Patents

Literature

61results about How to "Quick stripping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

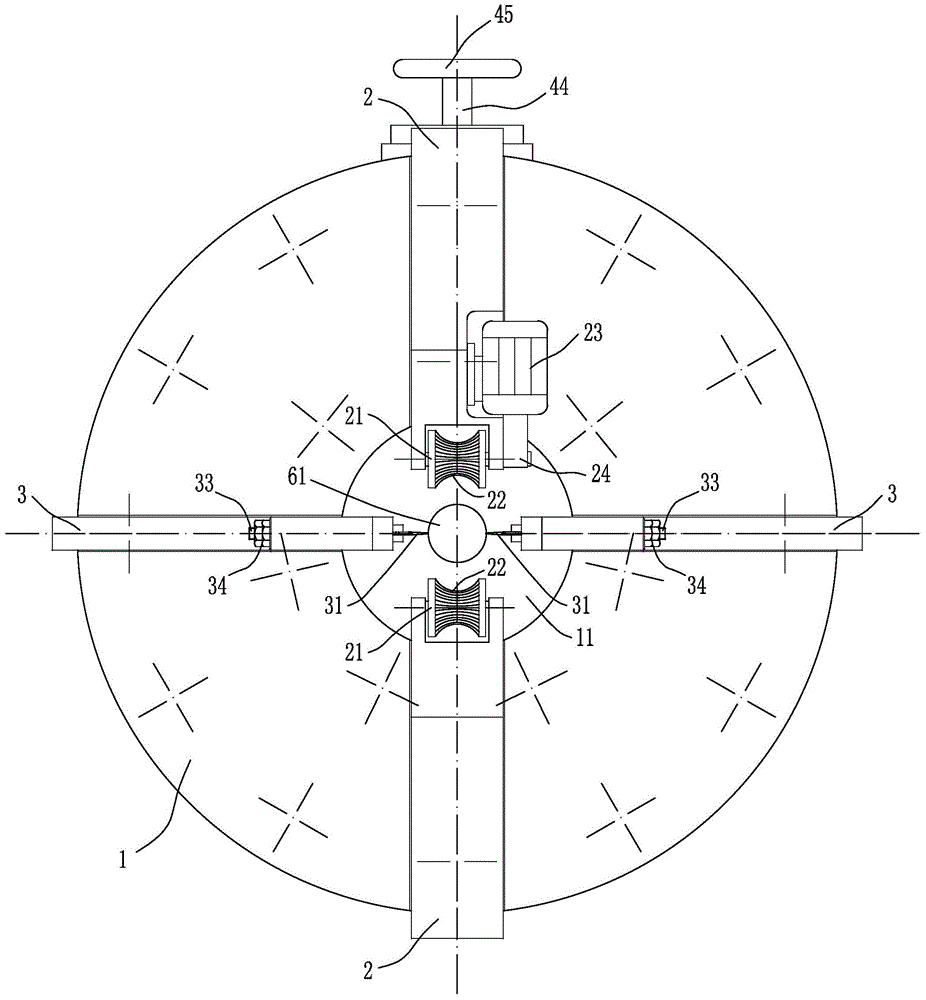

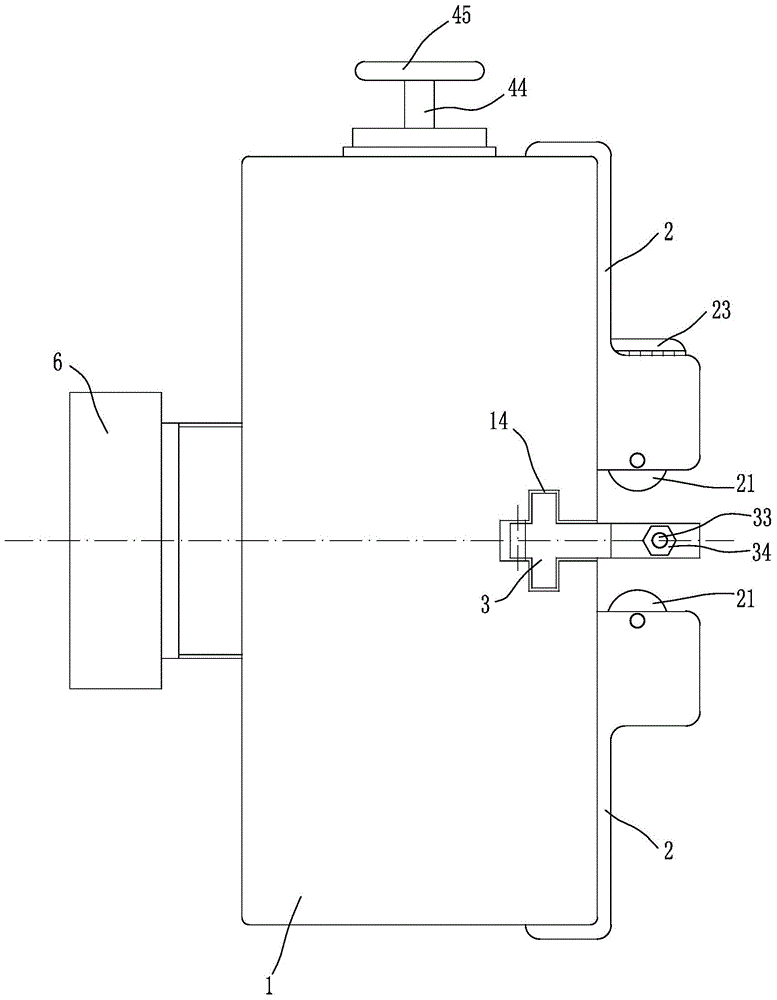

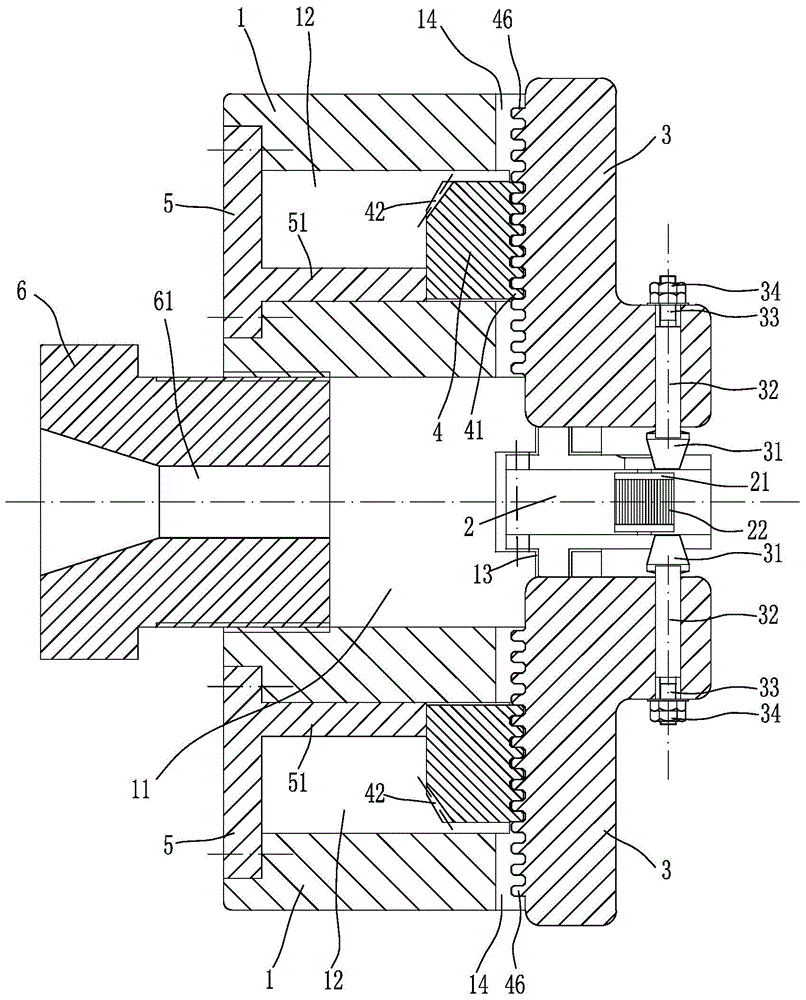

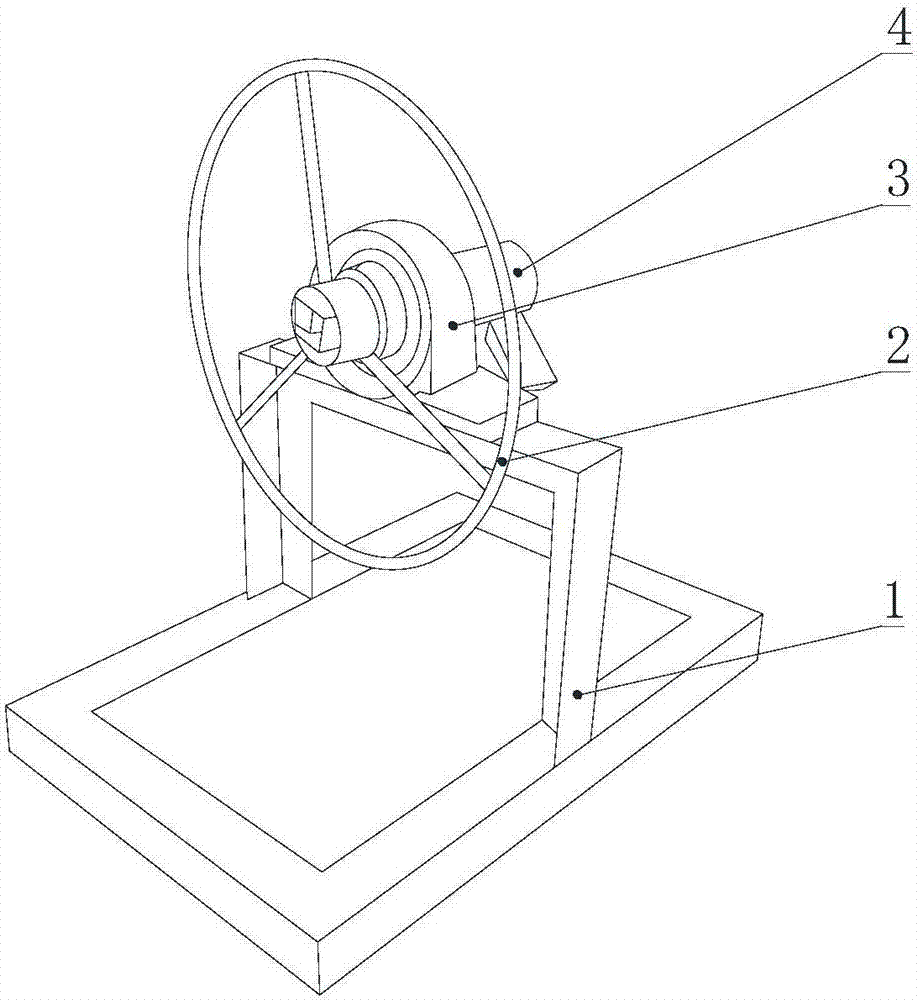

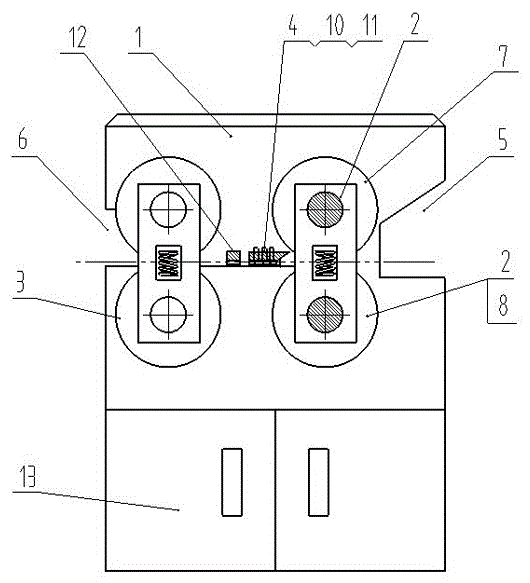

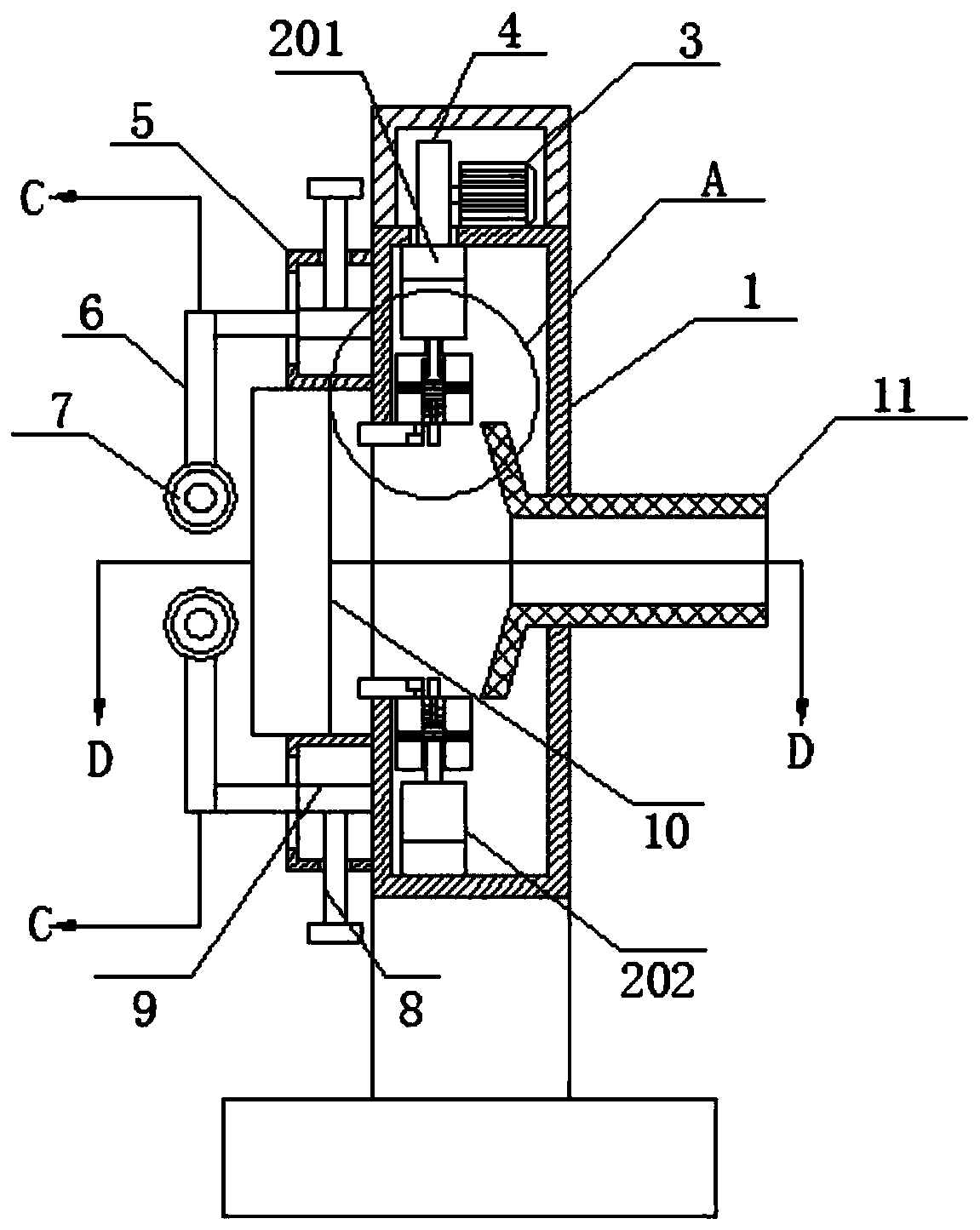

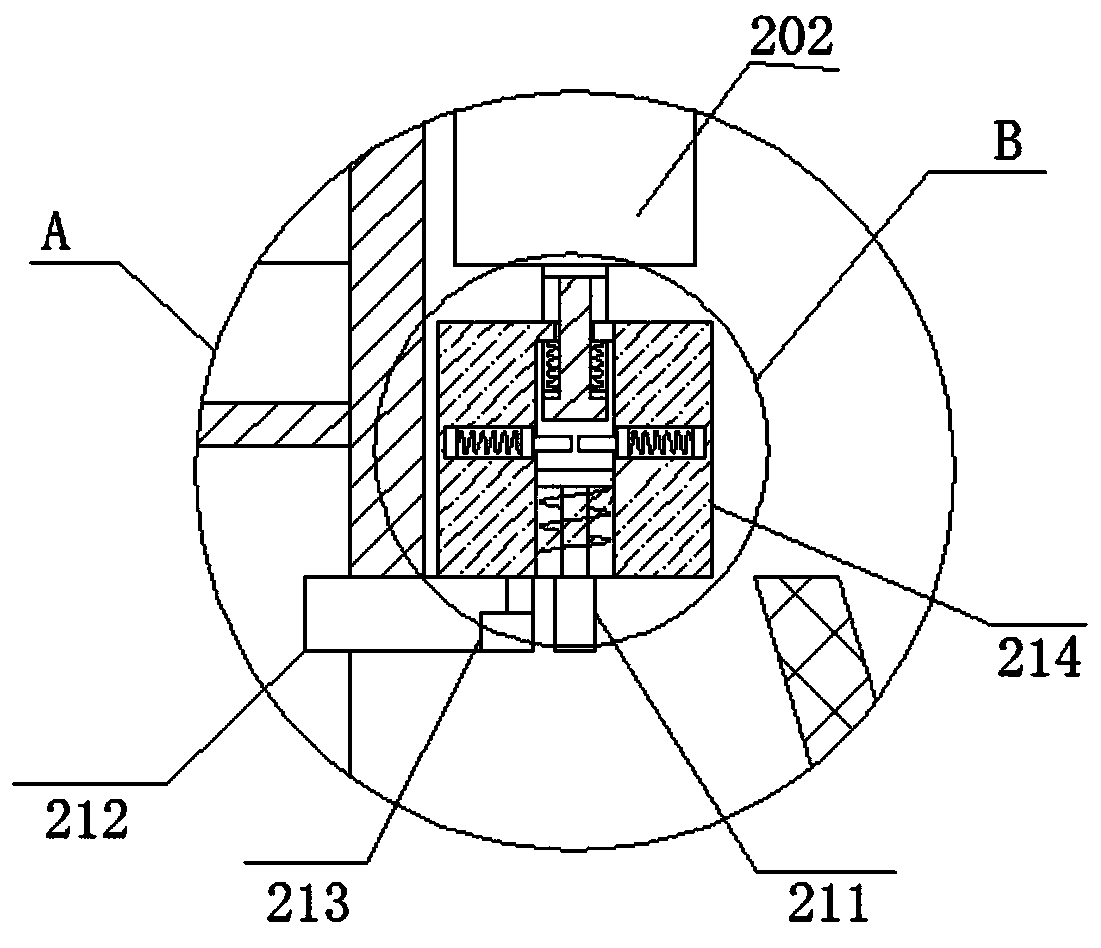

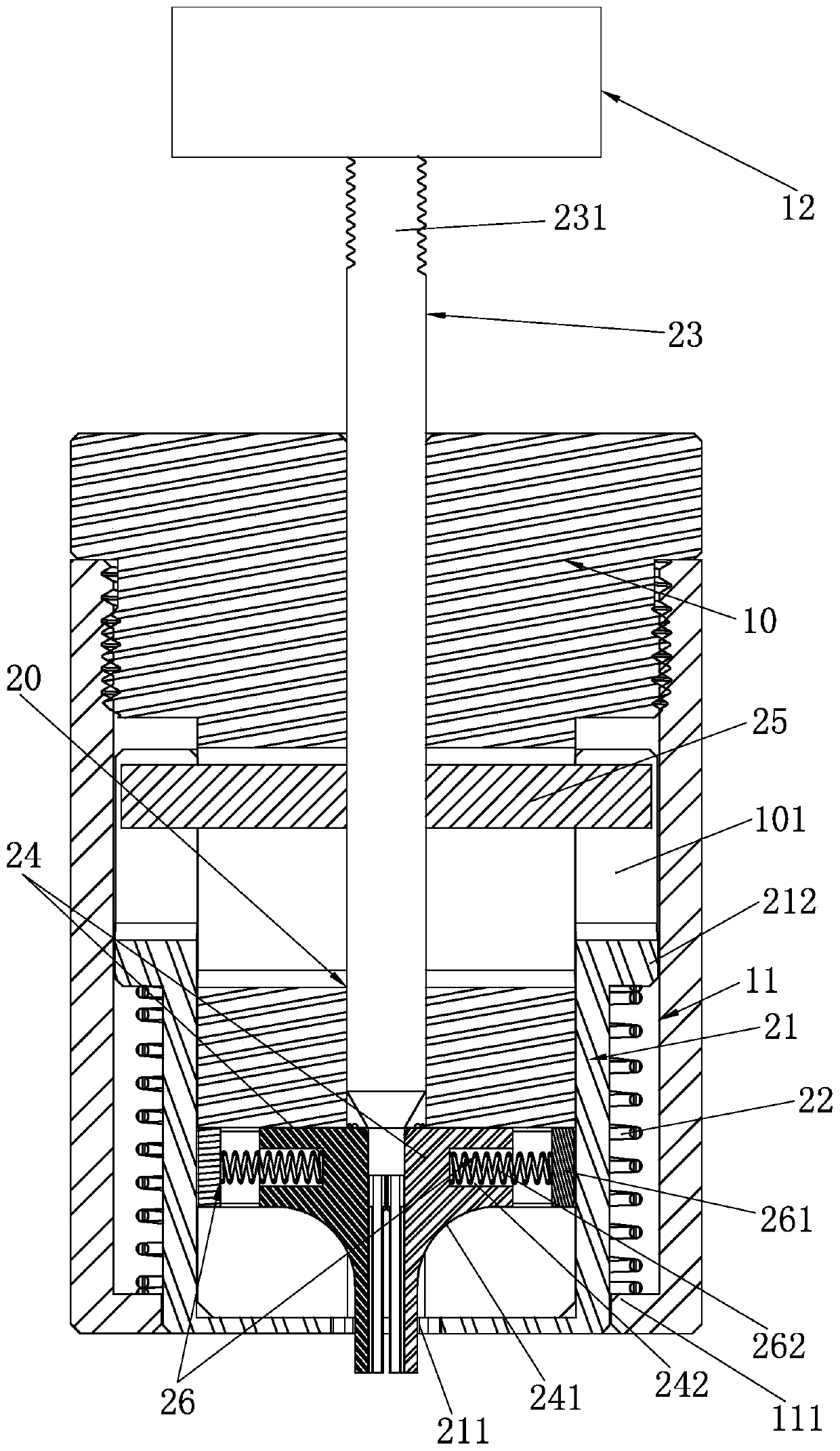

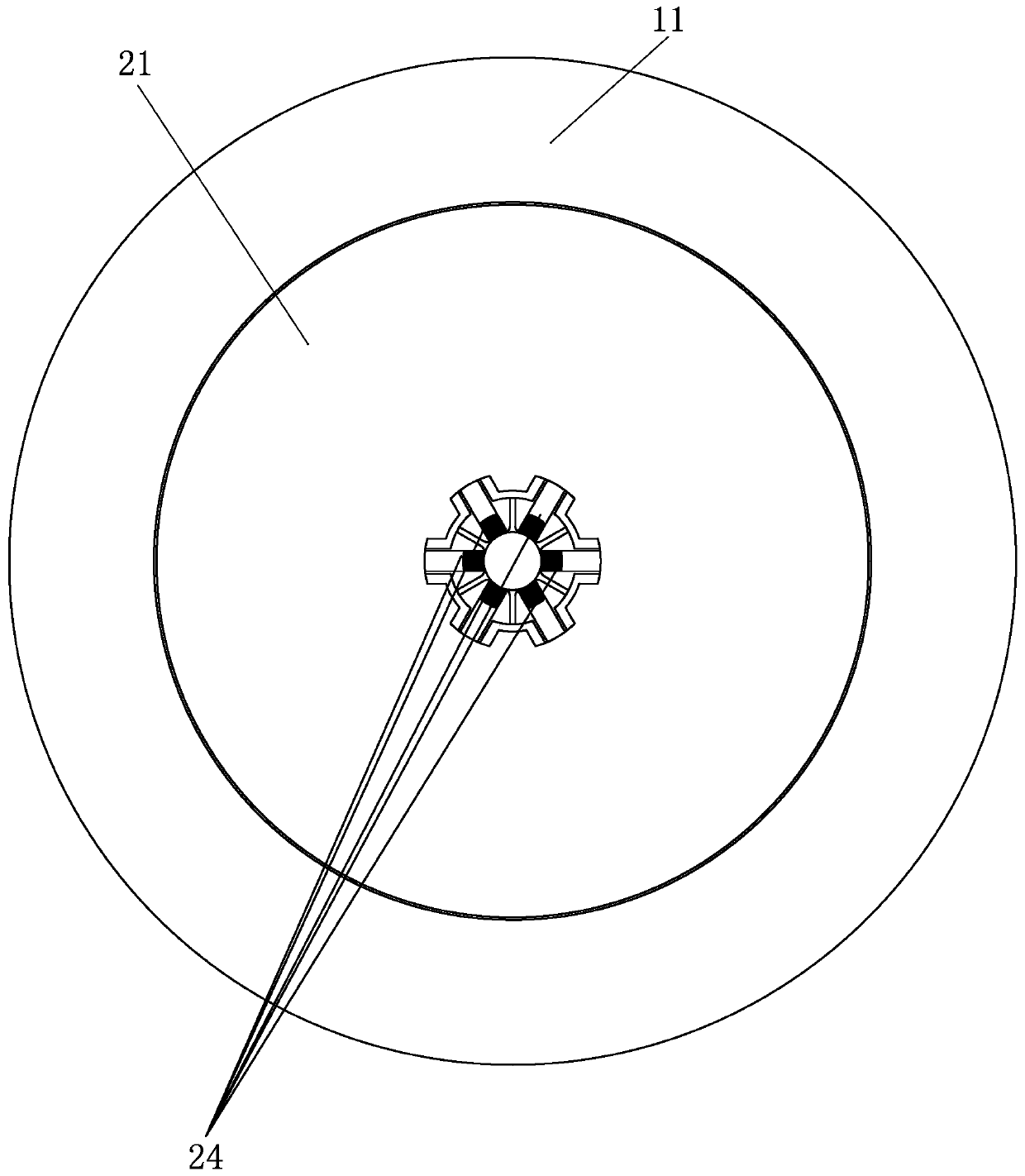

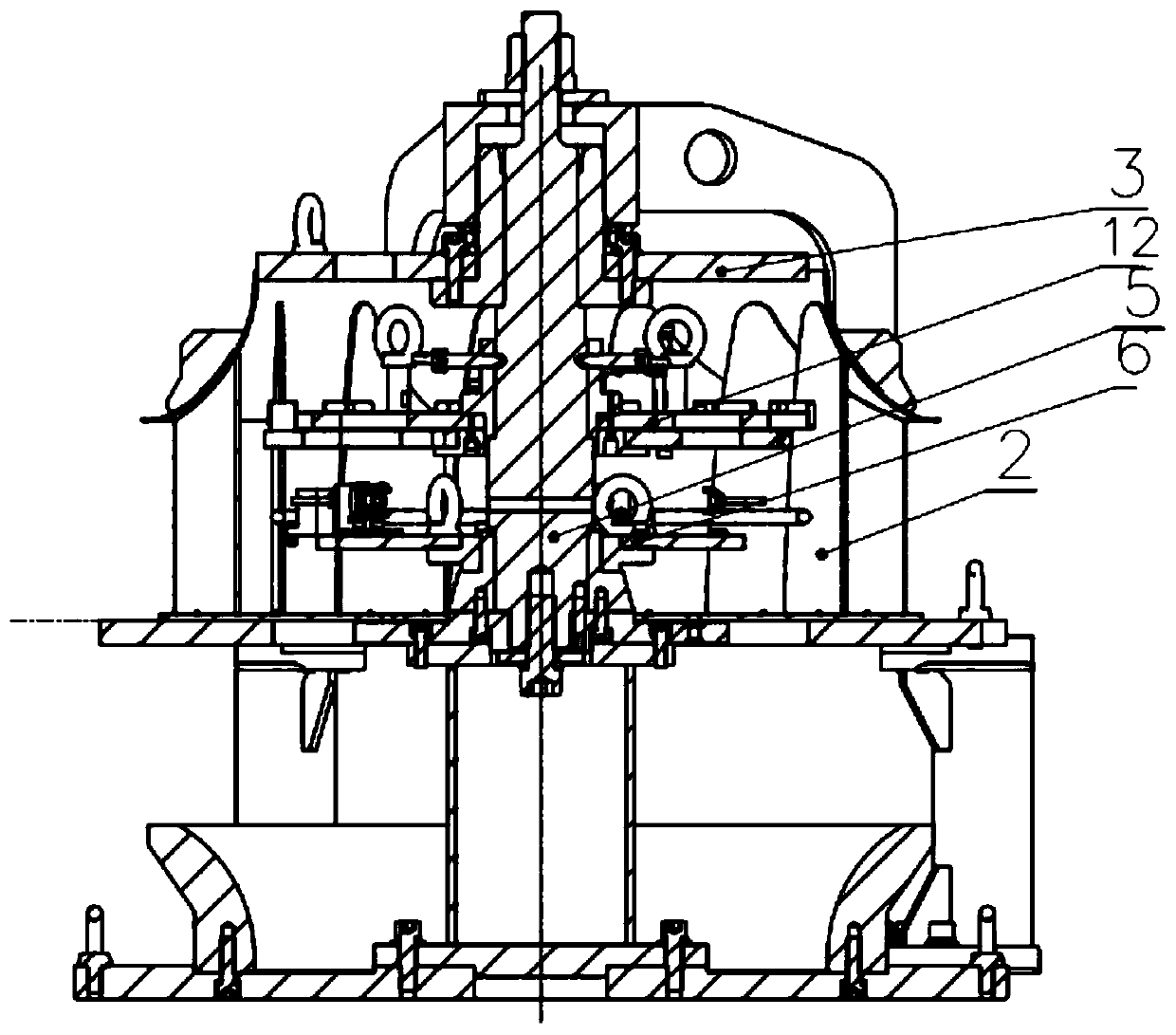

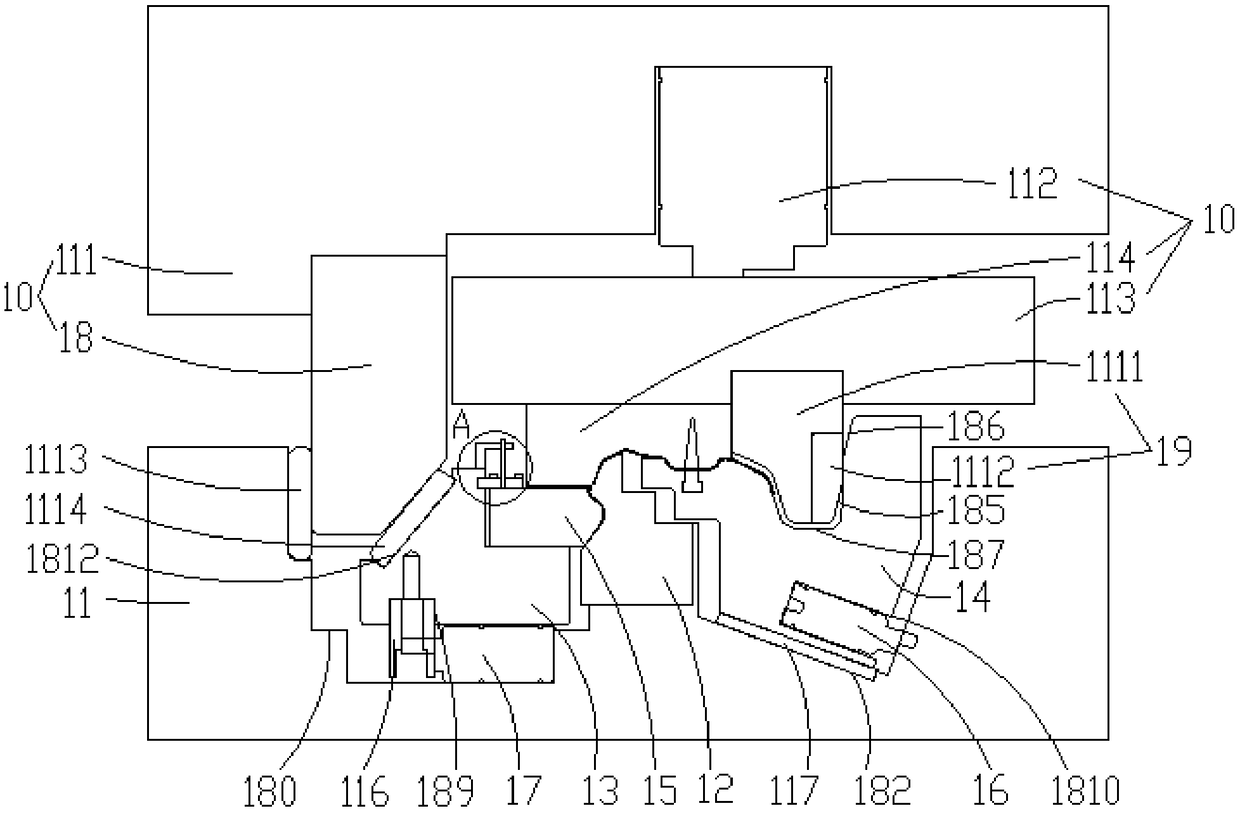

Automatic stripper for scrap cable

InactiveCN104821521AOperational securityQuick StripBasic electric elementsApparatus for removing/armouring cablesScrapEngineering

The invention discloses an automatic stripper for a scrap cable, which comprises a round disc seat. The central position of the disc seat is provided with a cable through hole; two clamping sliding blocks sliding along the radial direction are symmetrically arranged on the disc surface at the front side of the disc seat; two cutting sliding blocks are also symmetrically arranged on the disc surface at the front side of the disc seat; the clamping sliding blocks and the cutting sliding blocks are arranged in a mutual staggered mode; the inner end of the clamping sliding block is provided with a clamping wheel in a rotating mode; the outer peripheral surface of the clamping wheel is provided with a clamping groove sunk inwardly; the clamping wheel is in rotary connection with a clamping driving device; the inner end of the cutting sliding block is fixedly provided with a cutting knife; and the disc seat is provided with a synchronous driving device for driving the clamping sliding blocks and the cutting sliding blocks to slide synchronously. The outer skin of the scrap cable can be safely, conveniently and quickly stripped, the cable core is not cut damaged, and the cable core can be prevented from being damaged.

Owner:STATE GRID CORP OF CHINA +1

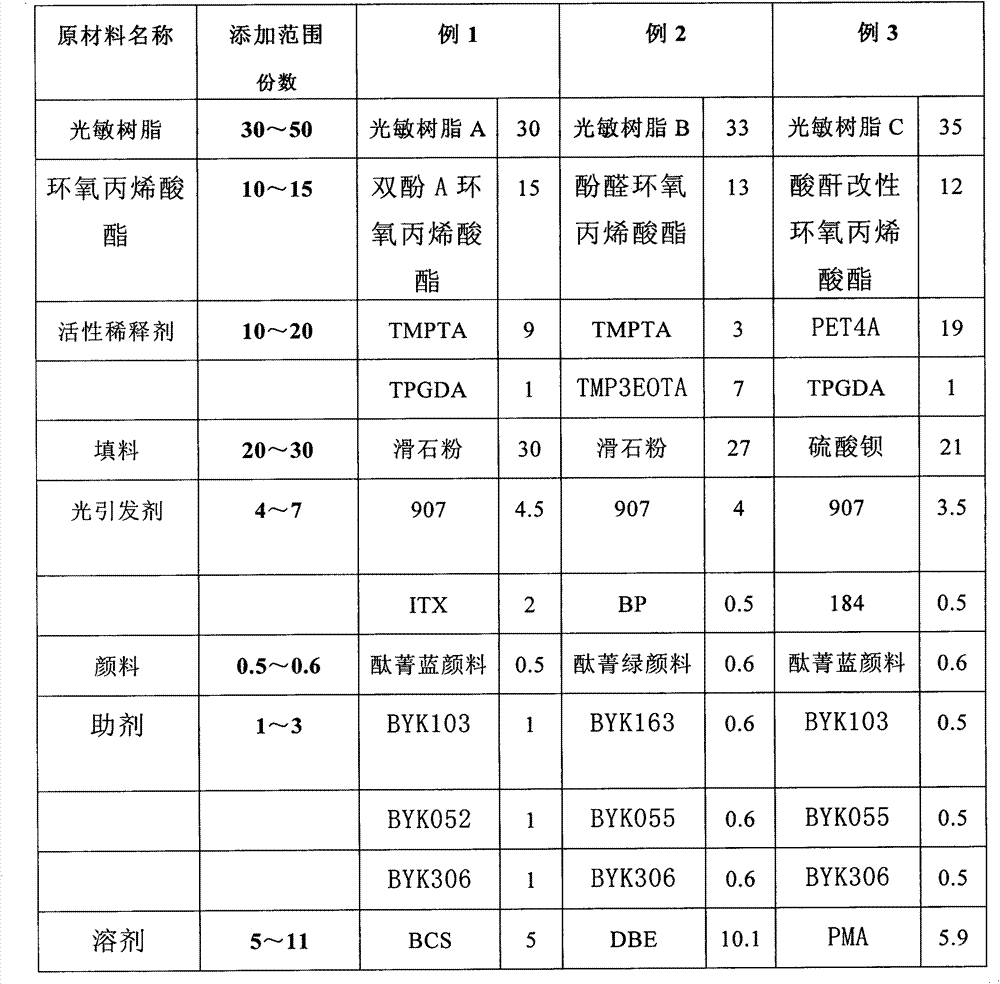

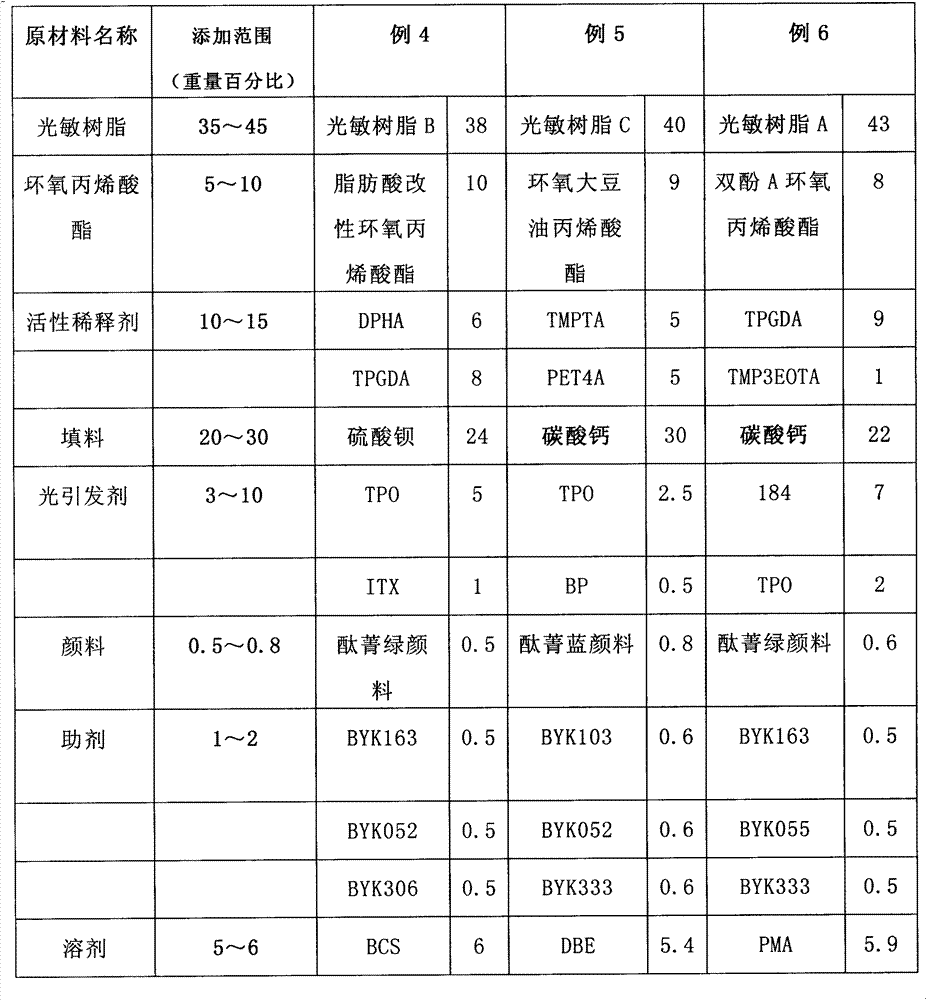

Liquid photo-imageable alkali developable and anodizing resistant ink and preparation method thereof

InactiveCN103045015AThe synthesis operation process is simpleGood anti-sandblasting performanceInksPhotosensitive materials for photomechanical apparatusMaleic anhydrideAnodic oxidation

The invention discloses a liquid photo-imageable alkali developable and anodizing resistant ink and a preparation method of the liquid photo-imageable alkali developable and anodizing preventive ink. The liquid photo-imageable alkali developable and anodizing resistant ink comprises the following components in parts by weight: 30 to 50 parts of photosensitive resin, 5 to 15 parts of epoxy acrylic resin, 10 to 20 parts of reactive diluent, 5 to 15 parts of solvent, 1 to 10 parts of photoinitiator, 1 to 3 parts of assistant, 20 to 40 parts of filler, and 0.5 to 0.8 part of pigment; the alkali soluble photosensitive resin is manufactured from the following raw materials in parts by weight: 35 to 50 parts of epoxy resin, 20 to 40 parts of DBE (Dibasic Ester), 15 to 20 parts of crylic acid, 8 to 15 parts of maleic anhydride, 0.5 to 1 part of hydroquinone, and 0.5 to 1 part of tetraethylammonium bromide. The liquid photo-imageable alkali developable and anodizing resistant ink is high in sand blasting resistance, strong alkali resistance, strong acid resistance, anodizing resistance and resolution ratio and image resolution, has no corrosion to the surface of IXEF (Aramids) substrate and remains the colour of the surface, and can be quickly and completely stripped from a composite substrate.

