Robot for steamer

A robot, multi-joint robot technology, applied in the directions of manipulator, loading/unloading, transportation and packaging, can solve the problems of high labor intensity, high technical requirements, high labor cost, and achieve fast response speed, flexible control, and increased friction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

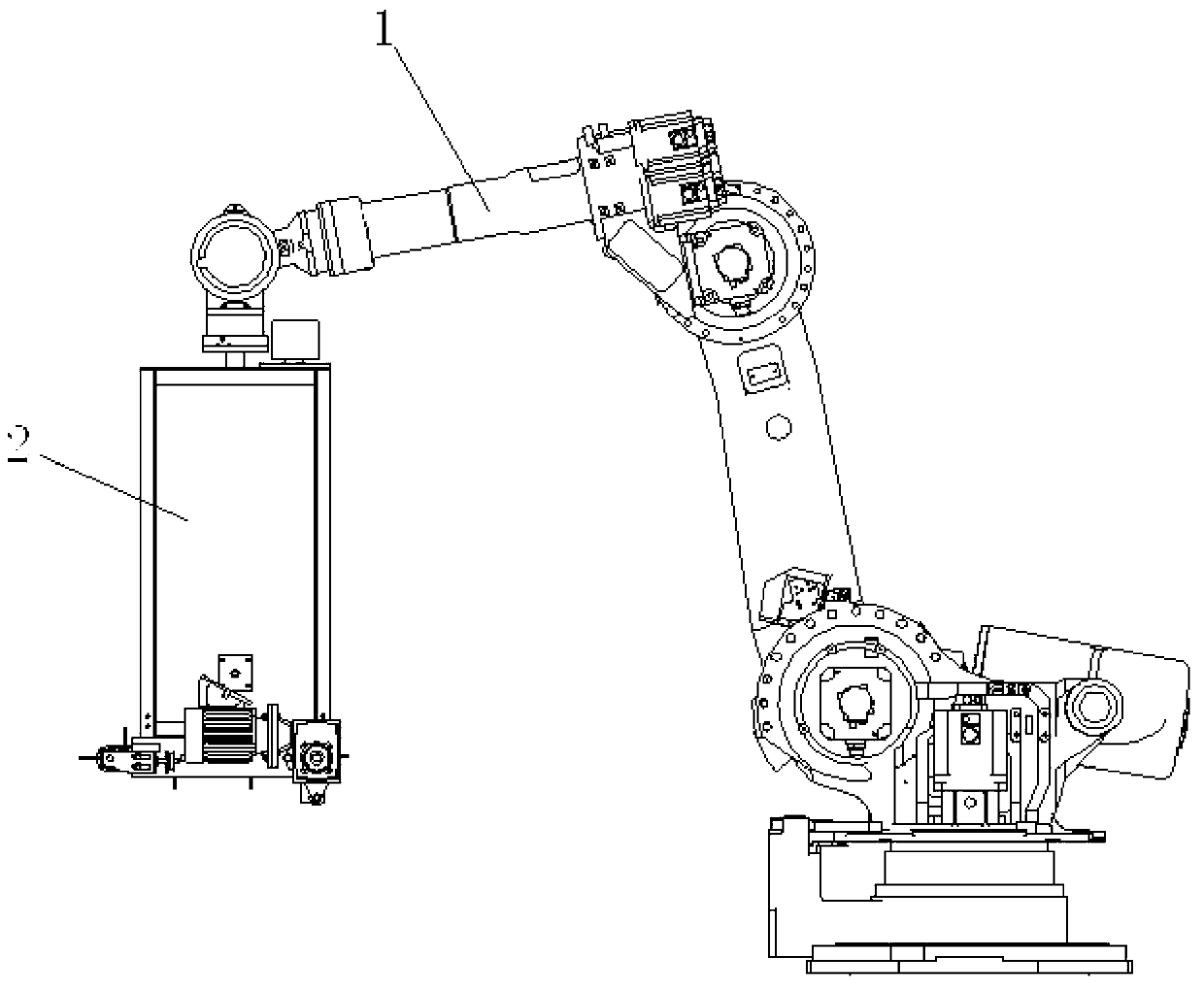

[0027] See Figure 1 to Figure 5 , the steamer loading robot of this embodiment includes a robotic arm 1 and a steamer loading actuator 2 .

