Multiple-interlayer salt cavern gas storage and building method of multiple-interlayer salt cavern gas storage

A construction method and technology for gas storage, which are applied in earth-moving drilling, mining equipment, mining equipment, etc., can solve the problems of low strength, small thickness, collapse, etc., and achieve strong operability, good generalizability, and increased cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

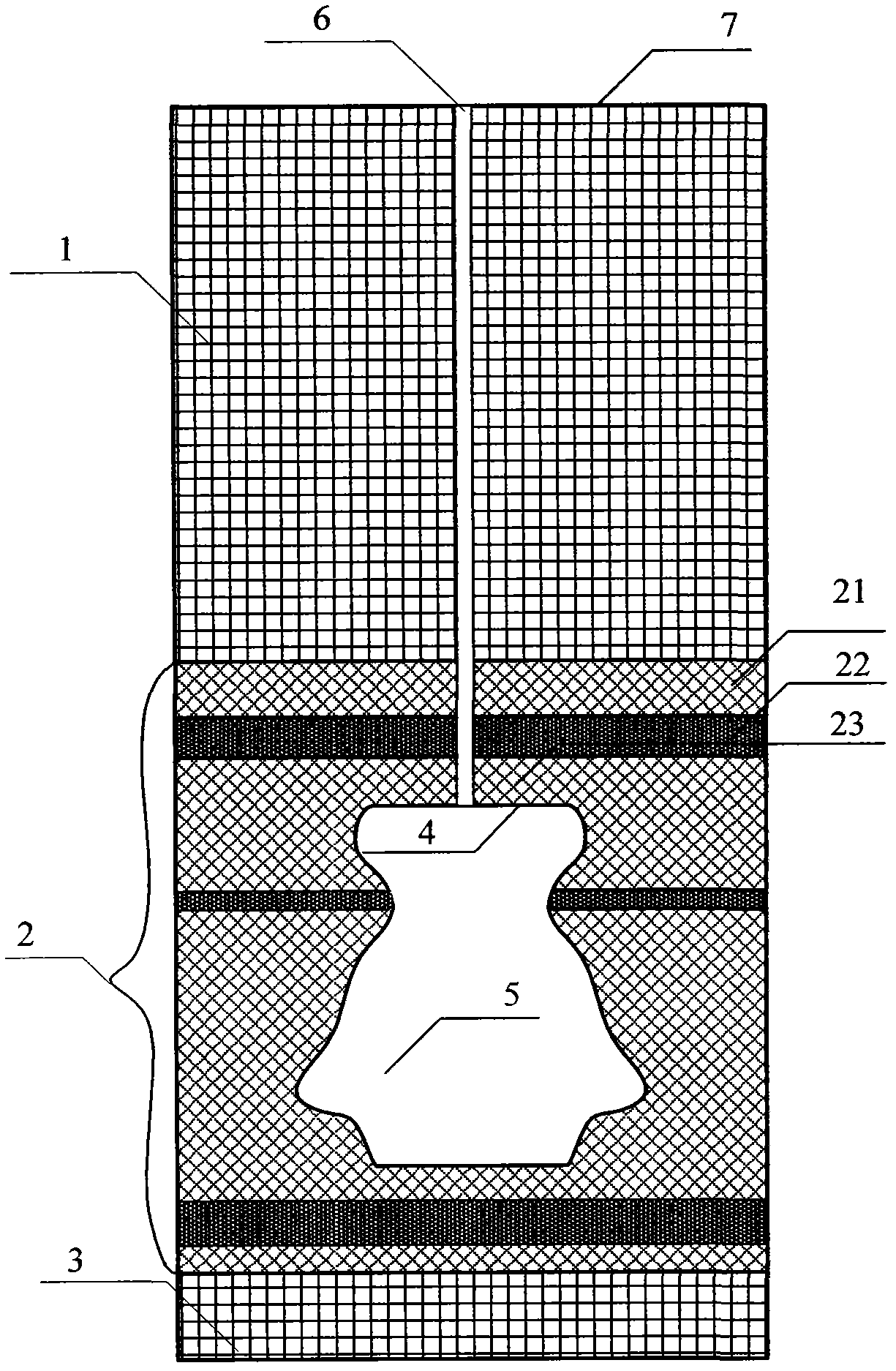

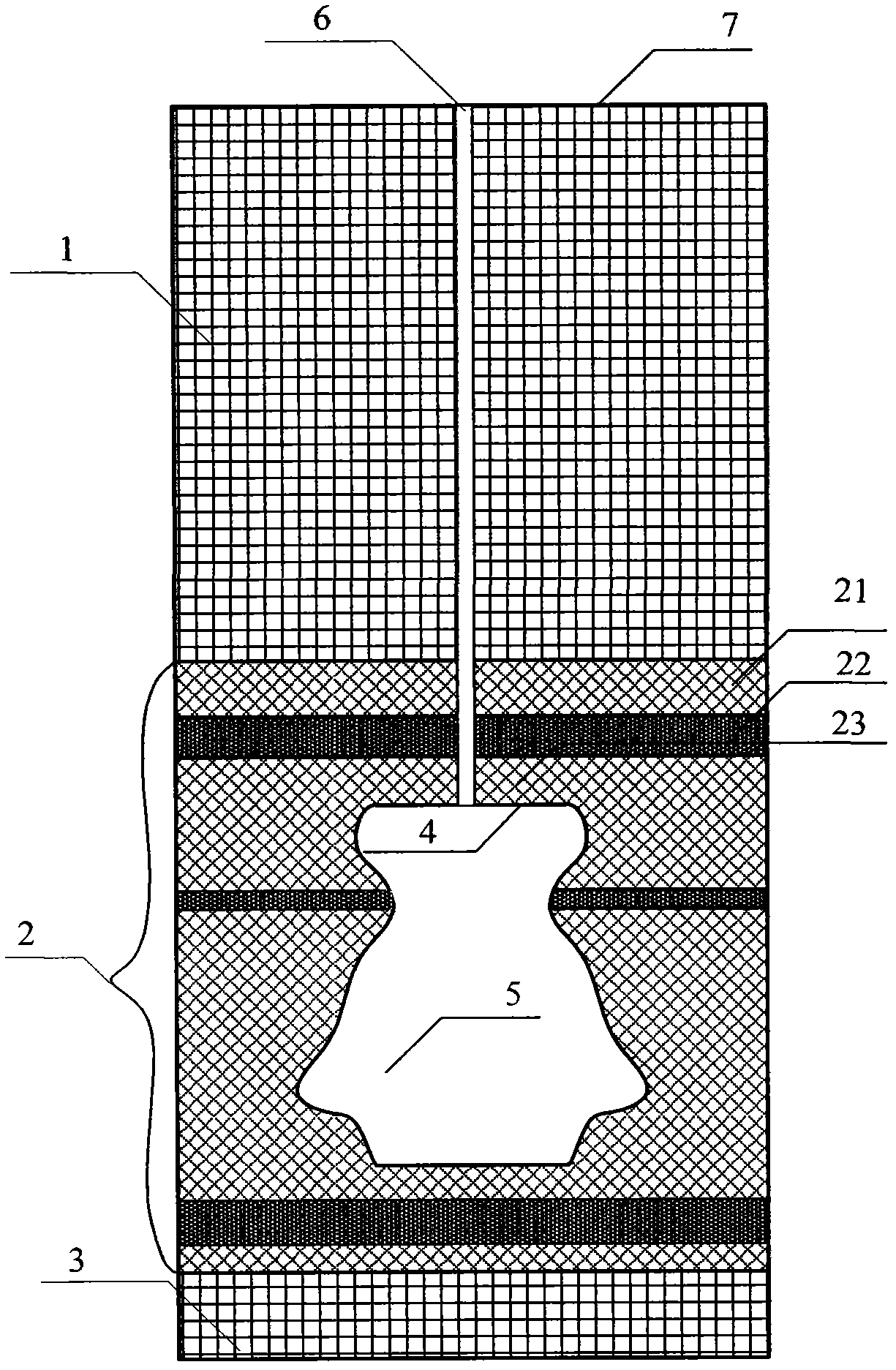

[0020] Such as figure 1 As shown, the multi-interlayer salt-cavern gas storage includes a salt cavern 5 and a natural gas injection-production string system 6; the natural gas injection-production string system 6 is connected to the top of the salt cavern 5; Salt rock 2 and bottom mudstone 3; multi-interlayer salt rock is composed of salt layers and interlayers, and salt layers and interlayers appear alternately; salt caverns are located in multi-interlayer salt rocks, and the shape of the top surface 4 of the salt caverns is circular. From the top mudstone bottom surface to the top surface of the salt cavern are the first salt-salt layer 21 , the interlayer 22 and the second salt-salt layer 23 . The top buried depth of the salt cavern is 951.2m, the bottom buried depth is 1045m, the minimum operating pressure is 6MPa and the minimum pressure operating time is 45 days. The design value of the top span of the salt cavern gas storage is 32m, the design value of the thickness of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com