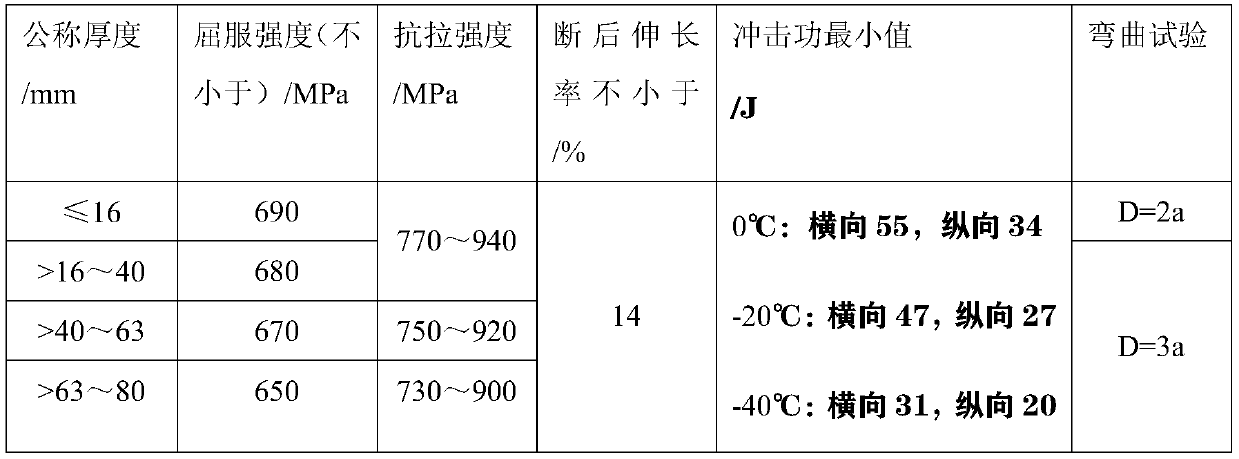

690 MPa grade high-strength low-yield-ratio medium-manganese steel medium-thickness steel and manufacturing method

A technology with low yield-strength ratio and manufacturing method, which is applied in the field of 690MPa high-strength, low-yield-ratio, medium-thickness steel and medium-thickness steel, can solve the problems of poor low-temperature toughness and high yield-strength ratio of high-strength structural steel. The effect of cracking performance, lower yield ratio and excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

