Patents

Literature

40results about How to "Judgment of tightness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

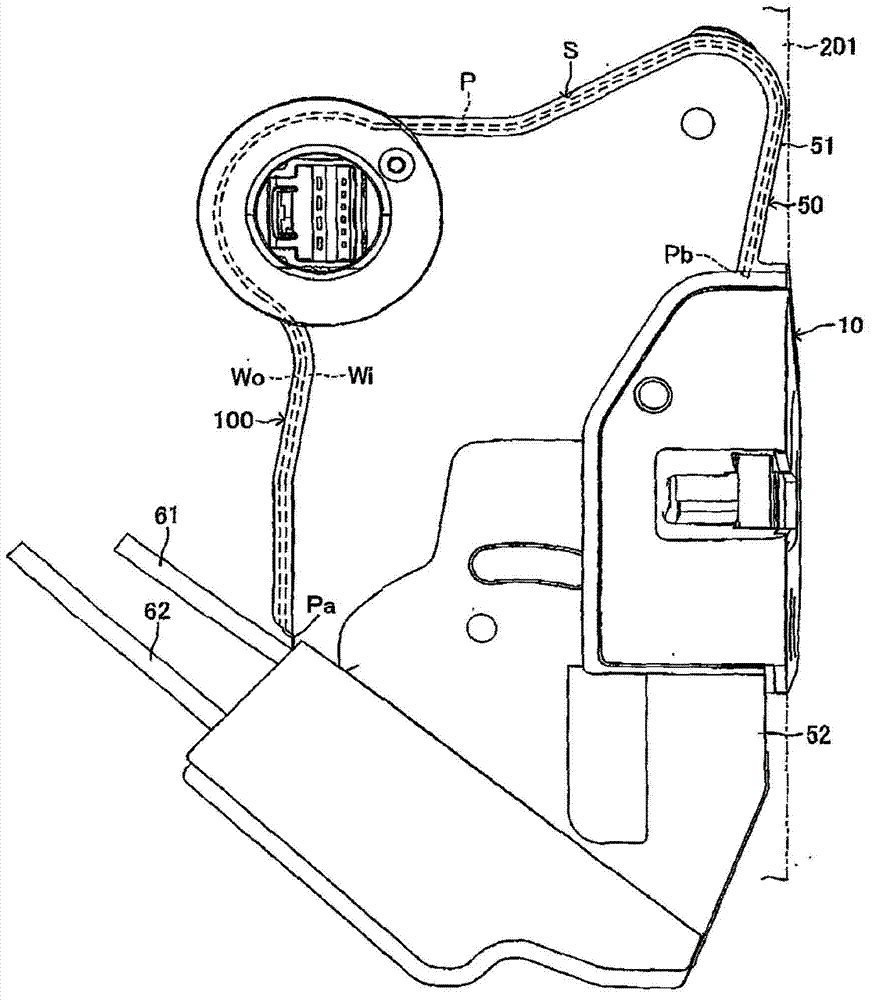

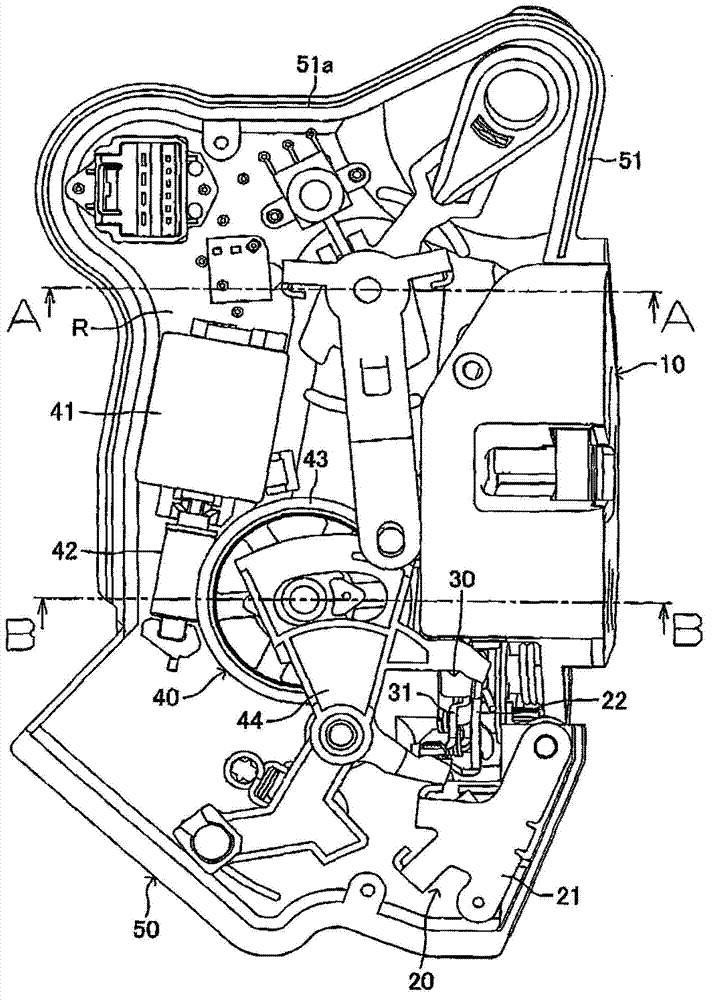

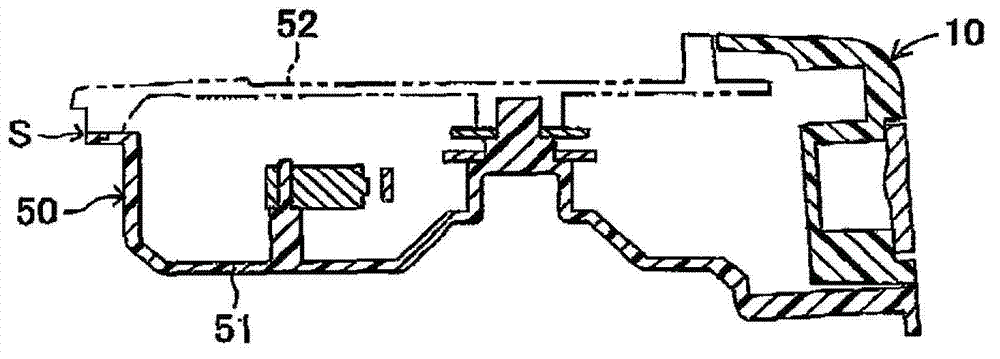

Vehicle door lock device

InactiveCN102822434AProtected from floodingSimple and cheapElectrical locking actuatorsFastening meansEngineeringActuator

The disclosed vehicle door lock device is equipped with a latch mechanism, a lever mechanism, a link mechanism and an electric actuator, which are assembled in a housing. The housing is provided with a housing body and a housing cover that are interconnected, and is arranged such that the connection surface extends vertically. A seal is formed at the connection between the housing body and the housing cover in a manner such that the seal surrounds the upper part of the housing space where the link mechanism and the electric actuator are accommodated. The seal is provided with a path, which has one open end, and inner and outer welded sections, which are contiguously formed along the passage on the inner side and the outer side of the housing. Thus, water-proofing measures (the seal) for the electric actuator (electrical part) are simply and inexpensively configured and it is easy to the condition of the seal.

Owner:AISIN SEIKI KK

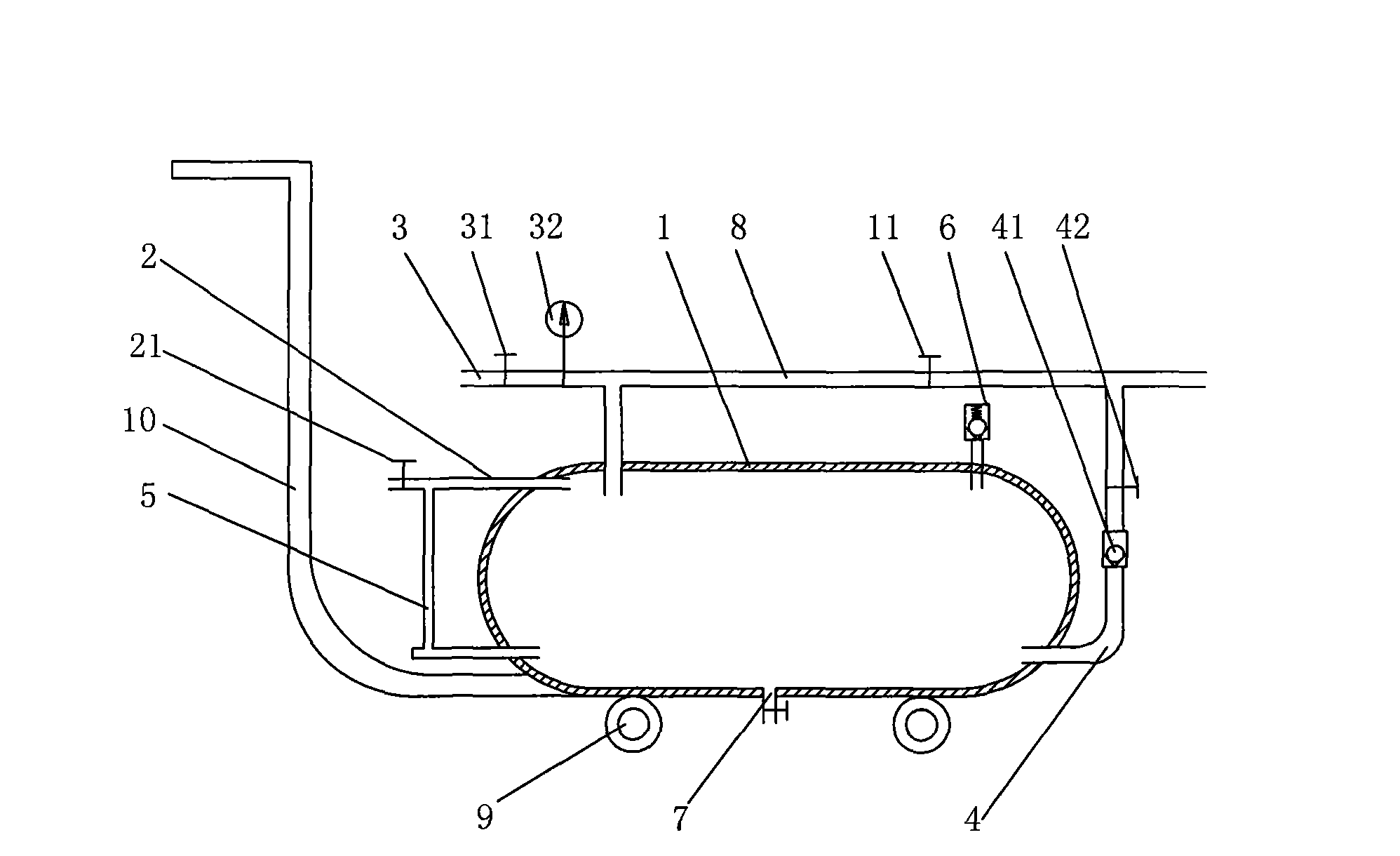

Device for detecting mould impermeability

InactiveCN101514936AAvoid the disadvantage of burstingImprove efficiencyMeasurement of fluid loss/gain rateWater sourceEngineering

The invention discloses a device for detecting mould impermeability, belonging to the technical field of mould. The device comprises a tank body which is communicated with a water inlet pipe, an air inlet pipe and a water and air outlet pipe. The water inlet pipe is connected with a water source. The water and air outlet pipe is connected with the mould. The air inlet pipe is connected with an air source. The device drives water into the mould by compressed air, thereby overcoming the disadvantage that the drive pressure of a water pump is too high as well as the disadvantage of the low efficiency of manual pressurizing.

Owner:QINGDAO HISENSE MOLD

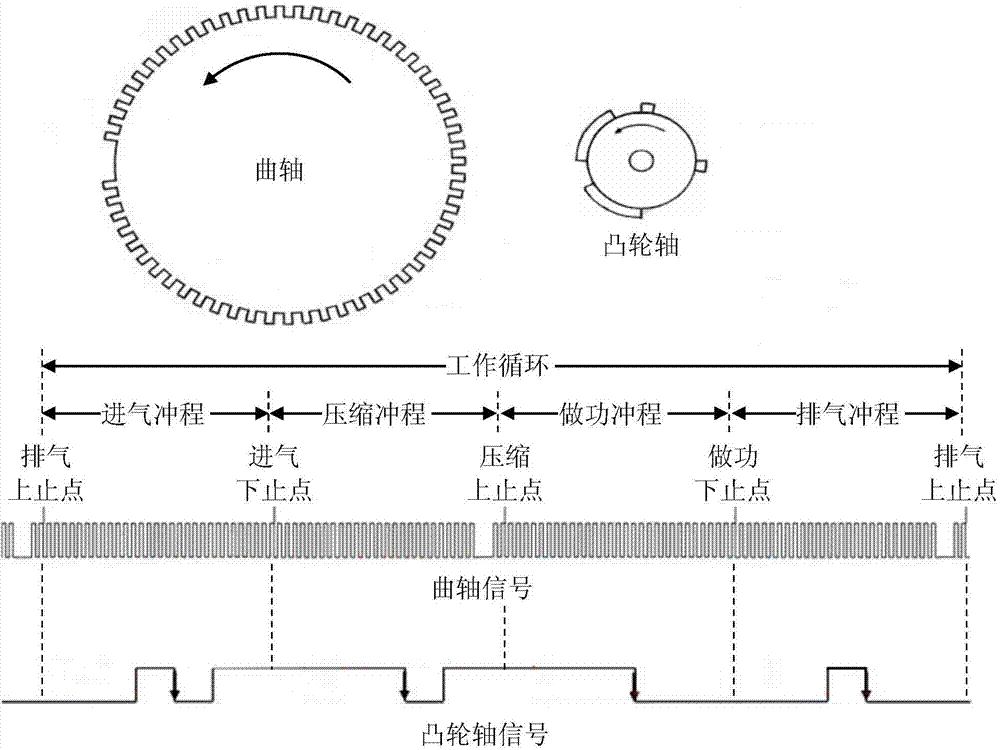

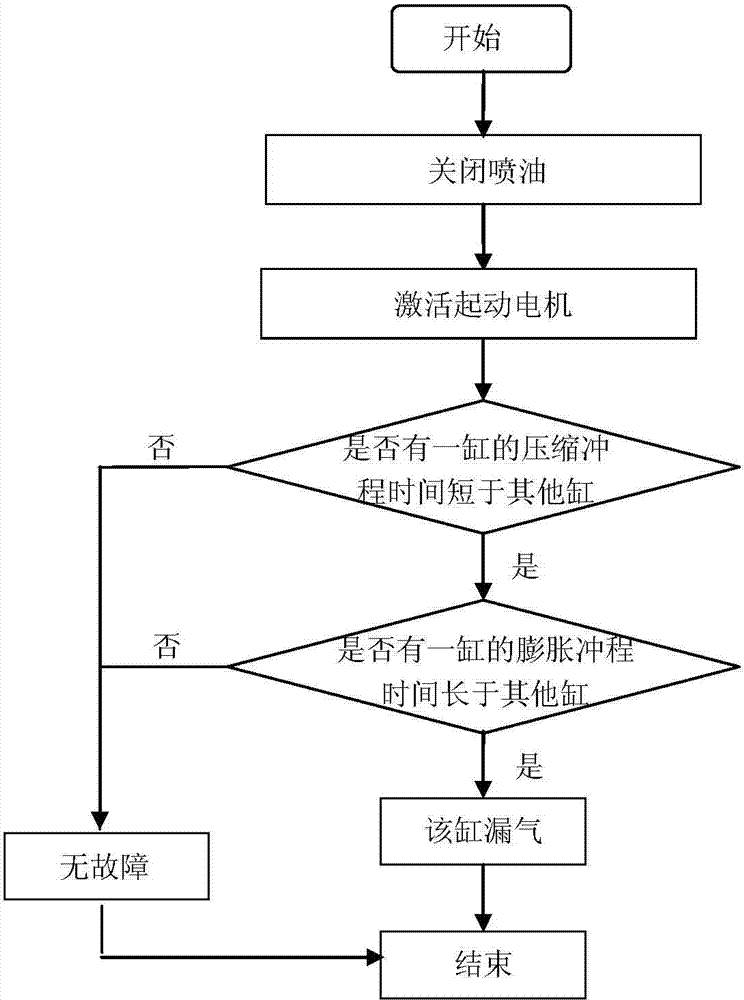

Gas leakage detection method for engine cylinder

InactiveCN103542983AShorten maintenance timeAvoid replacing normal componentsFluid-tightness measurement using fluid/vacuumAutomotive engineeringTroubleshooting

The invention discloses a gas leakage detection method for an engine cylinder. On the condition of no oil being sprayed to the engine, a motor is used to drive the engine to operate. If the compression stroke time of one or a plurality of cylinders of the engine is smaller than that of other cylinders and the power stroke time of the one or the plurality of the cylinders is larger than that of the other cylinders, determining the gas of the one or the plurality of the cylinders is leaked; if not, determining all the cylinders are complete in gas tightness. By the aid of the method, tightness of each cylinder of the engine can be determined rapidly, simply and accurately, the method can be applied in troubleshooting of vehicles, and repairing time can be reduced; normal components can be protected from being changed mistakenly, and repairing cost can be reduced.