Owner:VITAYON FINE CHEM SCI & TECH CO LTD SHENZHEN

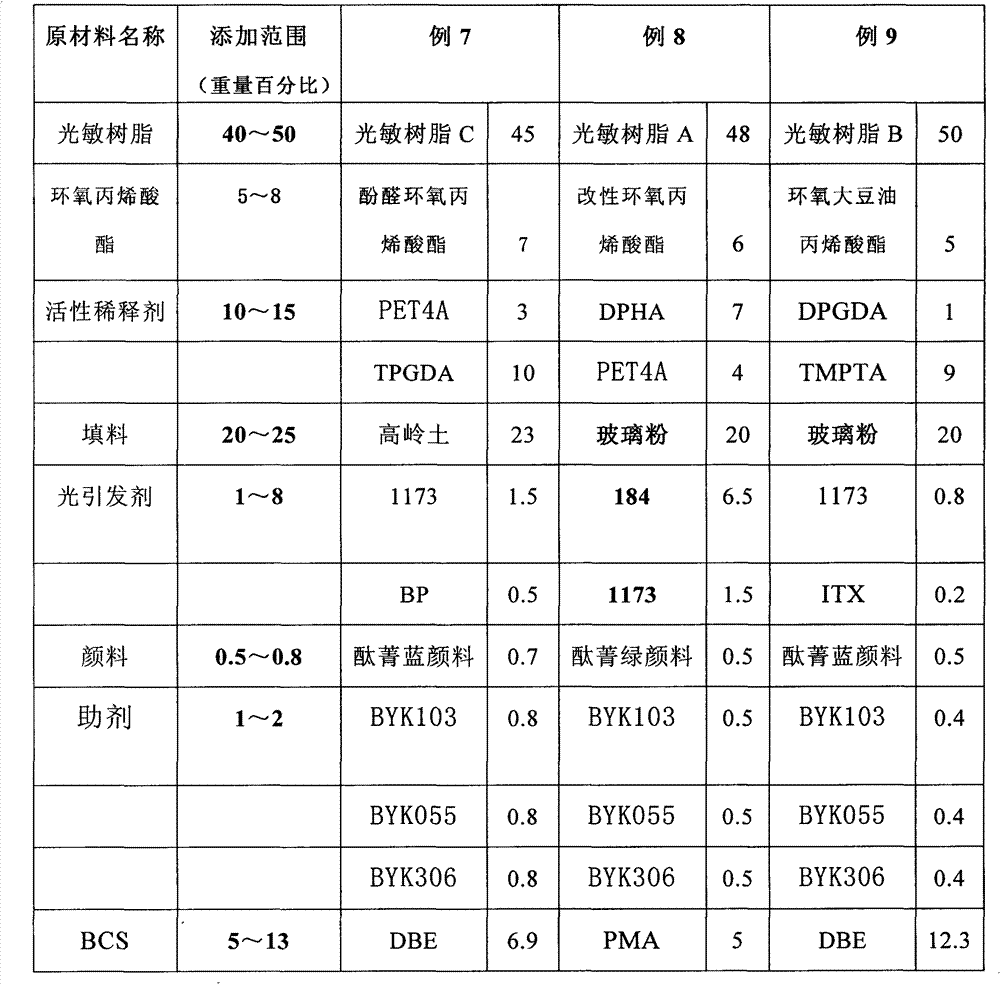

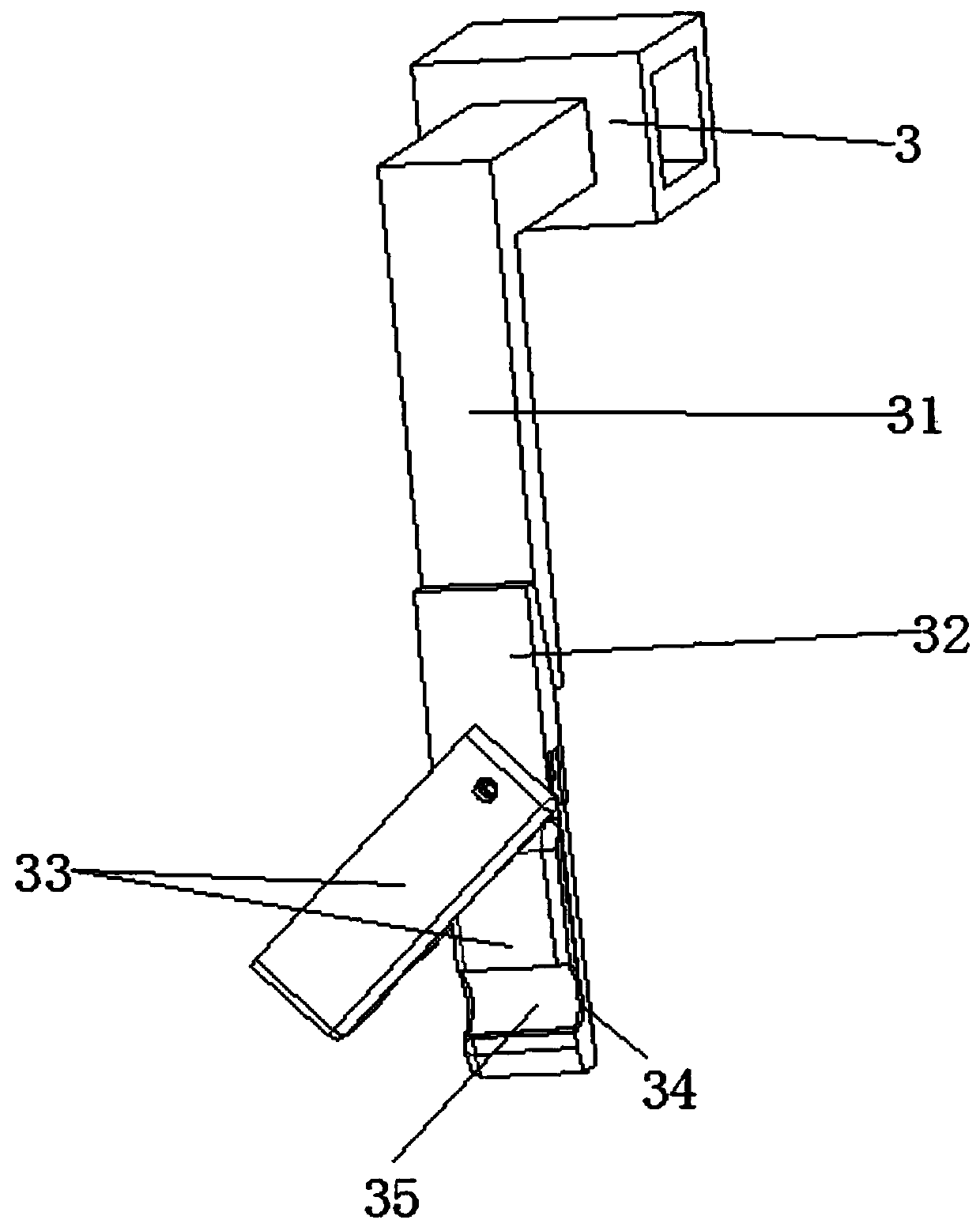

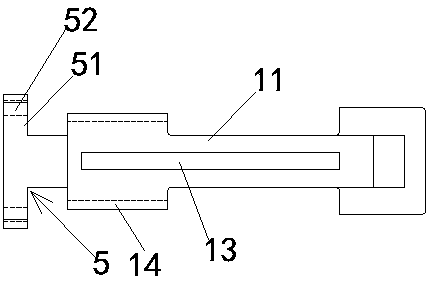

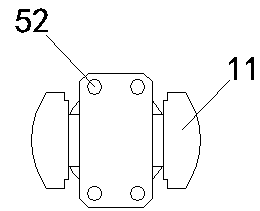

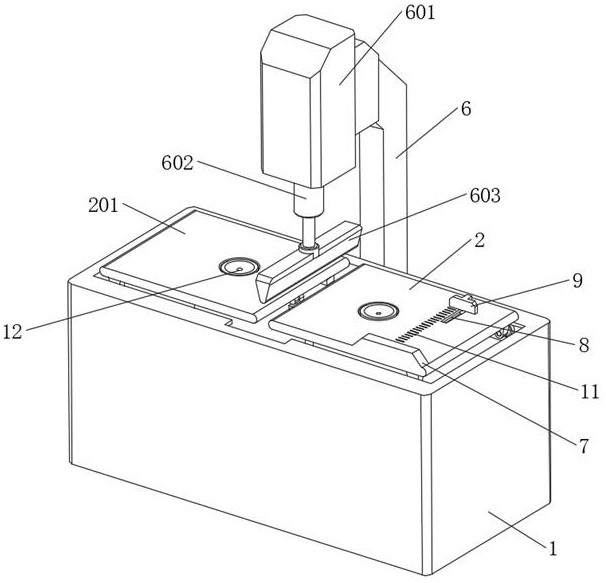

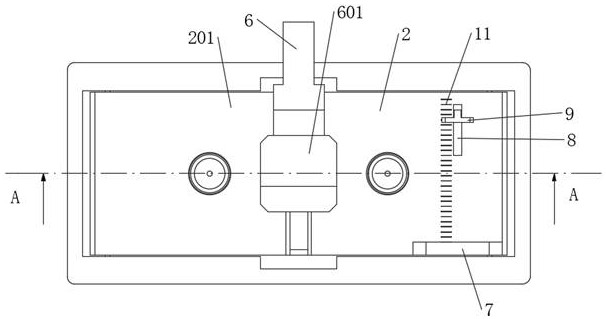

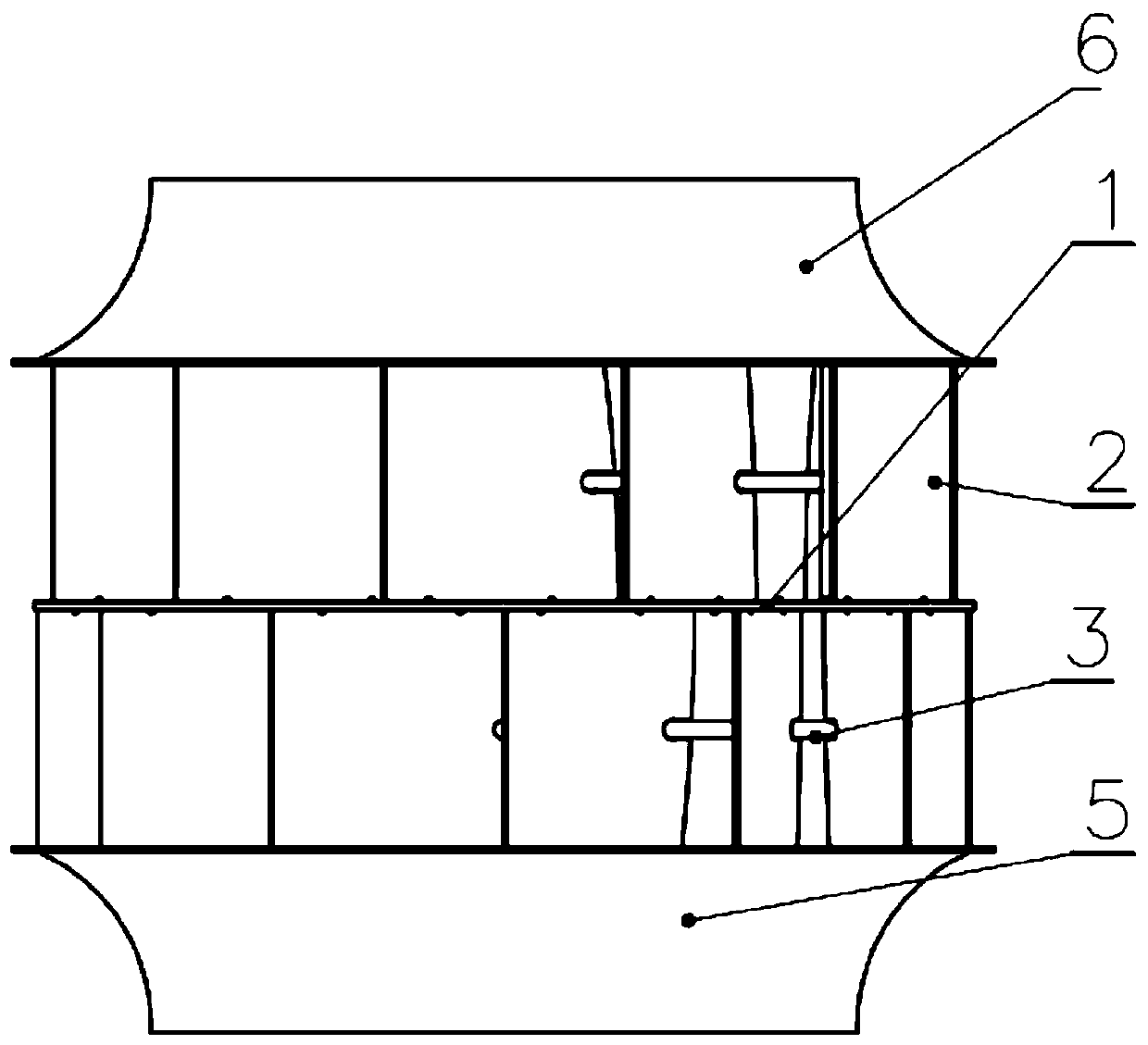

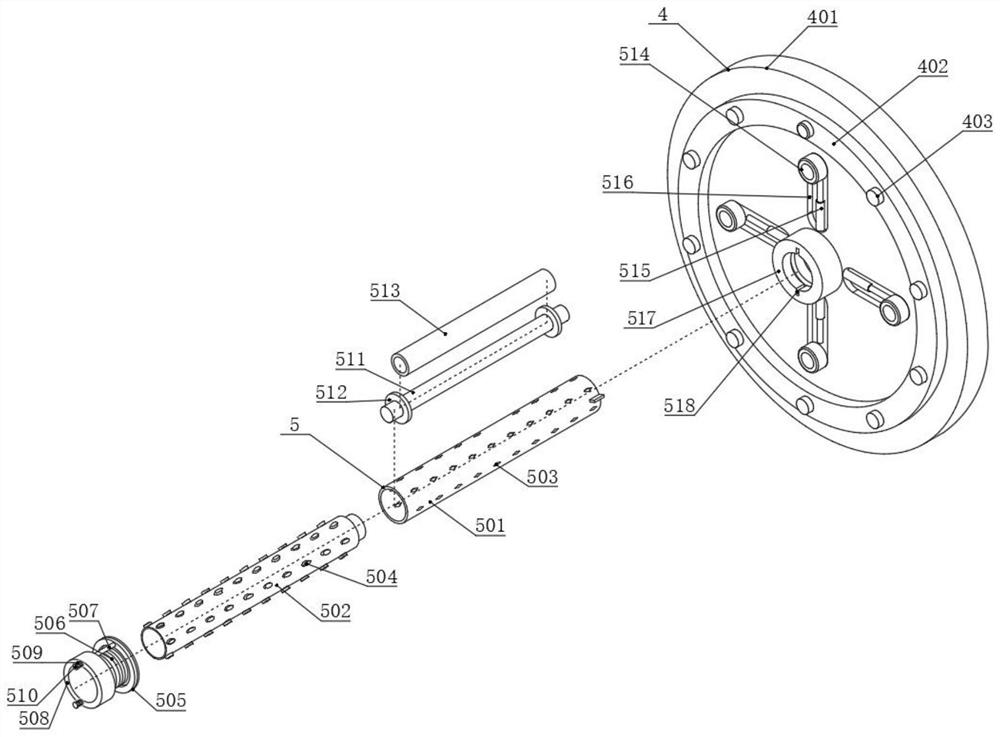

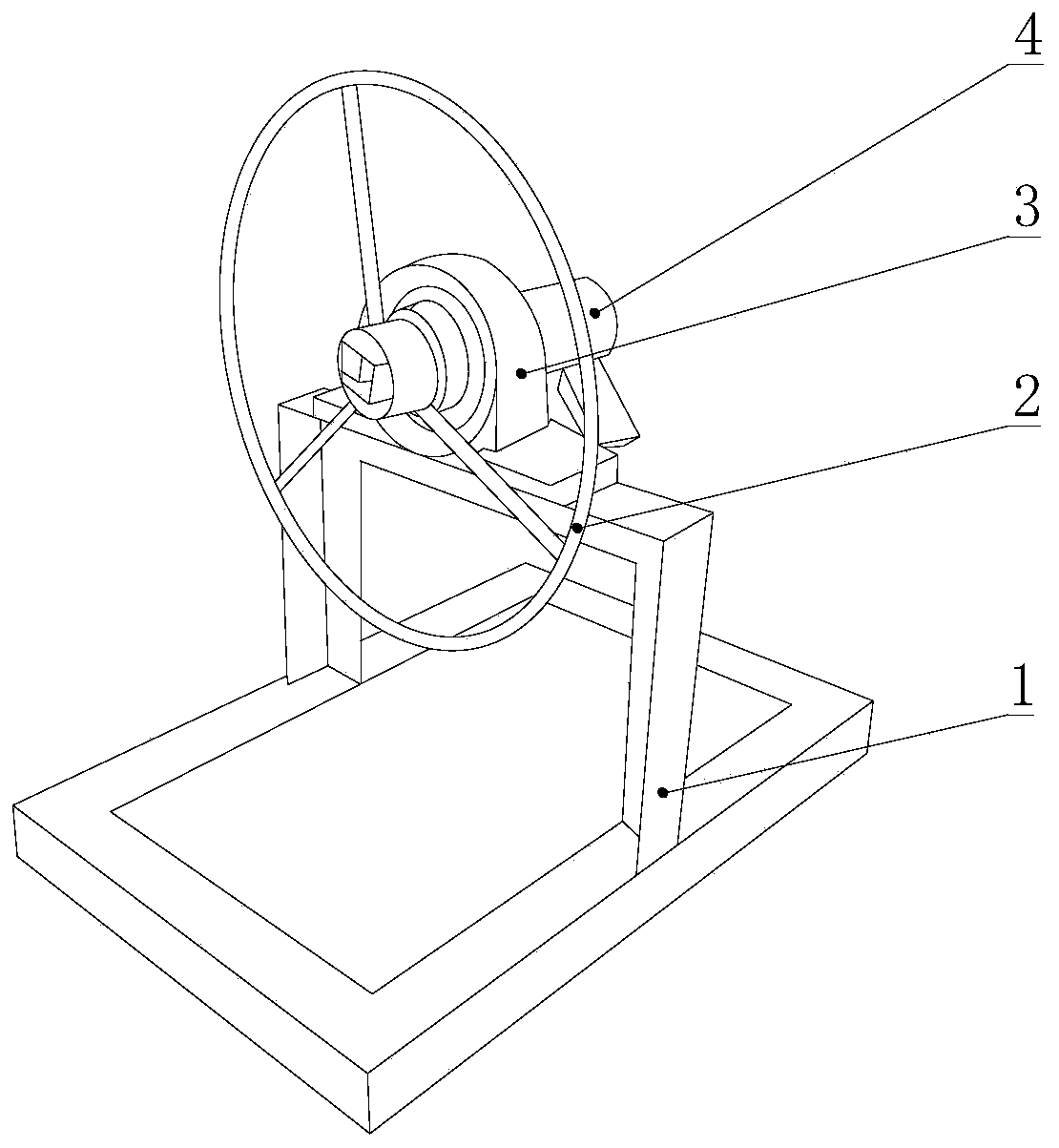

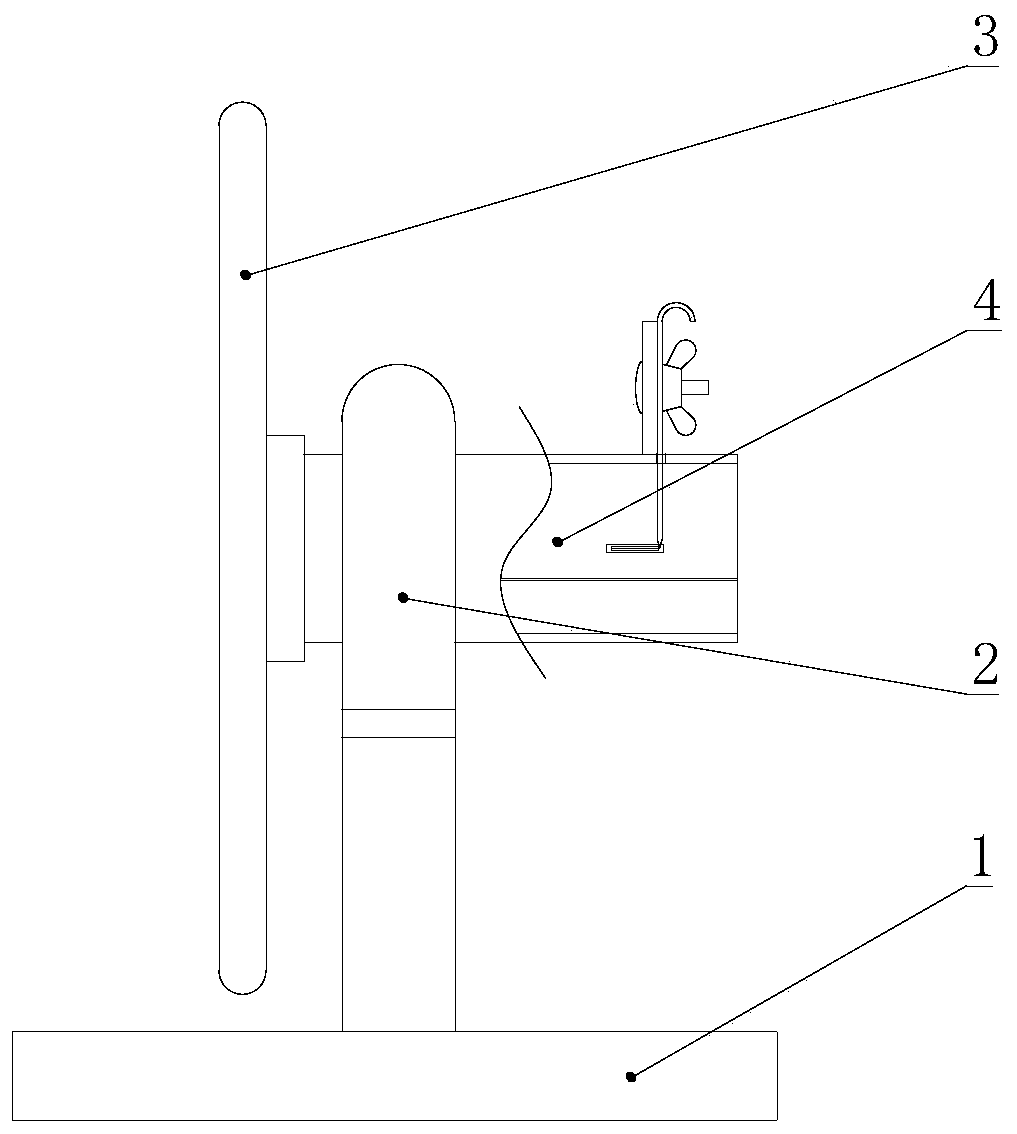

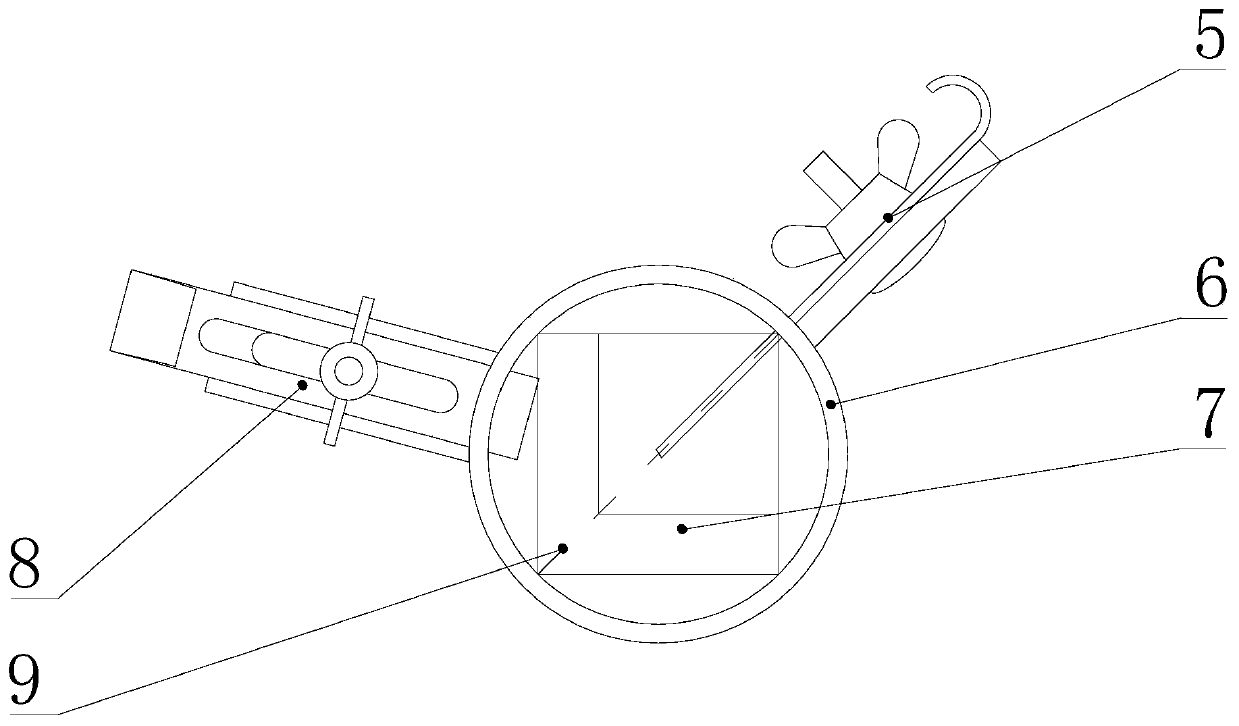

Cable stripping device and stripping method

ActiveCN107248713AImprove peeling efficiencyImprove versatilityApparatus for removing/armouring cablesEngineeringMechanical engineering

The invention discloses a cable stripping device and a stripping method. The cable stripping device comprises a base, a support seat, a rotary table and a cable stripper, wherein the support seat is fixed at the top of the base, the support seat is provided with the cable stripper that is perpendicular to the support seat and can rotate, a cable support is arranged inside the cable stripper, the rotary table is fixed at one end outside the cable stripper, and a transverse cutting knife and a longitudinal cutting knife that are perpendicular to each other are arranged at the other end at a certain deflection angle. Both the transverse cutting knife and the longitudinal cutting knife are arranged on the cable stripper, so that the outer skin of the cable is cut circularly and longitudinally so as to be removed, the cable core is not damaged, and the working efficiency is improved.

Owner:LINQU POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO +2

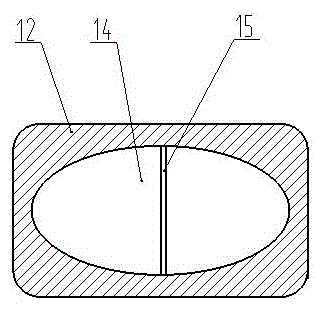

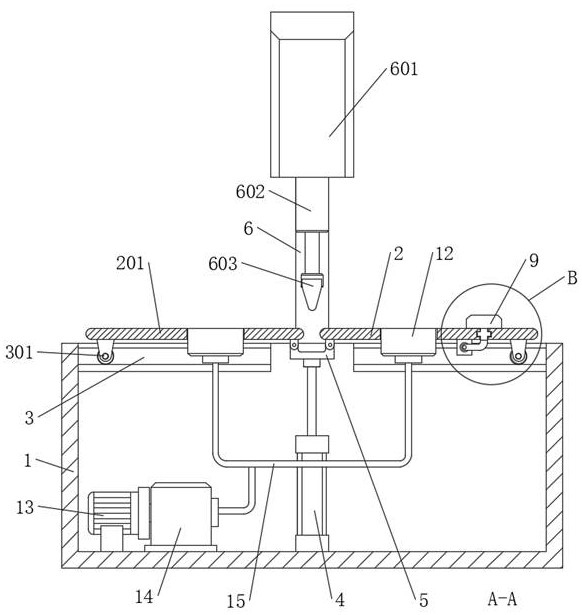

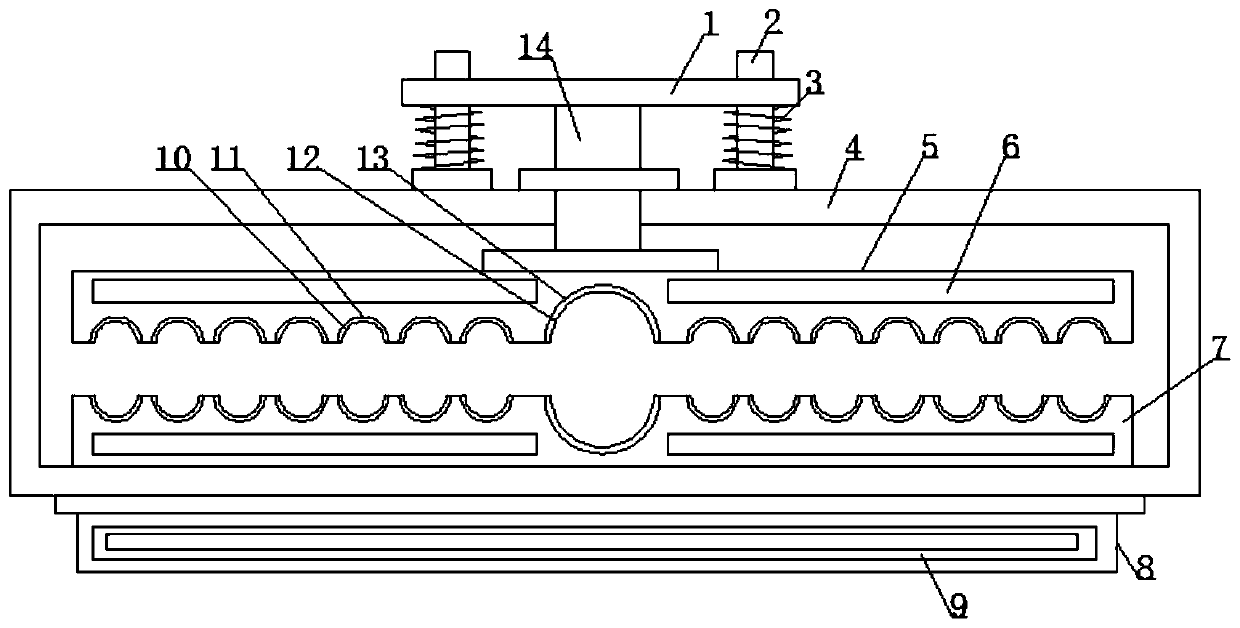

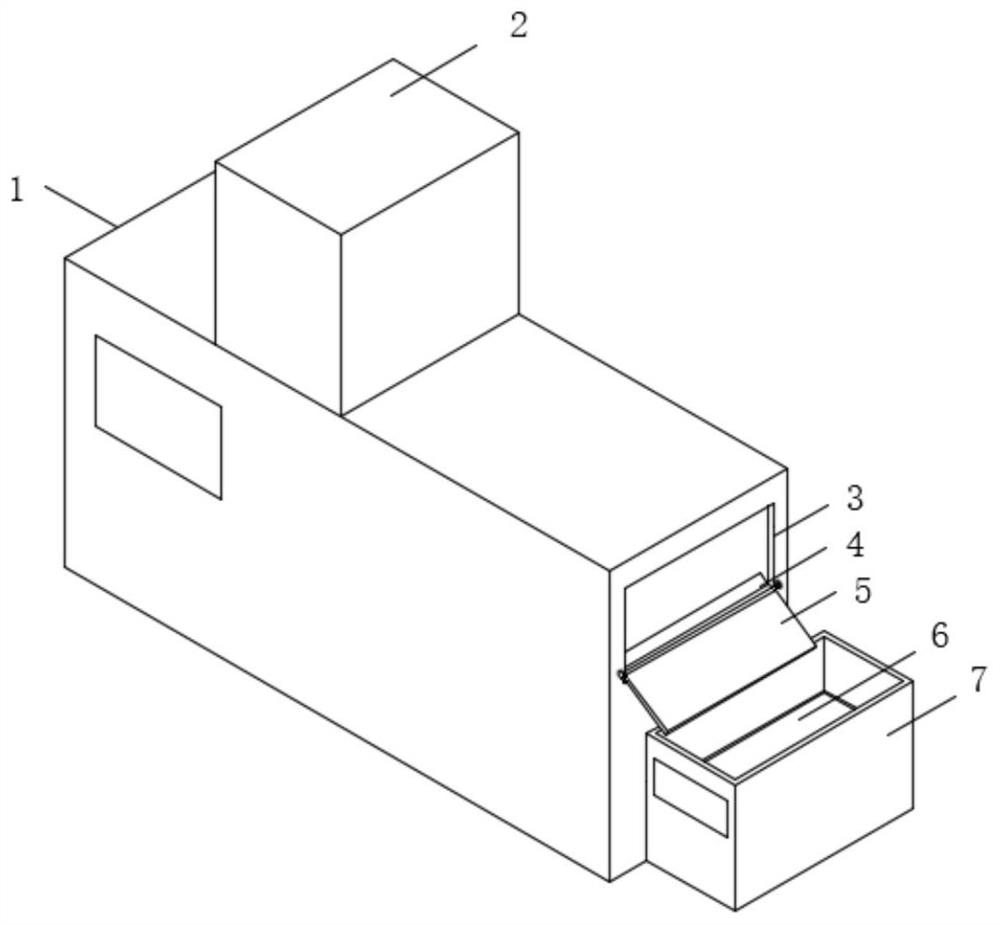

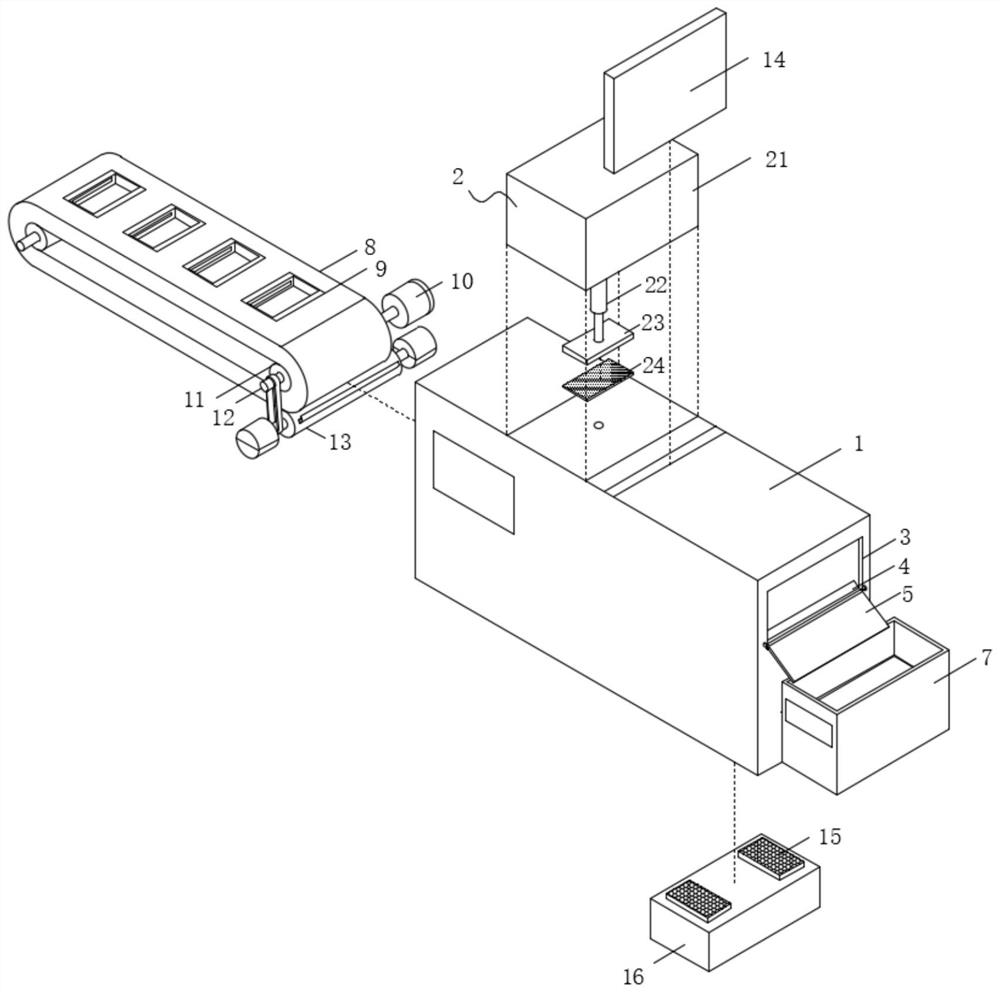

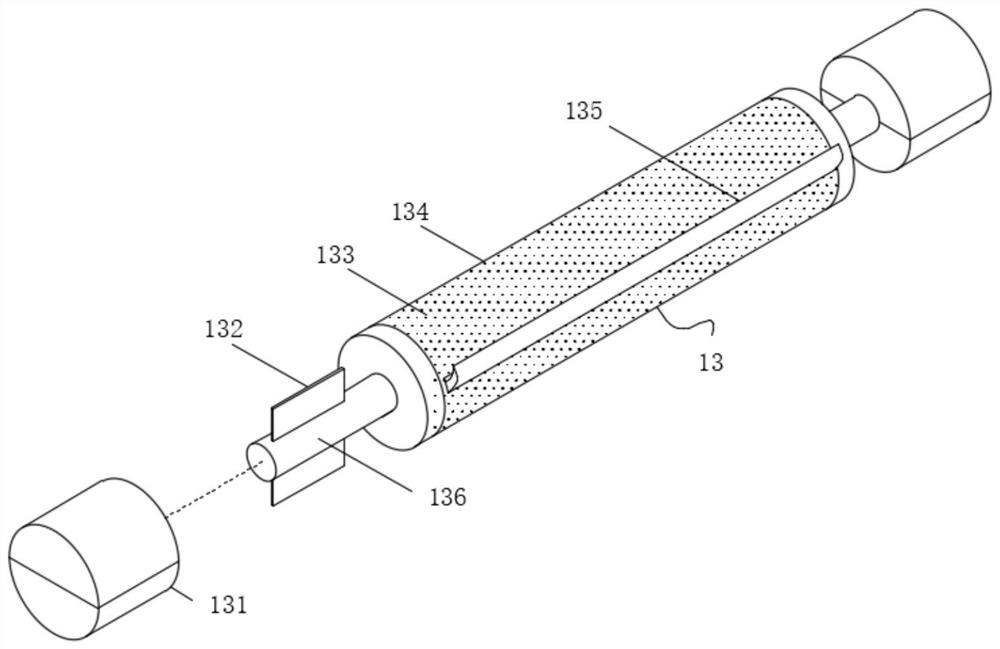

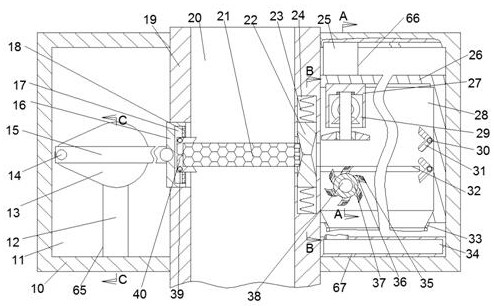

Automatic cable peeling system apparatus equipped with cable sheath recovery box

InactiveCN104967062AEasy to separateReduce toughnessApparatus for removing/armouring cablesEngineeringToughness

The invention discloses an automatic cable peeling system apparatus equipped with a cable sheath recovery box. The apparatus includes a box body, a cable inlet roller assembly, a cable outlet roller assembly and a cable-peeling cutter assembly. The cable inlet roller assembly is arranged in an inlet of the box body. The cable outlet roller assembly is arranged in an outlet of the box body. The cable-peeling cutter assembly is arranged between the cable inlet roller