High-conductivity self-adhesive graphene low-voltage heating slurry and preparation method and application thereof

A high-conductivity, graphene technology, applied in graphene, conductive coatings, nano-carbon, etc., can solve problems such as low electrical and thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

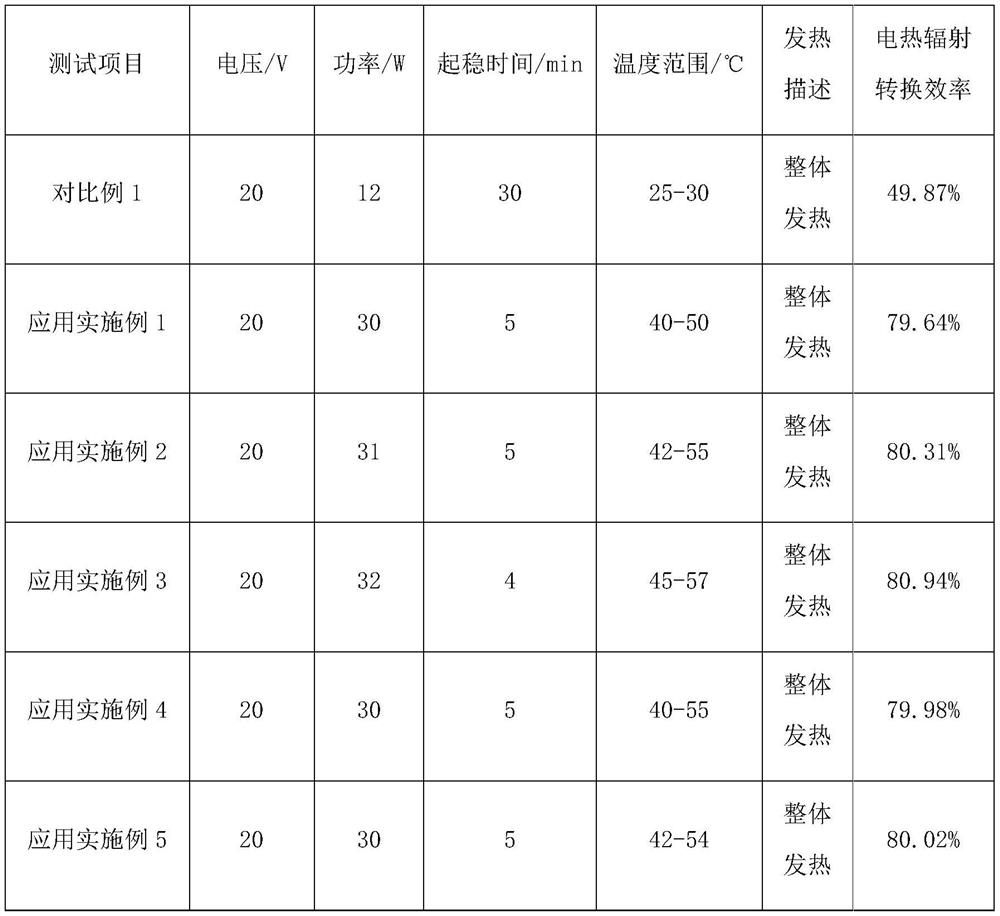

Examples

Embodiment 1

[0047] The high-conductivity self-bonding graphene low-pressure heating slurry of this embodiment is prepared by using the following raw materials in parts by mass:

[0048] Graphene 20g, heating carbon paste 35g, epoxy resin 2g, ethanol 5g, sodium dodecylbenzene sulfonate 10g, propylene imine 5g, BYK024 defoamer 2g, amino acid ester copolymer 3g; among them: the graphene It is prepared by the shear peeling method.

[0049] The high-conductivity self-adhesive graphene low-pressure heating paste described above in this embodiment is prepared by the following method, and the steps are as follows:

[0050] (1) Preparation of graphene: Dissolve 5g graphite and 25g expanded graphite in 1000mL methylpyrrolidone (NMP) in sequence, then add 0.15g surfactant polyethylene glycol-2000, and place the resulting mixture in a high-speed emulsifier , Shearing treatment for 3h under the condition of 15000rpm shearing speed. Then the mixture obtained after shearing is placed in a suction filter for ...