Owner:UNITED AUTOMOTIVE ELECTRONICS SYST

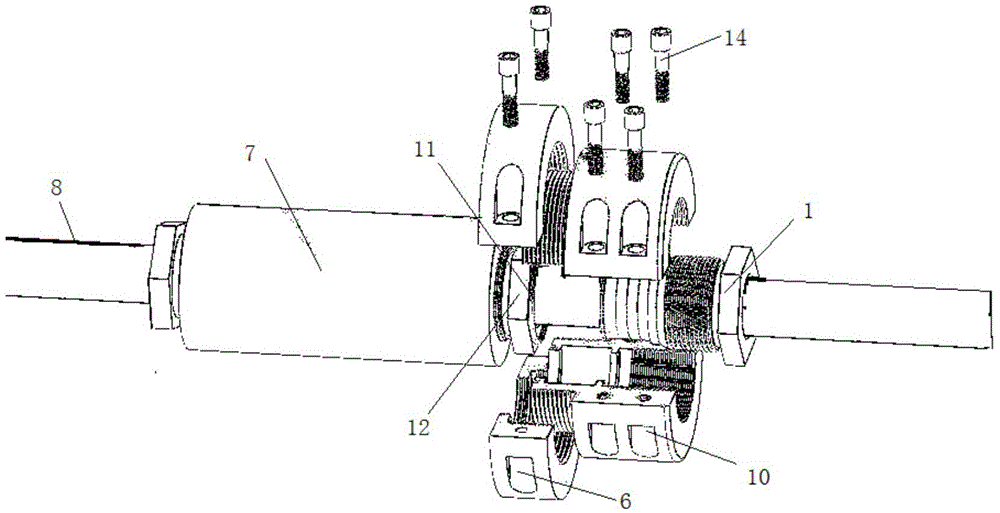

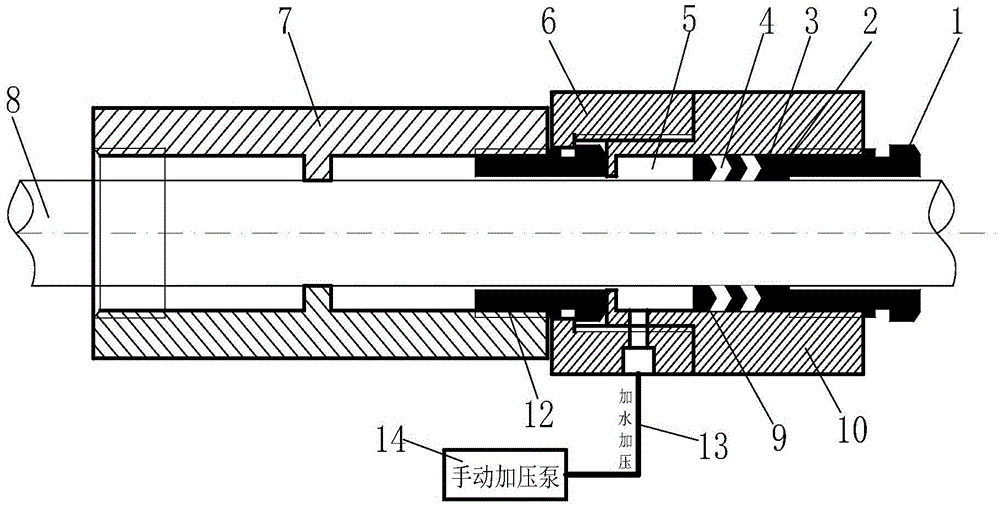

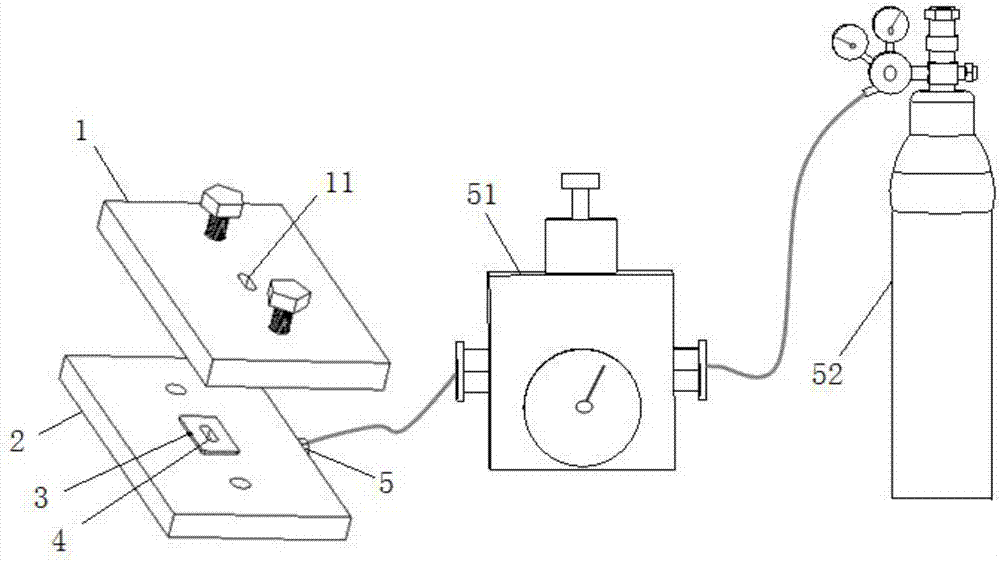

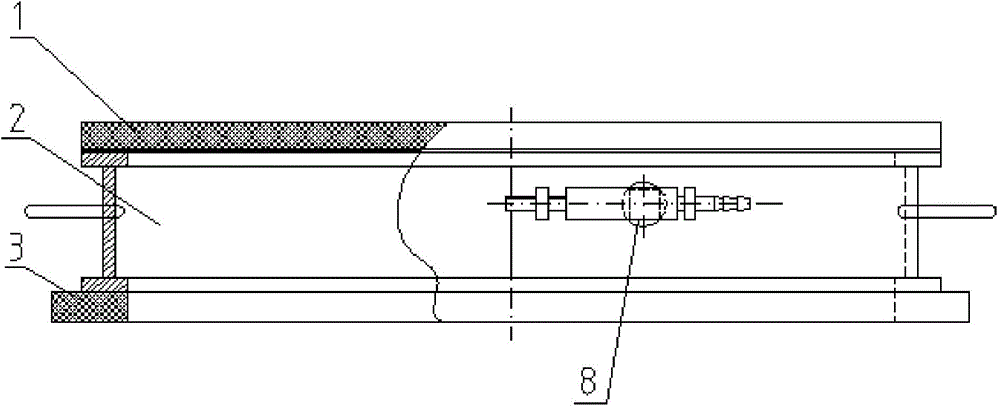

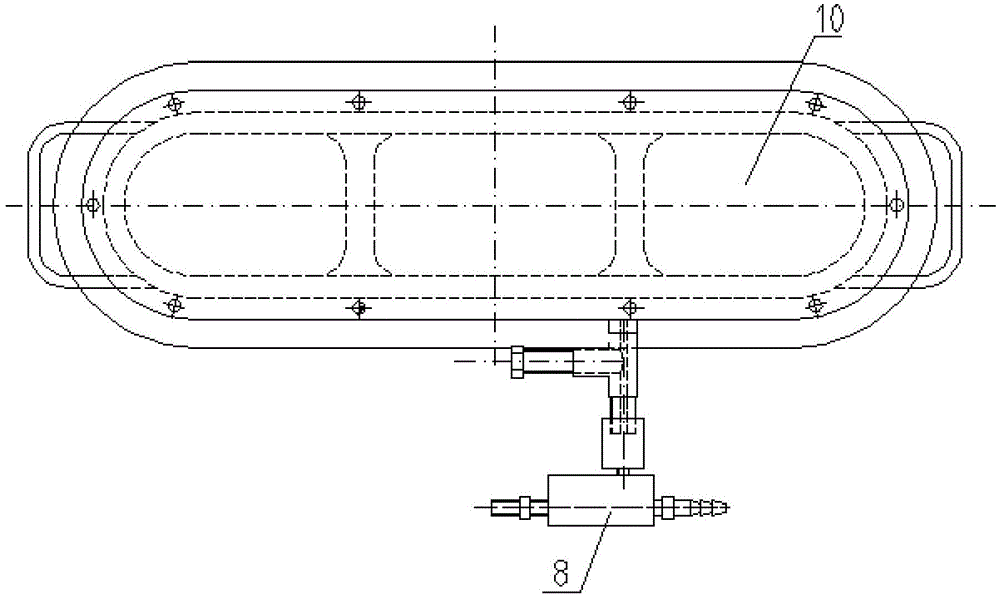

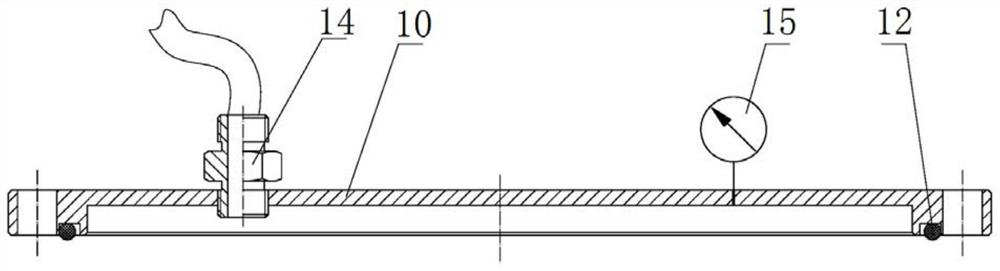

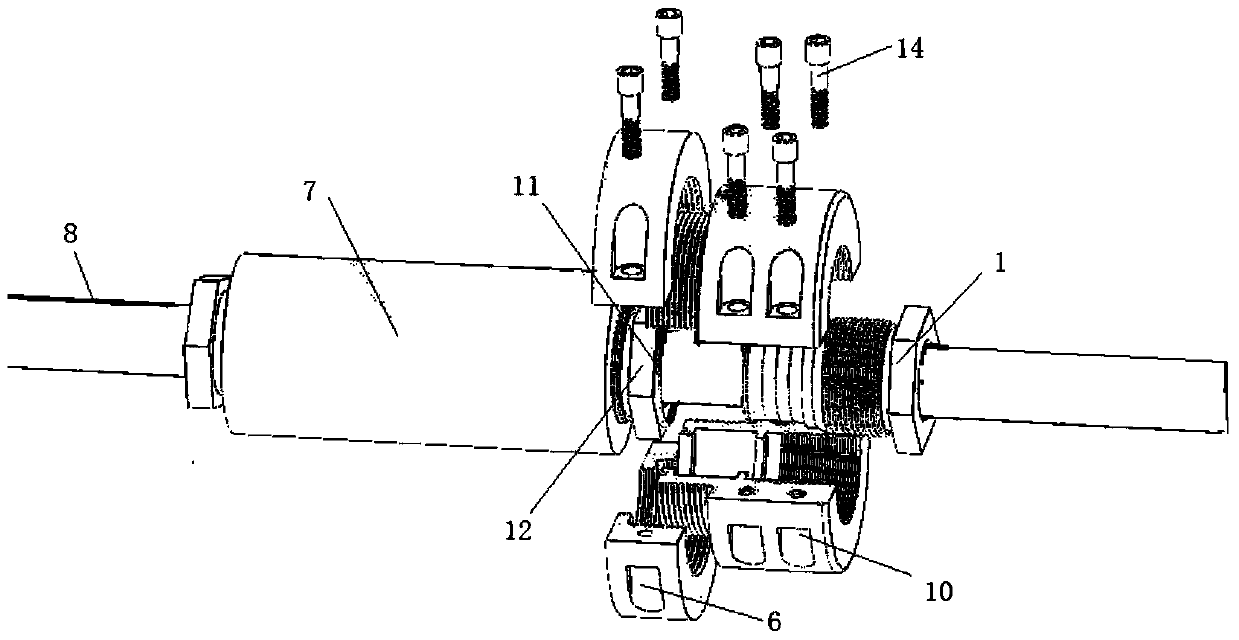

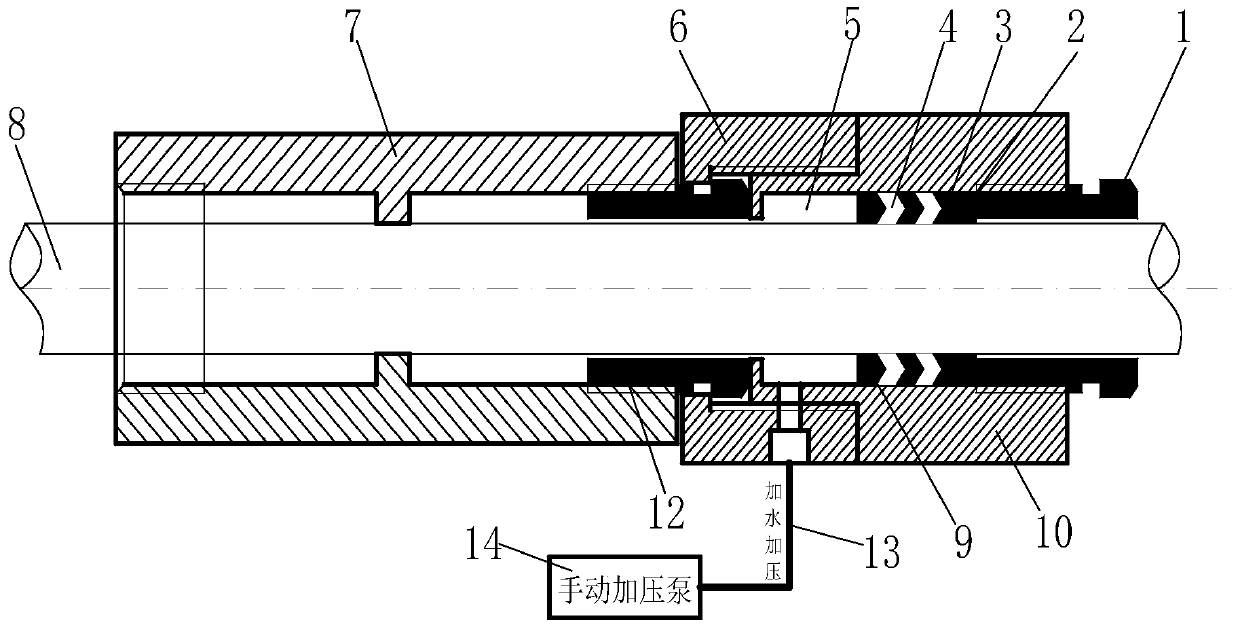

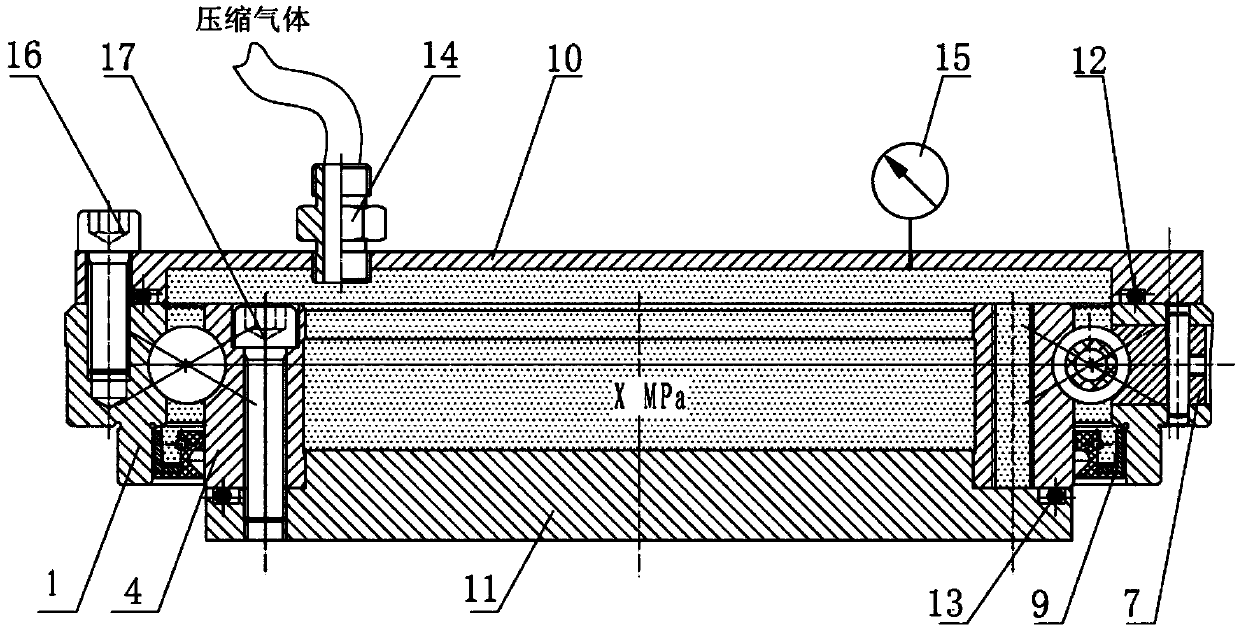

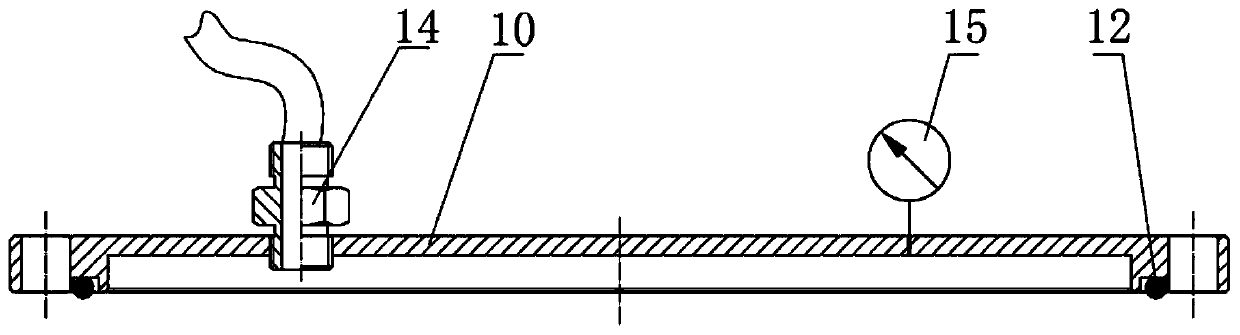

Sealing detection device of cable gland

ActiveCN105466651AJudgment of tightnessMeasurement of fluid loss/gain rateCable glandPetroleum engineering

The invention provides a sealing detection device of a cable gland, and the device comprises a manual pressurization pump, a water injection pipe, a first cup-shaped pipe joint nut, a second cup-shaped pipe joint nut as well as a first rear baffle ring, a combined sealing ring and a second rear baffle ring which are located between the first cup-shaped pipe joint nut and the second cup-shaped pipe joint nut, wherein the left end of the first cup-shaped pipe joint nut is connected to the first rear baffle ring and compresses the combined sealing ring; the left end of the combined sealing ring is connected to the second rear baffle ring; the first cup-shaped pipe joint nut, the first rear baffle ring, the combined sealing ring, the second rear baffle ring and the second cup-shaped pipe joint nut wrap a cable inside; a front clamping buckle and a rear clamping buckle which are connected through buckling and threaded connection sleeve the outer layer; a sealed water injection cabin is formed between a sleeve and the cable, and the sleeve is formed by the front clamping buckle and the rear clamping buckle; and the manual pressurization pump communicates with the water inject cabin by the water injection pipe. The device provided by the invention can simulate cable gland states under different depth conditions, can detect sealing performance of a sealing material of the cable gland and has the advantages of high control precision, small and compact appearance and convenient operation.