assembly and the cable outlet roller assembly. The cable inlet roller assembly includes an upper cable inlet roller and a lower cable inlet roller, and heating devices are arranged in the upper cable inlet roller and the lower cable inlet roller. A cable sheath separating device is arranged behind the cable-peeling cutter assembly. A cable sheath recovery box is arranged in the box body below the separating device. Heating devices, arranged in a cable inlet roller assembly of a cable peeling machine, heat cable sheaths before cables are peeled, the cable sheaths are usually rubber materials and become softened and expand after being heated, and the softened cable sheaths are greatly reduced in toughness so as to be convenient to peel by a peeling cutter. Moreover, after the cable sheaths are peeled, the cable sheaths can be easily separated from a cable core, so the cable peeling efficiency is improved.

Owner:成都新三电线厂

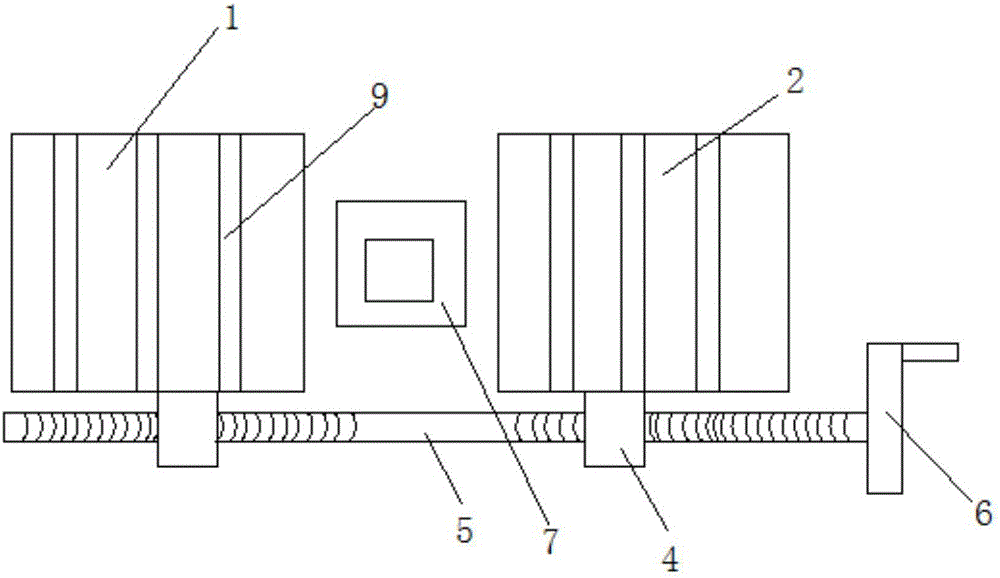

Cold welding machine for cable production

ActiveCN110911930APrevent leakageEnsure production safetySoldered/welded connectionsDomestic articlesPhysicsEngineering

The invention discloses a cold welding machine for cable production, and relates to the field of cable cold welding, which comprises a wire stripping mechanism, a butt joint mechanism and a welding mechanism, the wire stripping mechanism comprises a first sliding rail, a second sliding rail, a first air cylinder, a second air cylinder, a first mechanical claw, a second mechanical claw, a first groove, a second groove, a first heating sheet and a second heating sheet; the first mechanical claw and the second mechanical claw are used for clamping; the butt joint mechanism comprises a first buttjoint sliding rail, a second butt joint sliding rail, a first butt joint rod, a second butt joint rod, a first butt joint air cylinder, a second butt joint air cylinder, a first butt joint mechanicalclaw, a second butt joint mechanical claw, a first butt joint groove and a second butt joint groove, wherein the first butt joint mechanical claw and the second butt joint mechanical claw are used forclamping. The welding mechanism comprises a cold welding machine body used for welding and a cold welding table capable of sliding on the top face of the rack, and a welding groove is formed in the top face of the cold welding table and used for conveying welding cables. The cold welding machine has the functions of wire stripping, welding and welding protection, and also has the characteristicsof environmental protection in production and improvement of production efficiency.

