Pipe inner cavity pressure detector of evaporator

A technology for evaporator tubes and detection devices, which is applied in the direction of measuring the rate of increase and deceleration of fluids, and using liquid/vacuum degrees to measure liquid tightness, etc., which can solve the problems of insufficient sealing performance, many operating procedures, and large manufacturing investment. and other problems, to achieve the effect of saving tooling manufacturing investment, easy manufacturing, and quick operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

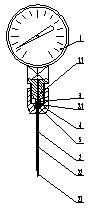

[0014] The evaporator tube lumen pressure detection device shown in the accompanying drawings includes a pressure gauge 1, a gasket 3, a needle 2, a gasket 5, a sleeve 4, and a cap 6 that is sealed and connected to the mouth of the evaporator lumen pipeline 7 , the cap 6 is a rubber part, which forms a closed space with the evaporator pipeline 7; the needle 2 is composed of a needle pin 2.1, a needle tube 2.2 fixedly connected to the front end of the pin pin 2.1, and a needle tip 2.3; the sealing gasket 3, needle 2. The gasket 5 is installed between the joint 1.1 of the pressure gauge 1 and the end face of the inner hole of the sleeve 4, and the sleeve 4 is threaded with the joint 1.1 of the pressure gauge 1 to realize the sealing between the needle 2 and the joint 1.1 of the pressure gauge 1 and the sleeve 4. Sealed connection; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com