Owner:NAVAL UNIV OF ENG PLA

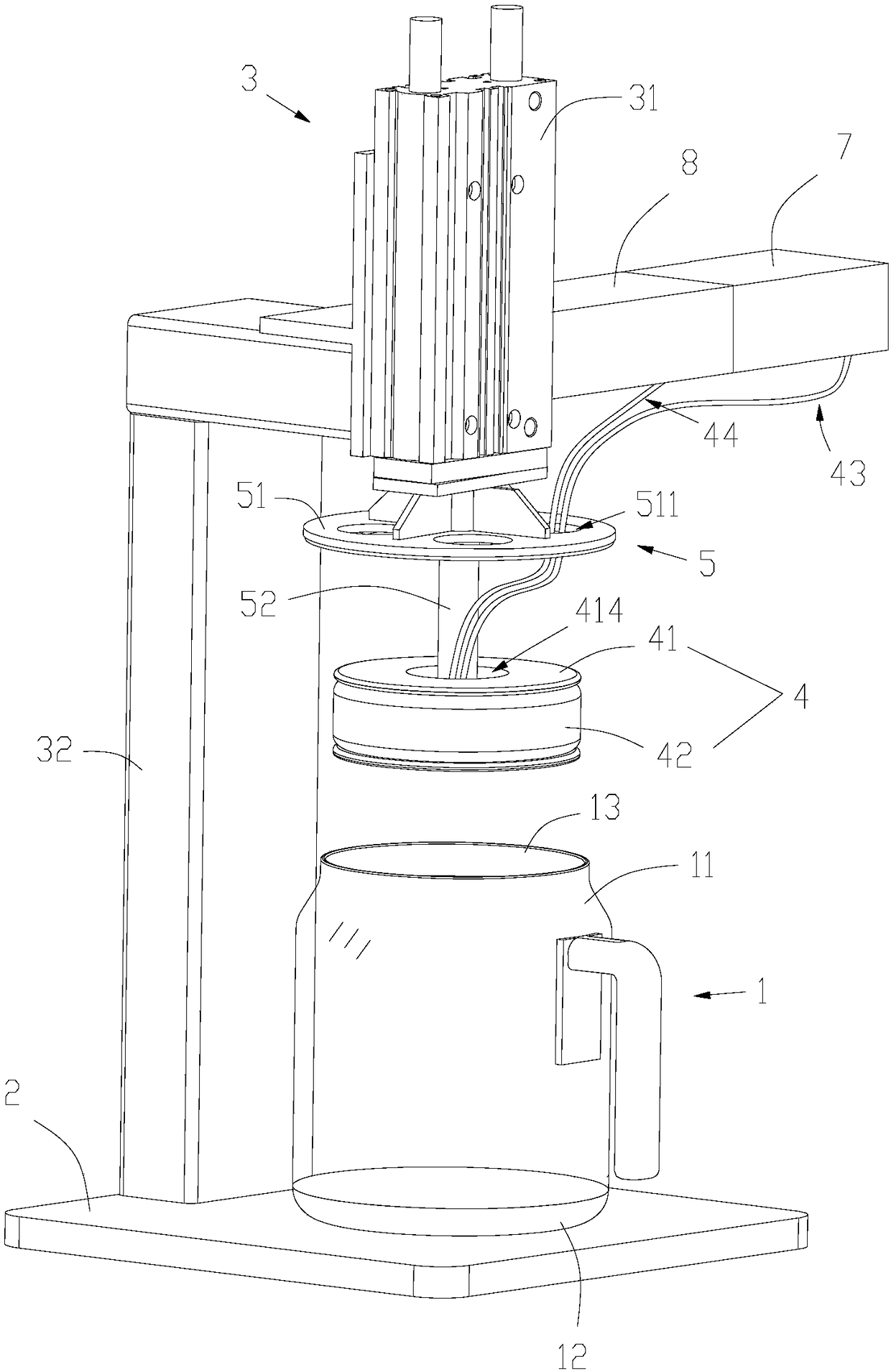

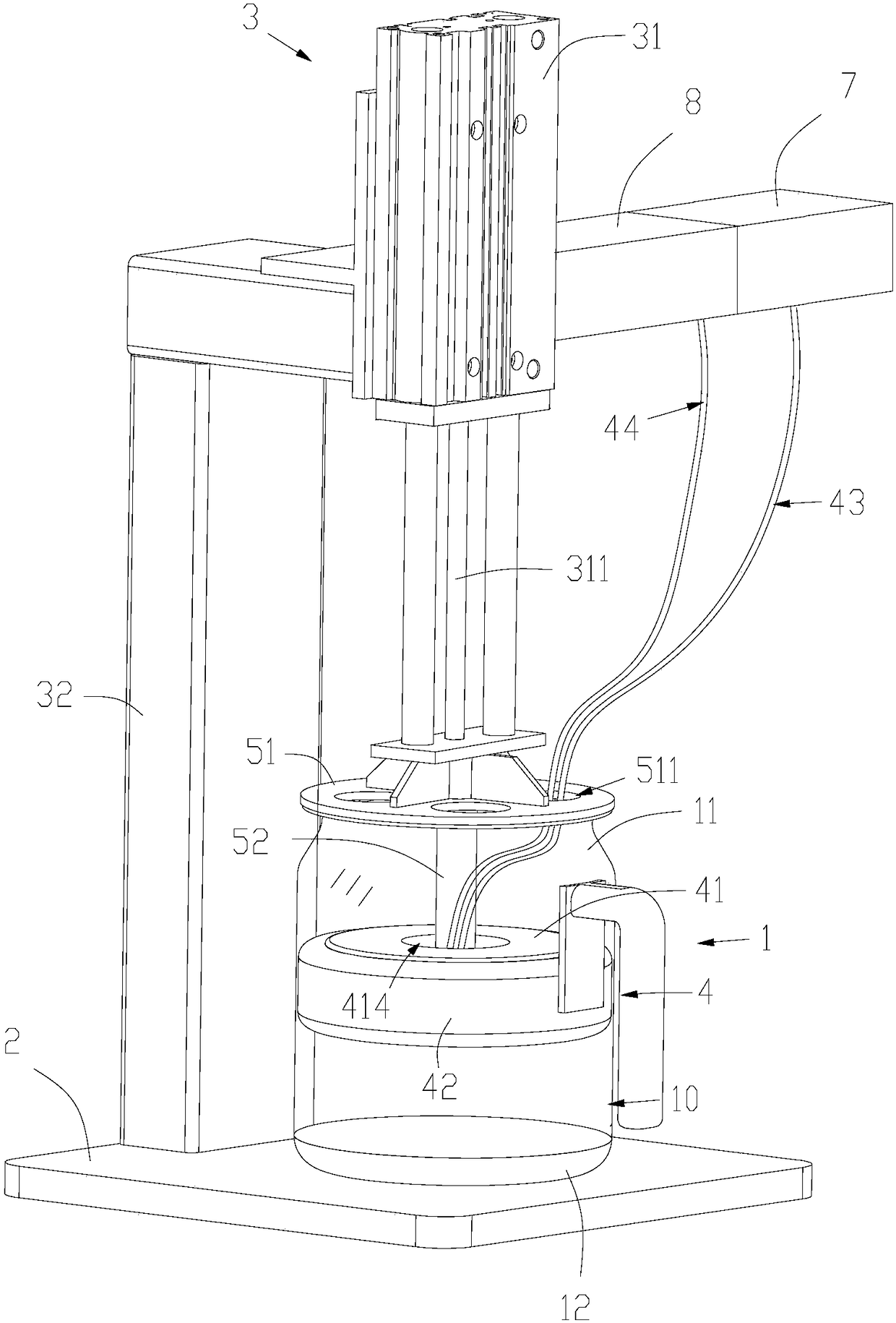

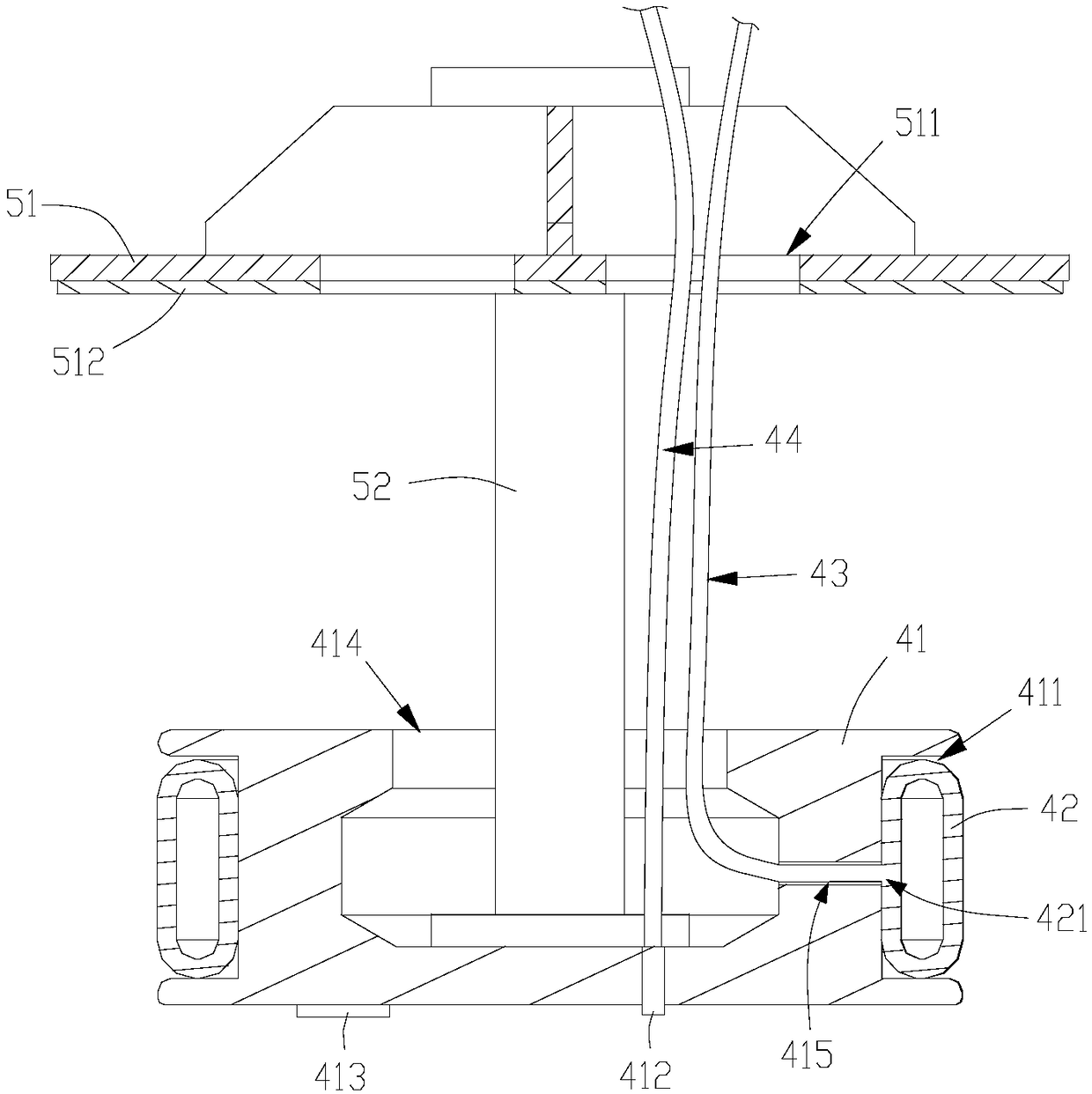

Kettle tightness detection device and detection method employing same

PendingCN108593226AImprove versatilityReduce wearMeasurement of fluid loss/gain rateEngineeringAtmospheric pressure

The invention relates to the technical field of tightness detection equipment, in particular to a kettle tightness detection device and a detection method employing the same. The kettle tightness detection device comprises a driving component and a detection component; the driving component drives the detection component to move up and down selectively so as to move into or leave an inner cavity of a kettle under detection placed below the detection component; the detection component comprises a support and an airbag in ring shape; the airbag surrounds the lateral side of the support; after being inflated, the airbag may attach to the inner wall of a kettle body; the bottom of the support is provided with a suction port and a vacuum sensor; the airbag is provided with an inflating port; the inflating port is connected with an air source through a first guide pipe; the suction port is connected with a vacuumizing device through a second guide pipe; during detection, the airbag moves down to the inner cavity of the kettle and expands and attaches to the inner wall of the kettle; air between the detection component and the bottom of the kettle is abstracted to increase the pressure toa threshold; tightness of the kettle is judged by detecting changes in the pressure. The detection component is tightly fitted to the kettle, the detection results are precise and reliable, and the kettle tightness detection device is good in practicality and universality.

