Method and apparatus for realizing double-gradient well drilling

A dual-gradient drilling technology, which is applied in underwater drilling, earthwork drilling, wellbore flushing, etc., can solve the problems of high risk, occupying platform space, and low system reliability, so as to simplify the well structure, save time, The effect of reducing the number of lower layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

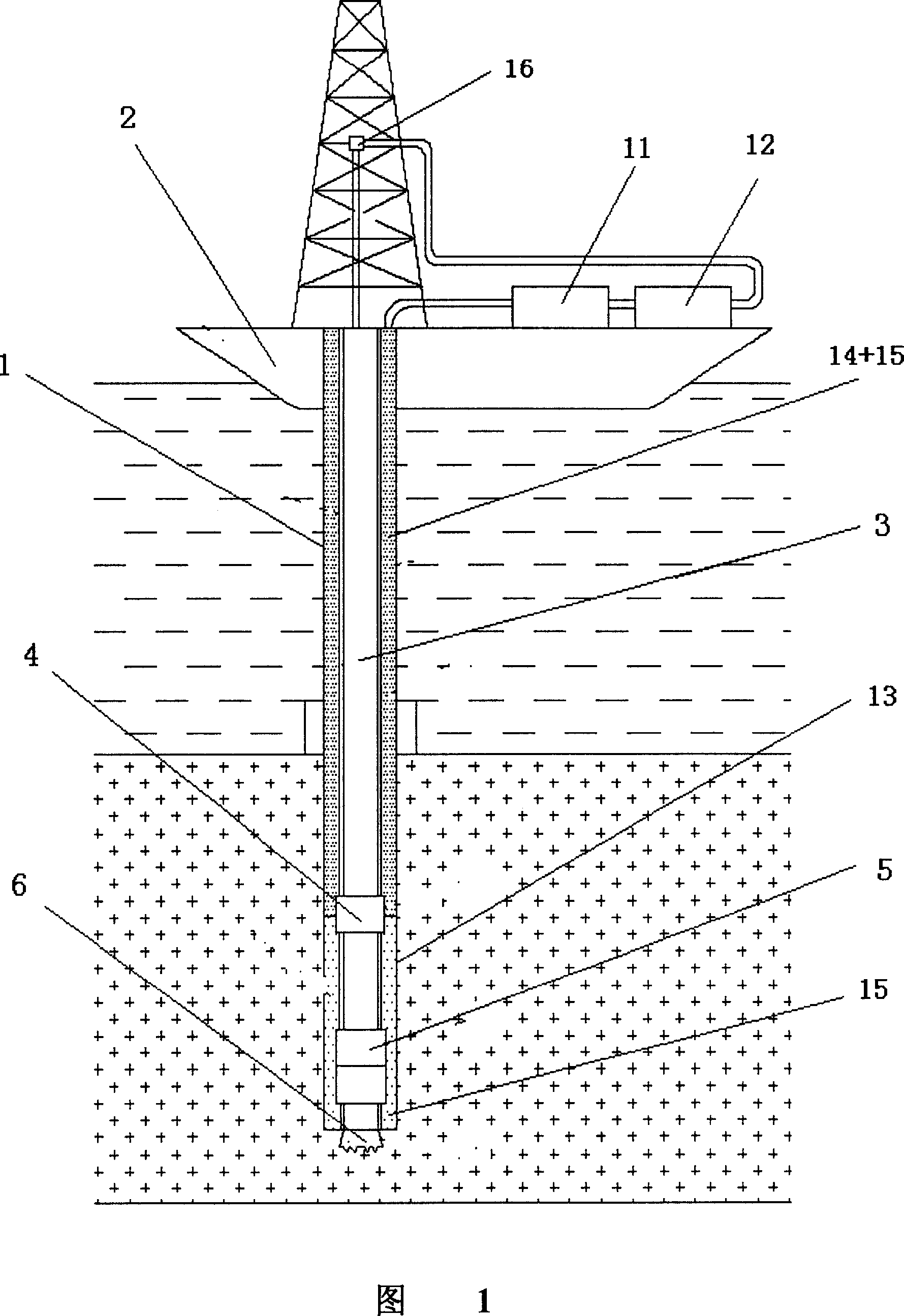

[0035] As shown in Figure 1, deepwater drilling platforms usually adopt dynamic positioning, and use large-diameter risers 1 (such as 21 inches) to connect the drilling equipment on the drilling platform 2 and the blowout preventer group at the subsea wellhead, guide the drill bit and other drilling tools From the drilling platform 2 to the subsea wellhead, and conduct mud and debris from the subsea wellhead to the drilling platform 2. The riser 1 is composed of a plurality of pipe sections, each pipe section being a special casing with a coupling device. The bottom end of the riser 1 is connected to the subsea blowout preventer unit, and the connection usually includes a rotatable flexible joint to move directly on the subsea wellhead along with the drilling platform 2 . There is an expansion joint at the upper end of the riser 1 to compensate the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com