Movable bending mechanism capable of facilitating discharging of large-bent-degree plates

A bending mechanism and mobile technology, applied in the direction of pushing out equipment, feeding devices, positioning devices, etc., can solve the problems of uneven bending quality, poor bending performance, and low work efficiency of plates, and meet the requirements of large batches. The effects of processing and production, avoiding excessive corner force deformation, and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

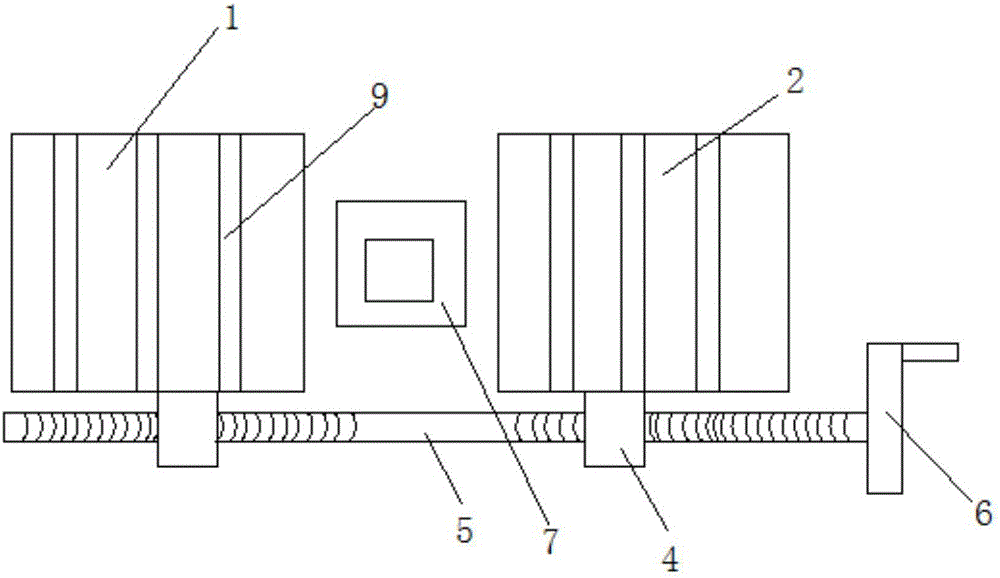

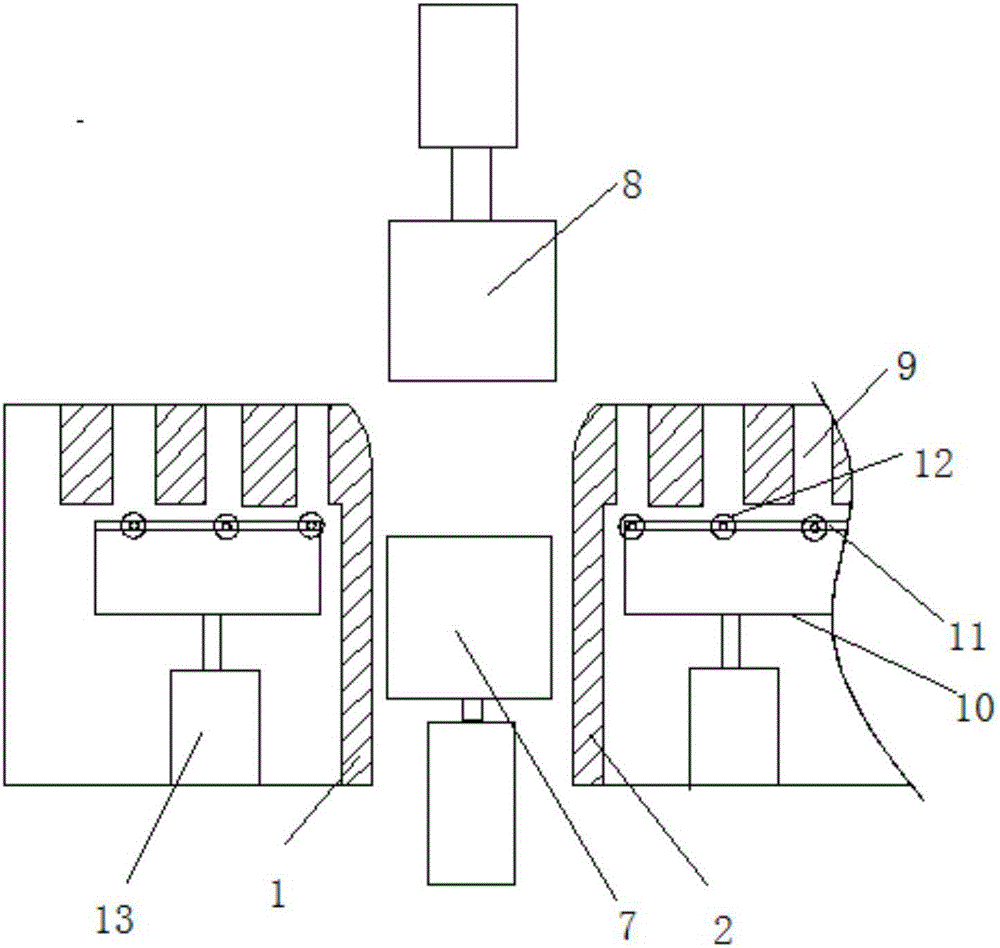

[0017] See attached picture.

[0018] A movable bending mechanism that facilitates the discharge of large-bending plates, including movable left and right worktables 1 and 2 that are symmetrically matched at two intervals, and the movement of the left and right worktables 1 and 2 passes through its two sides Driven by a nut screw mechanism, the nut screw mechanism includes nuts 4 respectively arranged on the outside of the left and right workbenches, and a screw 5 is screwed into the nuts on the same side, and the helical direction of the screw 5 from the center to both ends is opposite, and The protruding end of the screw rod at the same end is equipped with a handwheel 6, a movable lower mold base 7 is arranged between the left and right workbenches 1 and 2, and an upper mold base 8 is arranged above the left and right workbenches 1 and 2, The upper end faces of the left and right workbenches 1 and 2 are respectively provided with guide grooves 9 along the plate conveying di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com