Owner:BEAR ELECTRICAL APPLIANCE CO LTD

Plastic bottle negative pressure detecting device

ActiveCN103557997AJudgment of tightnessDetection of fluid at leakage pointDifferential pressureTest sample

The invention relates to a plastic bottle negative pressure detecting device which comprises a base, a cavity, a water container, a fixing unit and a pneumatic device. An air inlet hole is formed in the base, the cavity is formed in the base, a pressure applying cavity is formed by the cavity and the base, the air inlet hole is communicated with the pressure applying cavity, the water container is arranged above the cavity, the fixing unit is arranged between the cavity and the water container, and the pneumatic device is communicated with the air inlet hole. According to the plastic bottle negative pressure detecting device, pressure is applied to the exterior of a bottle opening through a negative pressure device, compressed air enters the pressure applying cavity through a reducing valve to apply pressure according to requirements, a tested sample has the internal-external differential pressure, the air overflowing conditions of the tested sample are observed, and the sealing performance of the tested sample is accordingly judged.

Owner:上海紫日包装有限公司

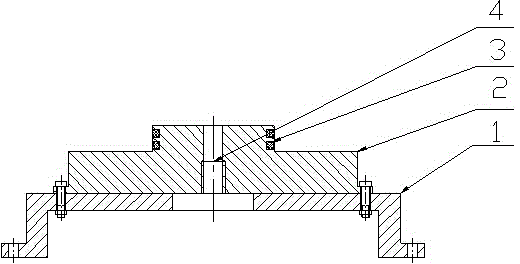

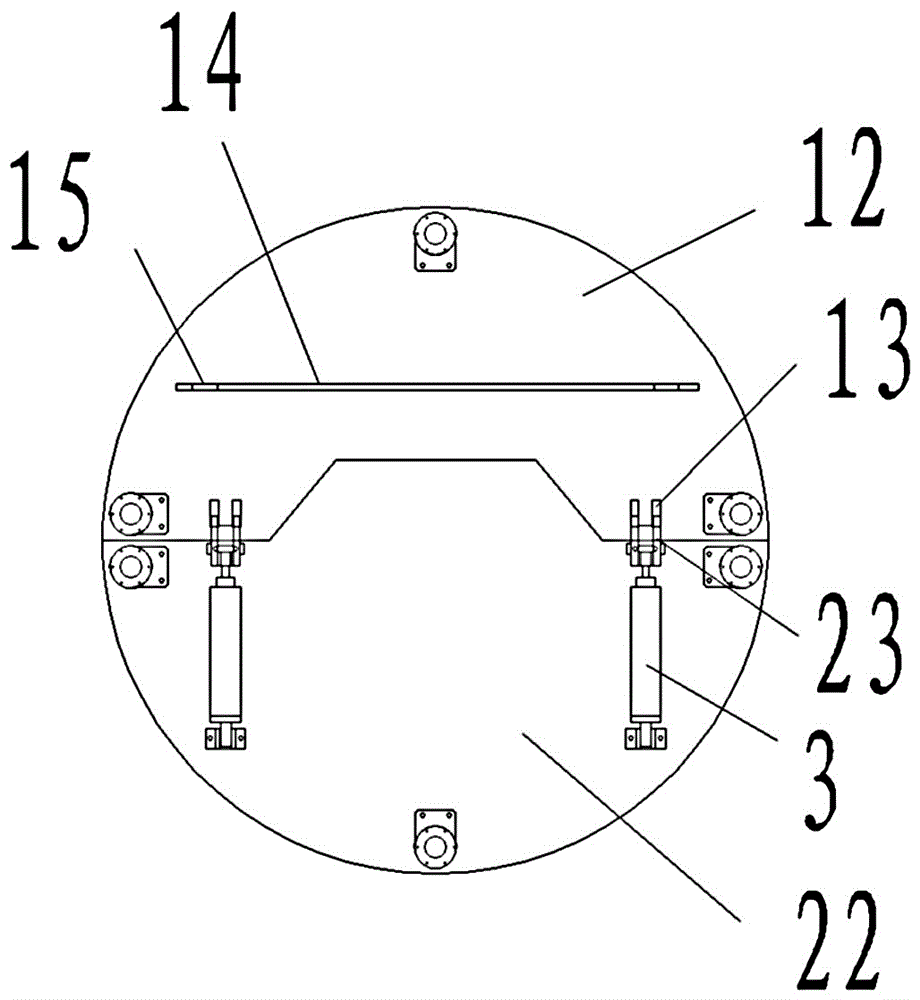

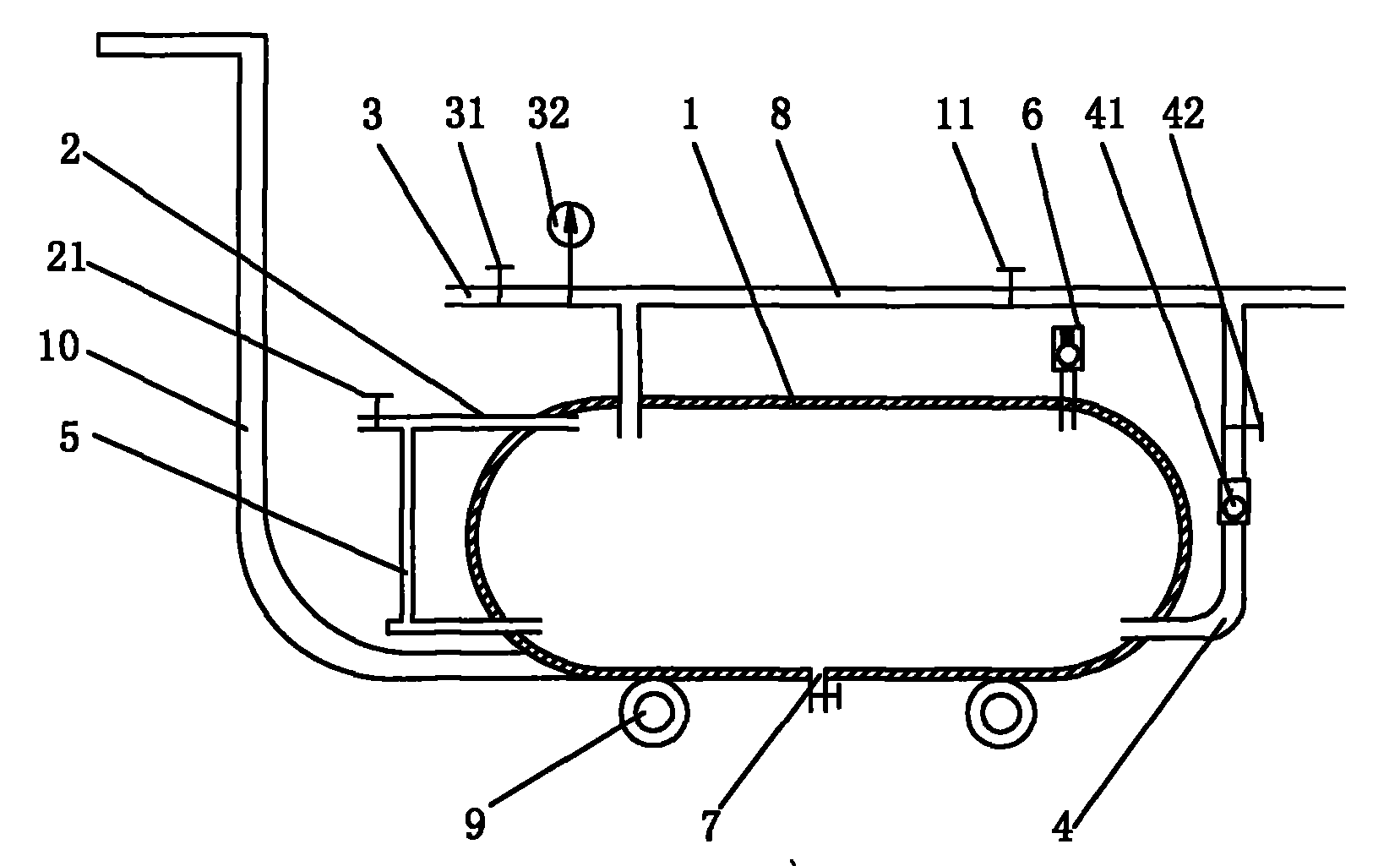

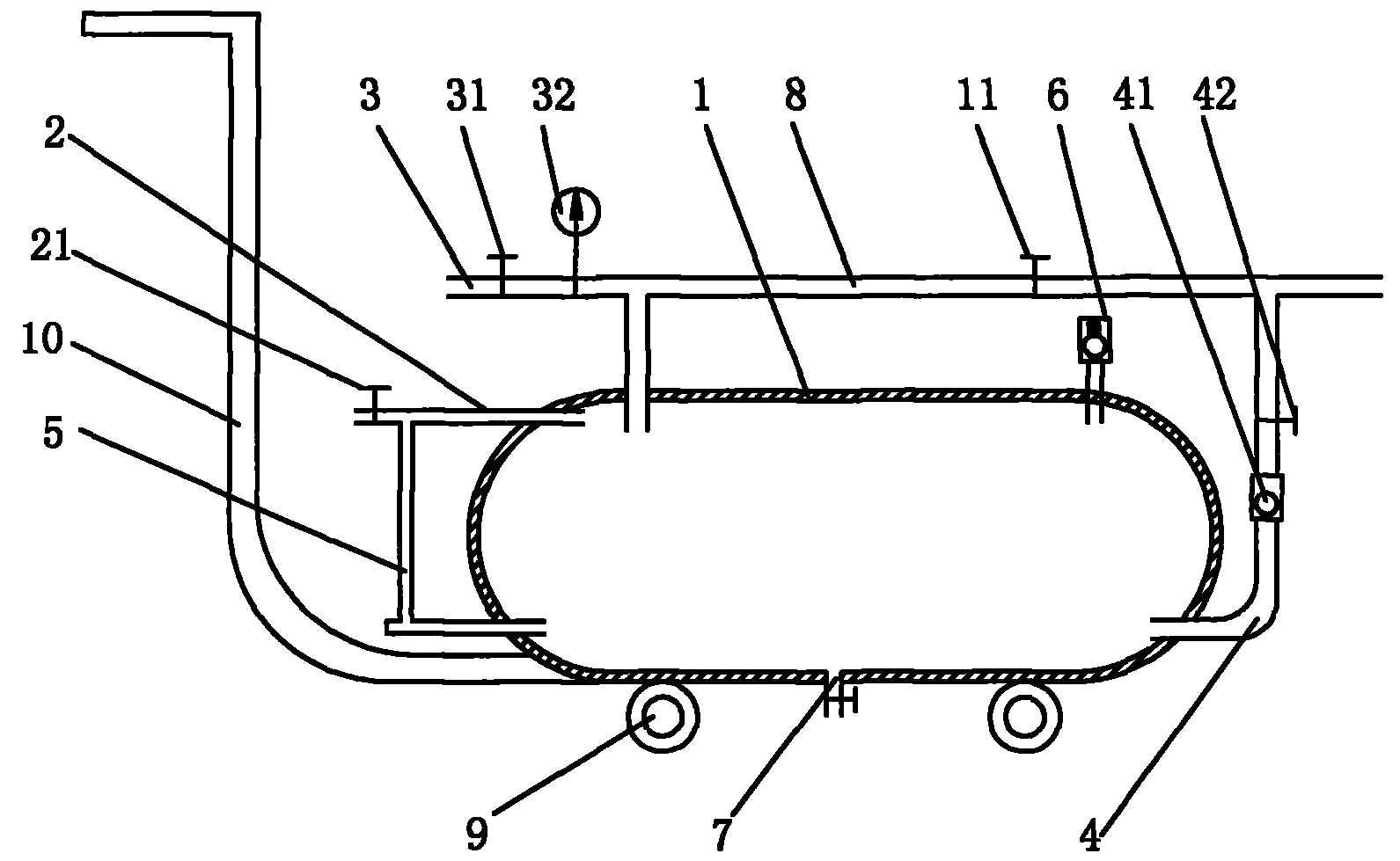

Plastic inspection well leakage test device and detection method

InactiveCN104833463AGuaranteed reliabilityEnsure safetyMeasurement of fluid loss/gain rateSmall footprintLeakage test

The invention relates to a plastic inspection well leakage test device and a detection method, and belongs to the field of product performance detection and tests. The device comprises a machine base, a workbench, a seal ring, a water injection hole, a plastic inspection well, and a locking hoop. The machine base is fixed on a foundation. The workbench is disposed on the machine base. The seal ring is installed on the workbench. The workbench is provided with the water injection hole. The plastic inspection well is installed on the upper part of the workbench through the locking hoop. The middle part of the plastic inspection well is provided with a welding joint. The joint sealing point of the test device uses two-stage sealing and the hoop to lock and seal, so as to preferably ensure reliability of sealing and security of tests. The test device has multiple functions. Compressed air can be used to pressure test water of the test device, and leakage gas flow of the compressed air and decompression speed of pressure maintaining are observed to determine sealing property. The device is simple and reliable, and takes little area. The device is not limited by height of the inspection well, and is simple and convenient in operation, and low in cost.