Owner:CHENGDU DATANG CABLE

Portable quick wire stripper

ActiveCN110137864AThe circumcision process is stableQuick strippingApparatus for removing/armouring cablesEngineeringMechanical engineering

The invention discloses a portable quick wire stripper which comprises a fixed box, an inner side wall of the fixed box is connected with a cutting device, the cutting device comprises an annular tooth ring and two electric telescopic rods, the annular tooth ring is rotatingly connected to an inner side wall of the fixed box, and one end of each of the electric telescopic rods is fixedly connectedto an inner side wall of the annular tooth ring. A cable is transmitted through two rollers, and the two rollers also have the effect of clamping the cable. The cable is stable in the process of ringcutting, the cable is driven to move by the rollers, then the outer layer of the cable is divided into two by the action of a dividing blade and a turning blade, the outer layer of the cable is completely stripped from a wire core under the action of a guiding plate, a quick stripping effect is achieved, and the device is easy to carry and convenient to use.

Owner:苏州乐赢科技咨询有限公司

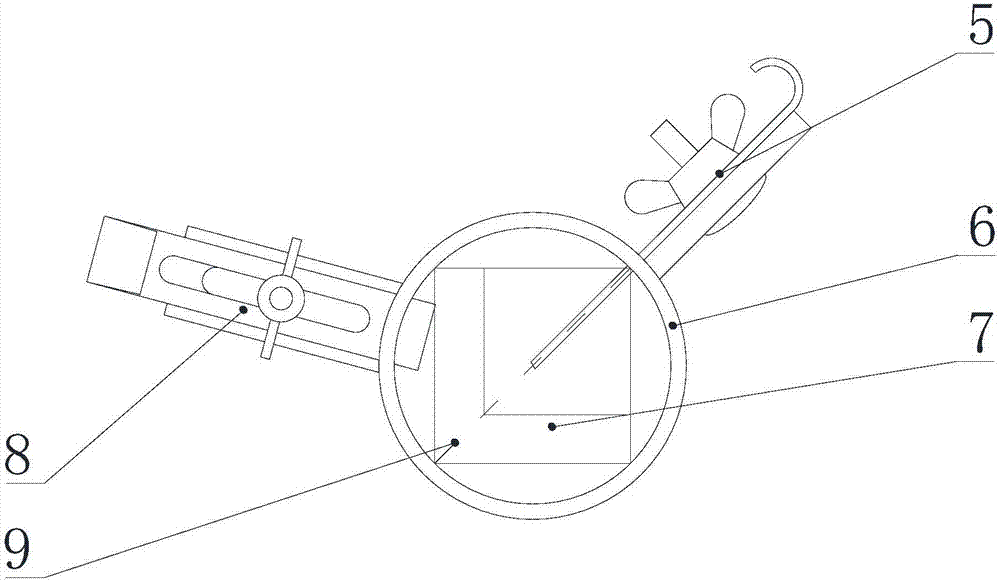

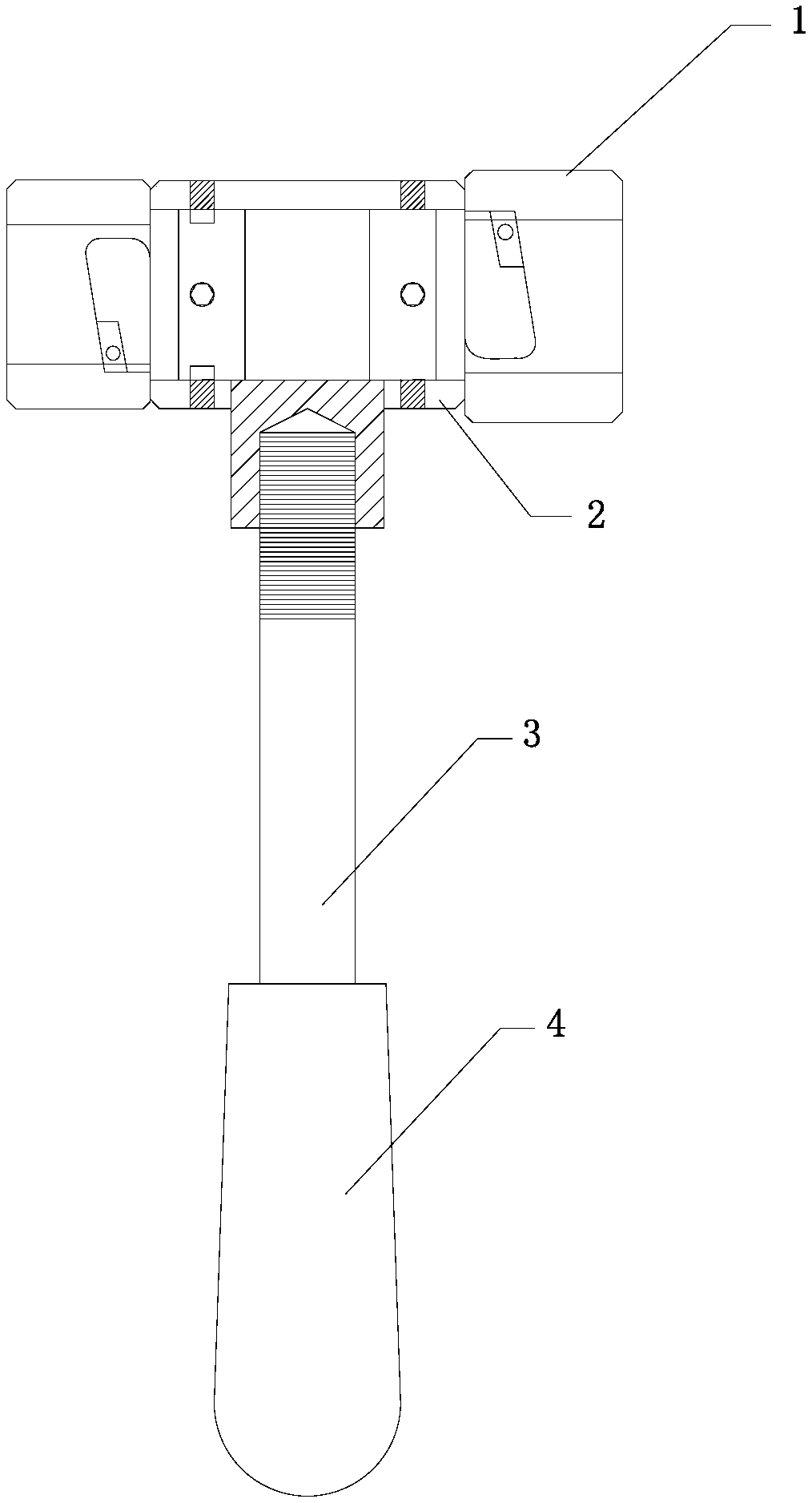

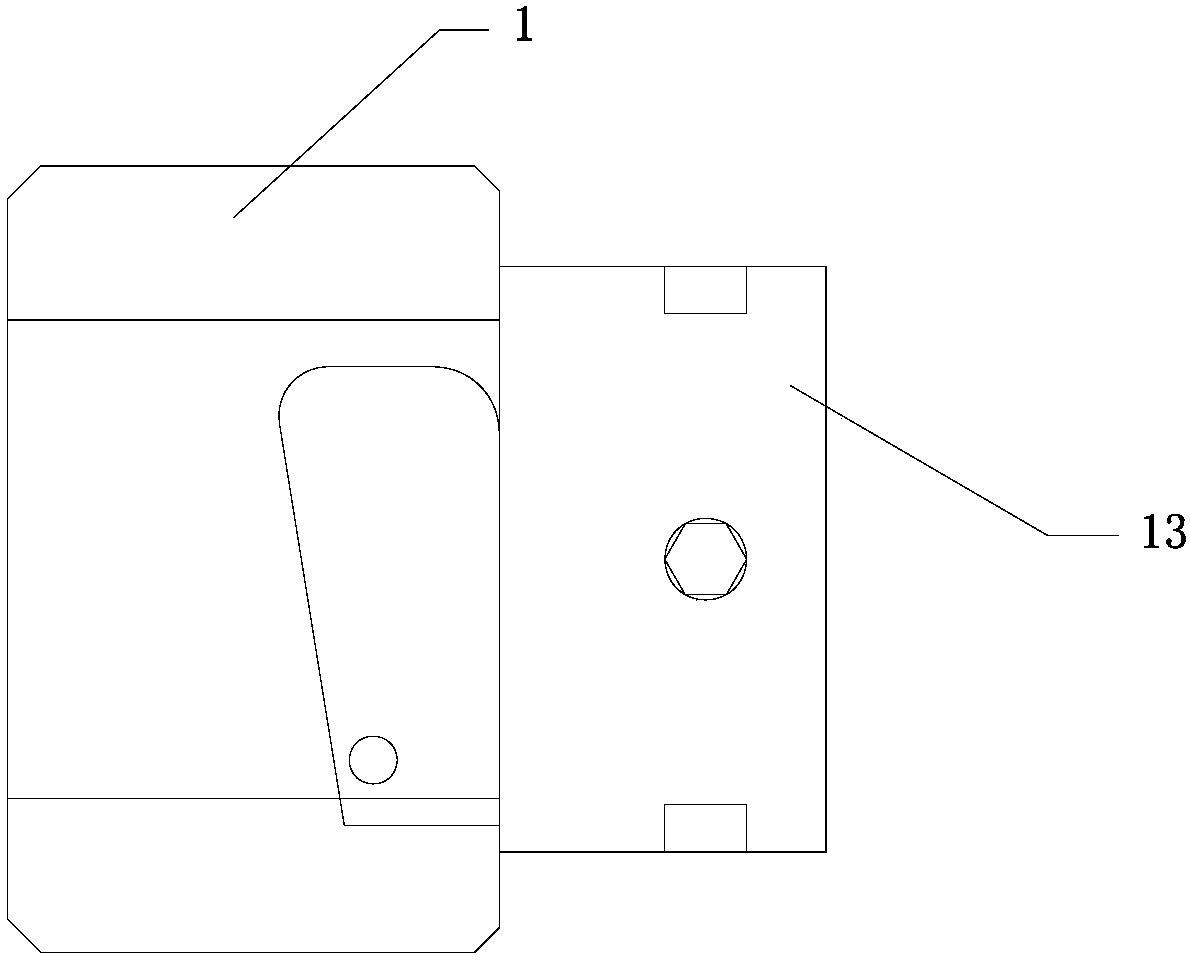

Hydraulic pressure stripper for steel-core aluminum stranded conductor

PendingCN108631221AStripped to achieveQuick strippingApparatus for removing/armouring cablesStrip steelEngineering

The invention relates to a hydraulic pressure stripper for a steel-core aluminum stranded conductor. The stripper includes a knife rest, a stationary knife, a movable knife and a hydraulic pressure drive device. The knife rest is provided with a cavity serving as a lead receiving cavity. The stationary knife is fixed on one side of the lead receiving cavity. The movable knife is movably arranged on the other side of the lead receiving cavity. The rear end of the movable knife is connected with the hydraulic pressure drive device used for driving the movable knife to move along the knife rest towards the stationary knife. The blade face of the stationary knife is provided with a semicircular first escape hole and the blade face of the movable knife is provided with a semicircular second escape hole. The radius of the first escape hole and the radius of the second escape hole are slightly greater than that of a steel core of the to-be-stripped steel-core aluminum stranded conductor. Thestripper provided by the invention is simple in structure, small in size and convenient to carry. The stripper can be used in combination with a field pump station for working so as to realize quick stripping of steel-core aluminum stranded conductors. The working efficiency is improved.

Owner:陕西送变电工程有限公司 +1

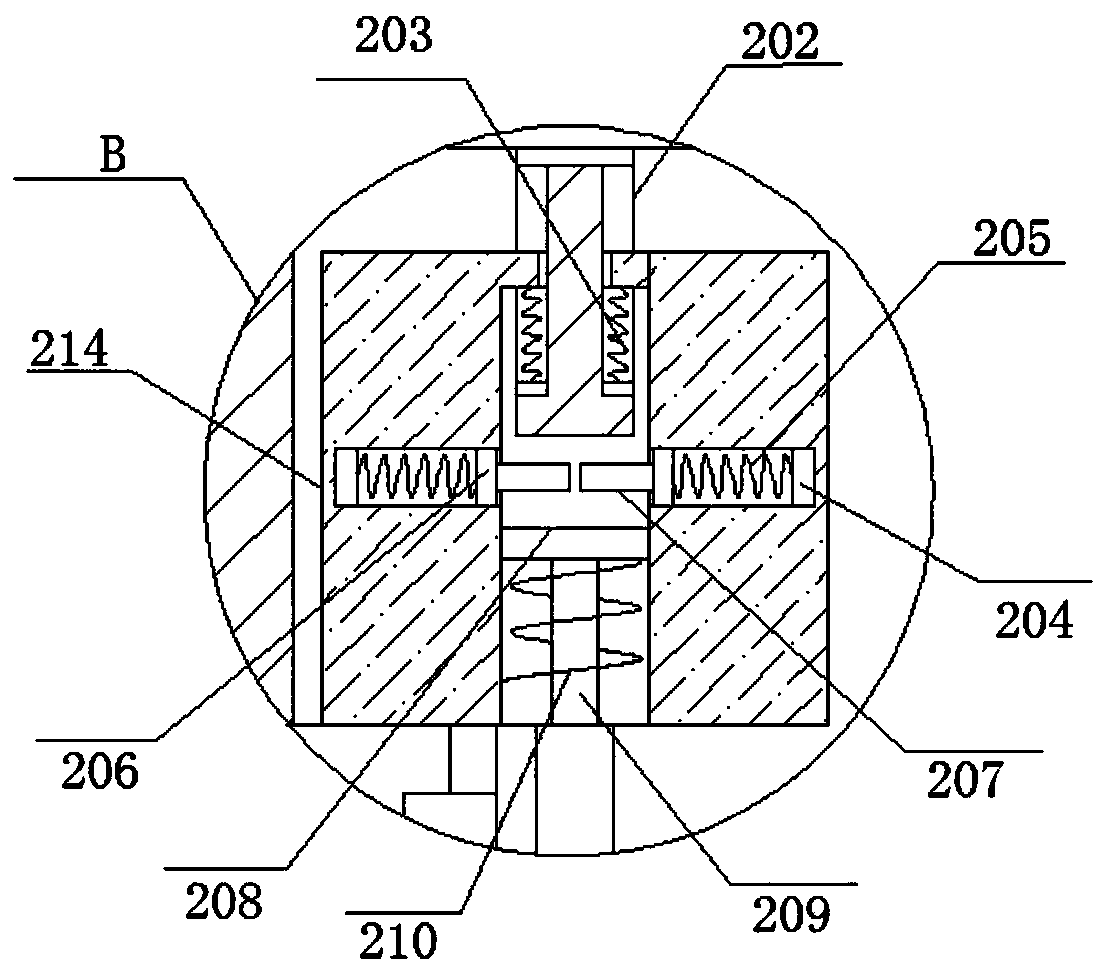

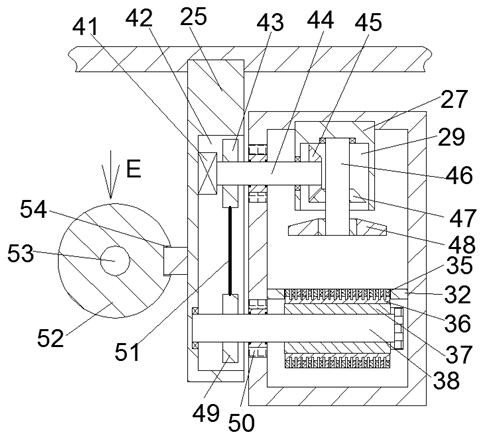

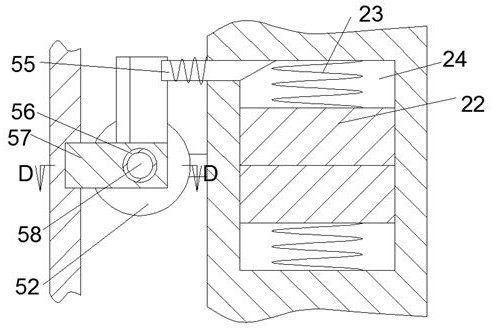

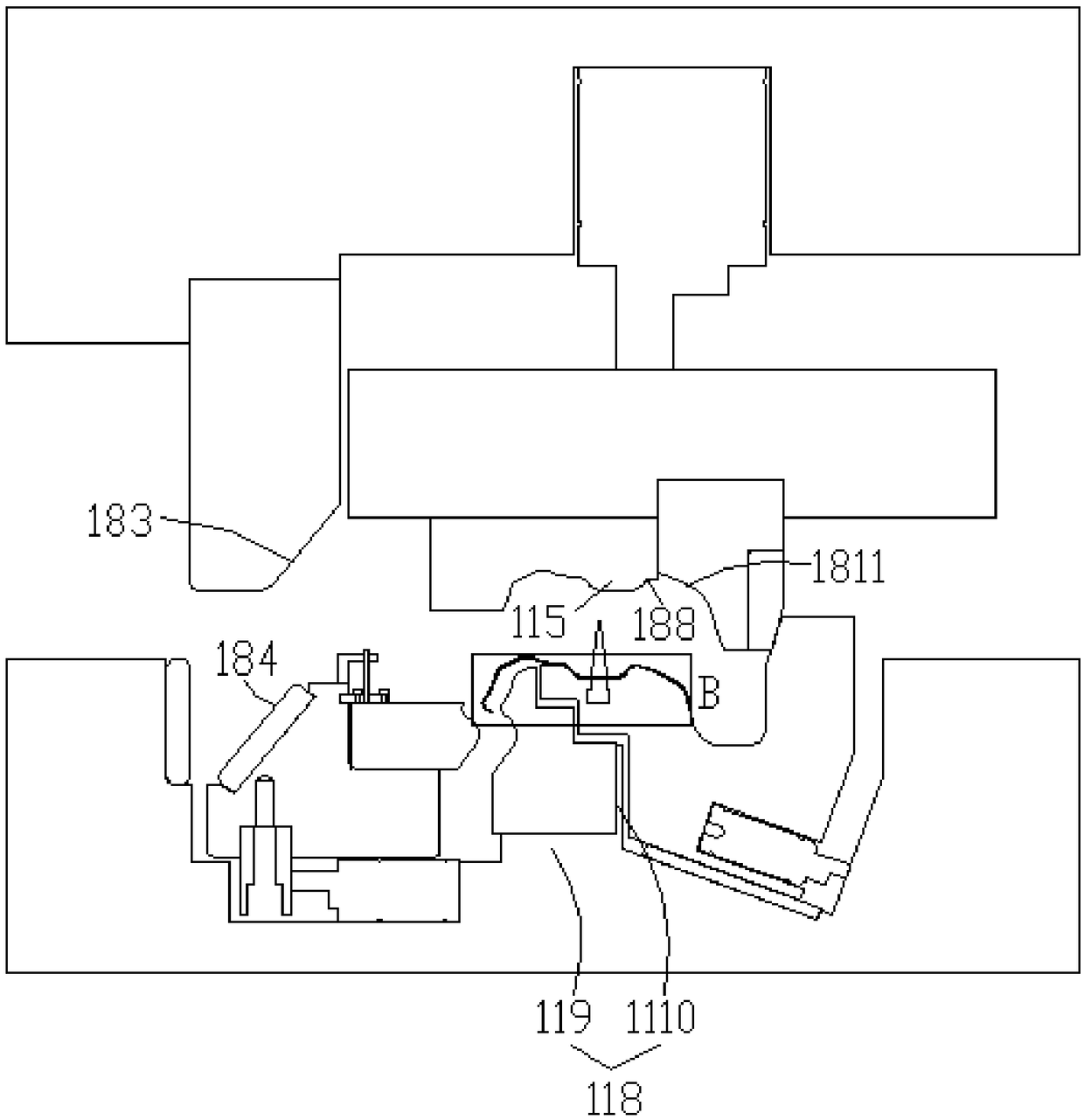

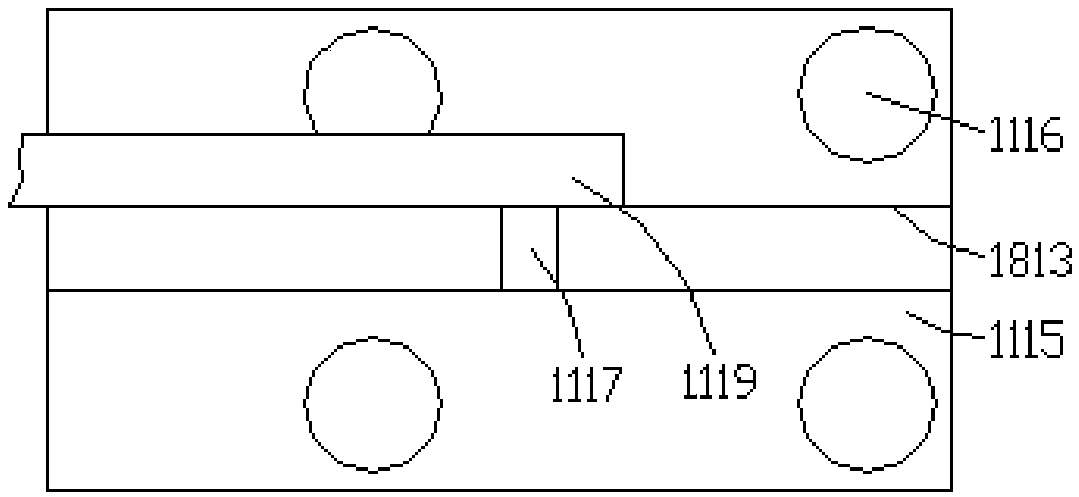

An automatic device for sleeving O-shaped ring

The invention relates to an automatic device for sleeving an O-shaped ring. The device comprises a fixed main body, a shell, a O-shaped ring sleeving mechanism and a driving mechanism; the O-shaped ring sleeving mechanism comprise a material stripping sleeve, an elastic returning part, a moving rod, a plurality of material taking claws which are positioned in the material stripping sleeve and arein linkage fit with the moving rod and a material stripping rod which corresponds to the position above the material stripping sleeve and is in linkage with the moving rod; and a through hole allowingone ends of the plurality of material taking claws to penetrate through is formed in the material stripping sleeve, the plurality of material taking claws are distributed in an annular array and aremovably arranged on the moving rod, returning components are arranged between the moving rod and the plurality of material taking claws, one ends of the plurality of material taking claws act along with the moving rod and can penetrate through the through hole of the material stripping sleeve and are mutually supported to be opened, and the material stripping rod moves along with the moving rod and can be used for driving one end of the material stripping sleeve to extend out of the shell. The device has the advantages of being simple in structure, stable and reliable in performance, high in efficiency and capable of saving manpower.

Owner:ZHEJIANG BLCH PNEUMATIC SCI & TECH

Machining table for bending plate metal and bending method thereof

PendingCN114515773AQuick fixAvoid bending errorsMetal-working feeding devicesPositioning devicesClassical mechanicsEngineering

The invention discloses a plate metal bending machining table and a bending method thereof, and relates to the field of bending machine equipment.The plate metal bending machining table comprises a machine case, and a first material bearing template and a second material bearing template which are in bilateral symmetry are arranged at an upper end opening of the machine case. The telescopic rod is recovered by matching the template offset hydraulic drive with the advancing speed of the bending ejection head, so that the inner ends of the first material bearing template and the second material bearing template are pulled down; the rollers are arranged at the outer ends of the first material bearing template and the second material bearing template and are in rolling connection with the roller track; therefore, the first material bearing template and the second material bearing template are also inclined along with bending of the metal plate, the first material bearing template and the second material bearing template are always attached to the metal plate in the bending process, the metal plate does not slide relative to the first material bearing template and the second material bearing template, and the surface of the metal plate is prevented from being scratched.