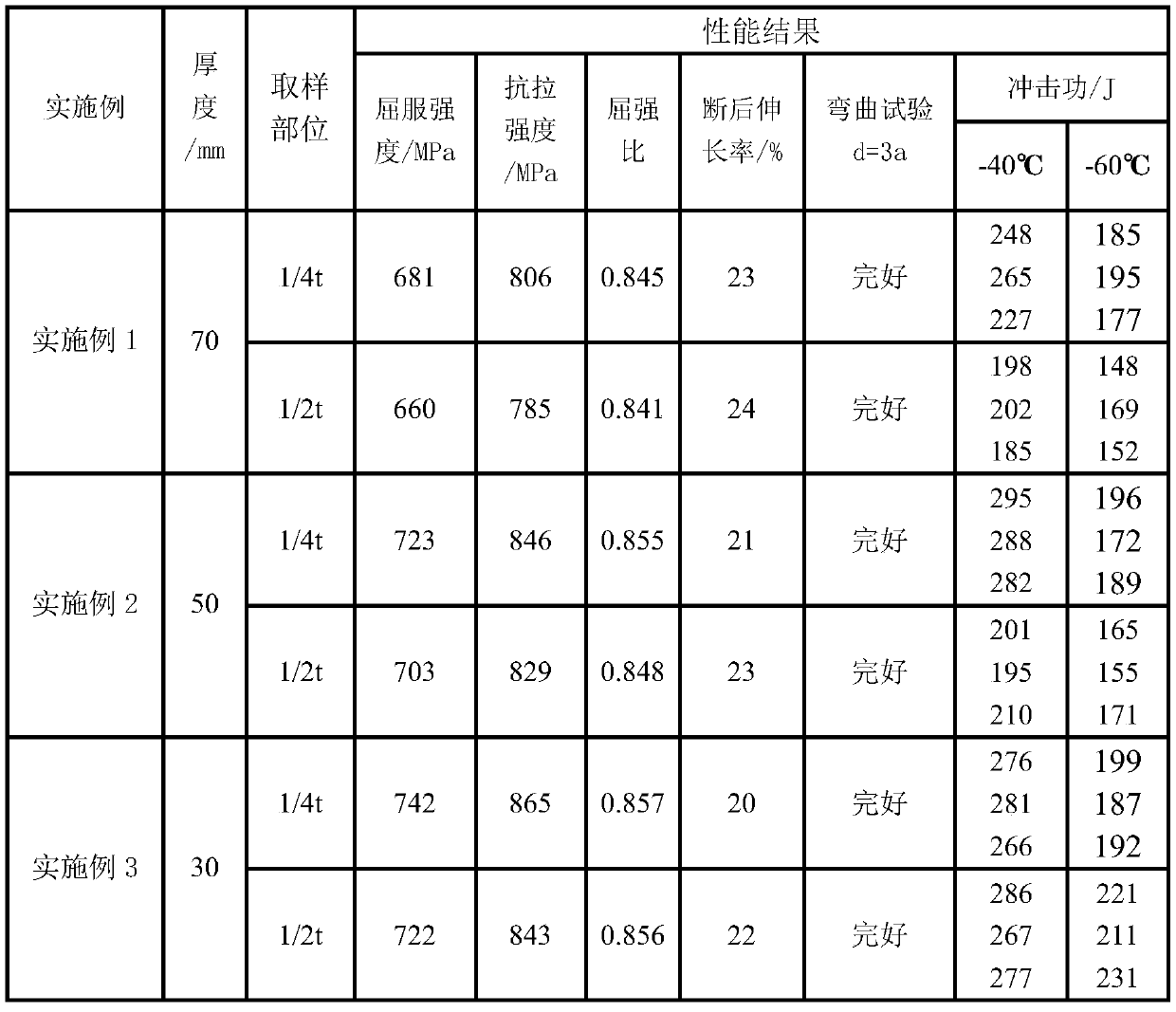

Embodiment 1

[0030] This embodiment provides a 690MPa-grade high-strength low-yield-ratio medium-manganese steel medium-thick steel with a thickness of 70 mm. Its chemical composition and mass percentage are as follows: C: 0.09%, Mn: 4.65%, Si: 0.22%, P: 0.008%, S: 0.001%, Ti: 0.028%, Ni+Cr+Mo: 0.58%, and the balance is Fe and unavoidable impurities.

[0031] The manufacturing method of above-mentioned steel plate is as follows:

[0032] Converter smelting after molten iron desulfurization treatment to reduce S and P content in molten steel; Alloying the required mass fractions of C, Mn, Si, Ti, Ni, Cr, Mo elements after LF refining; adopting continuous casting method, continuous casting slab The casting speed is 0.5m / min, the surface defects are cleaned up, and a slab with a thickness of 320mm is obtained; the slab is heated to 1130°C, and the soaking time is 70min; the heated slab is rolled in two stages, and the rolling temperature of the first stage is 1010 ℃, the finish rolling tempe...

Embodiment 2

[0034] This embodiment provides a 690MPa-grade high-strength low-yield-ratio medium-manganese steel medium-thick steel with a thickness of 50mm. Its chemical composition and mass percentage are as follows: C: 0.06%, Mn: 4.47%, Si: 0.26%, P: 0.009%, S: 0.001%, Ti: 0.026%, Ni+Cr+Mo: 0.46%, and the balance is Fe and unavoidable impurities.

[0035] The manufacturing method of above-mentioned steel plate is as follows:

[0036] Converter smelting after molten iron desulfurization treatment to reduce S and P content in molten steel; Alloying the required mass fractions of C, Mn, Si, Ti, Ni, Cr, Mo elements after LF refining; adopting continuous casting method, continuous casting slab The casting speed is 0.6m / min, the surface defects are cleaned up, and a slab with a thickness of 320mm is obtained; the slab is heated to 1130°C, and the soaking time is 70min; the heated slab is rolled in two stages, and the rolling temperature of the first stage is 1005 ℃, the finish rolling temper...

Embodiment 3

[0038] This example provides a 690MPa-grade high-strength low-yield-ratio medium-manganese steel medium-thick steel with a thickness of 30mm. Its chemical composition and mass percentage are as follows: C: 0.05%, Mn: 4.28%, Si: 0.21%, P: 0.008%, S: 0.001%, Ti: 0.033%, Ni+Cr+Mo: 0.39%, and the balance is Fe and unavoidable impurities.

[0039] The manufacturing method of above-mentioned steel plate is as follows:

[0040]Converter smelting after molten iron desulfurization treatment to reduce S and P content in molten steel; Alloying the required mass fractions of C, Mn, Si, Ti, Ni, Cr, Mo elements after LF refining; adopting continuous casting method, continuous casting slab The casting speed is 0.6m / min, the surface defects are cleaned up, and a slab with a thickness of 260mm is obtained; the slab is heated to 1110°C, and the soaking time is 59min; the heated slab is rolled in two stages, and the rolling temperature of the first stage is 1005 ℃, the finish rolling temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com