Owner:KUNMING UNIV OF SCI & TECH +1

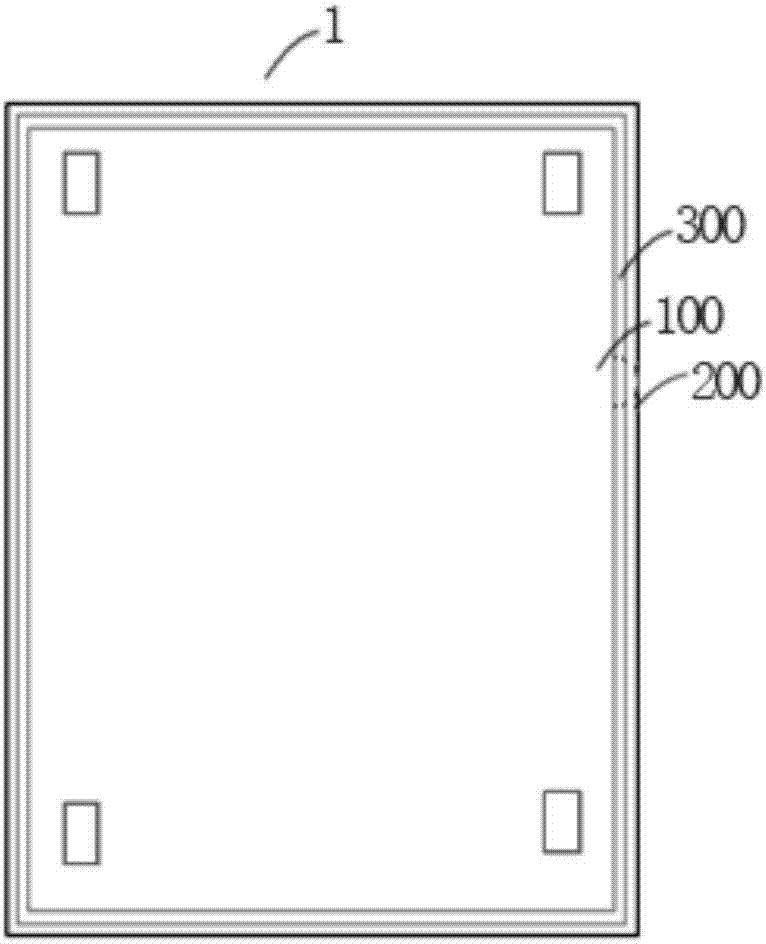

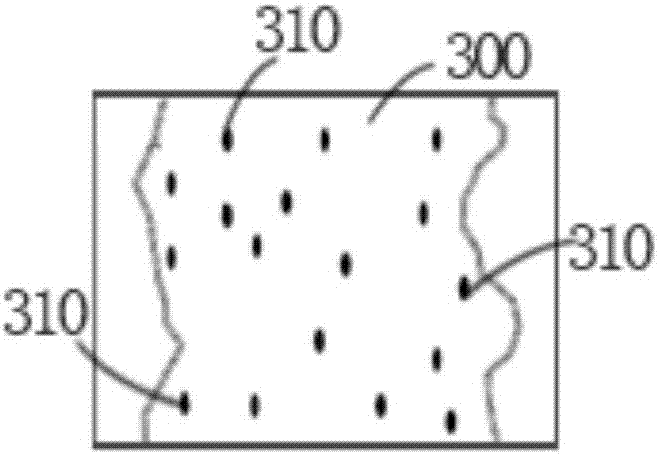

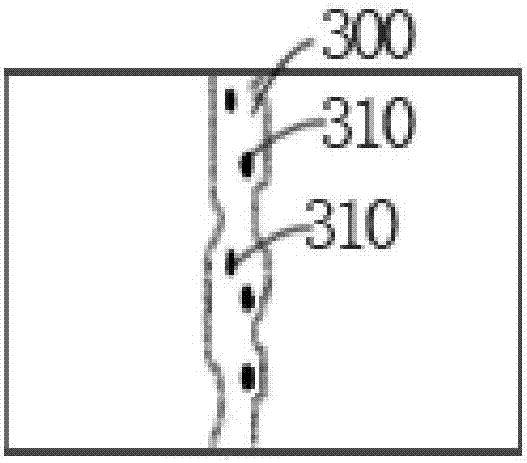

Package structure and airtightness detection method and manufacture method thereof

InactiveCN107331648AReliable detectionHigh degree of automationDetection of fluid at leakage pointSemiconductor/solid-state device testing/measurementDisplay deviceEngineering

The invention discloses a package structure and an airtightness detection method and a manufacture method thereof, a display device and a photovoltaic device. The package structure comprises a substrate and a package cover plate, which are arranged oppositely; and package glue formed between the substrate and the package cover plate and used for connecting the substrate and the package cover plate to form a seal space, wherein the package glue is mixed with a fluorescent agent. The package structure has the advantages of reliable detection and high automation degree and the like.

Owner:BOE TECH GRP CO LTD +1

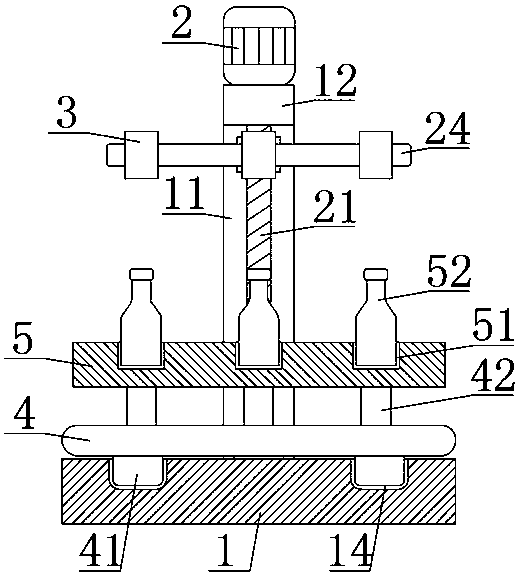

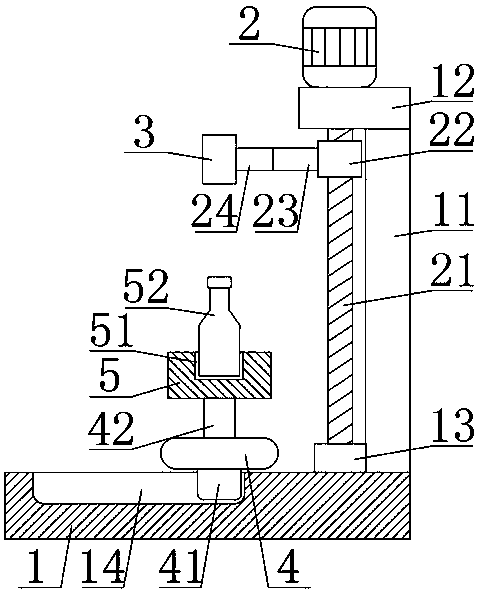

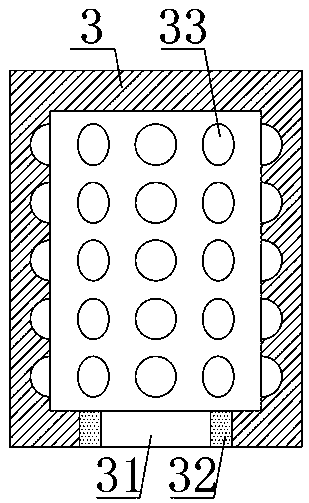

Quick testing device for wine bottle airtightness

PendingCN109443655AJudgment of tightnessIncrease bottling speedDetection of fluid at leakage pointChromium trioxideWine bottle

The invention discloses a quick testing device for wine bottle airtightness. The quick testing device comprises a base, a motor, testing covers, a supporting board and an installing board. One side ofthe upper surface of the base is provided with a vertical column which is fixedly mounted through a bolt. The top of the vertical column is provided with a crossbeam which is fixedly mounted througha bolt. The upper surface of the crossbeam is provided with the motor which is fixedly mounted through a bolt. A lifting screw rod which penetrates through the crossbeam sleeves the output end of themotor. The outer wall of the lifting screw rod is in threaded connection with a nut sleeve. One side of the outer wall of the nut sleeve is provided with a connecting rod which is fixedly mounted through a bolt. One side of a mounting transverse board is provided with the testing covers which are uniformly and fixedly mounted through bolts. The center of bottom of the testing cover is provided with an inserting hole. The inner wall of the testing cover is provided with liquid storing grooves which are uniformly arranged. The quick testing device can determine airtightness of the wine bottle body through color change of low-concentration chromium trioxide solution on the inner wall of the testing covers, thereby facilitating observation and improving wine bottling speed.

Owner:重庆江记酒庄有限公司

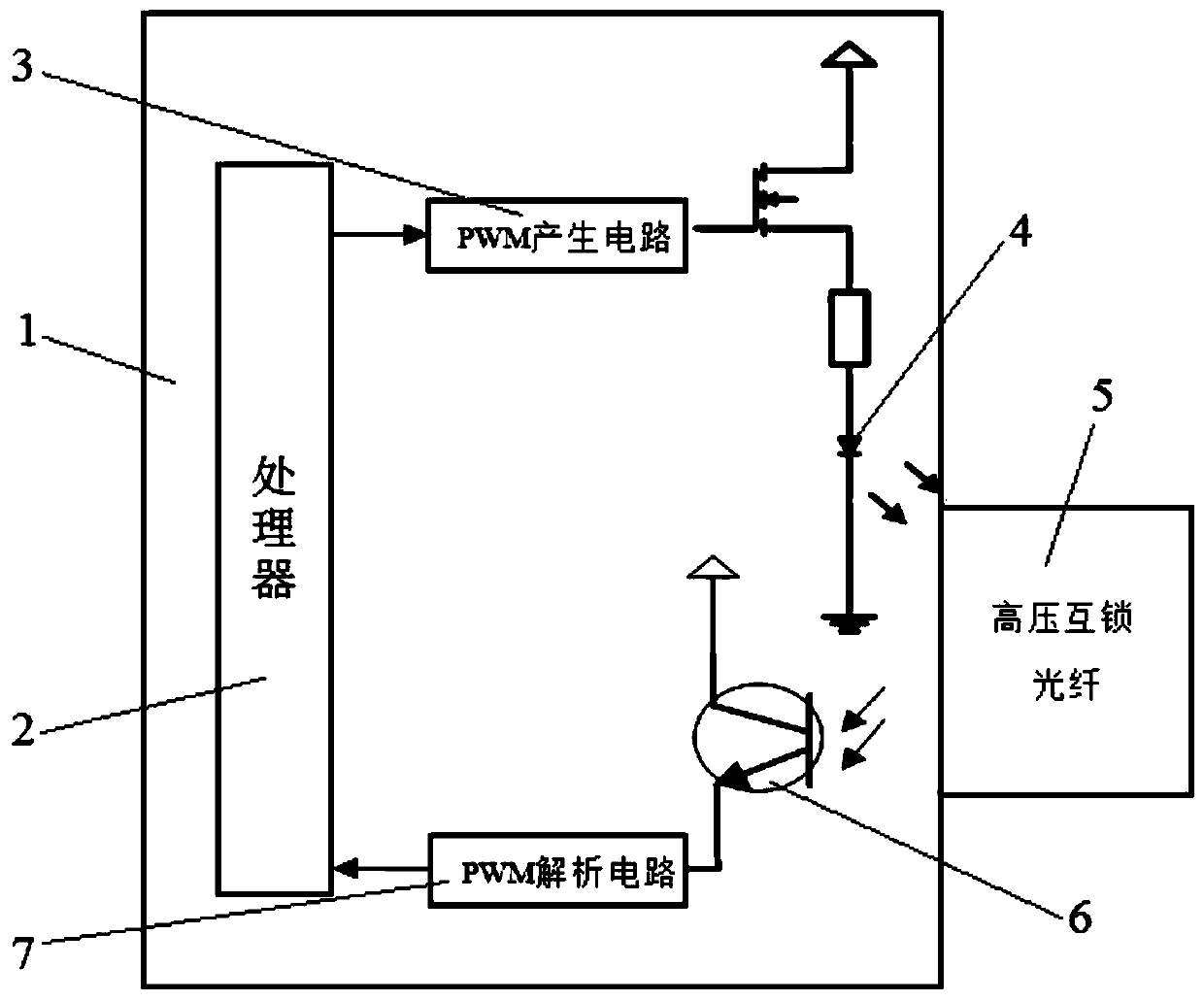

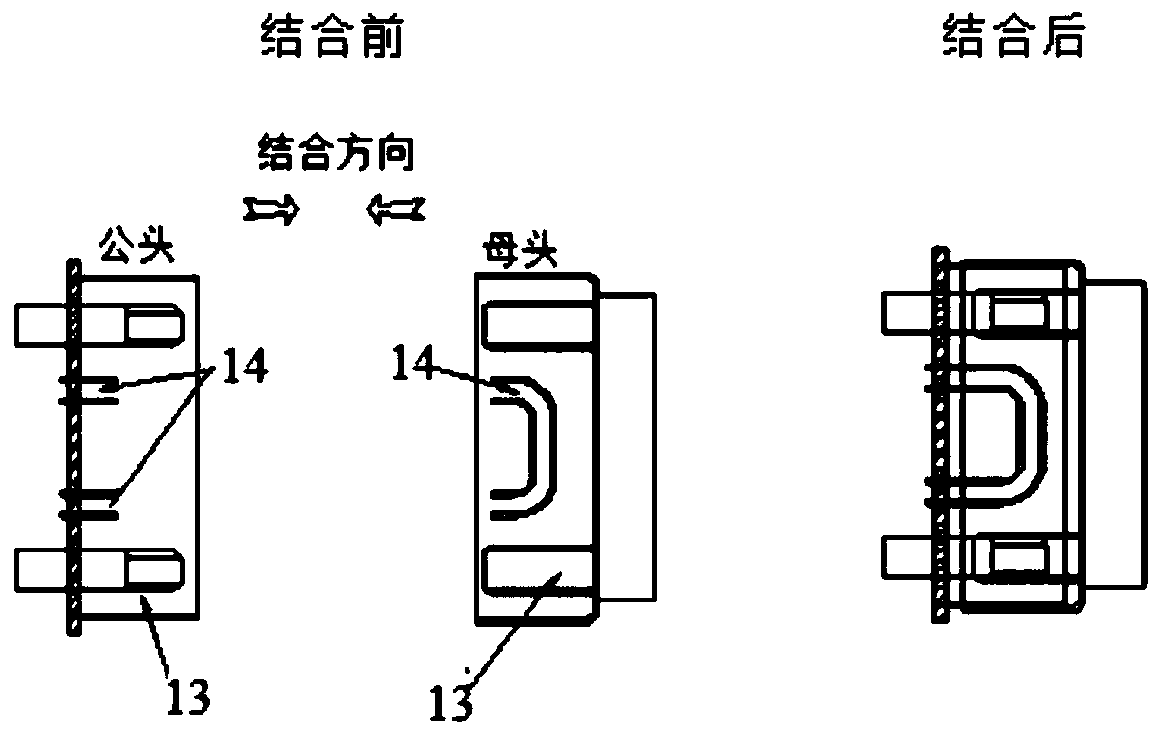

High-voltage interlocking device

InactiveCN109910620ALess susceptible to electromagnetic interferencePrecise processElectric devicesElectrical testingOpto electronicHigh pressure

The invention discloses a high-voltage interlocking device, comprising a high-voltage interlocking signal detection and transmission module (1); in the high-voltage interlocking signal detection and detection module (1), an illumination tube (4) is adopted to convert an electrical signal into an optical signal for transmission, through the transmission of a high voltage interlocking optical fiber(5), a photoelectric converter (6) is adopted to convert the returned optical signal into an electrical signal. With the above technical scheme, the optical signal is more stable, and the transmissionof the optical signal is not easy subjected to electromagnetic interference, and the optical signal is used instead of the electrical signal for interconnection outside the module in a complex environment, and then the electrical signal generated by a photoelectric coupling circuit is adopted inside a detection module for detection, and the process is more accurate; after the photoelectric coupling, the strength of the electrical signal is detected, and the entire circuit sealing level can be judged, thereby judging the sealing performance of an overall system; the simple optical signal can be used as the interlocking signal, and an interlocking signal generation and detection circuit is no longer complicated.

Owner:ZOTYE INT AUTOMOBILE TRADING CO LTD

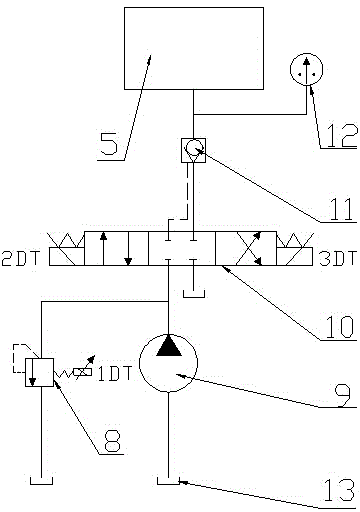

Airtight valve airtightness detection platform

InactiveCN104122052ASimple structureEasy to operateMeasurement of fluid loss/gain rateBall valveEngineering

The invention relates to an airtight valve airtightness detection platform. The airtight valve airtightness detection platform comprises an air compressor, a vacuum pump, a plenum chamber, an airtight valve and a reducer pipe, the reducer pipe is mounted on one side of the plenum chamber, a first ball valve, a second ball valve, a third ball valve and a fourth ball valve are mounted on the other side of the plenum chamber sequentially, the airtight valve is mounted at the end of the reducer pipe, the air compressor is mounted at the end of the first ball valve, the vacuum pump is mounted at the end of the second ball valve, a first pressure sensor is mounted at the end of the third ball valve, and a second pressure sensor is mounted at the end of the fourth ball valve. The airtight valve airtightness detection platform is simple in structure, good in measurement effect and quite high in practicality.