Owner:谭小兵

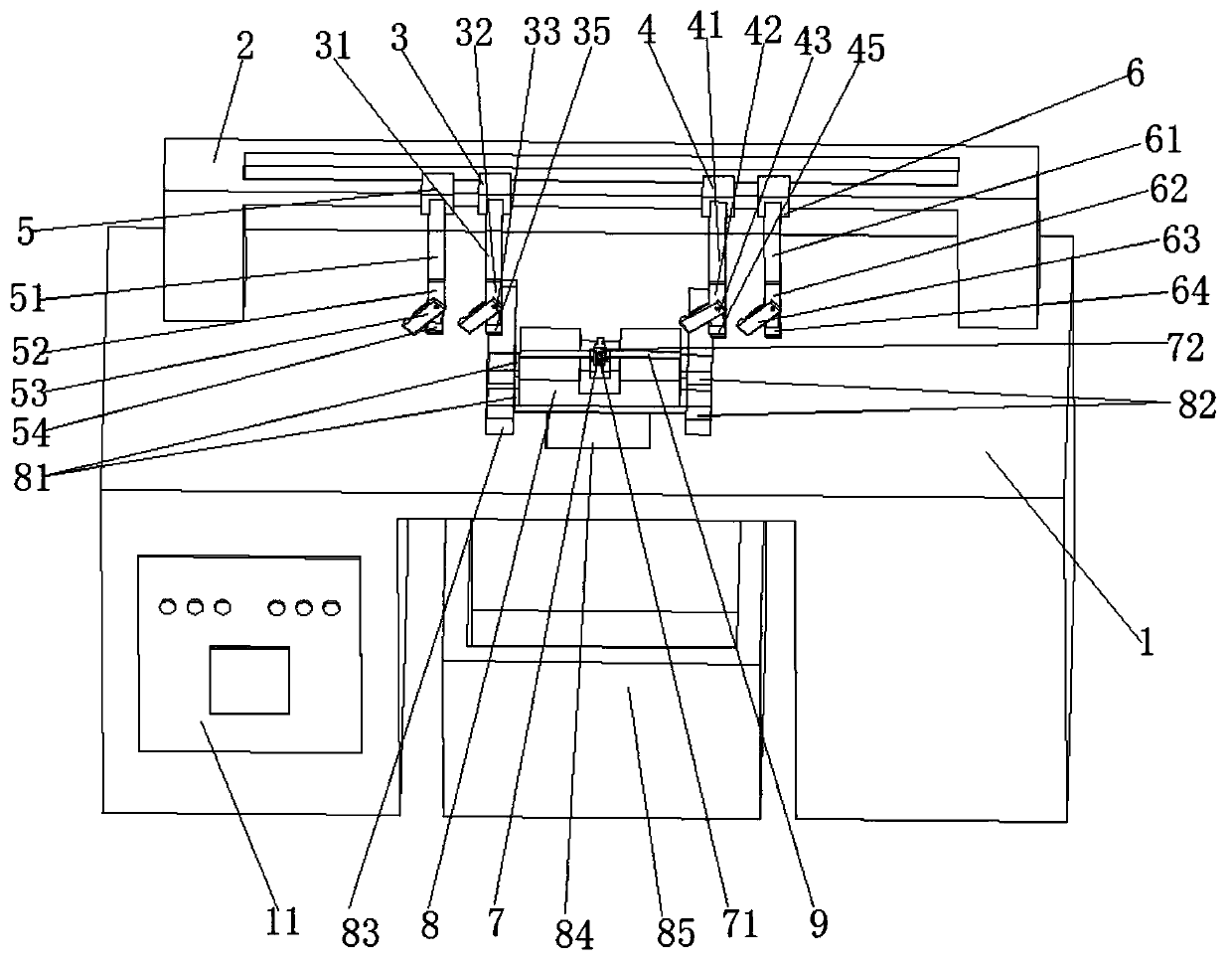

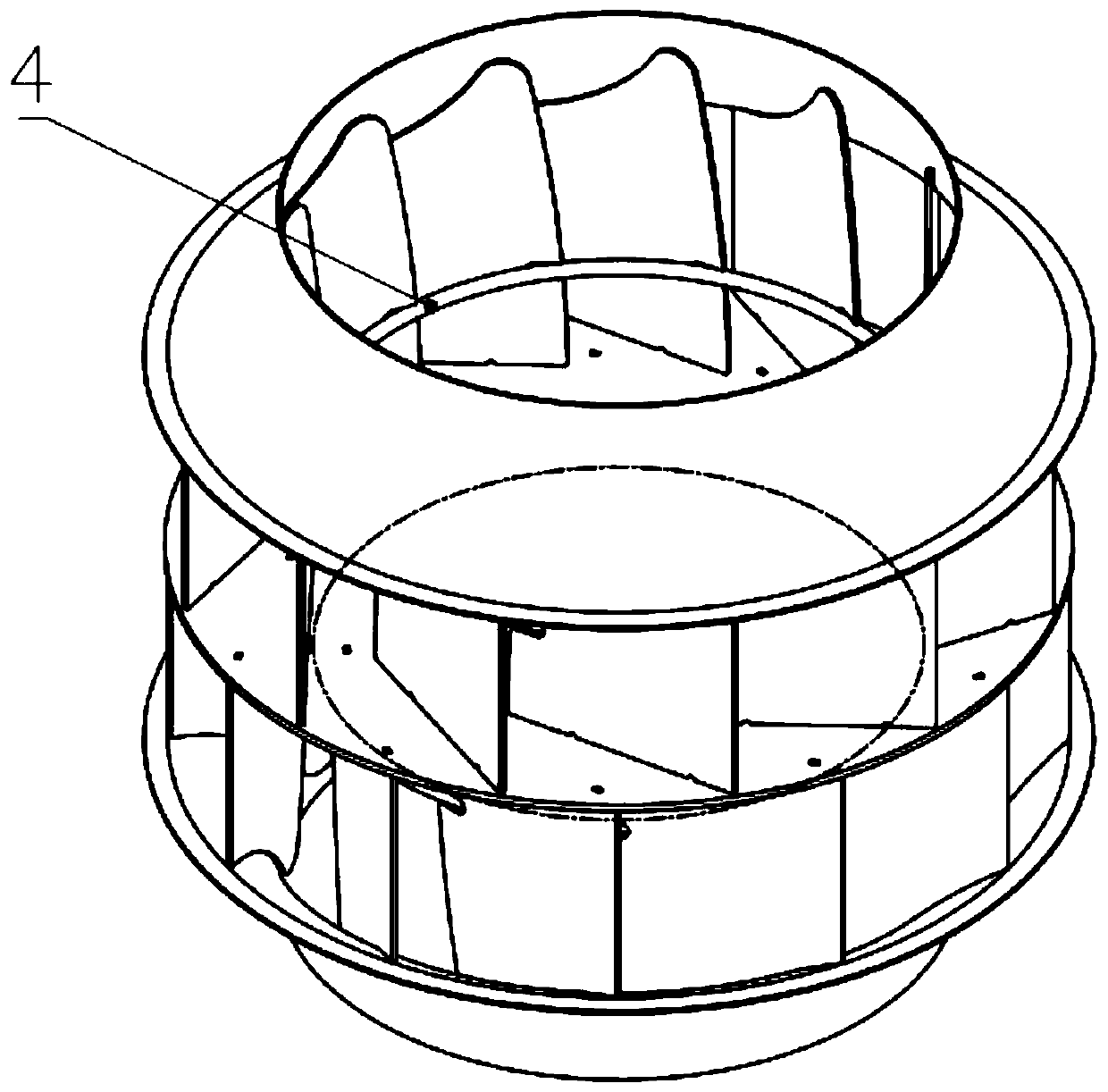

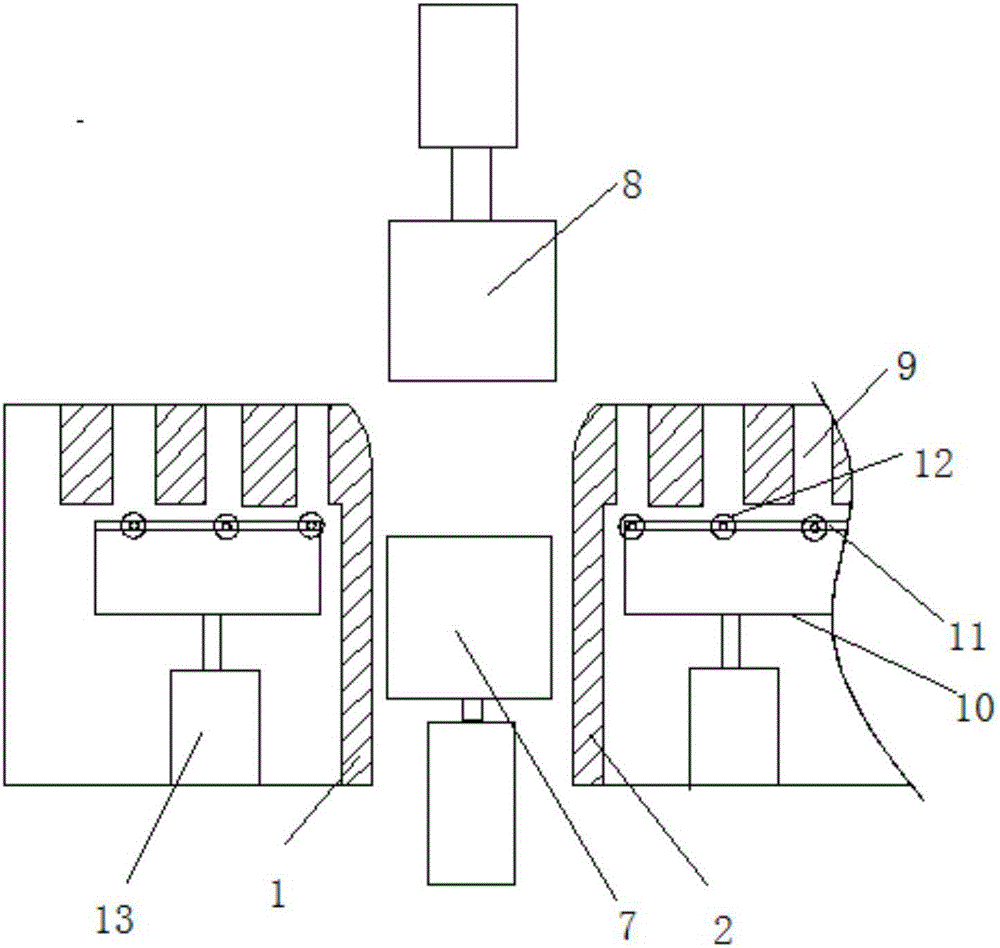

Carbon steel impeller assembling and welding device, and method

PendingCN111015065ASimple and fast operationPrecise positioningWelding/cutting auxillary devicesAuxillary welding devicesImpellerStructural engineering

The invention discloses a carbon steel impeller assembling and welding device, and a method. The carbon steel impeller assembling and welding device comprises a main body forward assembling device, acentral shaft, a central supporting ring, a compression plate, a conical plate centering component, an impeller directional group forward assembling device, a main body reverse assembling device and an impeller directional group reverse assembling device, wherein the main body forward assembling device comprises a bottom plate, a tray, a supporting plate, lower stand columns and a cushion block; the bottom plate and the supporting plate are connected through a plurality of lower stand columns subjected to array distribution; the tray is arranged between the bottom plate and the supporting plate; the lower end surface of the tray is provided with the cushion block; the central shaft comprises a central supporting device, a positioning plate, a rhombic pin, a threaded rod and a connecting shaft; and the upper end of the central supporting device is provided with a positioning plate. The carbon steel impeller assembling and welding device is convenient in operation and is quick and accurate in positioning, positioning accuracy is guaranteed through machine tool machining, 12 groups of blades are separated in one time through a forward rotation blade reference side positioning group and a reverse rotation blade compaction group for positioning, stripping is quick, and production efficiency is improved.

Owner:YANTAI WALU ROBOT AUTOMATION CO LTD

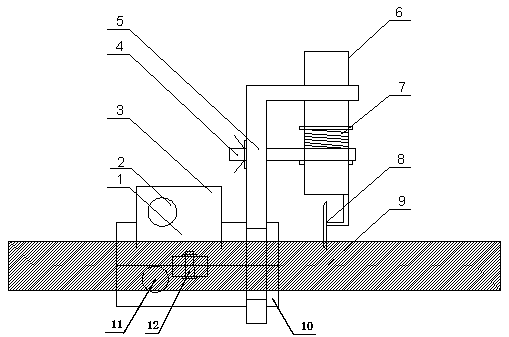

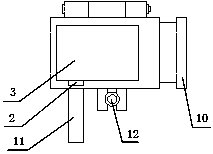

Electric wire breaking device for carbon-fiber composite-core wire

InactiveCN107732757AAchieve clampingAchieve circumferential strippingApparatus for cutting/splicing cablesApparatus for removing/armouring cablesWire cuttingEngineering

The invention relates to an electric wire breaking device for a carbon-fiber composite-core wire so that problems of poor cutting effect, low work efficiency and high labor consumption can be solved.The electric wire breaking device comprises a wire clamping device, a rotating fixed bracket, a cutting feed adjusting device and an electric saw. The rotating fixed bracket and the wire clamping device are connected; and the cutting feed adjusting device and the electric saw are connected with the rotating fixed bracket respectively. The electric wire breaking device has the following beneficialeffects: the cutting performance is good; the application range is wide; wire stripping and wire cutting are realized at a high speed; and the manpower is saved.

Owner:郑州永锡电力科技有限公司

Power cable stripping device

PendingCN110932191AReasonable designEasy to carryApparatus for removing/armouring cablesPower cableElectric cables

The invention belongs to the technical field of electric power, and particularly relates to a power cable stripping device. When the power cable stripping device is used, four fingers of a user are clamped through an air bag, a user inserts one end of the cable into the first groove by the other hand; a push plate is pressed by a thumb to push the first clamping plate through the sliding rod; a first cutter is contacted with the surface of the cable sheath; a heating rod is used for heating the cable to soften the cable, thus wire stripping is easier, the user presses the push plate forcibly,the first cutter is used for cutting the sheath of the cable; then the power cable stripping device is rotated or the cable is rotated to realize stripping of cable sheath, wires of the cable inner core are scattered, then the scattered wires are placed in the second groove, the second cutter makes contact with the wires, stripping of the wires of the inner core is achieved through cutting of thewire sheath by the second cutter through the same method, and rapid stripping of the cable can be achieved.

Owner:GUANGDONG POWER GRID CO LTD +1

Non-woven cloth hot-sticking forming equipment and non-woven cloth hot-sticking forming process

The invention discloses a non-woven fabric hot sticking forming device and process in the technical field of hot sticking forming, the non-woven fabric hot sticking forming device comprises a machine shell, an outlet groove is formed in one side of the machine shell, an inner folded plate is arranged in the outlet groove, and a feeding plate is rotatably mounted at the position, close to the outlet groove, of the outer wall of one side of the machine shell through a mounting frame; a storage box is fixedly mounted on the outer wall of one side of the machine shell, a weighing plate is arranged in the storage box, a driving motor is fixedly mounted on the outer wall of one side of the machine shell, and a driving roller is fixedly mounted at one end of an output shaft of the driving motor through a mounting shaft; the inner forming mechanism is arranged inside, materials which do not fall off in time due to hot bonding can be effectively and automatically stripped, the design is reasonable and ingenious, the materials are subjected to effective falling treatment after hot bonding forming, the function is powerful, the problem that the materials adhere to a plate face after hot bonding is effectively solved, and the service life of the materials is prolonged. And stable proceeding of subsequent work is ensured.

Owner:TAIZHOU GAOXIN NONWOVENS CO LTD

Filtering treatment device of textile equipment

InactiveCN111841183AImprove filtration efficiencyQuick strippingGas treatmentDispersed particle filtrationYarnEngineering

The invention discloses a filtering treatment device of textile equipment. The device comprises a mounting box; a mounting cavity is formed in the mounting box; a pushing mechanism is arranged in themounting cavity; the pushing mechanism comprises an exhaust pipe which is fixedly mounted on the lower end surface of the mounting box and is connected to the outside of the mounting box; an exhaust cavity is formed in the exhaust pipe; filter plates internally provided with magnets are slidably mounted on the front end wall and the rear end wall of the exhaust cavity; a pushing block connected into the mounting cavity is slidably mounted in the left end face of the exhaust cavity; and a pushing groove with a rightward opening is formed in the pushing block. The filter plate is pushed out, thefilter plate is blown to enable water vapor on the filter plate to be lost, and meanwhile, the broken yarn is blown out, so that the broken yarn can be stripped more quickly and the filter plate canbe wiped.

Owner:南京溧水高新产业股权投资有限公司

3D printing device for preparing cardiovascular stent and use method

InactiveCN114176856AImprove cross-link supportImprove multi-axis outputStentsAdditive manufacturing apparatus3d printWire rod

The invention discloses a 3D printing device for preparing a cardiovascular stent and a using method, and belongs to the technical field of 3D printing equipment, the 3D printing device comprises a material base, the material base is fixedly mounted on one side of a 3D printer main body, a plurality of storage mechanisms are detachably connected to an inner cavity of the material base, and a vacuumizing mechanism is fixedly mounted at the top of the material base; the vacuumizing mechanism is movably connected with the bottom storage mechanism, and the air curtain mechanism is fixedly installed on one side of the storage mechanism. By means of the designed storage mechanism, vacuum storage of consumables in a wire disc is achieved through vacuumizing treatment on a vacuum cover, the influence of external water vapor on the consumables during storage is reduced, the storage requirement of the self-water-absorption consumables is met, meanwhile, a heating jacket is arranged on the front portion of the mixing mechanism in advance, the pretreatment length of the consumables after discharging is reduced, and the storage efficiency of the consumables is improved. The storage safety of the wire rod after 3D printing is stopped is improved, the wire rod pretreatment adaptive capacity of small-amount multi-frequency printing is met, and the instant storage effect after consumable material treatment is improved.

Owner:浙江机电职业技术学院

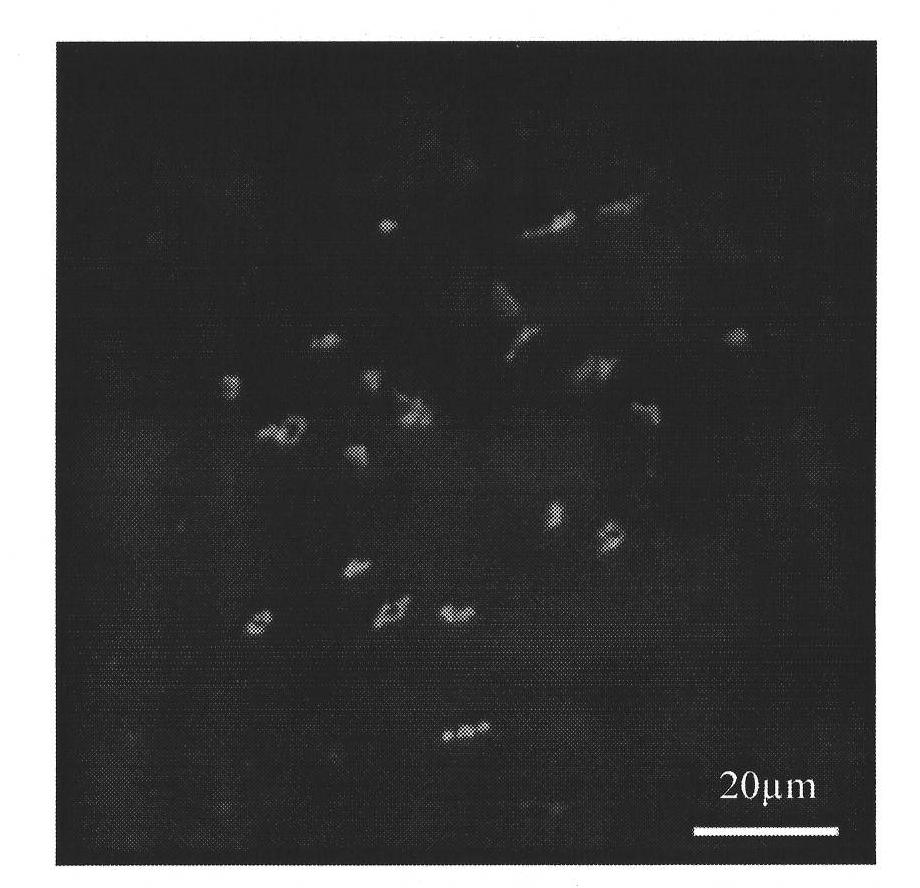

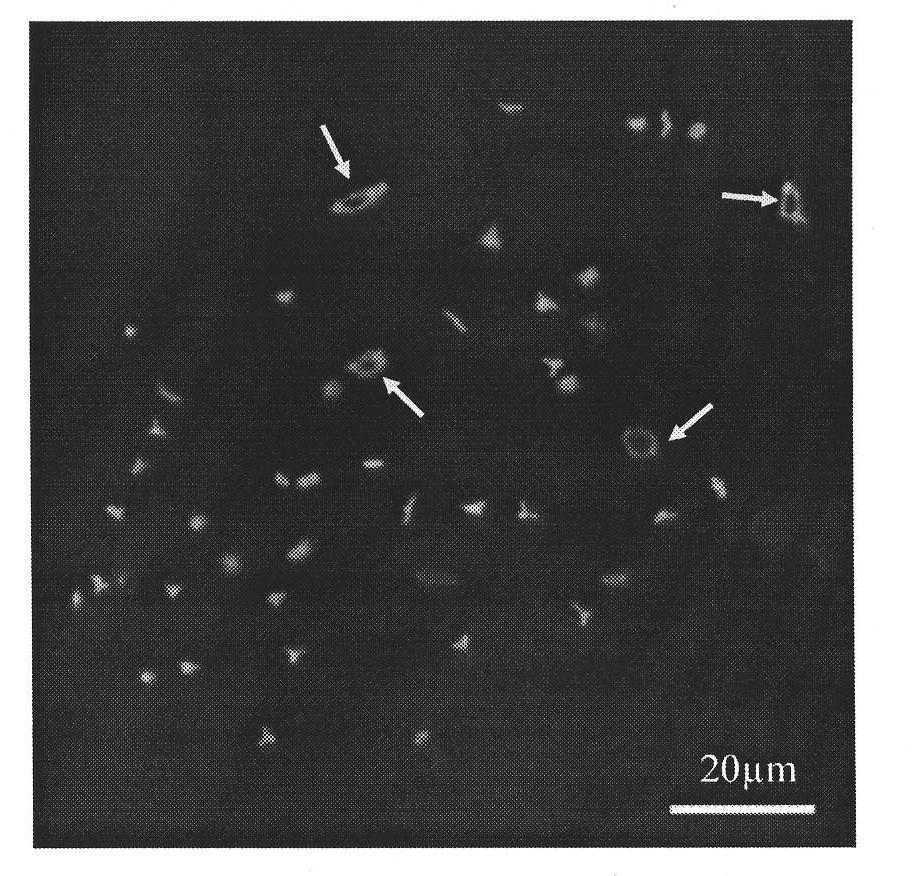

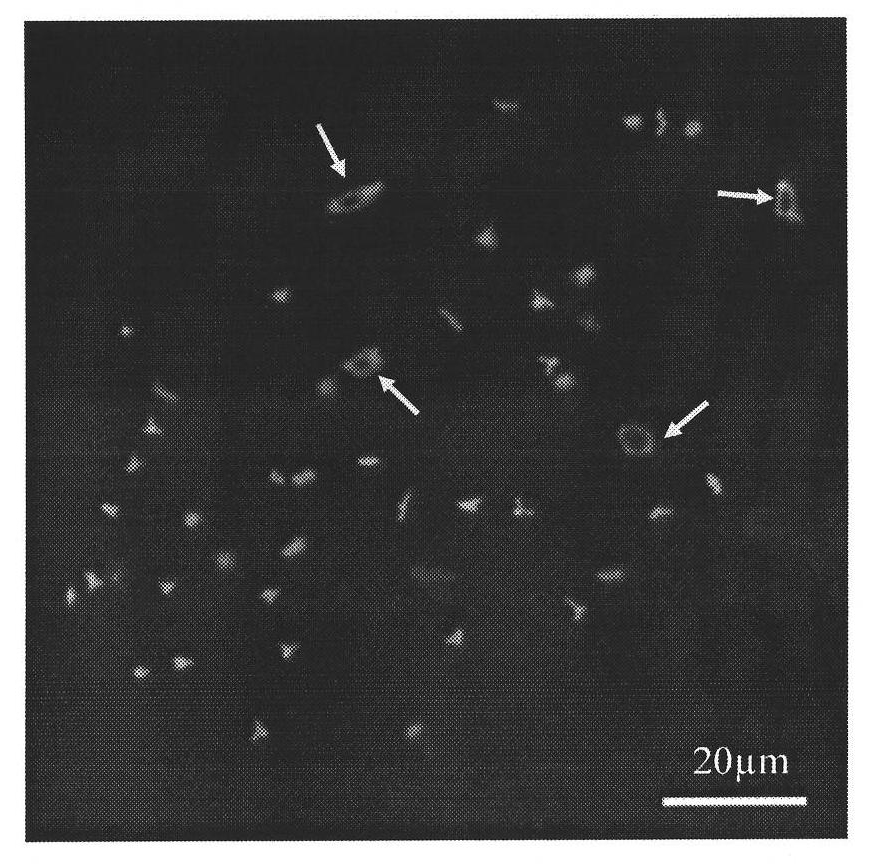

Method for preparing fish ovary germ cell chromosome

InactiveCN101974627AShortcut imageClear imagingMicrobiological testing/measurementPlant Germ CellsZoology

The invention discloses a method for preparing a fish ovary germ cell chromosome. The method comprises the following steps of: preparing a living mature ovary and washing the living mature ovary with normal saline; putting the ovary in normal saline containing 1mug / ml estrogen, cutting the ovary into small sections, and putting the ovary sections on a shaker for culturing for 1-3 hours at room temperature by keeping out of the sun; coating a layer of 1 percent agar at the bottom of a culture dish and filling a 4 percent glacial acetic acid solution; putting several cultured ovary sections into the 4 percent glacial acetic acid solution; after the ovary sections move to an animal pole, peeling off the ovokaryons; peeling off yelks on the peripheries of the ovokaryons; putting the ovokaryons in pre-cooled Kano stationary liquid for freezing overnight, wherein the Kano stationary liquid is prepared by mixing methanol and glacial acetic acid together, and the volume ratio of the methanol to the glacial acetic acid is 3:1; putting 3-5 ovokaryons frozen overnight on a glass slide for 10-20 seconds; then putting the glass slide carrying the ovokaryons into a dye vat containing a coloringagent for dying for 30-45 minutes by keeping out of the sun; and after the glass slide is soaked for 30 minutes in pure water by keeping out of the sun, covering cover glass on the glass slide.

Owner:DALIAN OCEAN UNIV

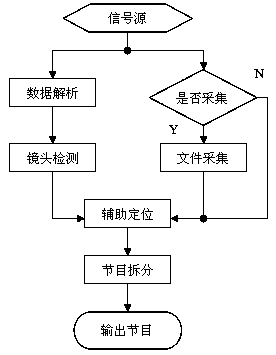

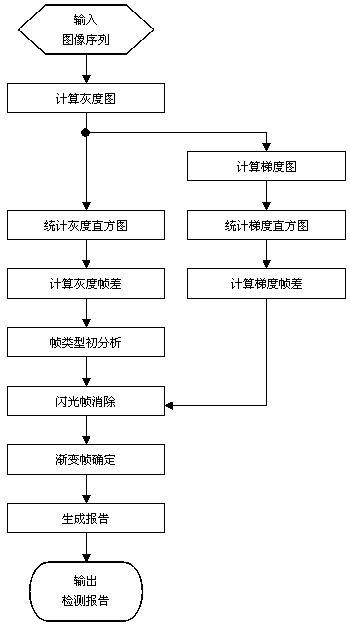

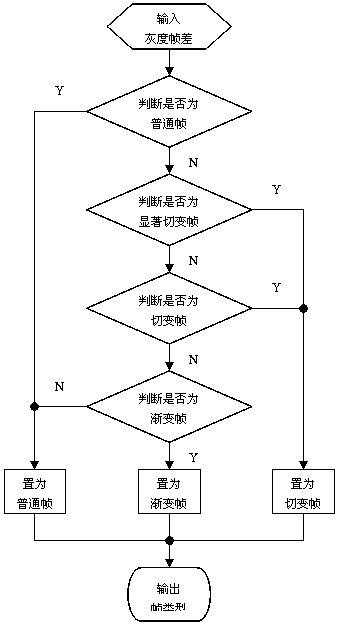

A Lens Inspection Method for High-Speed and Accurate Stripping

ActiveCN103051923BAvoid recodingAvoid steps such as format conversionTelevision systemsRgb imageGray level histogram

The invention discloses a lens detection method for high-speed accurate segmentation. The method comprises the following steps of: data analysis: for an SDI (Source Data Information) source, extracting YUV (Luma and Chroma) data from an SDI signal, and for a non-SDI source, carrying out decoding or signal separation to obtain the YUV or RGB (Red, Green, Blue) image information; lens detection: carrying out lens detection analysis on an input YUV or RGB image sequence, thus obtaining a detection result; assistant locating: locating a to-be-segmented file according to the lens detection result; and program segmentation: segmenting the located material. The method supports common variety of YUV and RGB formats, supports synchronization of acquisition and segmentation, and is free from recoding or format conversion, so that efficiency is improved; by utilization of small-sized images, the detection efficiency is improved, and the timeliness of the segmentation work is guaranteed; a grey level histogram difference and a gradient histogram difference are used comprehensively, and the detection accuracy is improved; by a gradient histogram, an adaptive threshold and a tolerance judging method, the detection accuracy is improved, and the influence of frequent flashing of news materials on the detection result is weakened.