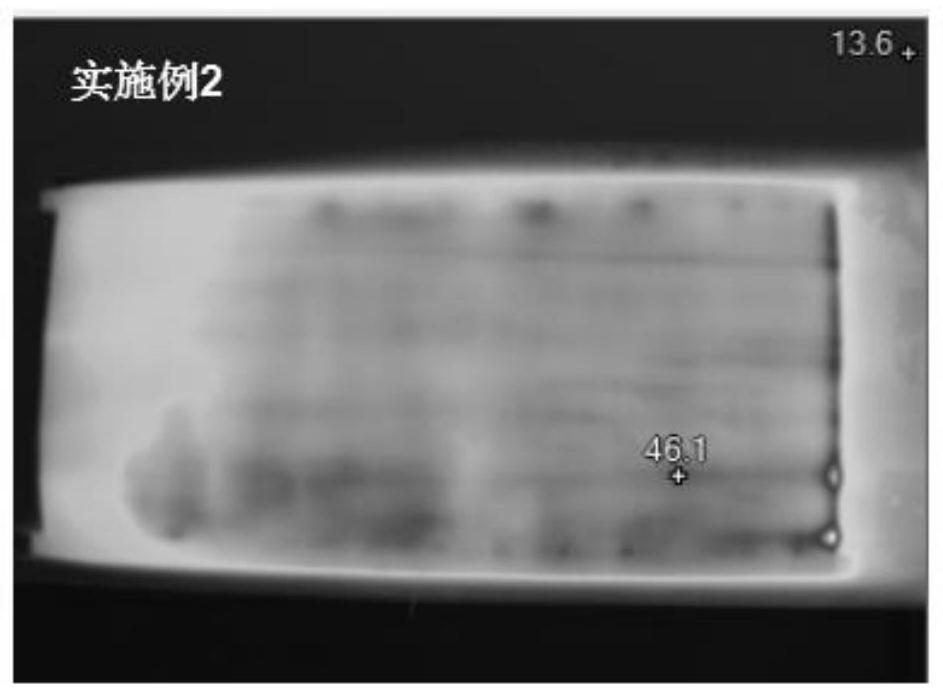

Embodiment 2

[0053] The high-conductivity self-bonding graphene low-pressure heating slurry of this embodiment is prepared by using the following mass parts of raw materials:

[0054] Graphene 40g, heating carbon paste 45g, phenolic resin 5g, 2-propanol 15g, sodium lauryl sulfate 20g, propylene imine 10g, BYK024 antifoaming agent 6g, amino acid ester copolymer 4g; among them: the graphene It is prepared by the shear peeling method.

[0055] The high-conductivity self-adhesive graphene low-pressure heating paste described above in this embodiment is prepared by the following method, and the steps are as follows:

[0056] (1) Preparation of graphene: Dissolve 30g graphite and 20g expanded graphite in 2000mL methylpyrrolidone (NMP), add 0.5g surfactant polyethylene glycol-4000, and place the resulting mixture in a high-speed emulsifier. The shearing treatment is 3h under the shearing speed of 15000rpm. The mixture obtained after shearing is placed in a suction filter for vacuum filtration, and the...

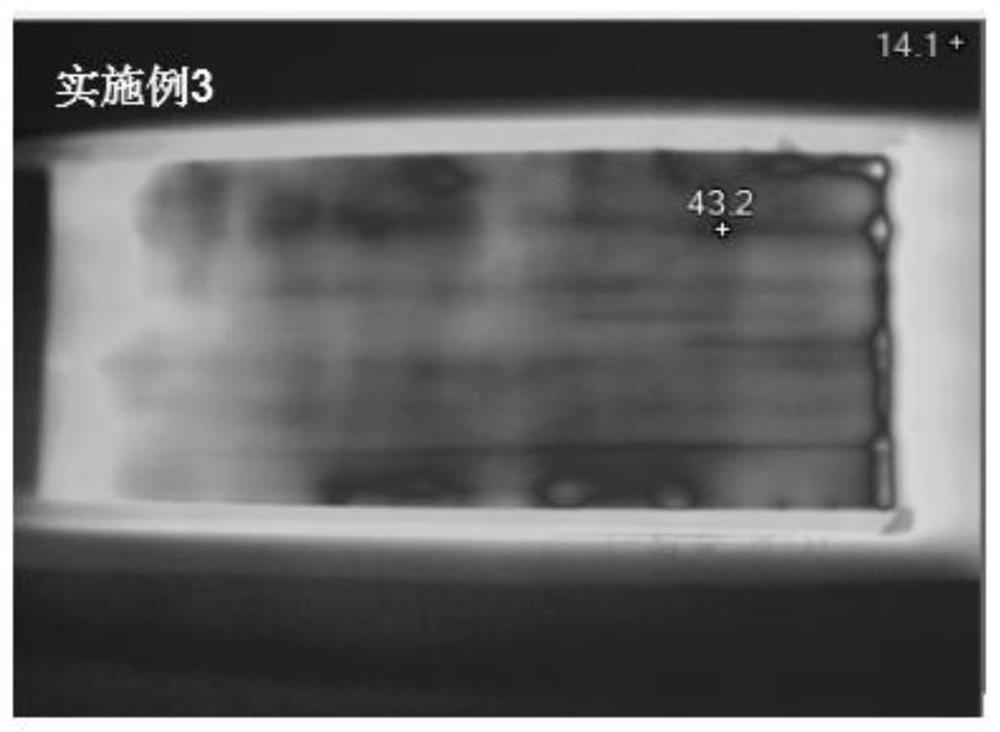

Embodiment 3

[0059] The high-conductivity self-bonding graphene low-pressure heating slurry of this embodiment is prepared by using the following mass parts of raw materials:

[0060] Graphene 35g, heating carbon paste 50g, acrylic resin 4g, 1-butanol 10g, polyvinylpyrrolidone 15g, propylene imine 8g, BYK024 defoamer 5g, amino acid ester copolymer 5g; wherein: the graphene is made of shear Prepared by cutting and peeling method.

[0061] The high-conductivity self-adhesive graphene low-pressure heating paste described above in this embodiment is prepared by the following method, and the steps are as follows:

[0062] (1) Preparation of graphene: Dissolve 50g graphite and 10g expanded graphite in 2000mL methylpyrrolidone (NMP), then add 1.2g surfactant polyethylene glycol-2000, and place the resulting mixture in a high-speed emulsifier. Under the condition of 15000rpm shearing speed, the shearing process is 3h. The mixture obtained after the shearing treatment is placed in a suction filter to pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com