Owner:NANJING NUODESI INTELLIGENT TECH

Device for preventing moisture diffusion inside oil immersed transformer

InactiveCN108735455AJudgment of tightnessJudge the situationTransformers/inductances coolingUnwanted magnetic/electric effect reduction/preventionTransformerMoisture absorption

The present application discloses a device for preventing moisture diffusion inside an oil immersed transformer for absorbing moisture inside the oil immersed transformer, which comprises a moisture absorbing layer and a metal shielding mesh, wherein the moisture absorbing layer is disposed at the bottom of the transformer and located in the transformer, and can absorb the moisture inside the transformer to prevent the moisture from diffusion in a large range to affect the insulation performance inside the transformer; the moisture absorbing layer is made of a moisture-absorbing color-changingmaterial, and the moisture absorption situations of the moisture absorbing layer can be marked out through the color changing degree of the moisture-absorbing color-changing material; when during maintenance, the sealing and wetting situations of the transformer can be judged according to the color changing situations of the moisture-absorbing color-changing material; the metal shielding mesh isarranged on the moisture absorbing layer; and the metal shielding mesh is used for electric shielding. The device for preventing moisture diffusion inside the oil immersed transformer has simple structure and convenience for use, can be mounted in combination with transformer manufacturing, returning to factory for repair, on-site lifting cover inspection and the like, and does not affect the normal operation of the transformer.

Owner:YUNNAN POWER GRID CO LTD ELECTRIC POWER RES INST

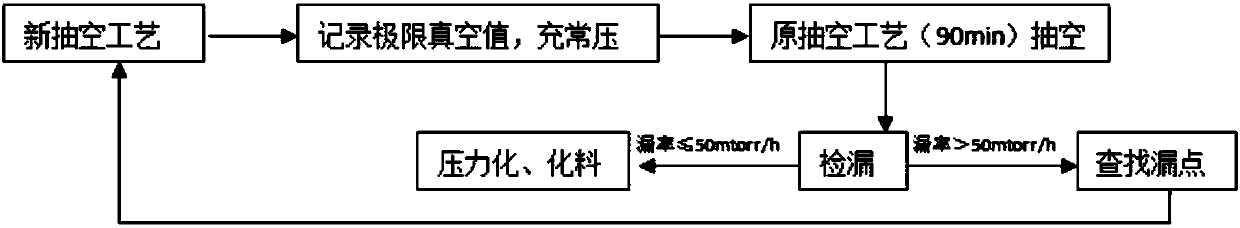

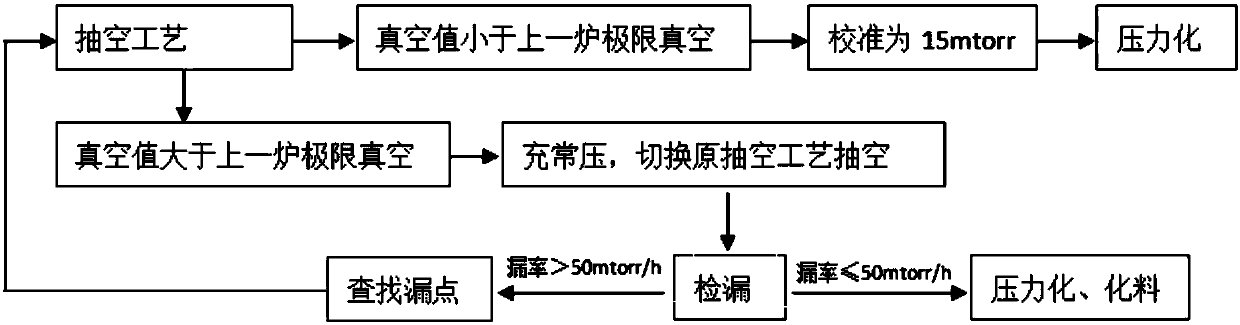

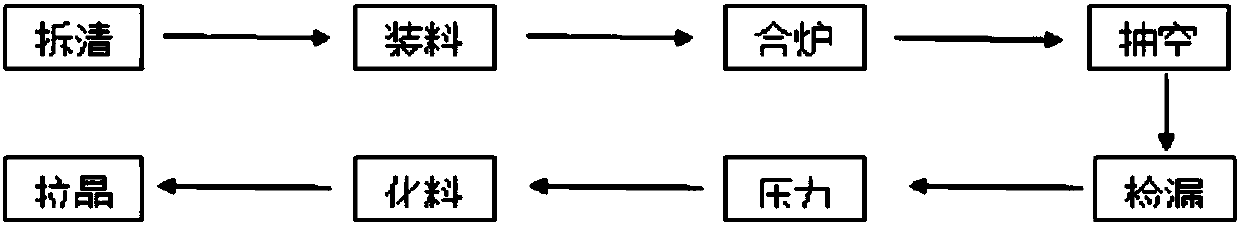

Crystal pulling production process of single crystal furnace, and method for obtaining limited vacuum value of single crystal furnace

ActiveCN107761164AAdvantages of crystal pulling production processAdvantages of production processPolycrystalline material growthBy pulling from meltMetallurgyEconomic benefits

The invention provides a crystal pulling production process of a single crystal furnace. The crystal pulling production process of the single crystal furnace comprises the following steps: 1) measuring the limit vacuum value when the single crystal furnace is vacuumized for m minutes (m is less than n, and n is the conventional single crystal furnace crystal pulling production vacuumizing time); and 2) after the single crystal furnace is charged and closed, vacuumizing for m minutes, detecting the vacuum value in the furnace, judging that sealing of the furnace body is qualified if the detection value is less than or equal to the limit vacuum value and continuing production, and judging that sealing of the furnace body is unqualified if the detection value is more than the limit vacuum value, performing leakage measurement and maintenance on the furnace body until the sealing of the furnace body is qualified and performing subsequent production. According to the crystal pulling production process of the single crystal furnace, the vacuum degree value is compared with the limit vacuum value after the furnace is closed, so that the sealing property of the furnace body is judged, operation is facilitated, the process route is optimized, the crystal pulling time is saved, the production efficiency is improved and great economic benefit is brought to production.

Owner:INNER MONGOLIA ZHONGHUAN SOLAR MATERIAL

Battery cover plate leak detection method

InactiveCN106872116AJudgment of tightnessPrevent leakage hazardsDetection of fluid at leakage pointNitrogenEngineering

The invention discloses a battery cover plate leak detection method including the following steps that S1 a battery cover plate is clamped in an elastic washer; S2 an upper pressing plate and a lower pressing plate are locked and sealed, and a gas pipe is communicated with the lower pressing plate, a gas pressure adjusting valve, and a nitrogen tank; S3 the upper pressing plate and the lower pressing plate are immersed in the water vessel; S4 the nitrogen tank is opened, the gas pressure adjusting valve is opened, and the circulated gas pressure is adjusted to the range of 0.6-1MP; and S5 after 1-5 min, whether the opening of the upper pressing plate has bubbles blown out is observed. The method realizes the leak detection of the battery cover plate at the incoming material stage, avoids the risk of later leakage, and is quick and easy.

Owner:GUOXUAN NEW ENERGY SUZHOU CO LTD

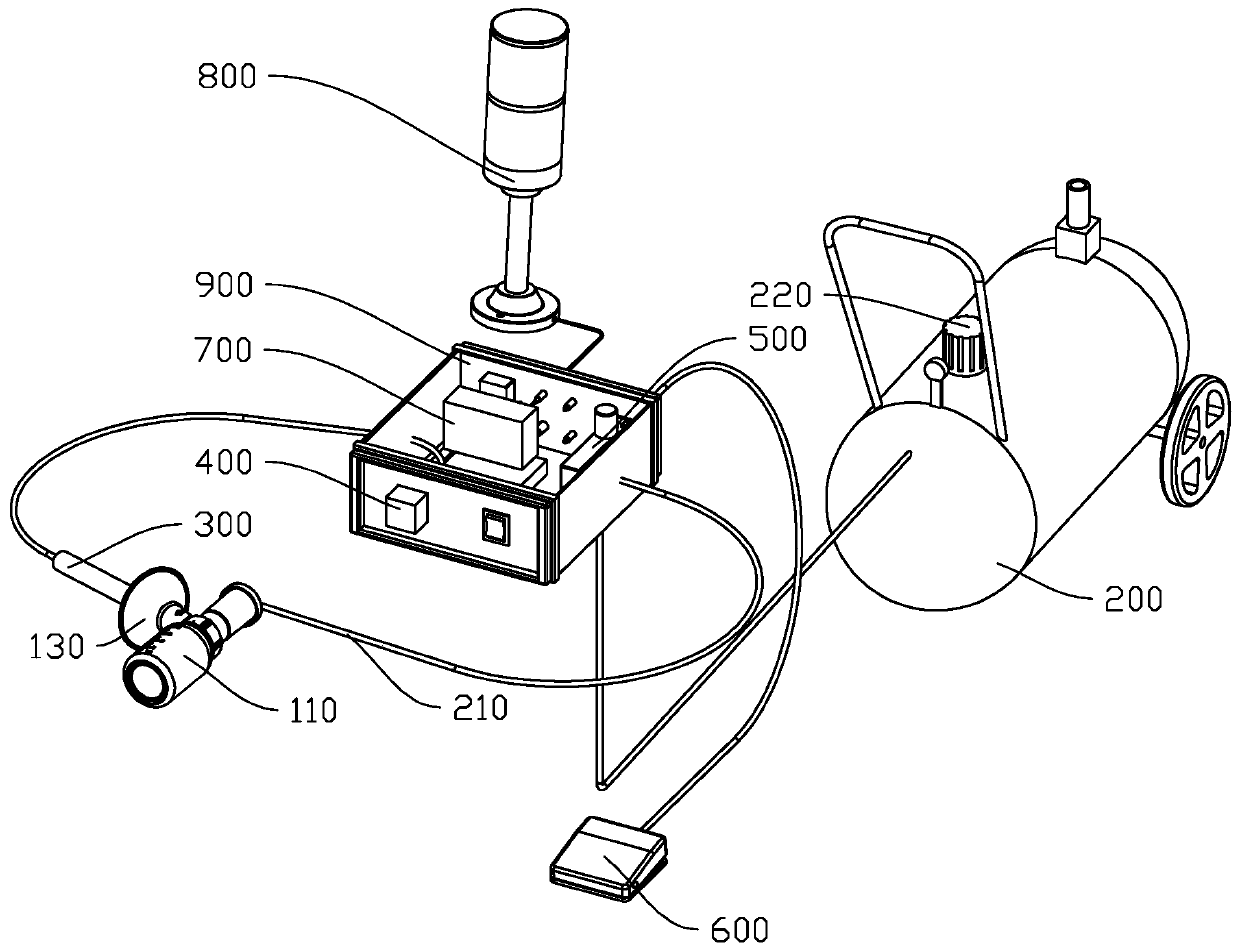

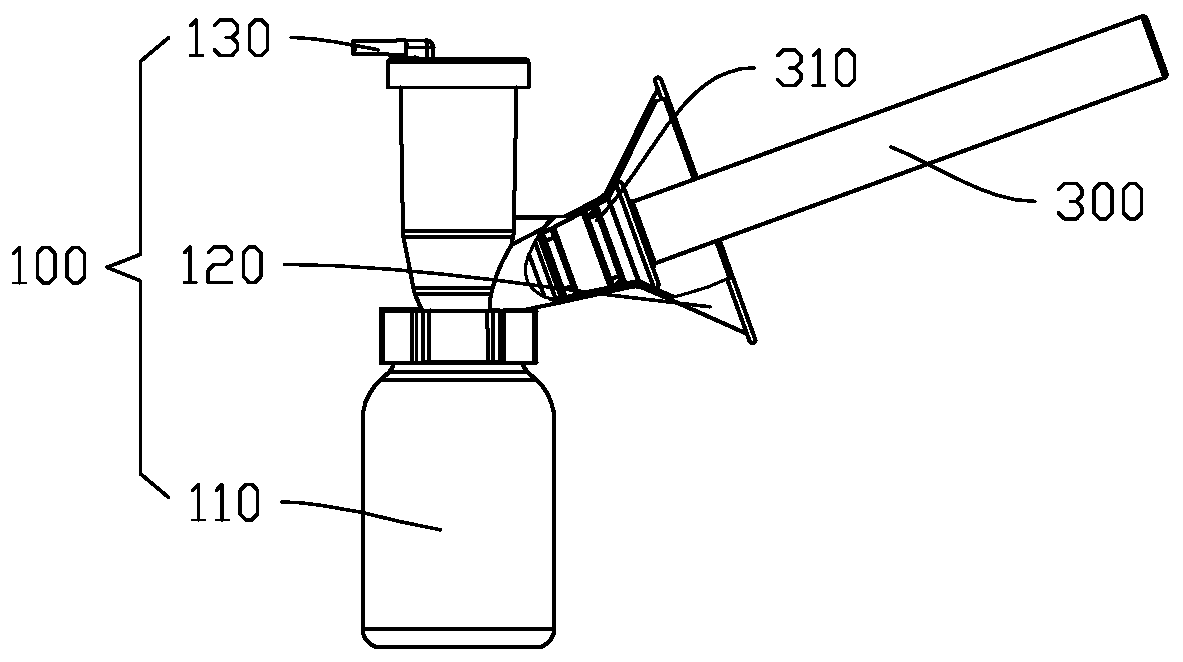

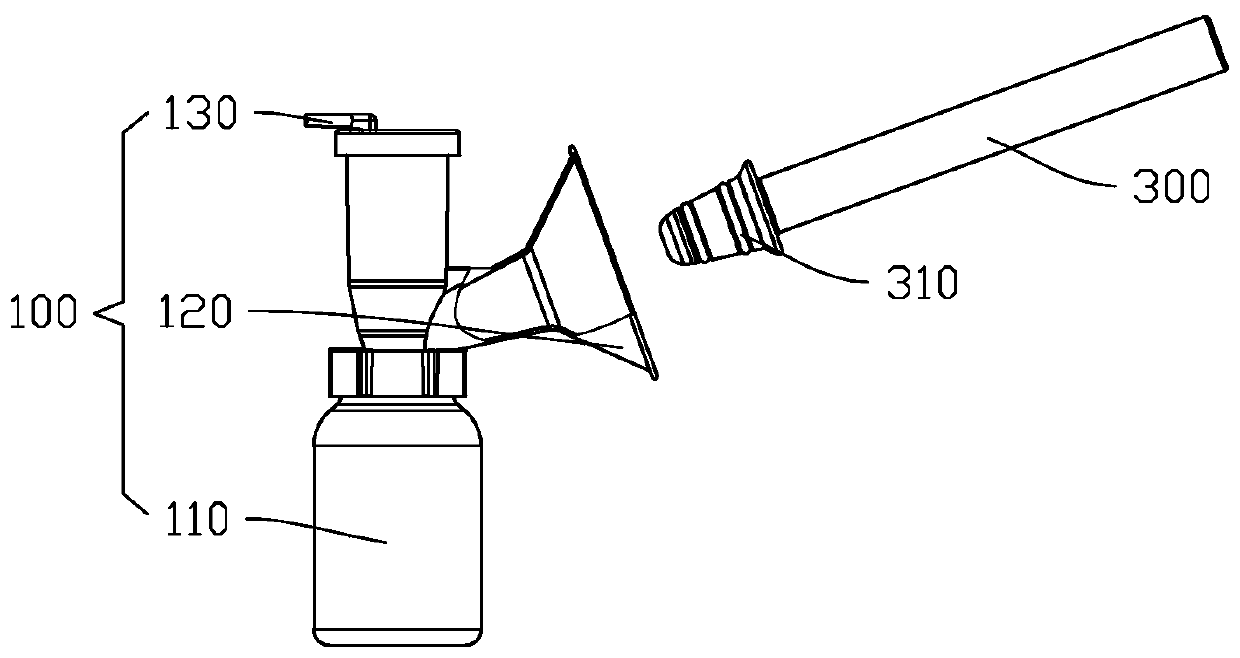

Breast pump negative pressure test assembly and method

PendingCN111103104AJudgment of tightnessFast and stable detectionMeasurement of fluid loss/gain rateBottleGeneral surgery

The invention discloses a breast pump negative pressure test method which comprises the following steps: a conduction step: abutting against and sealing a suction nozzle by using a test rod, communicating a detector with the interior of a feeding bottle through a detection channel, communicating an air suction nozzle by using a negative pressure pipeline and communicating a negative pressure pumpwith the interior of the milk bottle; and an air exhaust detection step: starting a negative pressure pump to set a negative pressure value to form negative pressure in the feeding bottle, measuring the actual negative pressure value in the feeding bottle by using a detector, and comparing the set negative pressure value with the actual negative pressure value to obtain a test result. According tothe breast pump negative pressure test method, at least the following beneficial effects can be realized: the negative pressure is formed in the feeding bottle through the negative pressure pump according to the set negative pressure value, then the suction nozzle is sealed through the detection rod, the actual negative pressure value in the feeding bottle is measured through the detector, the set negative pressure value and the actual negative pressure value are compared to judge the sealing performance of the feeding bottle, detection is fast and stable and operation is easy.