Owner:CHENGDU SOBEY DIGITAL TECH CO LTD

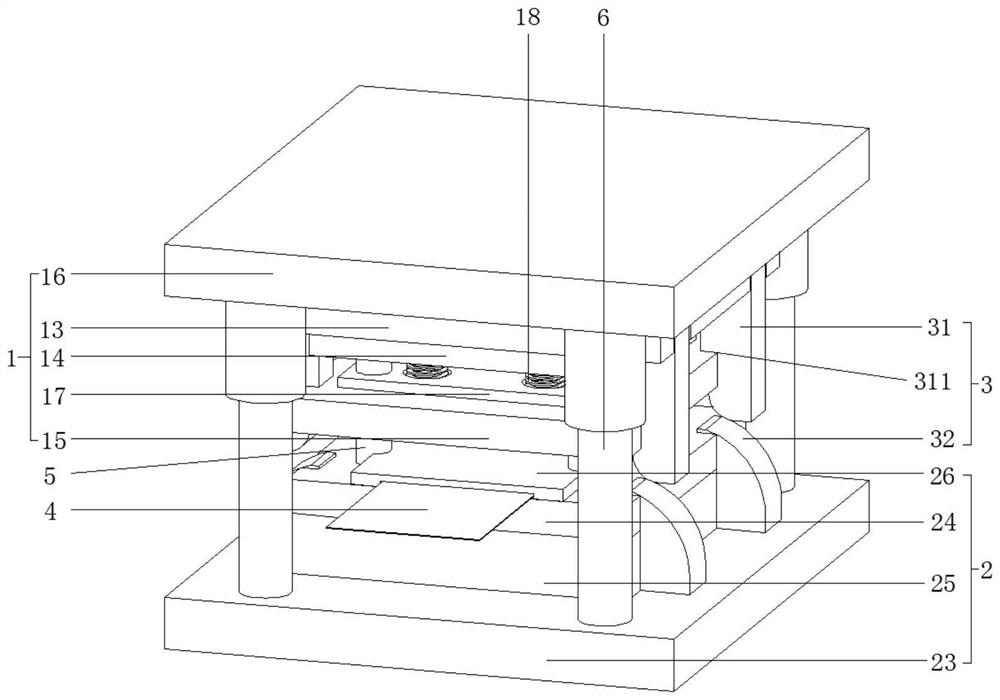

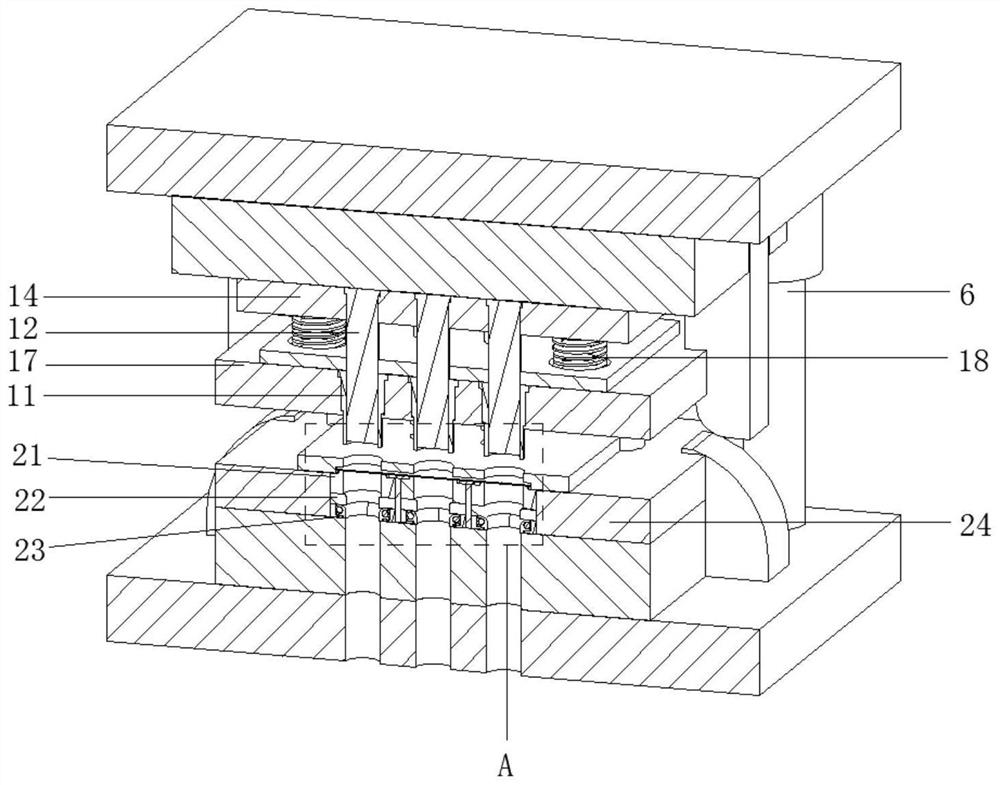

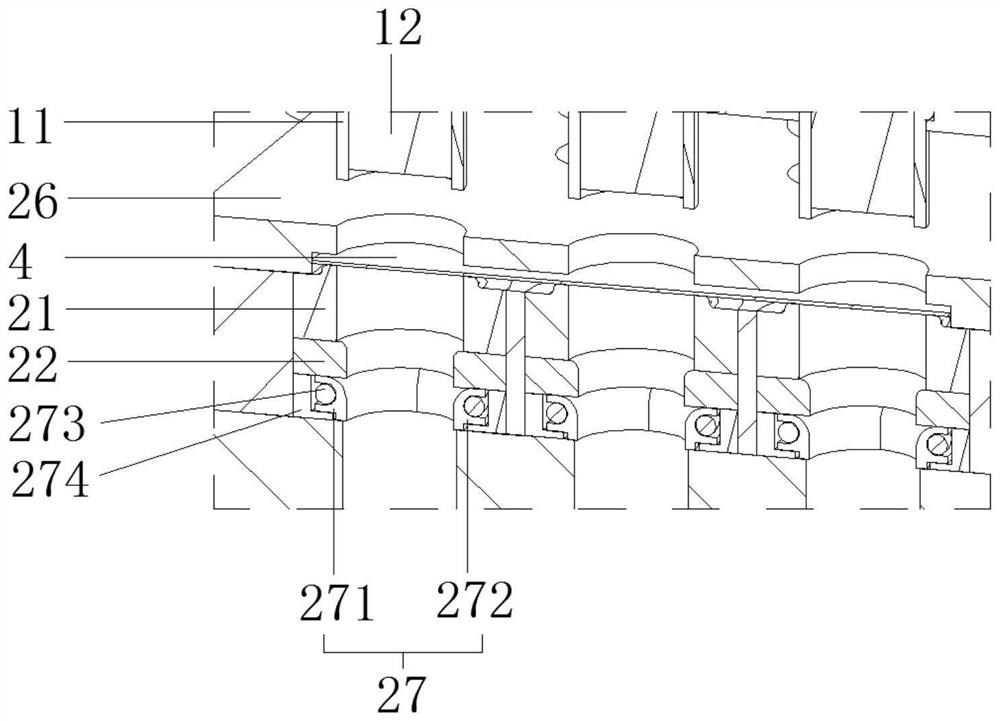

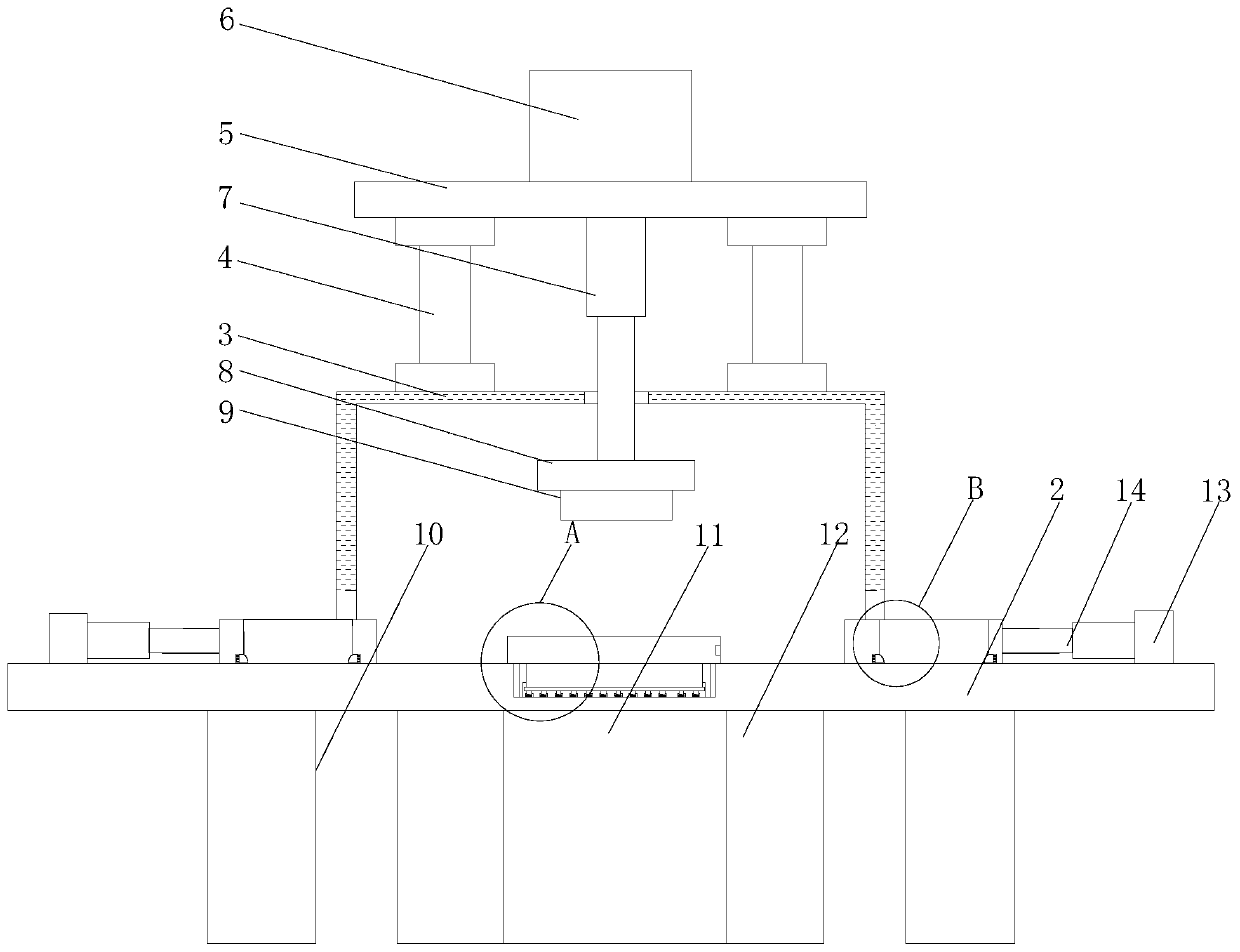

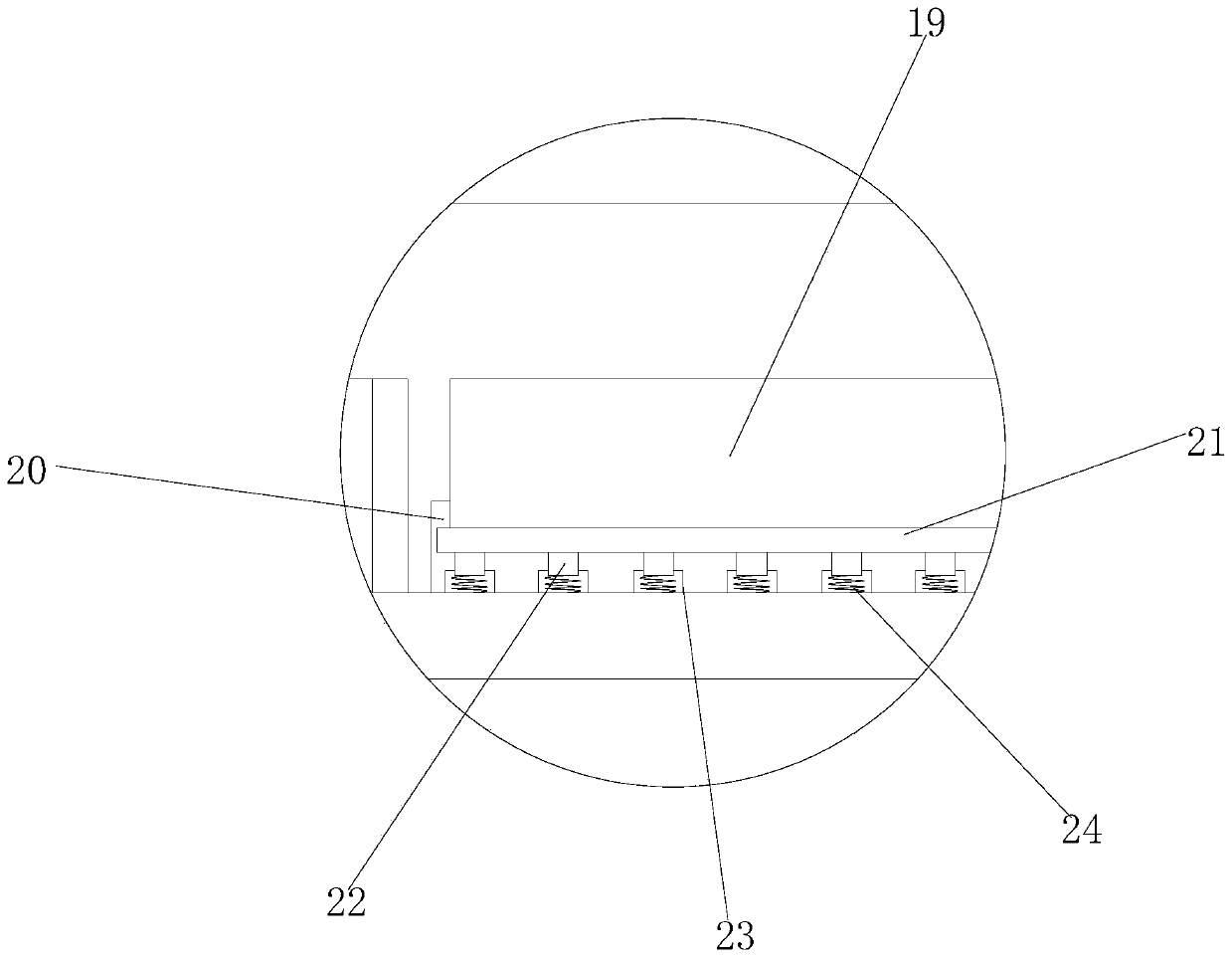

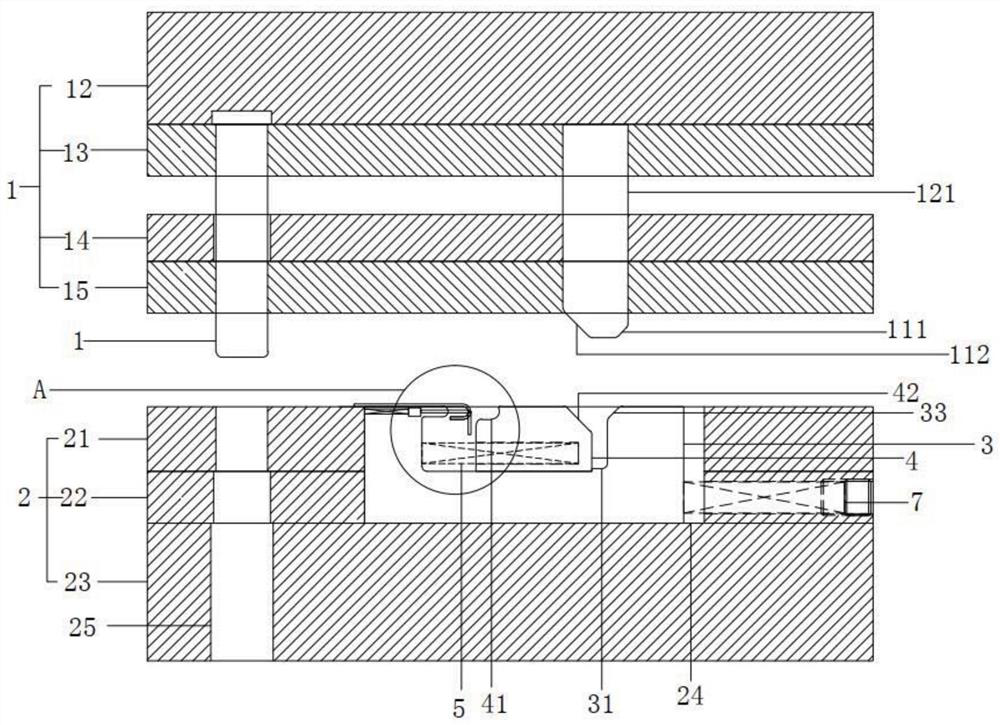

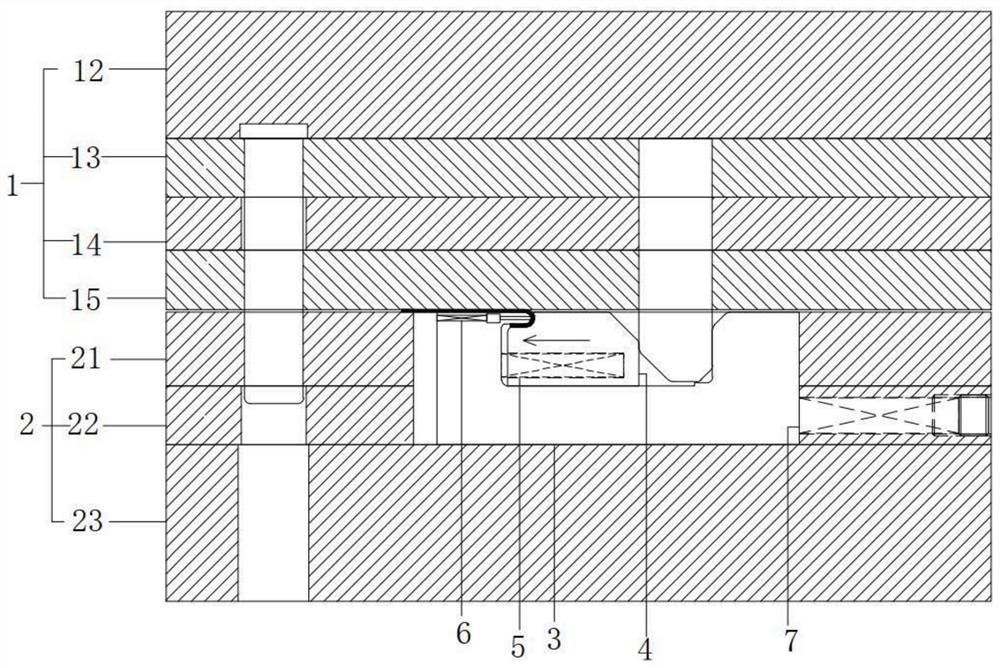

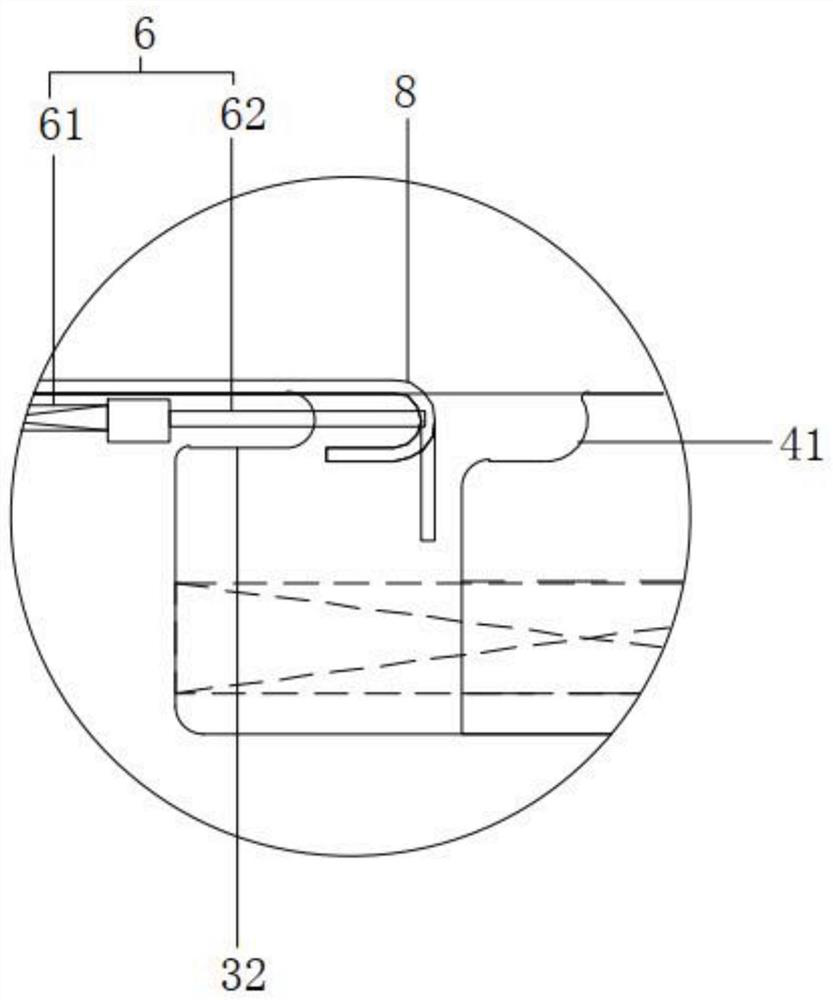

Compact type punching device capable of stripping materials rapidly and use method for compact type punching device

ActiveCN109396271AHigh strengthExtended service lifeShaping toolsEjection devicesPunchingEngineering

The invention relates to a compact type punching device capable of stripping materials rapidly. The compact type punching device comprises an upper mold and a lower mold, wherein the lower mold is provided with a first containing groove, the first containing groove is internally provided with an edge overturning concave mold and an edge overturning sliding block and a material moving sliding blocklocated on the two sides of the edge overturning concave mold correspondingly, the edge overturning sliding block is fixedly connected with an edge overturning convex mold, and the first containing groove comprises a moving groove and is further internally provided with a first reset component and a second reset component; and the upper mold is provided with an edge overturning driving rod and amaterial moving driving rod, the edge overturning driving rod is provided with a driving inclined plane A, the edge overturning sliding block is provided with a first inclined plane coinciding with the driving inclined plane A, the material moving driving rod is provided with a driving inclined plane B, and the material moving sliding block is provided with a second inclined plane coinciding withthe driving inclined plane B and a first avoiding groove for the material moving driving rod stretching in. The compact type punching device capable of stripping the materials rapidly has the advantages of being compact in structure and high in production efficiency.

Owner:深圳数码模汽车技术有限公司

Movable bending mechanism capable of facilitating discharging of large-bent-degree plates

InactiveCN106270031AGuarantee product qualityImprove discharge efficiencyMetal-working feeding devicesPositioning devicesEngineeringMachining

The invention discloses a movable bending mechanism capable of facilitating discharging of large-bent-degree plates. The movable bending mechanism comprises a left movable workbench and a right movable workbench which are matched symmetrically at an interval, the left workbench and the right workbench are driven to move by nut-screw mechanisms on two sides, the nut-screw mechanisms comprise nuts arranged on the outer sides of the left workbench and the right workbench respectively, screws are screwed into the nuts on the same sides, a movable die holder is arranged between the left workbench and the right bench, a punch holder is arranged above the left workbench and the right workbench, guide grooves are formed in the upper end faces of the left workbench and the right workbench along the plate conveying direction, movable U-shaped fixing frames are arranged in the left workbench and the right workbench below the guide grooves, two parallel fixing rods are mounted on U-shaped end ports of the U-shaped fixing frames, and guide rollers corresponding to the guide grooves are mounted on the fixing rods rotationally sequentially. The movable bending mechanism capable of facilitating discharging of the large-bent-degree plates is capable of machining the large-size plates, guaranteeing product quality and completing bending requirements automatically so as to meet the requirement on large-batch machining production.