[0028] The retort actuator 2 is fixed on the end of the robot arm 1 . The robot arm 1 adopts a multi-joint robot.

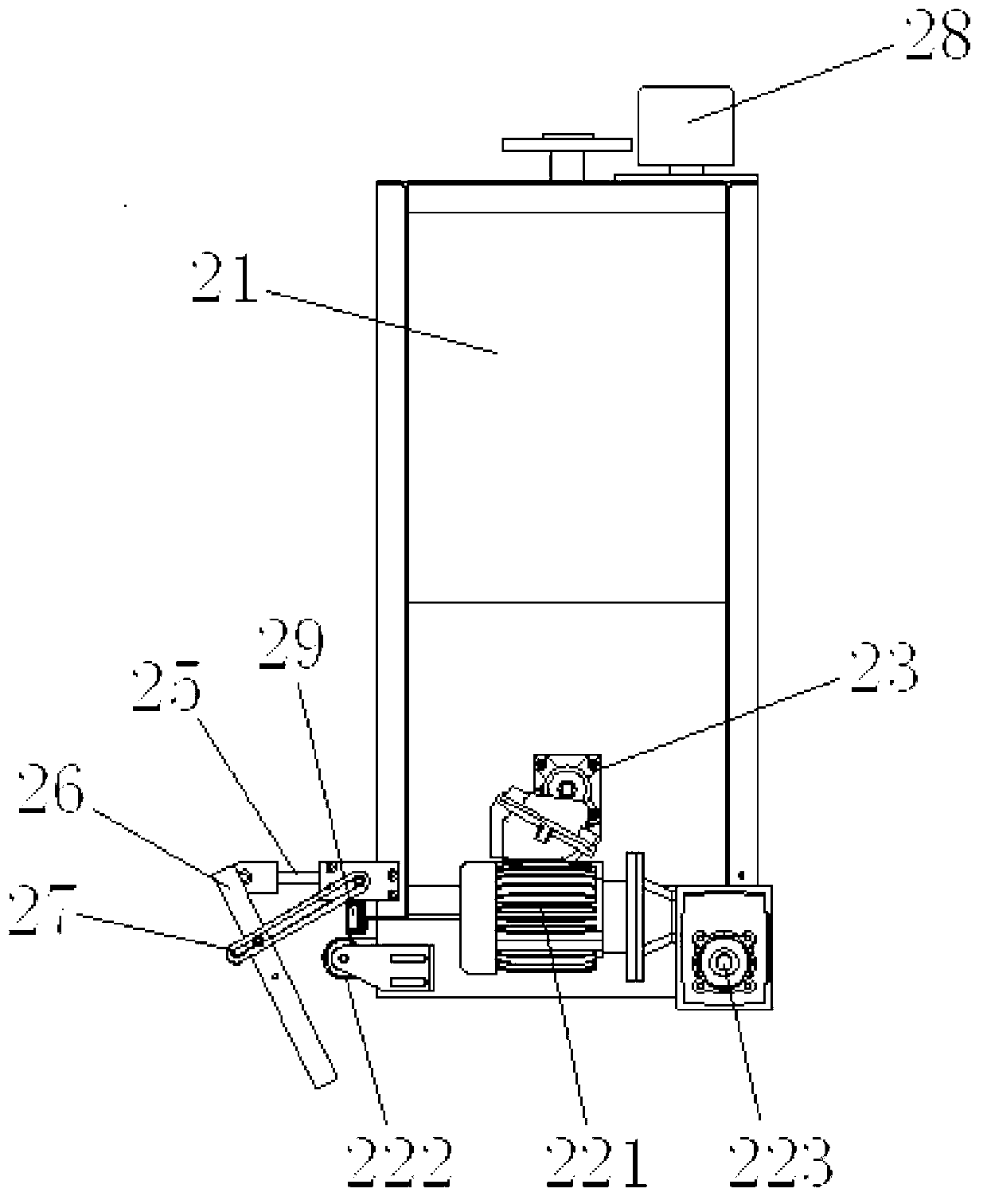

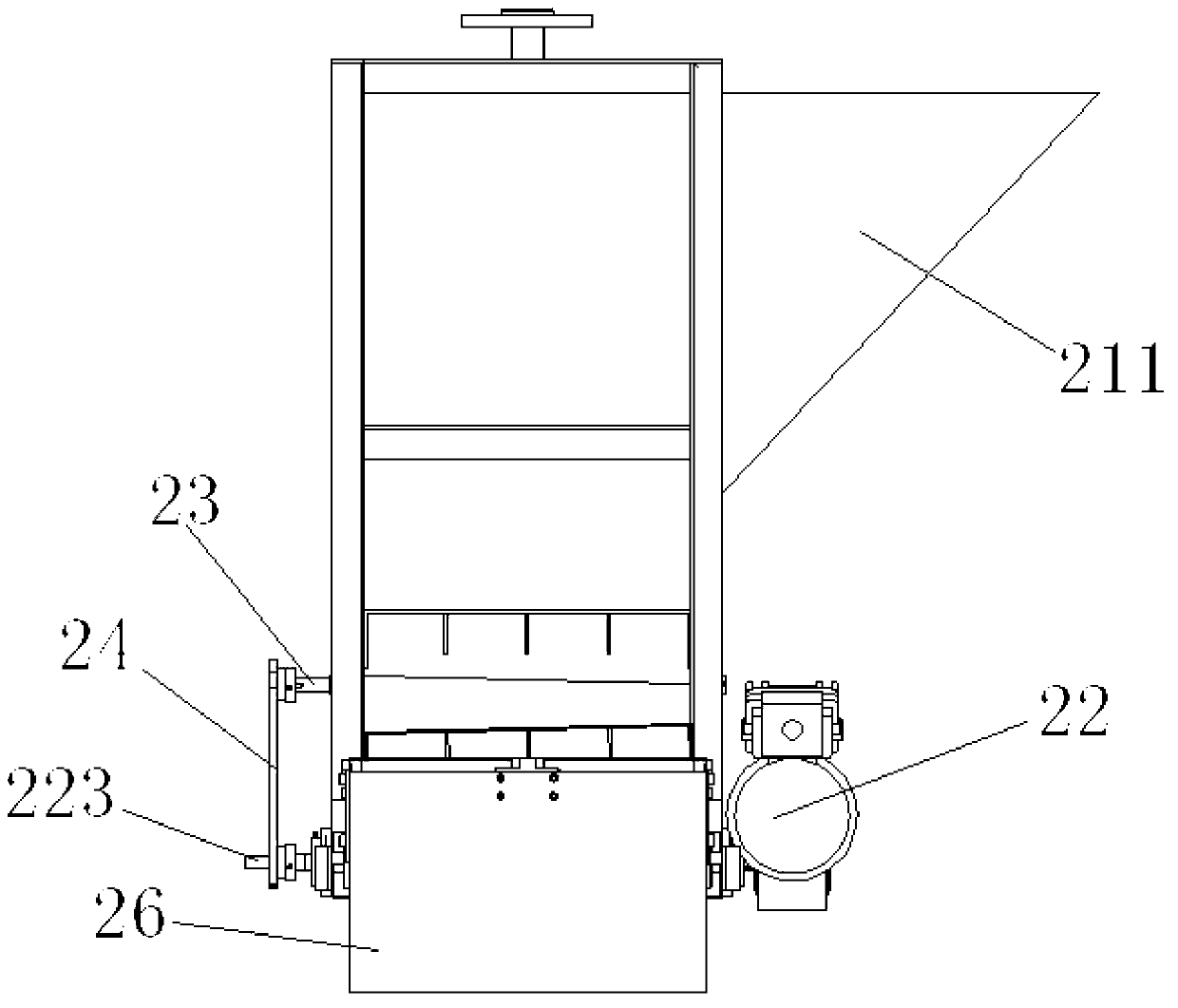

[0029] The retort actuator 2 includes a silo 21 , a conveying device 22 , a stirring device 23 , a chain 24 , a support rod 25 , an inclined baffle 26 , a pull rod 27 and a level gauge 28 . One side of the feed bin 21 is provided with a feed port 211 . The conveying device 22 is arranged at the bottom of the silo 21 . The conveying device 22 includes a geared motor 221 , a conveyor belt 222 , a drive shaft 223 and a rib 224 . The reduction motor 221 drives the transmission shaft 223 to drive the conveyor belt 222 to rotate. The stirring device 23 is arranged in the feed bin 21 . The transmission shaft 223 drives the stirring device 23 to rotate through the chain 24 . The conveyor belt 222 is a belt, and the rib plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com