Owner:珠海德瑞医疗器械有限公司

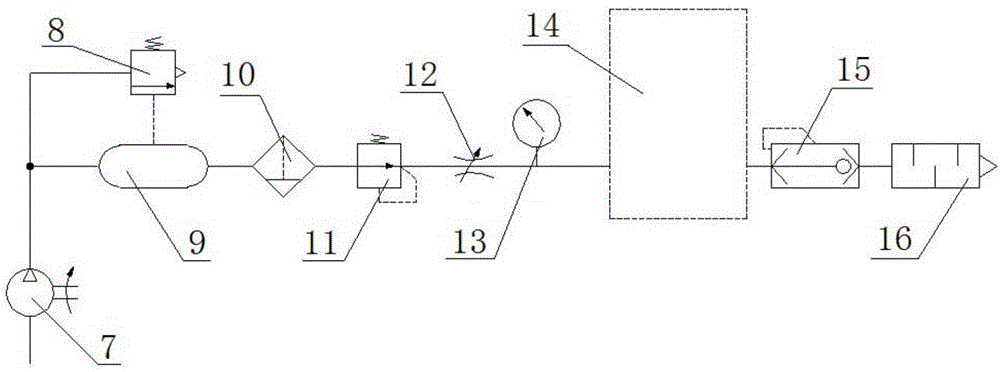

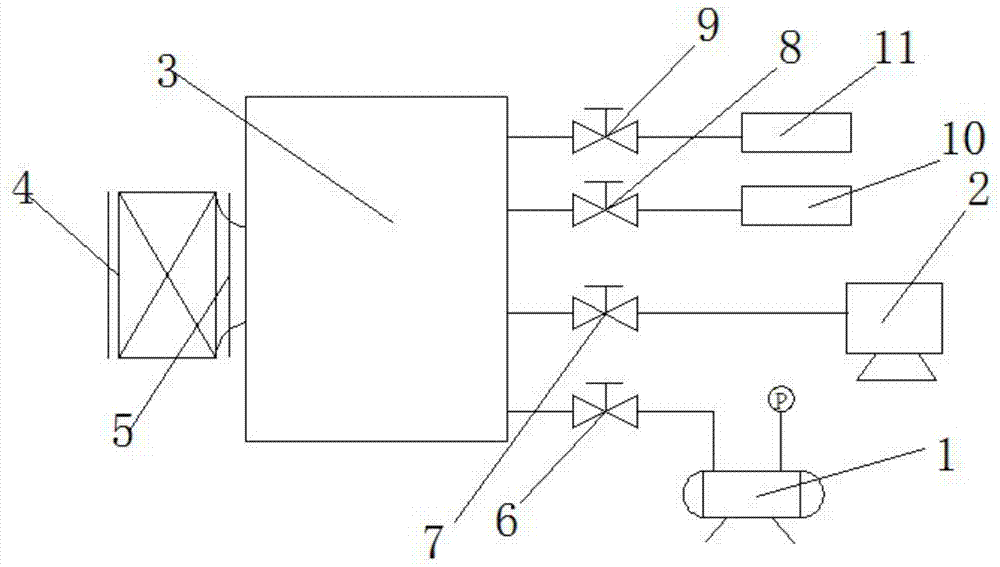

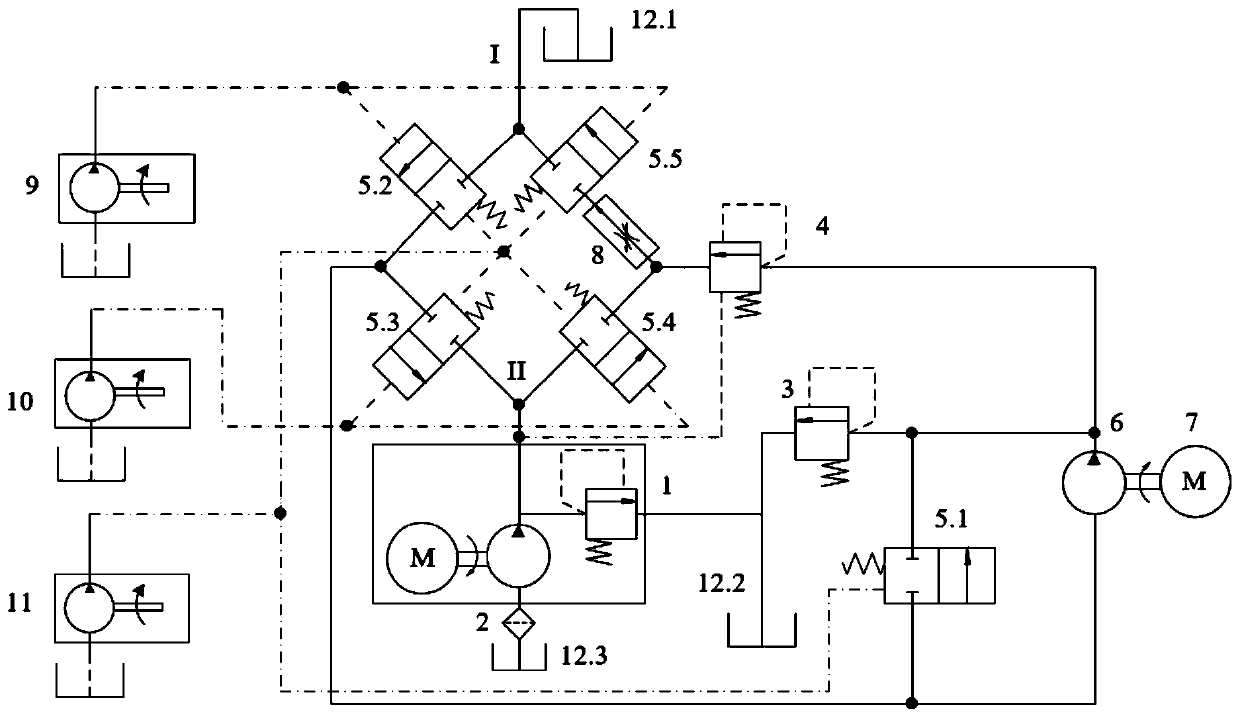

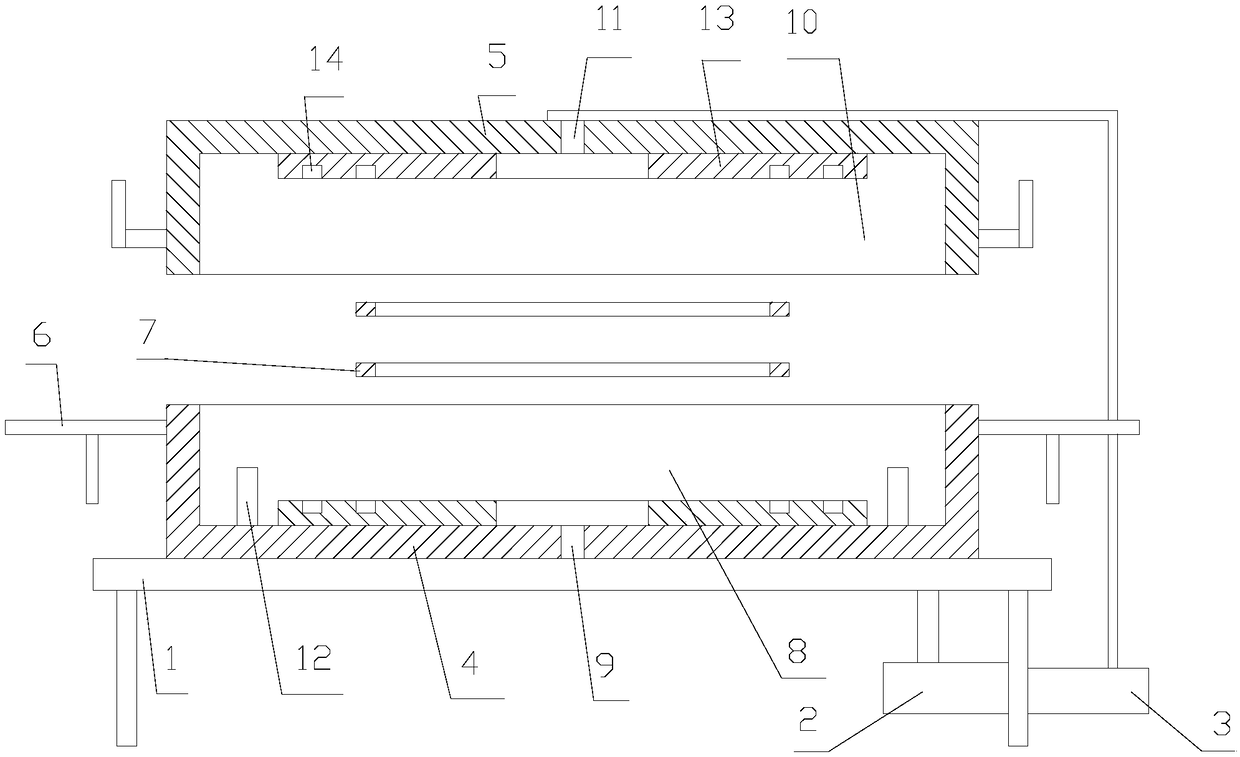

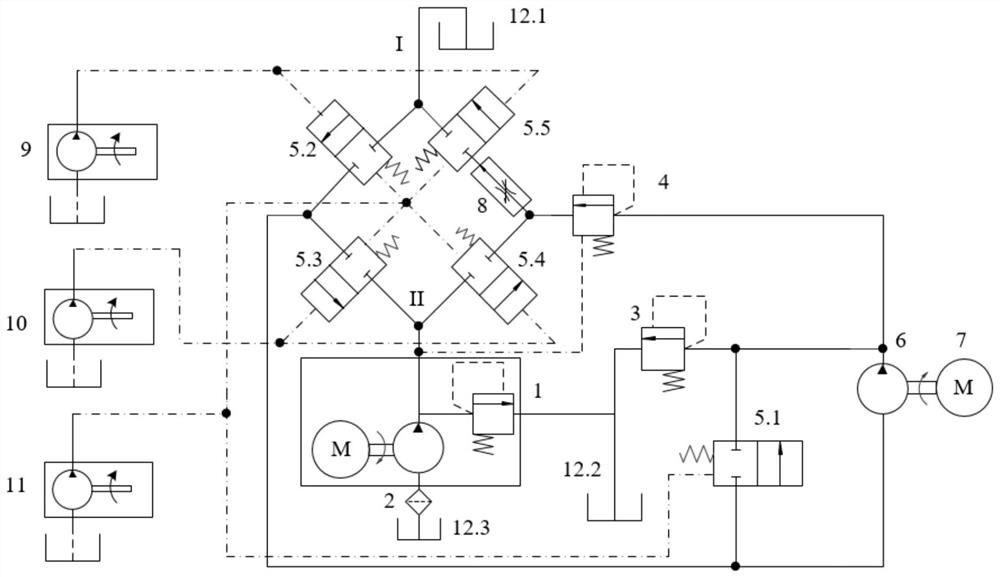

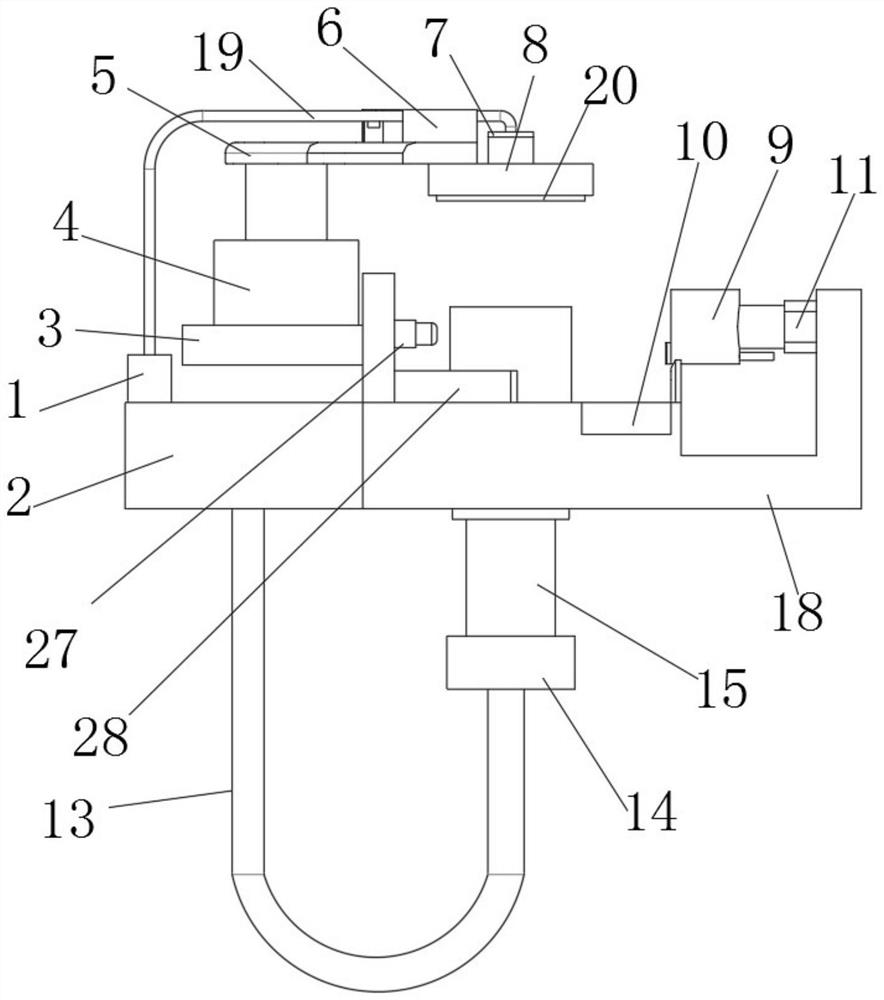

Full-sea-depth working condition simulation test system of seawater hydraulic adjustable ballast device

ActiveCN110553866AThe test phenomenon is obviousJudgment of tightnessDetection of fluid at leakage pointMeasurement of fluid loss/gain rateWater sourceControl valves

The invention discloses a full-sea-depth working condition simulation test system of a seawater hydraulic adjustable ballast device, and belonging to the related field of submersibles; the test systemcomprises a control valve group, three hand pumps, a three-plunger pump station and an open type water tank, wherein the control valve group is formed by integrating a plurality of valves; the control valve group comprises a plurality of stop valves, a port I and a port II are formed in the integrated control valve group; the port I is connected with the open type water tank; the port II is connected with an outlet of the three-plunger pump station; the three hand pumps are respectively a first hand pump, a second hand pump and a third pressure pump; each stop valve is controlled to be openedand closed through the first hand pump and the second hand pump, the three-plunger pump station and the third hand pump are adopted to simulate the marine environment, the first hand pump and the second hand pump are adopted to simulate a hydraulic source, and the open type water tank is adopted to simulate the ballast water tank and provide a water source for the three-plunger pump station. According to the system, various experimental data can be conveniently obtained, and reliable guidance is provided for the actual seawater hydraulic adjustable ballast device to work under the sea.