Owner:讯龙型材折弯(合肥)有限公司

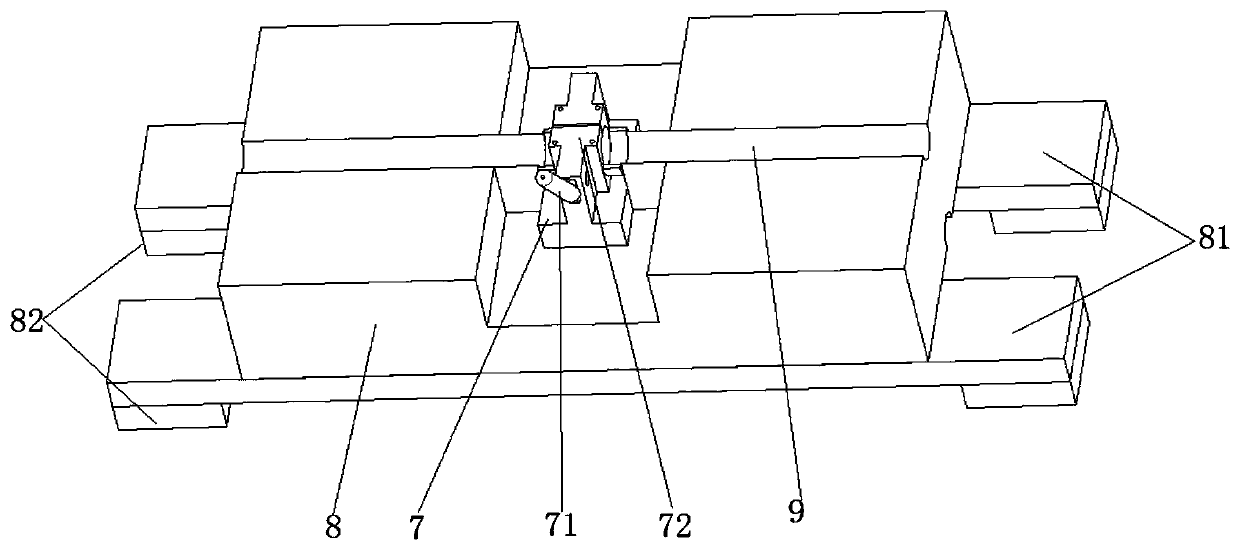

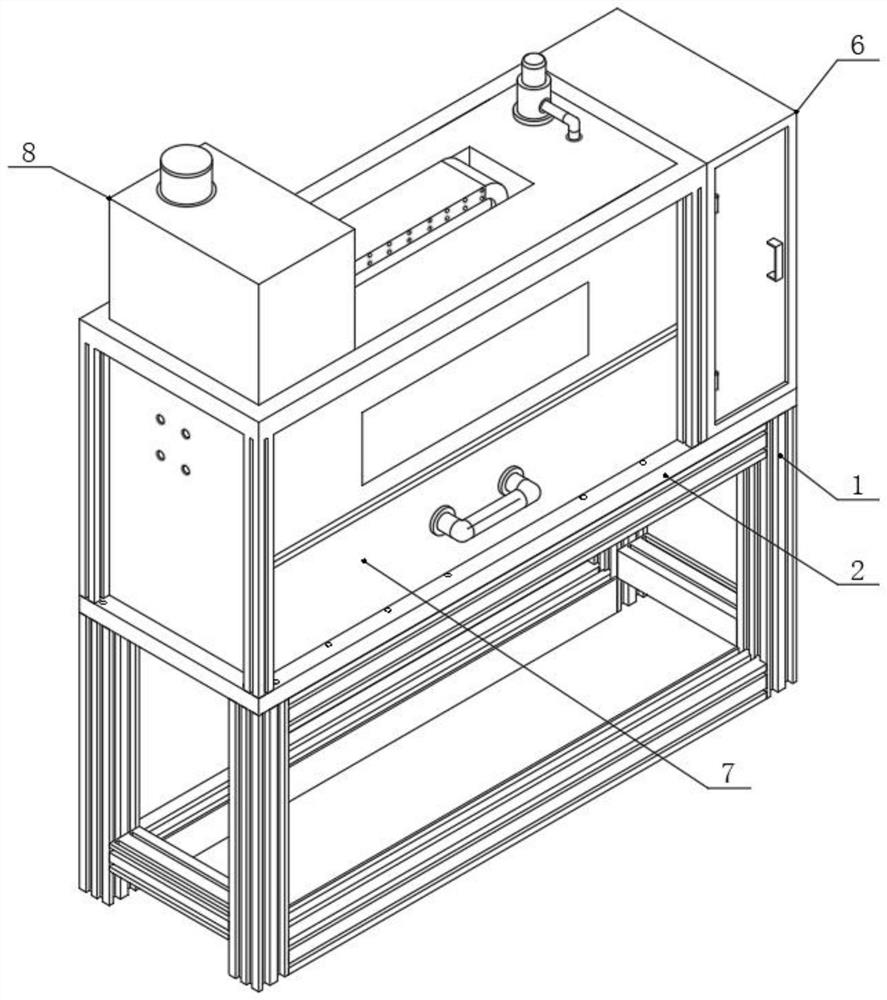

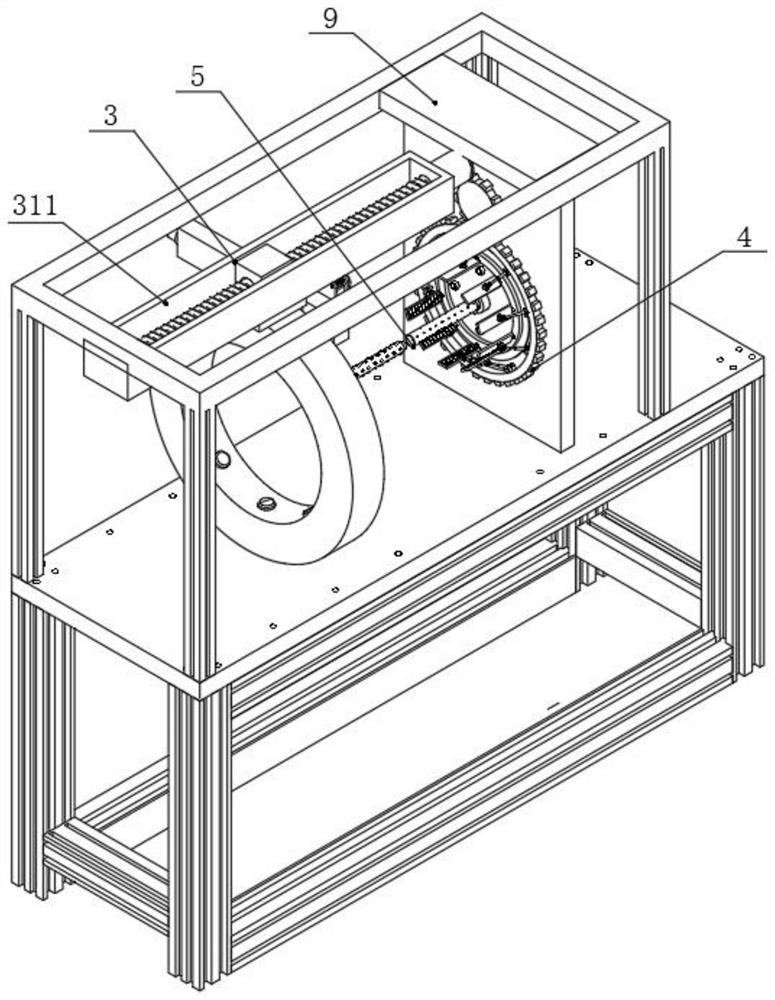

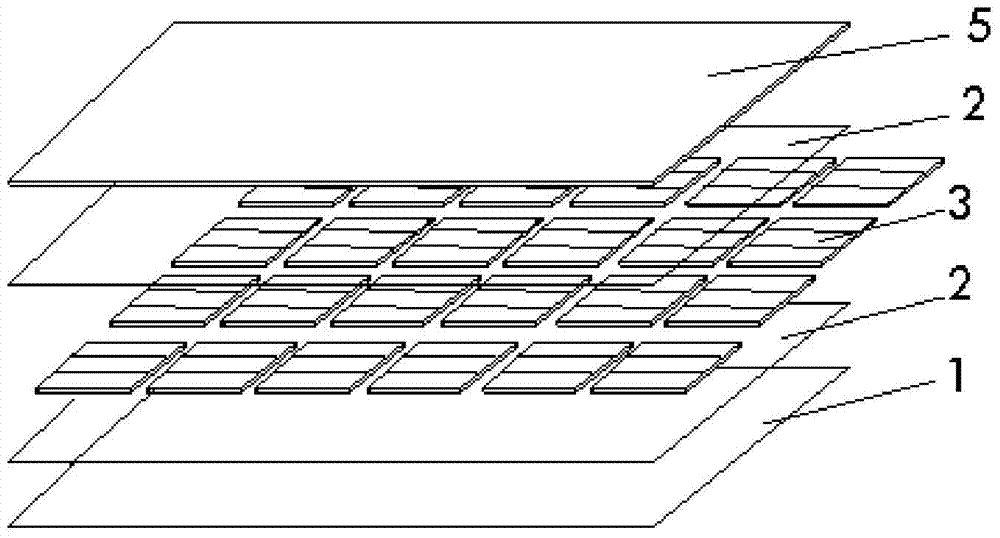

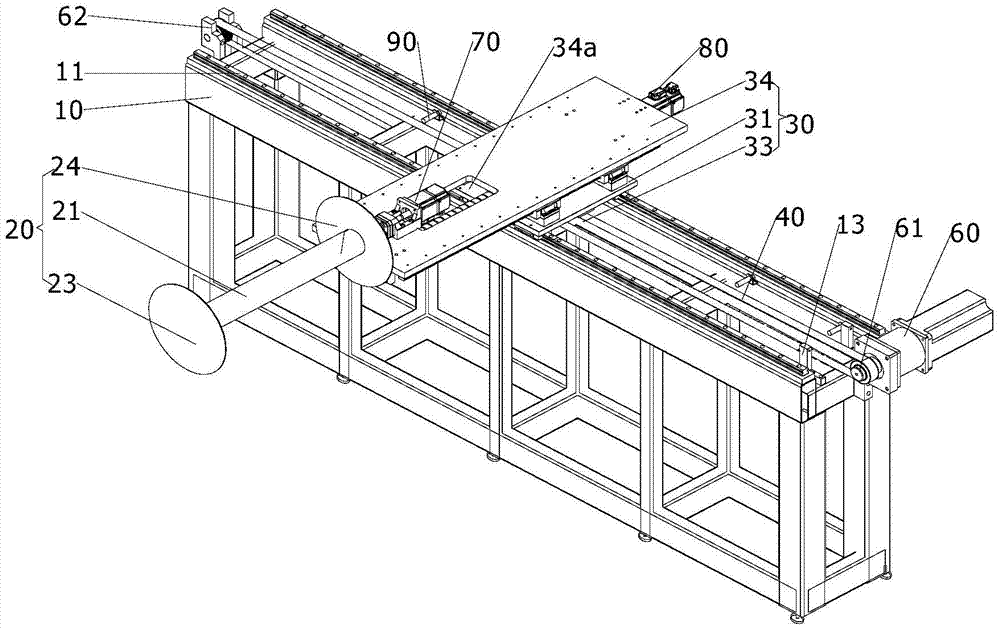

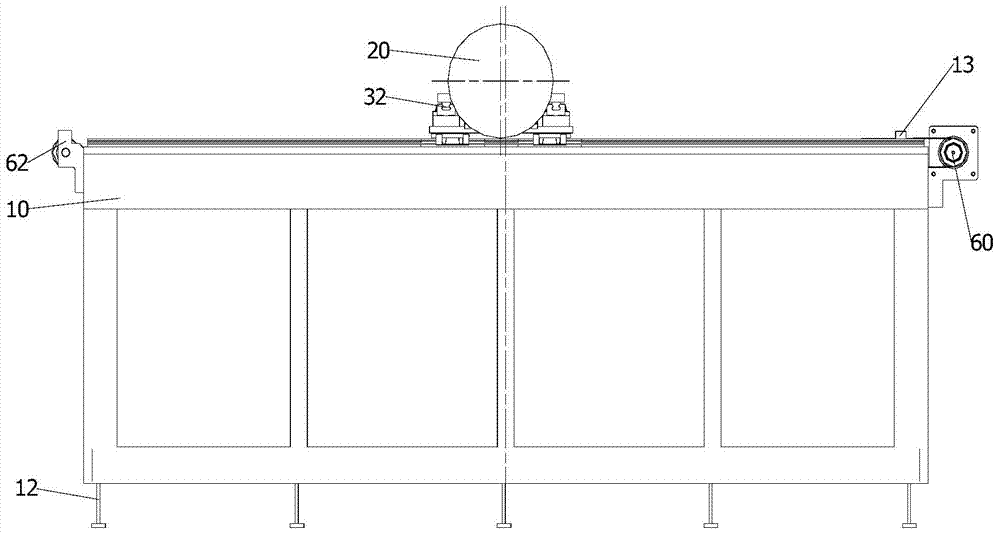

Stripping machines and stripping systems for photovoltaic module backsheets

ActiveCN105118897BQuick strippingAchieve mechanical propertiesFinal product manufactureSemiconductor devicesEngineeringMechanization

The invention provides a stripper and a stripping system for a photovoltaic assembly backboard. The stripper comprises a frame and a stripping mechanism. The frame is equipped with a first guide rail. The stripping mechanism is pivotally arranged on the frame and is arranged along the first guide rail in a sliding manner. The stripping mechanism is equipped with a positioning structure for fixing a component to be stripped. The stripper firstly connects the component to be stripped with the positioning structure of the stripping mechanism. Then the stripping mechanism rotates and slides along the first guide rail in order that the component to be stripped is wound around the stripping mechanism continuously. Thus, the component to be stripped can be removed highly efficiently and fast and stripping mechanization and automation of the component to be stripped is achieved. Since the component to be stripped is stripped by the stripper, the component to be stripped always bears stable force in a stripped process such that the stripping quality of the stripper is guaranteed.

Owner:YINGLI ENERGY CHINA

One-time forming die for stamping button surface piece

The invention discloses a one-step forming die for stamping a button surface piece, which comprises an upper die, a lower die, a lower die, a lower die, a punching sleeve and a punching insert pin, the upper die is provided with a punching sleeve and a punching insert pin, and the punching sleeve is coaxially sleeved on the punching insert pin; a first insert and a second insert are sequentially arranged on the lower die in the punching direction; and the limiting assembly can enable the punching insert pin to move or be static relative to the blanking sleeve. The punching sleeve and the punching insert pin which are coaxially designed can be used for manufacturing a finished product through single-time mold closing, so that the machining time is saved, the first insert and the second insert are sequentially arranged in the material punching direction, the utilization rate of the mold machining area is increased, more forming holes can be designed in the unit area, the machining number of products can be increased, and the machining efficiency is improved. Compared with the prior art, more products can be processed within shorter time.

Owner:东莞市钮纽实业有限公司

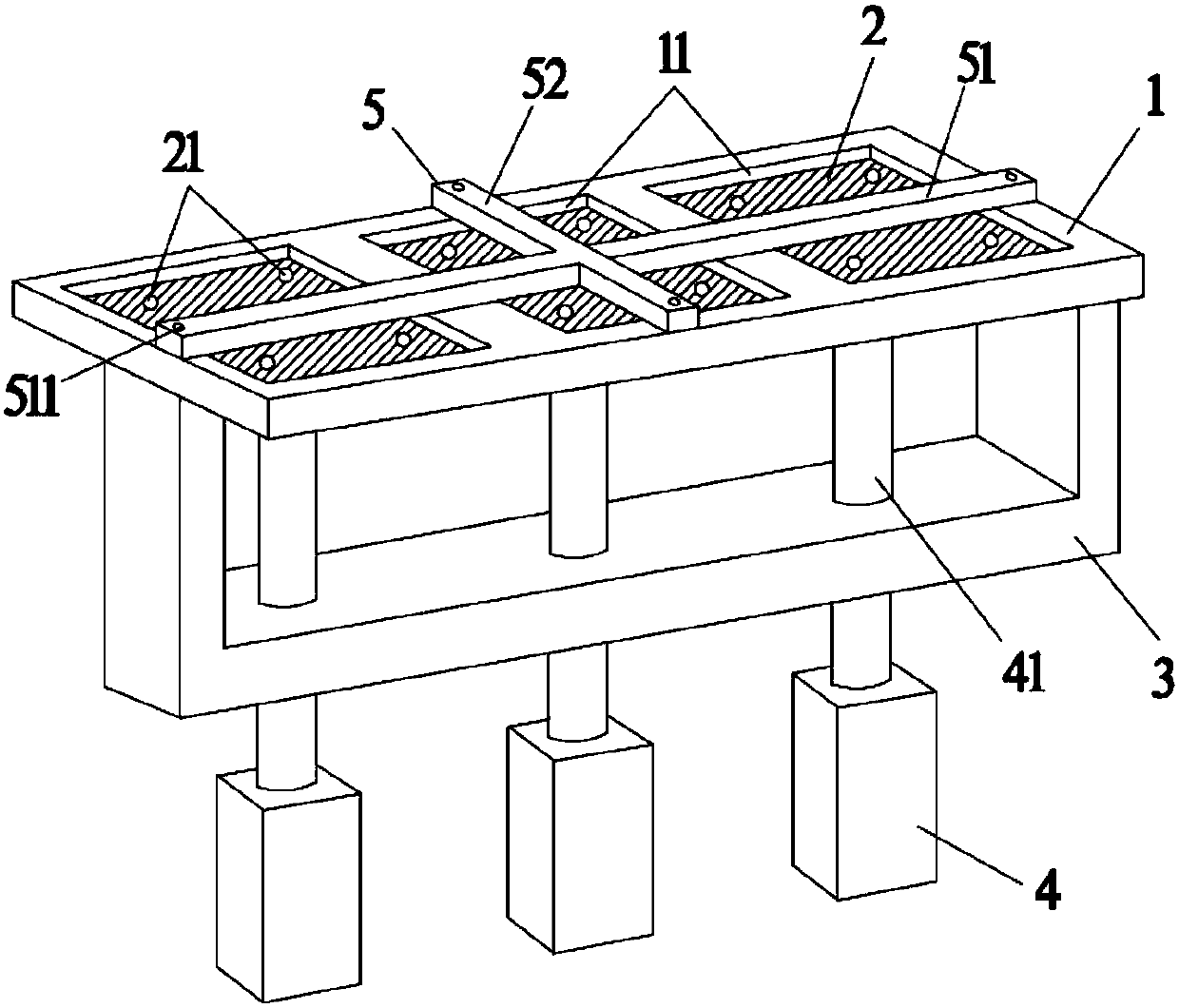

Automatic clamp for mobile phone cover glass

InactiveCN107727491AMeet the needs of mass production testingSimple structureGrinding work supportsStrength propertiesEngineeringCover glass

The invention relates to the field of mobile phone glass processing fitting technology, and more specifically relates to an automatic clamp for mobile phone cover glass. The structure of the automaticclamp comprises an operating platform, a support which is fixed on the operating platform and several cylinders which are fixed on the support; the operating platform is provided with several stationslotted holes which are used for processing or detecting the cover glass, each station slotted hole is internally provided with an operation panel which can be moved up and down, and a cylinder shaftof each cylinder passes through the support and is fixedly connected to the bottom of the corresponding operation panel; the shape of the operation panel and the shape of the cover glass are matched.Compared with the prior art, the automatic clamp has a simple structure, material loading and stripping operation is rapid and convenient, and detective products due to manual operation are avoided in order to guarantee product quality; in addition, automatic operation is realized, and demands on mass production and detection of mobile phone cover glass are better satisfied.

Owner:广东星弛光电科技有限公司

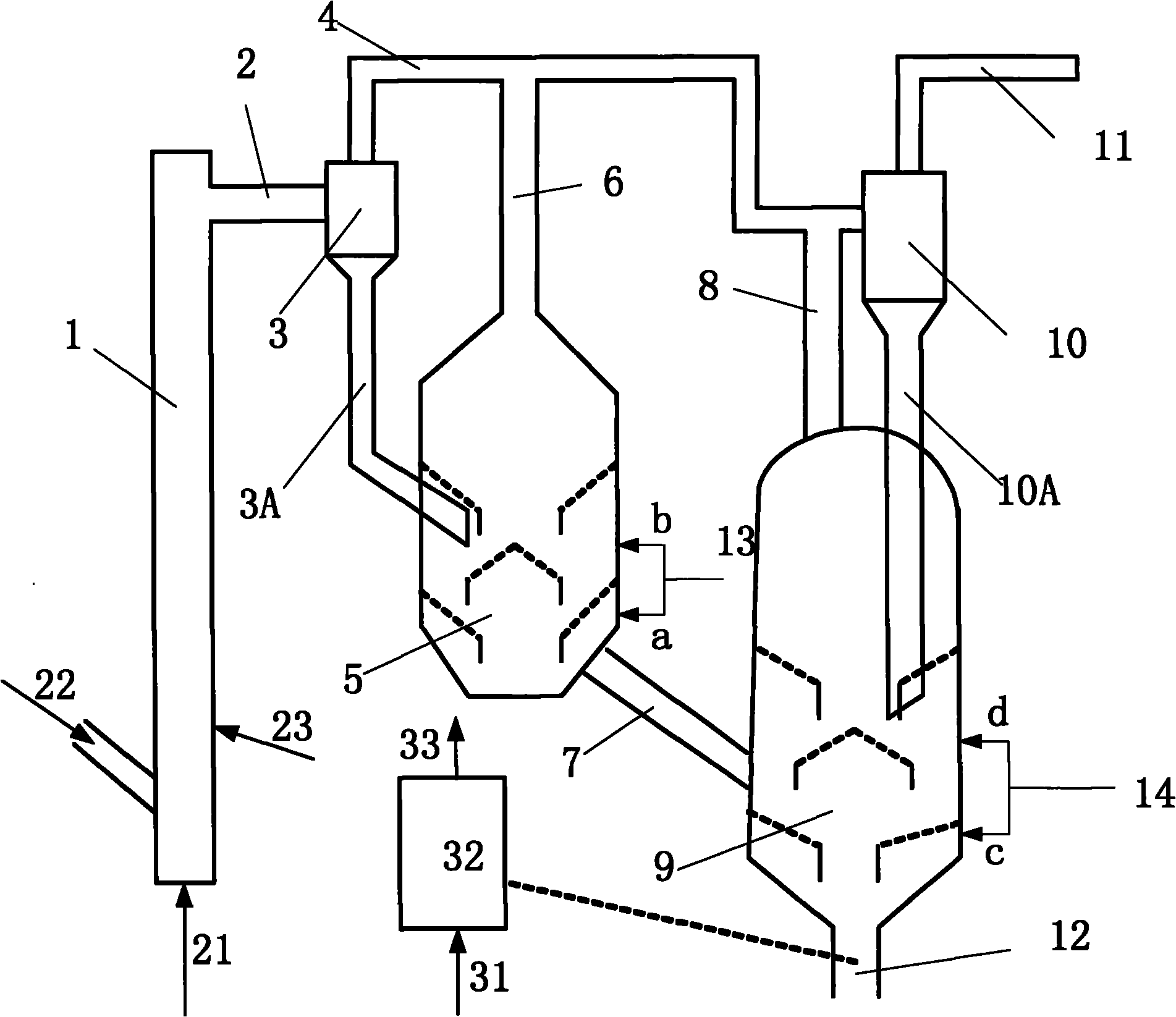

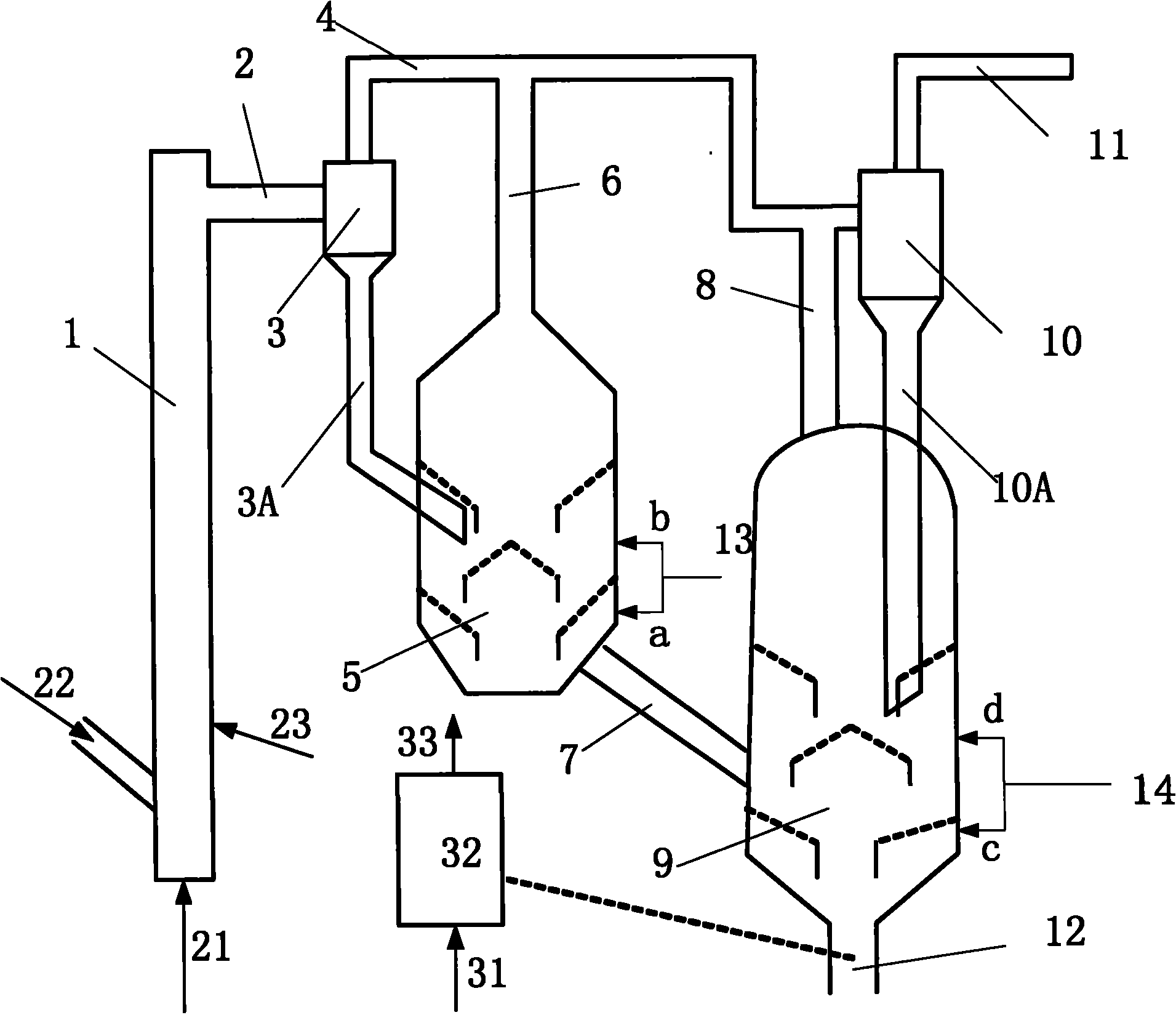

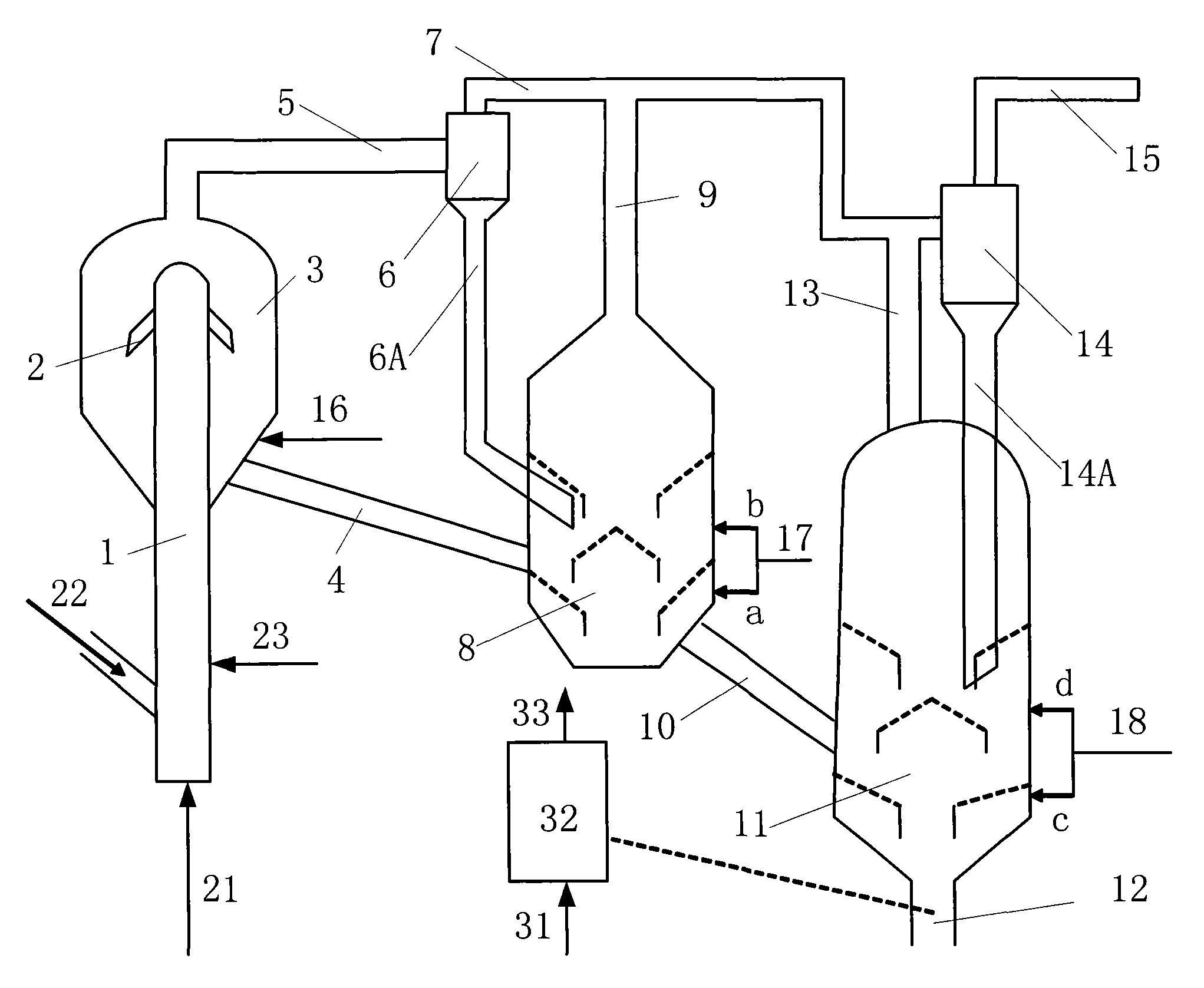

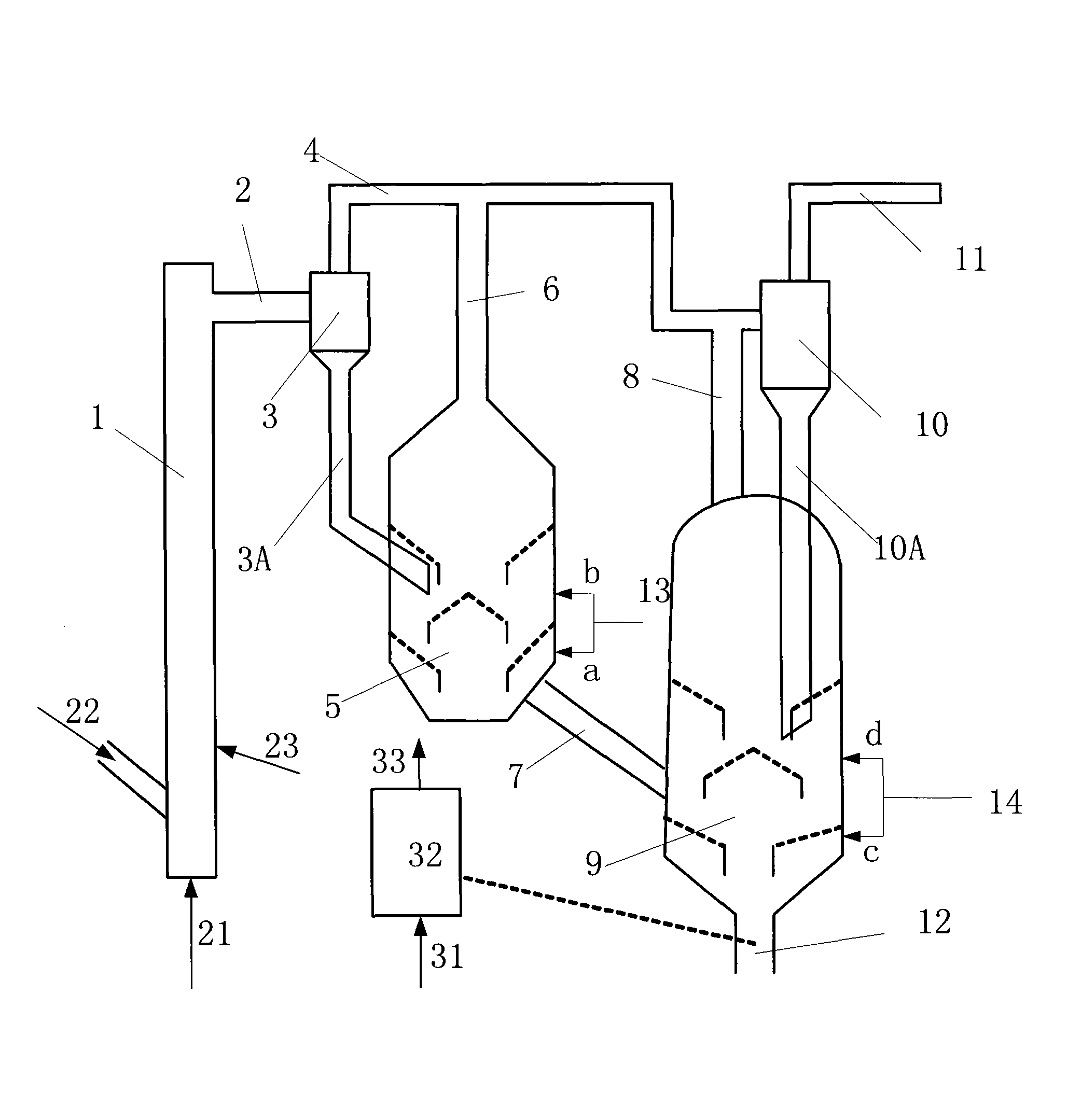

Fluid catalytic cracking gas-oil separating and stripping device and method thereof

ActiveCN101955789AQuick leadEasy to separateCatalytic crackingDispersed particle separationCycloneGas phase

The invention relates to a fluid catalytic cracking gas-oil separating and stripping device and a method thereof. The fluid catalytic cracking gas-oil separating and stripping device comprises a first-level cyclone separating device, a second-level cyclone separating device, a first stripper and a second stripper, wherein an inlet of the first-level cyclone separating device is connected with an outlet of a lifting pipe reactor; diplegs of the first-level cyclone separating device and the second-level cyclone separating device respectively extend into the first stripper and the second stripper; gas-phase outlets of the first-level cyclone separating device, the first stripper and the second stripper are connected with an inlet of the second-level cyclone separating device, and the first stripper and the second stripper are connected by a catalyst pipeline. The corresponding method comprises the following steps of: separating reaction oil gas and a catalyst when entering the first-level cyclone separating device, wherein the catalyst enters a regenerator after being stripped twice, and the reaction oil gas and each stripped gas phase enter a follow-up fractionating system after being separated by entering the second-level cyclone separating device. The device and the method can quickly extract the reaction oil gas out of the device, and gas phase hydrocarbon carried in spent catalyst granule gaps is quickly stropped and extracted, thereby reducing hydrogen content in coke and internal coking trend of the device.

