Automatic clamp for mobile phone cover glass

A technology for cover glass and plate glass, which is used in measuring devices, instruments, grinding workpiece supports, etc., which can solve the problem of inability to meet the needs of rapid, batch, and finishing production, high processing error rate, and unguaranteed product quality, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with specific embodiments.

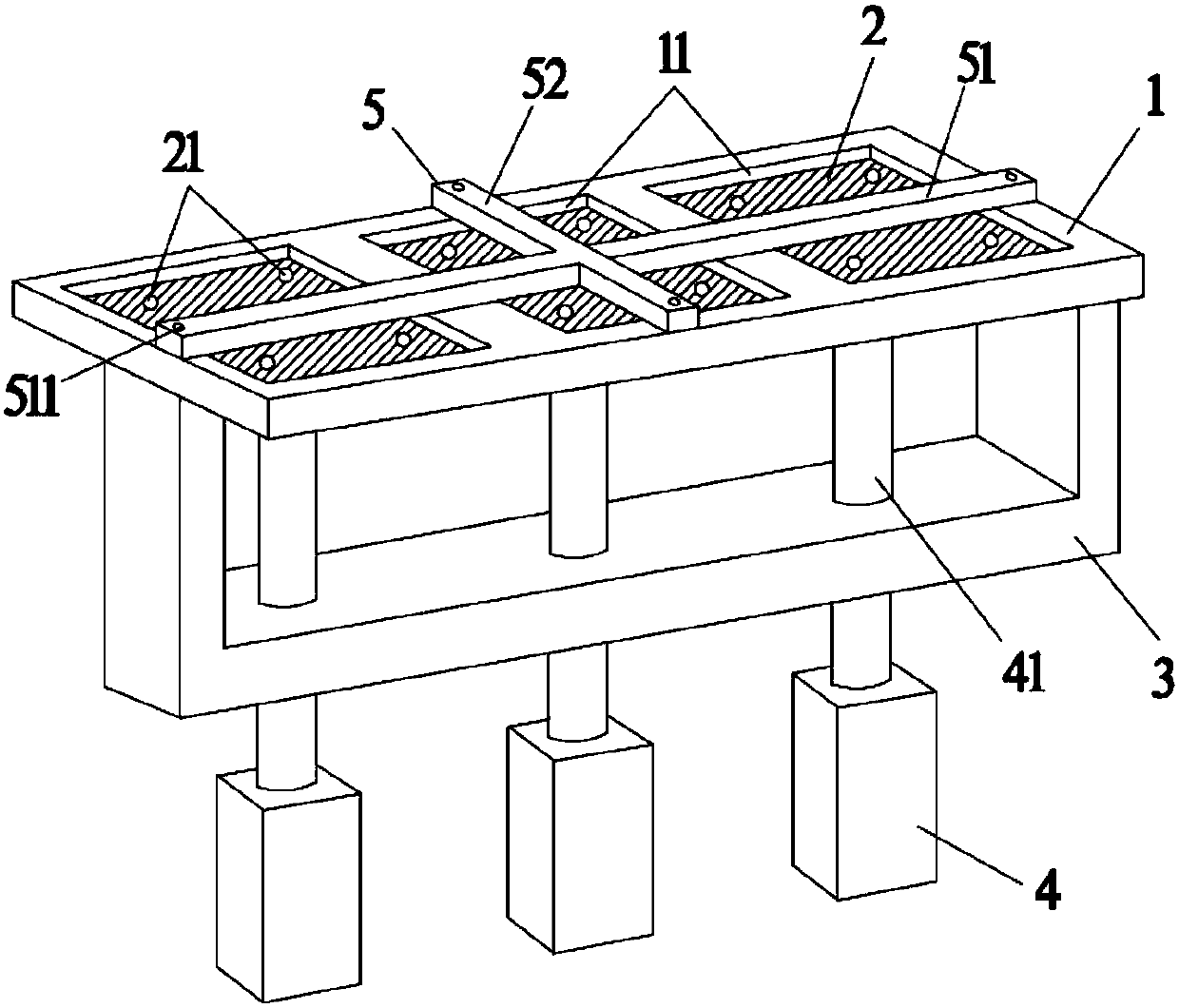

[0023] Automatic fixture for mobile phone cover glass, such as figure 1 As shown, it includes an operating platform 1, a bracket 3 fixed on the operating platform 1, and three sets of cylinders 4 fixed on the bracket 3. The operating platform 1 is provided with three station slots 11 for processing or testing the cover glass. Each station slot 11 is provided with an operation panel 2 that can move up and down, and the cylinder shaft 41 of each cylinder 4 passes through the bracket 3 and is fixedly connected with the bottom of the corresponding operation panel 2 . The operation panel 2 matches the shape of the cover glass. If the cover glass is a planar structure, the surface of the operation panel 2 is planar. If the cover glass is 3D glass, the surface of the operation panel 2 is arc-shaped, and the radian is consistent with that of the 3D glass, so that the cover glass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com