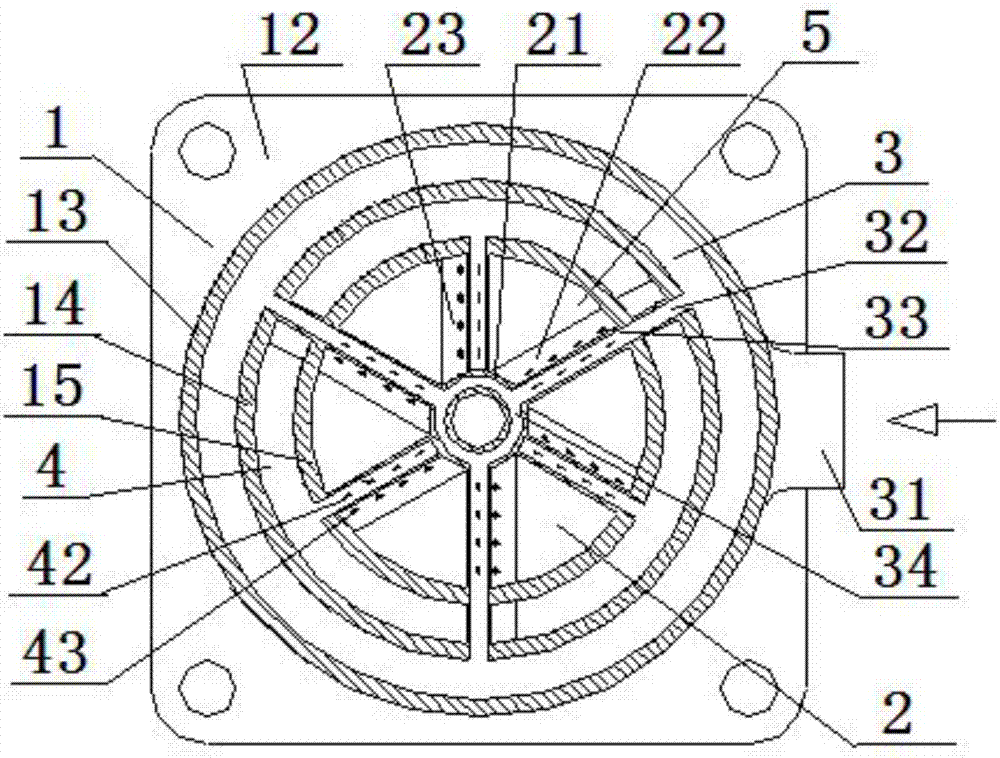

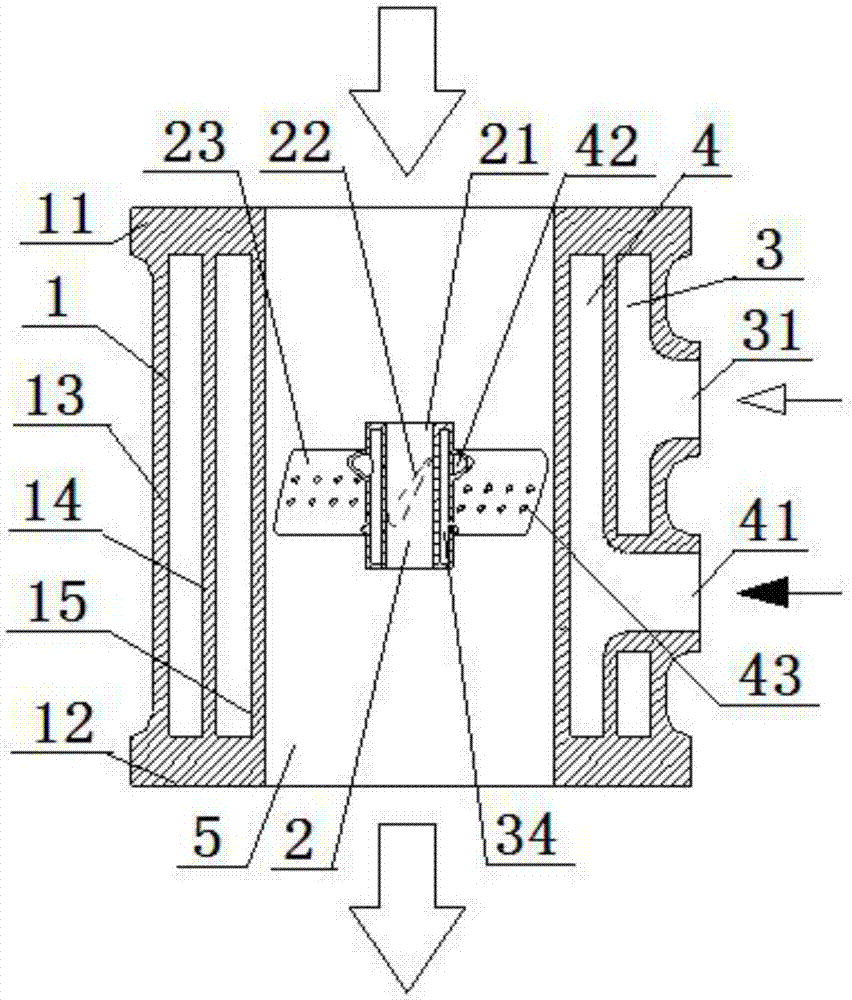

[0058] A multi-fluid mixer, comprising a gas mixing seat 1 and a mixing core 2, the mixing core 2 is arranged inside the gas mixing seat 1, the gas mixing seat 1 includes a top plate 11 and a bottom plate 12, the top plate 11 and the bottom plate 12 An outer cavity wall 13, a middle cavity wall 14, and an inner cavity wall 15 are arranged coaxially therebetween, and a first fluid chamber 3 is formed between the outer cavity wall 13 and the inner cavity wall 14, and the inner cavity wall 14 and the inner cavity A second fluid chamber 4 is formed between the walls 15, the inner chamber wall 15 is a gas mixing chamber 5, and the outer chamber wall 13 is provided with a first fluid inlet 31 and a second fluid inlet 41, The first fluid inlet 31 communicates with the first fluid chamber 3, and the second fluid inlet 41 communicates with the second fluid chamber 4; the mixing core 2 includes a middle support 21, a first fluid mixing vane 22 and the second fluid mixing blade 23, one e...

Embodiment 2

[0060] Embodiment 2 is basically the same as Embodiment 1, and its difference is:

[0061] The middle support 21 is a circular tube structure, and the first fluid mixing vanes 22 and the second fluid mixing vanes 23 are evenly distributed on the outer circumference of the middle support 21; the first fluid mixing vanes 22 and The sum of the number of the second fluid mixing blades 23 is six pieces; the angle between the first fluid mixing blades 22 and the top plate 11 is 60 degrees; the upper and lower sides of the first fluid blade cavity 32 First air mixing holes 33 are opened on the cavity walls, and second air mixing holes 43 are opened on the upper and lower sides of the second fluid vane cavity 42 .

Embodiment 3

[0063] Embodiment 3 is basically the same as Embodiment 2, and its difference is:

[0064] In the pipe wall of the middle support 21, a first fluid mixing cavity 34 is provided, and the first fluid mixing cavity 34 communicates with the first fluid cavity 3 through the first fluid vane cavity 32; the first fluid mixing cavity The cross-sectional shape of the vane 22 is the same as the cross-sectional shape of the second fluid mixing vane 23, and the thickness of the first fluid mixing vane 22 gradually becomes thicker from the side of the top plate 11 to the side of the bottom plate 12, and the main fluid is at the top plate 11. The inflow point, the bottom plate 12 is the outflow point of the main fluid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com