Owner:CHINA PETROLEUM & CHEM CORP +1

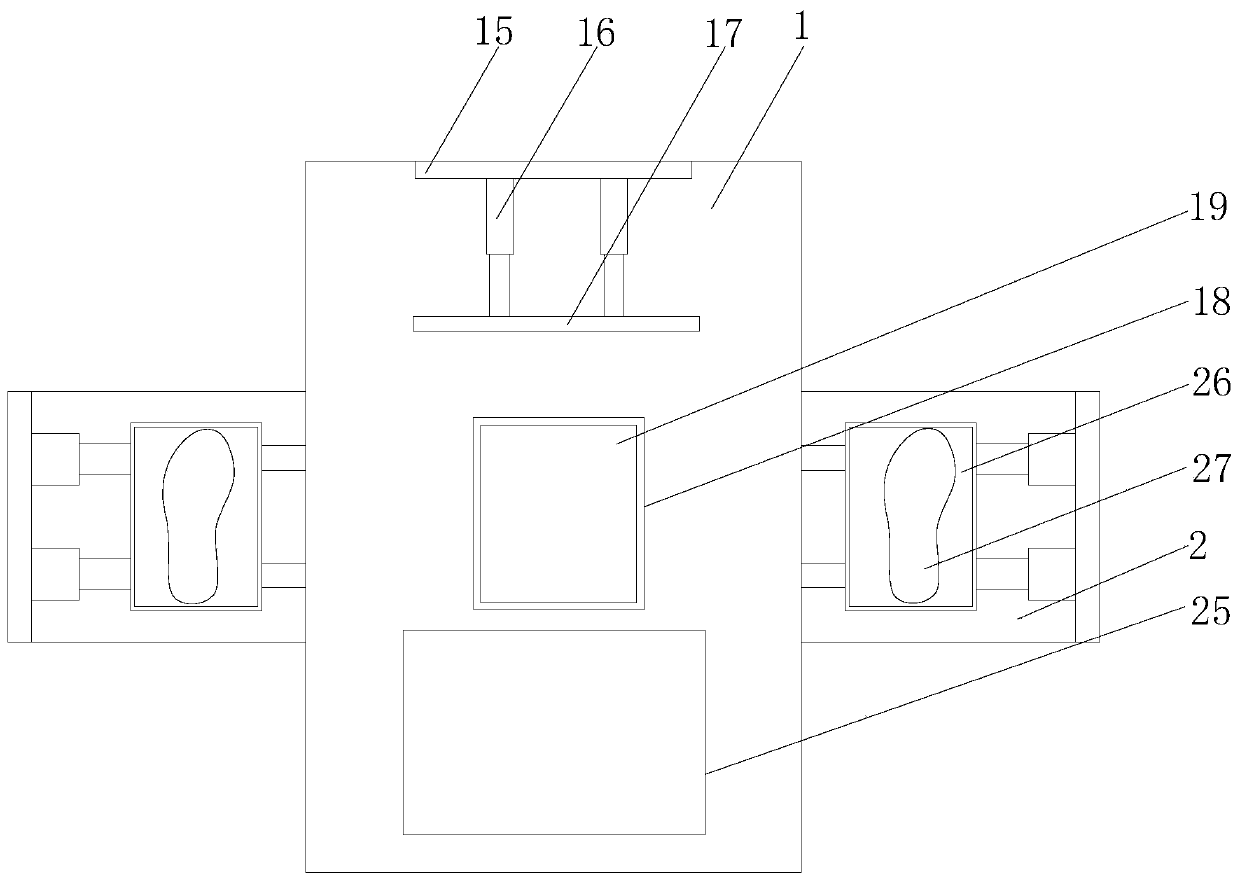

Shoe sole positioning and pressing device for shoe processing

ActiveCN110973768ASave loading timeIncrease the pressing speedSolesEngineeringStructural engineering

The invention discloses a shoe sole positioning and pressing device for shoe processing. The device comprises first mounting plates and second mounting plates fixedly connected to the two sides of thefirst mounting plate, first mounting side plates are fixedly mounted on the upper surfaces of the first mounting plates on the two sides, first electric push rods are fixedly mounted at the two endsof one side of the first mounting side plate, a pressing plate is fixedly connected to one side of the first electric push rod, a shoe groove matched with the shoe sole is formed in the upper end of the pressing plate in a penetrating mode, first grooves are formed in the two sides in the shoe groove, abutting blocks are movably connected into the first grooves, the lower ends of the abutting blocks are flush with the lower end of the pressing plate, and first springs are fixedly connected between the abutting blocks and the adjacent side faces of the first grooves. By arranging the pressing plates on the first mounting side plates on the two sides, continuous shoe sole pressing and feeding can be conducted, compared with a traditional pressing device, the feeding time is saved, the shoe sole pressing speed is increased, shoe soles obtained after pressing can be rapidly stripped, discharging is rapid, and time is saved.

Owner:含山县华侨鞋业有限公司

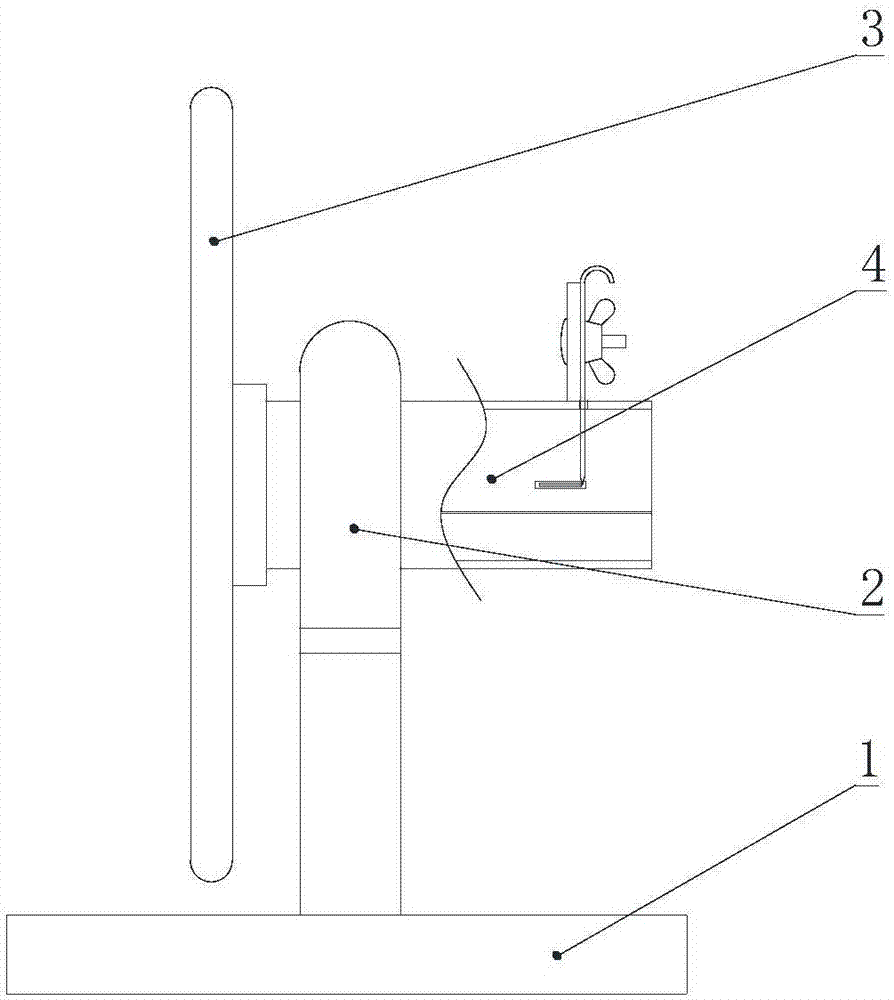

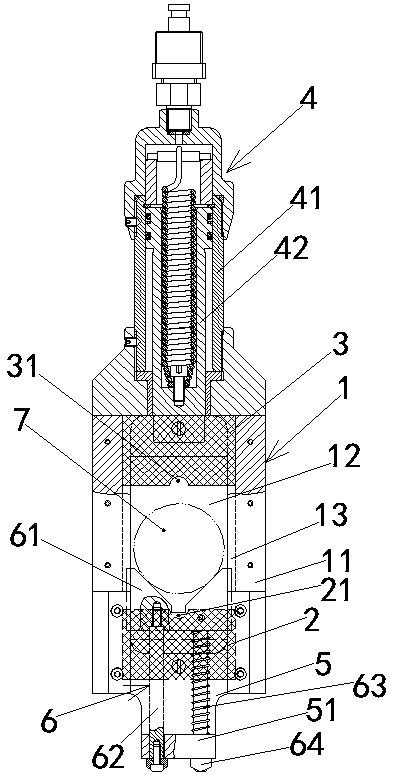

A stripping device for electrical engineering cables

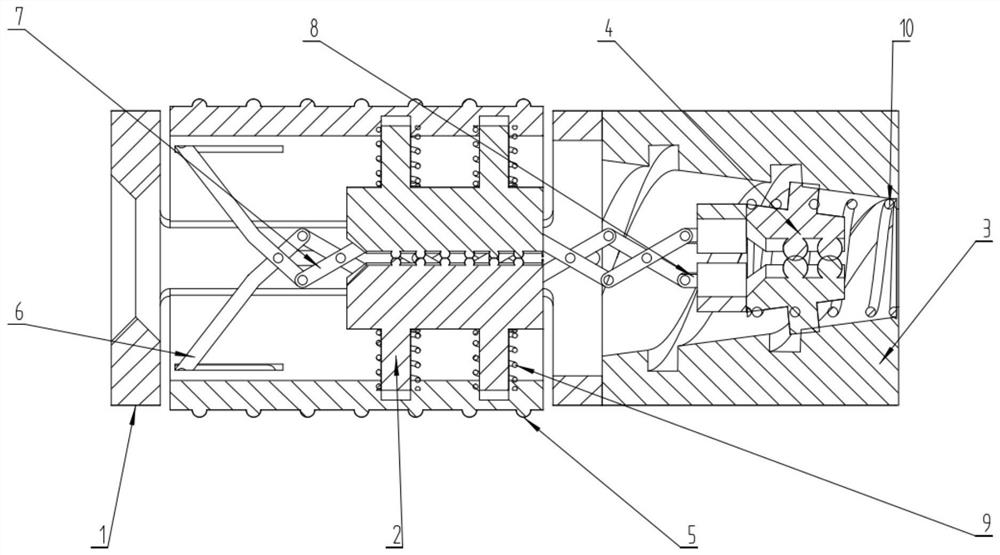

ActiveCN113488922BMove quicklyQuick strippingApparatus for removing/armouring cablesElectronic waste recyclingBraced frameMechanical engineering

A stripping device for electrical engineering cables, including a skeleton, an extruding and fixing part, an advancing part, and a rotating and separating part; the extruding and fixing part includes: a fixed head, a cover plate and a spring support frame; Rod, small connecting rod and push head; the rotating separation part includes: the outer screw of the extrusion head, the extrusion head and the spring fixed head; the skeleton provides the installation position for other parts, and the extrusion fixed part is slidably installed The pressing and fixing part squeezes and fixes the cables that have been put into the device; the pushing part is slidably installed in the slot hole inside the support frame, and the pushing part provides power for the rotating and separating part; the rotating and separating part is fixedly installed on the end face of the supporting frame, The rotating and separating part clamps the cable and rotates to separate the wire sheath from the wire core; the device can automatically reset, has a simple structure, is easy to carry, and is easy to operate, which can provide convenience for workers in related fields.

Owner:湖南省融盛电力工程建设有限公司

Fluid catalytic cracking oil and gas separation and steam stripping equipment and method

ActiveCN101955790BQuick leadEasy to separateCatalytic crackingDispersed particle separationCycloneGas phase

The invention relates to fluid catalytic cracking oil and gas separation and steam stripping equipment. The equipment comprises an inertia separator, a pre-stripper, a first-stage cyclone separator, a second-stage cyclone separator, a first stripper and a second stripper, wherein the inertia separator is positioned in the pre-stripper; the gas phase outlet of the pre-stripper is connected with the inlet of the first-stage cyclone separator; diplegs of the first-stage and second-stage cyclone separators extend into the first and second strippers respectively; the gas phase outlets of the first-stage cyclone separator, the first stripper and the second stripper are connected with the inlet of the second-stage cyclone separator; and the first stripper is connected with the pre-stripper and the second stripper through catalyst pipelines respectively. A fluid catalytic cracking oil and gas separation and steam stripping method comprises the following steps of: separating reaction oil gas from a catalyst by using the inertia separator; stripping the catalyst by using the pre-stripper, the first stripper and the second stripper in turn and feeding the stripped catalyst into a regenerator; separating all reaction oil gas in the first-stage cyclone separator; and feeding an obtained gas phase and the gas phase obtained by every stripping into the second-stage cyclone separator for separating. In the equipment and the method, the reaction oil gas can be rapidly led out of a device and gas-phase hydrocarbons carried in particle gaps of the catalyst are stripped and led out rapidly, so that internal coking tendency of the device is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Fluid catalytic cracking gas-oil separating and stripping device and method thereof

ActiveCN101955789BQuick leadEasy to separateCatalytic crackingDispersed particle separationCycloneGas phase

The invention relates to a fluid catalytic cracking gas-oil separating and stripping device and a method thereof. The fluid catalytic cracking gas-oil separating and stripping device comprises a first-level cyclone separating device, a second-level cyclone separating device, a first stripper and a second stripper, wherein an inlet of the first-level cyclone separating device is connected with an outlet of a lifting pipe reactor; diplegs of the first-level cyclone separating device and the second-level cyclone separating device respectively extend into the first stripper and the second stripper; gas-phase outlets of the first-level cyclone separating device, the first stripper and the second stripper are connected with an inlet of the second-level cyclone separating device, and the first stripper and the second stripper are connected by a catalyst pipeline. The corresponding method comprises the following steps of: separating reaction oil gas and a catalyst when entering the first-level cyclone separating device, wherein the catalyst enters a regenerator after being stripped twice, and the reaction oil gas and each stripped gas phase enter a follow-up fractionating system after being separated by entering the second-level cyclone separating device. The device and the method can quickly extract the reaction oil gas out of the device, and gas phase hydrocarbon carried in spent catalyst granule gaps is quickly stropped and extracted, thereby reducing hydrogen content in coke and internal coking trend of the device.

Owner:CHINA PETROLEUM & CHEM CORP +1

Stamping device with die inner side pushing and bending structure

PendingCN113020446AQuick strippingIncrease productivityShaping toolsEjection devicesStructural engineeringMechanical engineering

The invention provides a stamping device with a die inner side pushing and bending structure. The stamping device comprises: an upper die mechanism, wherein a punch pin is disposed on the upper die mechanism, and a first inclined face and a second inclined face are disposed at the bottom of the punch pin; and a lower die mechanism, wherein a first mounting groove is formed in the lower die mechanism, a first sliding block is arranged in the first mounting groove, one end of the first sliding block is connected into the first mounting groove through a first elastic component, a second mounting groove is formed in the first sliding block, a second sliding block is arranged in the second mounting groove, the second sliding block is connected to the first sliding block through a second elastic component, one end of the first sliding block is provided with a convex corner used for folding a negative angle, an ejector pin assembly is arranged in the convex corner, the other end of the first sliding block is provided with a third inclined face matched with the first inclined face, one end of the second sliding block is provided with a concave cavity matched with the convex corner, and the other end of the second sliding block is provided with a fourth inclined face matched with the second inclined face. Compared with the prior art, the problem that the material belt feeding is affected due to the fact that a material belt of a die floats too high can be effectively solved.

Owner:SHENZHEN EVA PRECISION TECH GRP CO LTD

Stripping device and stripping method

ActiveCN107248713BImprove peeling efficiencyImprove versatilityApparatus for removing/armouring cablesEngineeringMechanical engineering

The invention discloses a cable stripping device and a stripping method. The cable stripping device comprises a base, a support seat, a rotary table and a cable stripper, wherein the support seat is fixed at the top of the base, the support seat is provided with the cable stripper that is perpendicular to the support seat and can rotate, a cable support is arranged inside the cable stripper, the rotary table is fixed at one end outside the cable stripper, and a transverse cutting knife and a longitudinal cutting knife that are perpendicular to each other are arranged at the other end at a certain deflection angle. Both the transverse cutting knife and the longitudinal cutting knife are arranged on the cable stripper, so that the outer skin of the cable is cut circularly and longitudinally so as to be removed, the cable core is not damaged, and the working efficiency is improved.

Owner:LINQU POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO +2

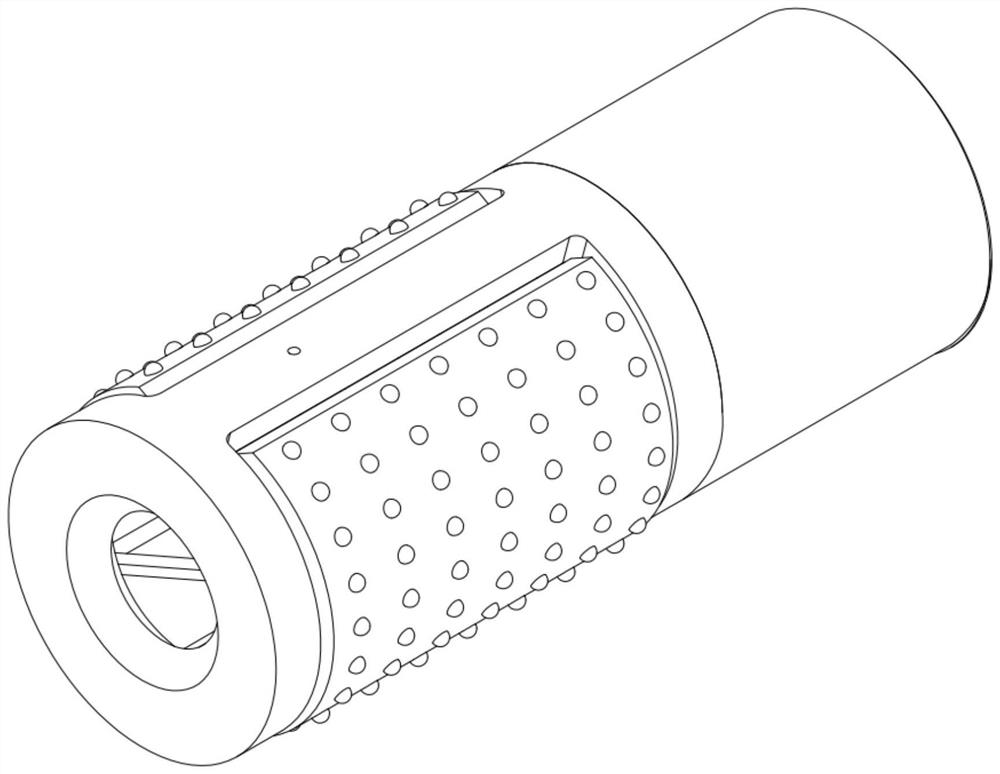

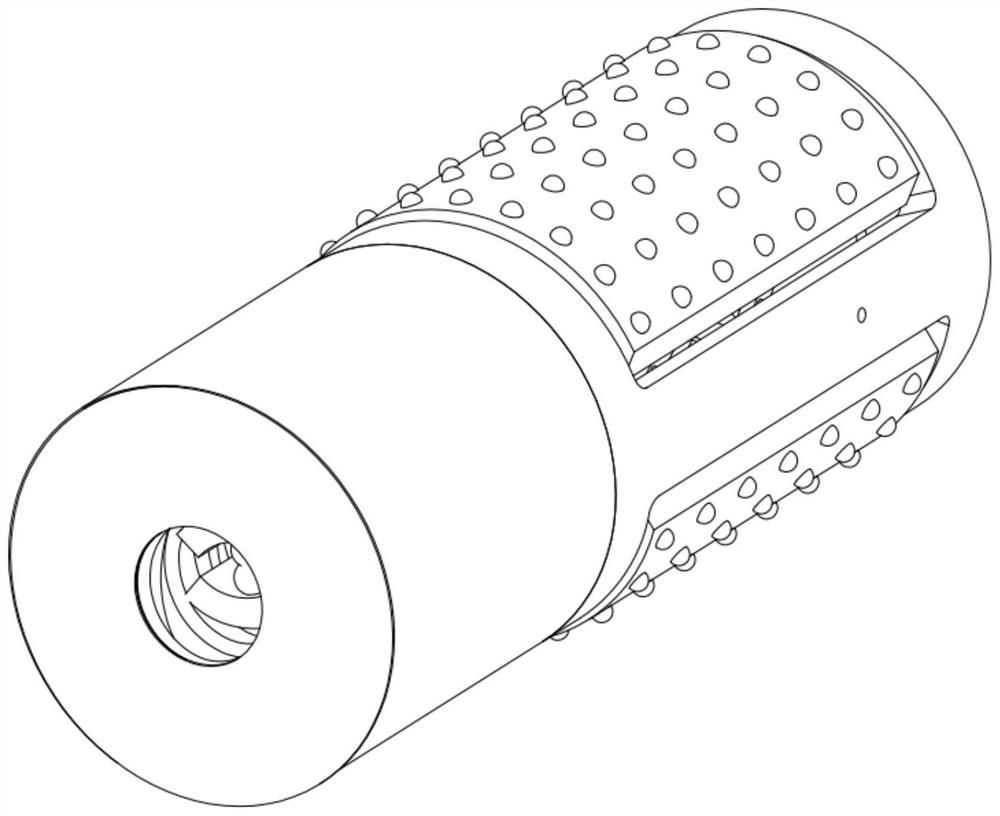

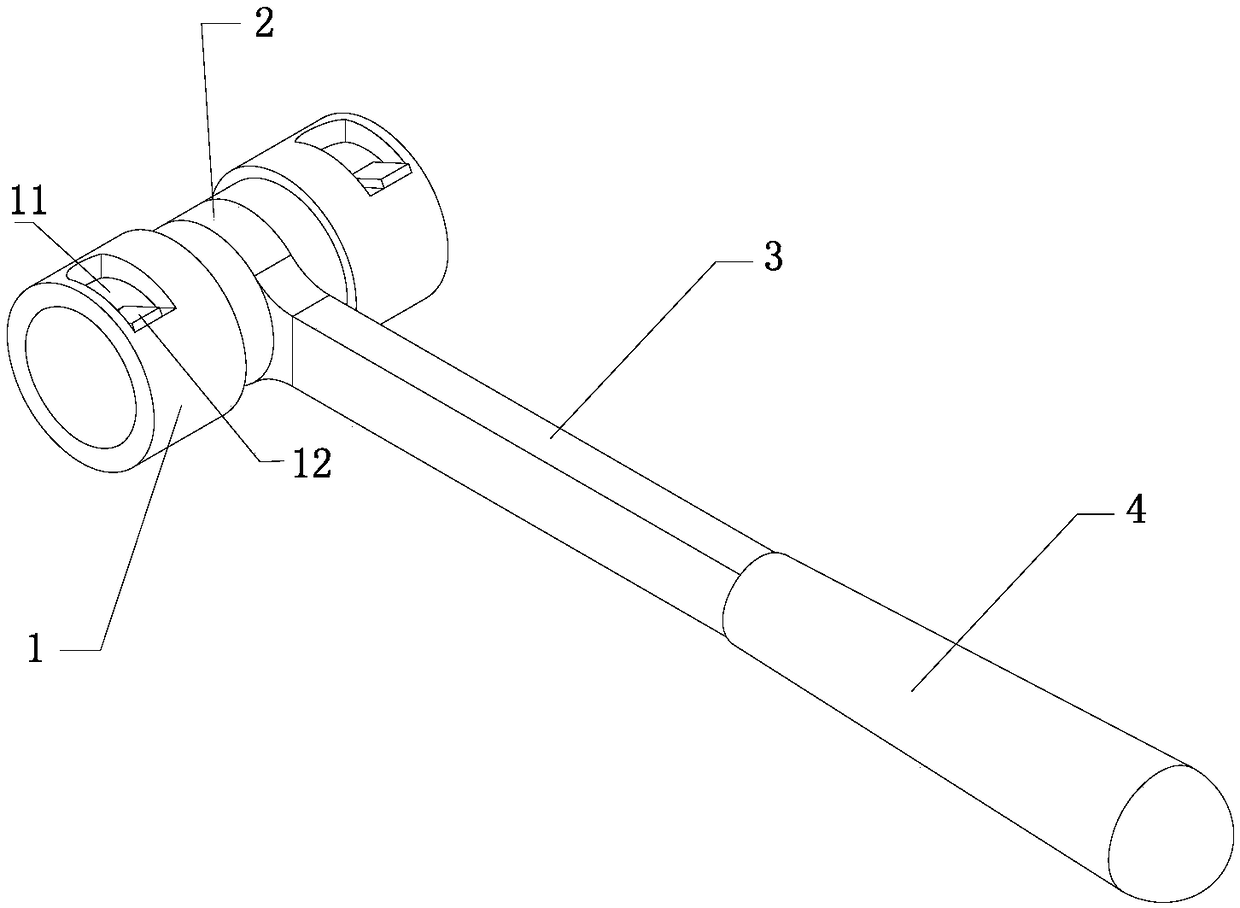

Sleeve insulating lead quick wire stripper

ActiveCN108493847AReduced peel strengthReduce development costsApparatus for removing/armouring cablesEngineeringElectrical and Electronics engineering

The invention provides a sleeve insulating lead quick wire stripper. Two sleeve stripping heads are respectively arranged on the two ends of a connecting mother sleeve along the length direction and form detachable connection with the connecting mother sleeve. Each sleeve stripping head is provided with a cavity along its length direction. The ends away from each other of the two cavities are openends. The side walls of the cavities are provided with openings enabling the cavities and the outside to be communicated. An inclined internal wall is connected on one end of each opening along the circumferential direction of the side wall. The inclined internal wall extends along the circumferential direction of the side wall and includes towards the inside of the cavity. The inclined internalwall is provided with a threaded hole on which a blade is fixed. The blades in the two cavities are different in the depth into the cavities. The side wall of the connecting mother sleeve is providedwith a connecting hole extending along its width direction. A connecting rod is connected with the connecting hole. A handheld handle is arranged on one side, which is away from the connecting hole, of the connecting rod. According to the wire stripper, the insulating layer of the lead can be stripped and the insulating layers of different thickness in the leads of the unified specification can bestripped.

Owner:XIAMEN ELECTRIC POWER SUPPLY COMPANY OF STATE GRID FUJIAN ELECTRIC POWER +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com