Preparation method and application of graphene slurry

A graphene and slurry technology, applied in the field of preparation of sulfur-free graphene slurry, can solve the problem of high sulfur content in graphene products, improve the rate charge-discharge performance and cycle performance, good electrical conductivity, and reduce the amount of addition. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

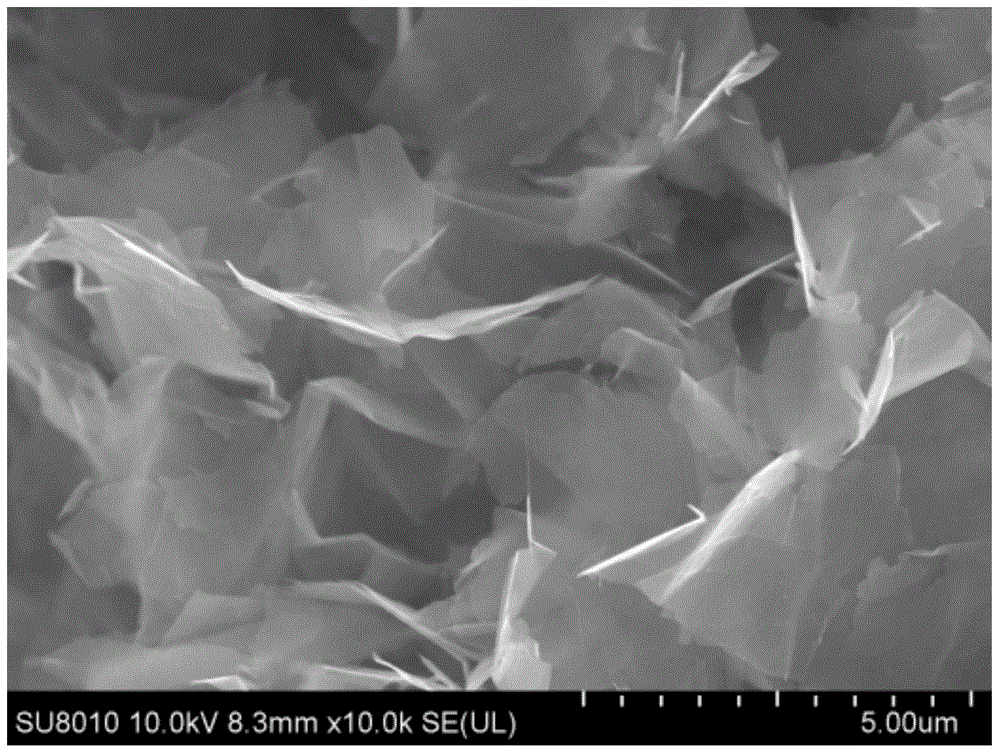

Image

Examples

preparation example Construction

[0020] The embodiment of the present invention provides a kind of preparation method of graphene slurry, the preparation method of this graphene slurry comprises the following steps:

[0021] A. Weigh the reaction material according to the ratio of graphite: intercalant: oxidizing agent: 1g: (3-30) mL: (0.1-3.0) g, then carry out the mixing reaction treatment of the weighed reaction material, and then Washing and drying treatment to obtain graphite intercalation compound;

[0022] B. Expanding the graphite interlayer compound to obtain expanded graphite;

[0023] C. Perform mixing and dissociation treatment of the graphite expanded body according to the mass percentage of graphite expanded body: dispersing aid: solvent (1.0-10.0): (0.1-2.0): 100.0, to obtain graphene slurry.

[0024] Wherein, in one embodiment, the graphite in step A is natural flake graphite. Natural flake graphite is a hexagonal crystal system with a layered structure, which is convenient for oxidation int...

Embodiment 1

[0045] A. Preparation of graphite interlayer compound: according to natural flake graphite: nitric acid: KMnO 4 =1g: 20mL: 0.8g, weigh a certain amount of natural flake graphite, nitric acid and potassium permanganate respectively, wherein the carbon content of the weighed natural flake graphite is 99.9%, 30 mesh. Put the weighed natural flake graphite into a dry and clean reaction kettle, then add the weighed nitric acid with a mass concentration of 98%, and stir and mix evenly. Gradually add the weighed KMnO to the kettle in batches 4 , and control the reaction temperature at 25°C, and stir the reaction for 60min. Finally, deionized water is slowly added to the reaction system, wherein the volume of deionized water added is 2 times the volume of the intercalation agent (nitric acid). °C drying to obtain graphite intercalation compound.

[0046] B. Preparation of graphite extruded body: place the dried graphite interlayer compound in a muffle furnace for heat treatment at ...

Embodiment 2

[0049] A. Preparation of graphite interlayer compound: according to natural flake graphite: a mixture of nitric acid and acetic acid: K 2 Cr 2 o 7 =1g: 3mL: 0.1g, take a certain amount of natural flake graphite, the mixture of nitric acid and acetic acid and potassium dichromate respectively, wherein, the carbon content of the natural flake graphite taken by weighing is 90%, 1000 mesh, the nitric acid In the mixture of nitric acid and acetic acid, the mass concentration of nitric acid is 65%, and the mass ratio of nitric acid to acetic acid is 1:1. Put the weighed natural flake graphite into a dry and clean reaction kettle, then add the weighed mixture of nitric acid and acetic acid into it, and stir and mix evenly. Gradually add the weighed potassium dichromate into the kettle in batches, control the reaction temperature at 60°C, and stir for 100 minutes. Finally, deionized water is slowly added to the reaction system, wherein the volume of deionized water added is twice t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com