Owner:HUAZHONG UNIV OF SCI & TECH

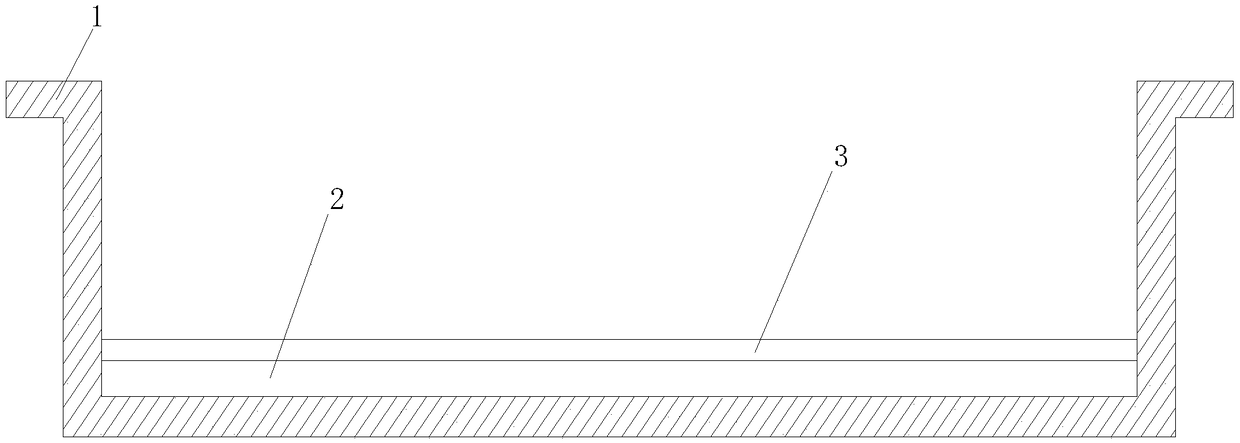

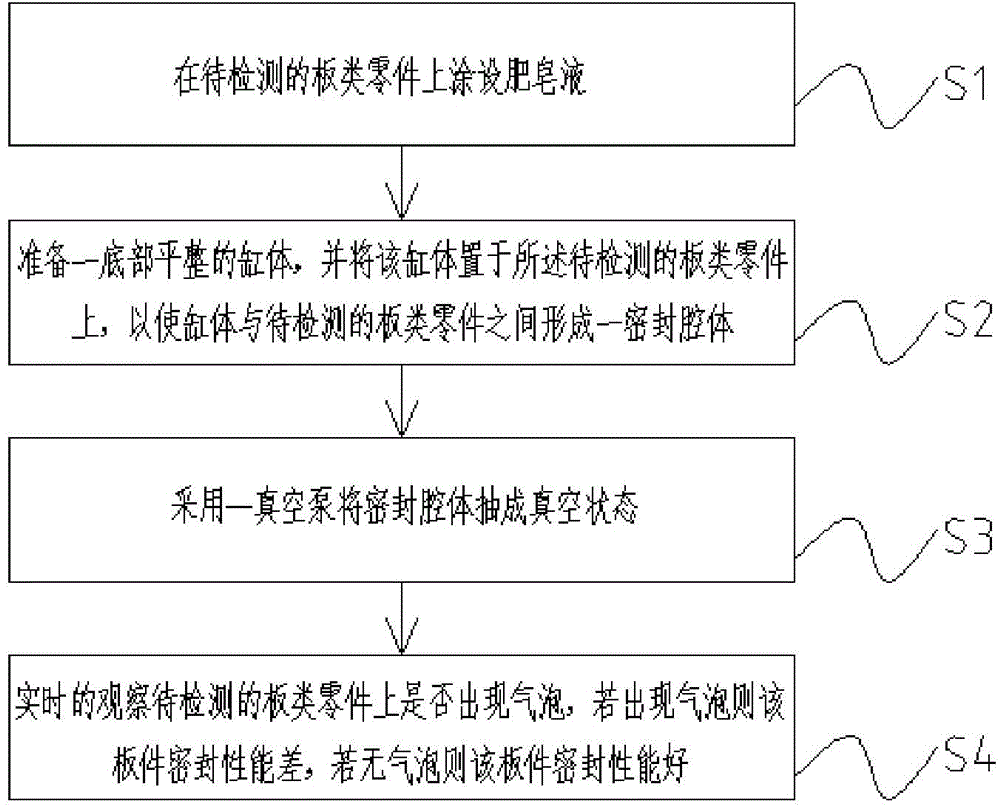

Method for detecting sealing property of plate parts

InactiveCN104819810AJudgment of tightnessDetection of fluid at leakage pointVacuum pumpingPulp and paper industry

The invention relates to the technical field of sealing property tests, and discloses a method for detecting sealing property of plate parts. The method comprises the following steps: step S1, coating liquid soap on a to-be-detected plate part; S2, preparing a cylinder which is smooth on the bottom, placing the cylinder on the to-be-detected plate part, so as to form a sealing cavity between the cylinder and the to-be-detected plate part; S3, using a vacuum pump to vacuate the sealing cavity; S4, and observing whether the to-be-detected plate part has bubbles in real time, if bubbles occur, the sealing property of the part being poor, and if no bubbles occur, the sealing property of the part being good. The method uses the vacuum-pumping method to detect. In detection, the part is coated with the liquid soap, and the cylinder is placed on the to-be-detected plate part, and the vacuum pump is started, and then the sealing property of the part can be determined through observing whether bubbles occur on the to-be-detected plate part.

Owner:GUANGXI JINDA SHIPBUILDING

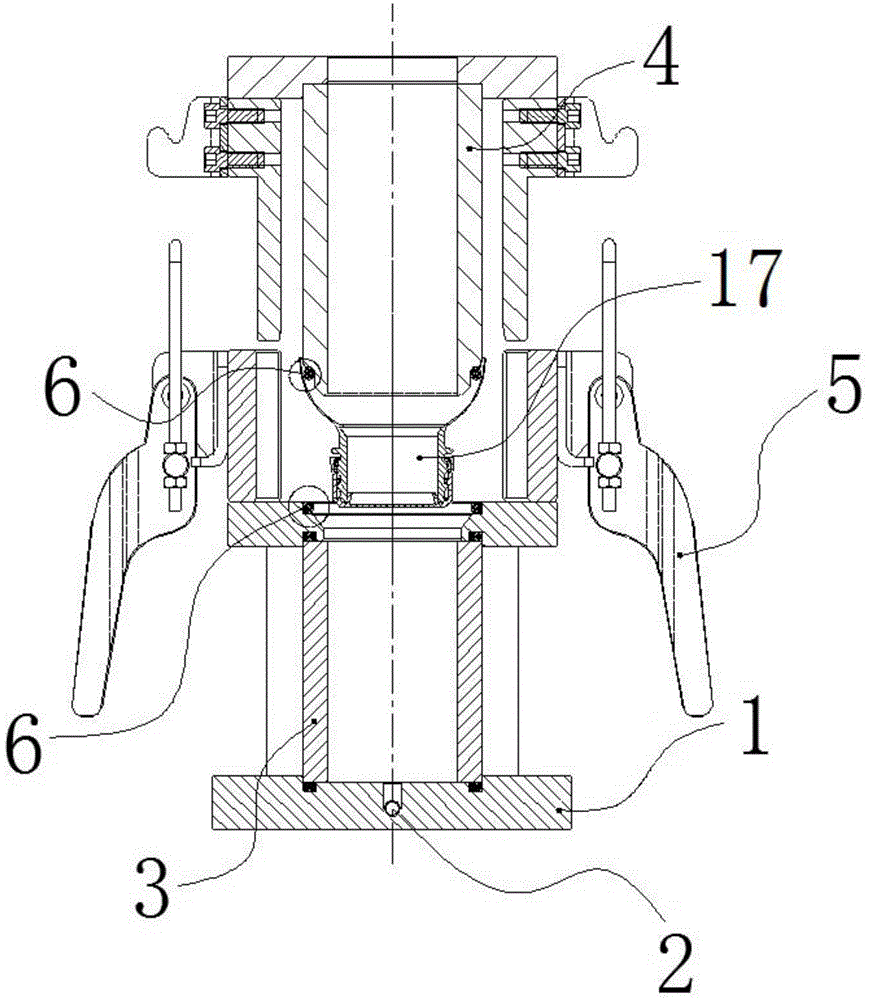

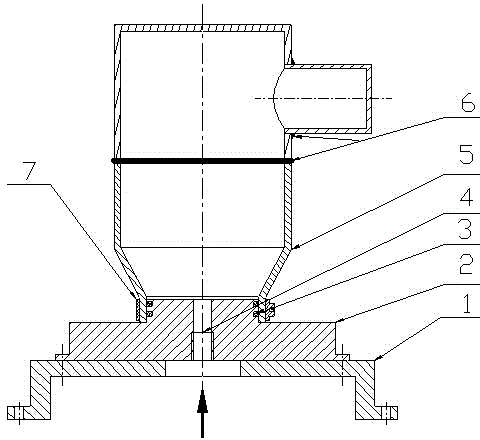

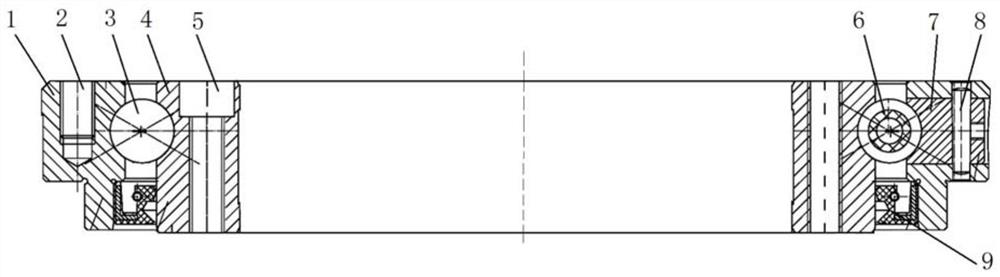

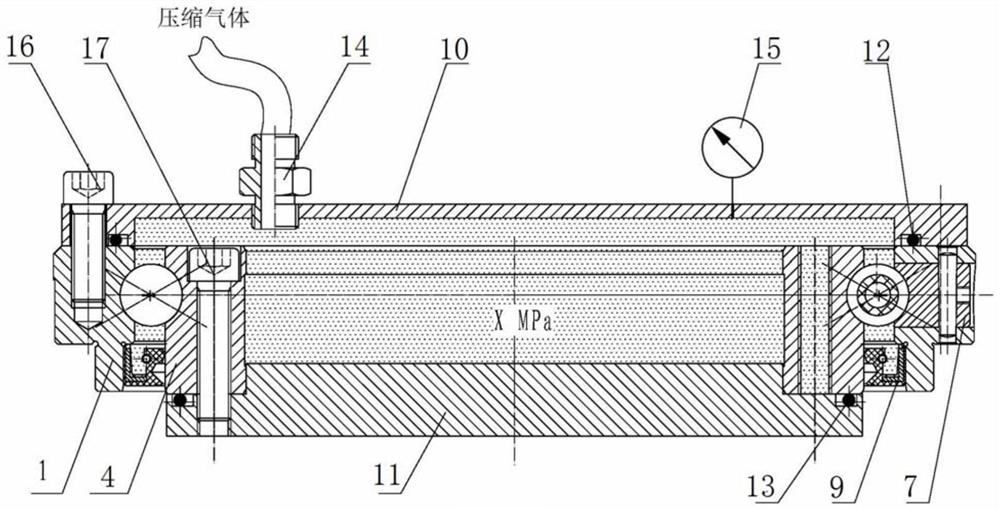

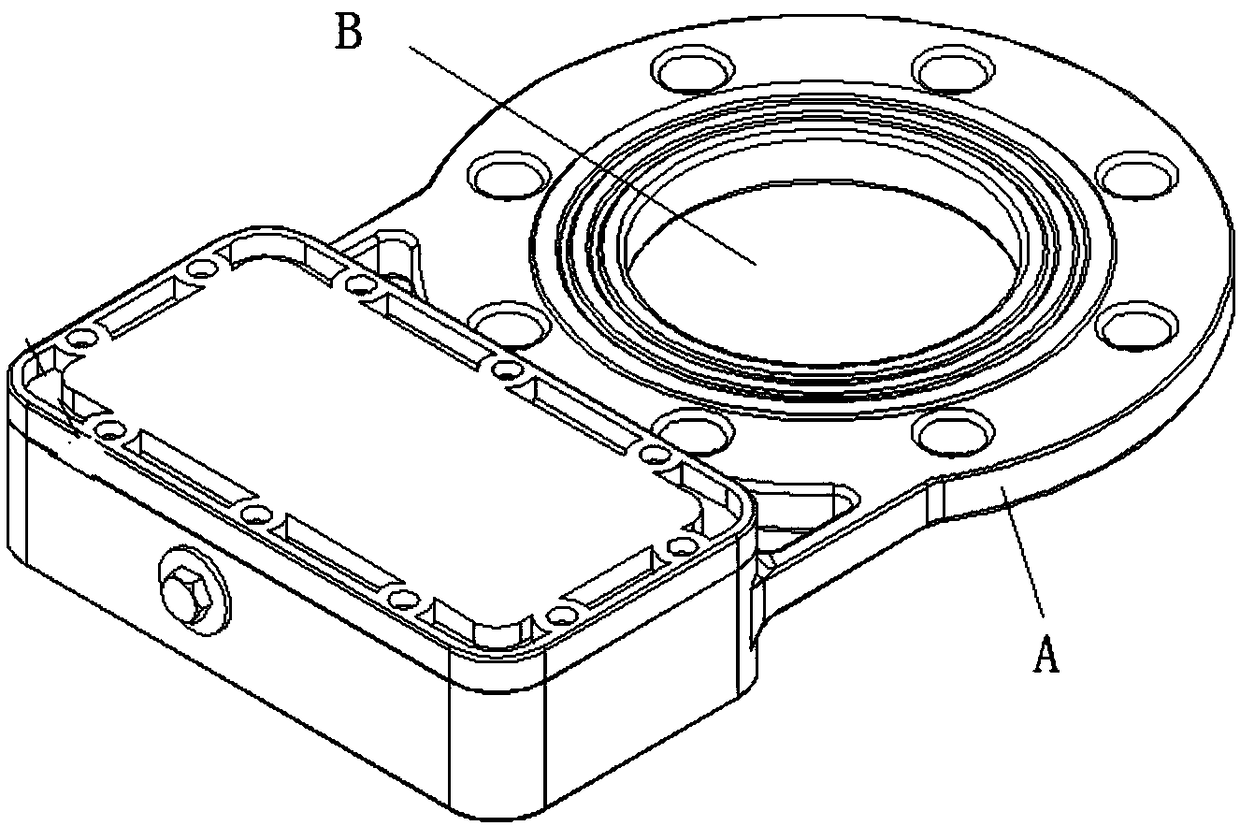

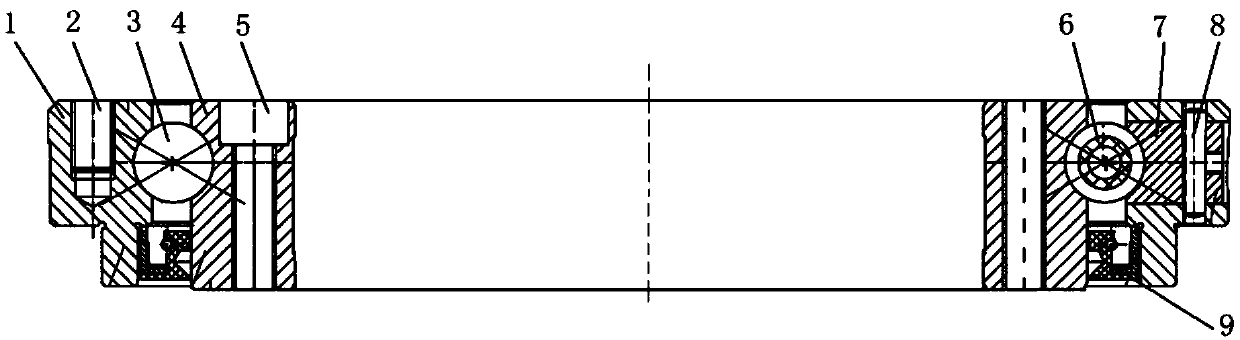

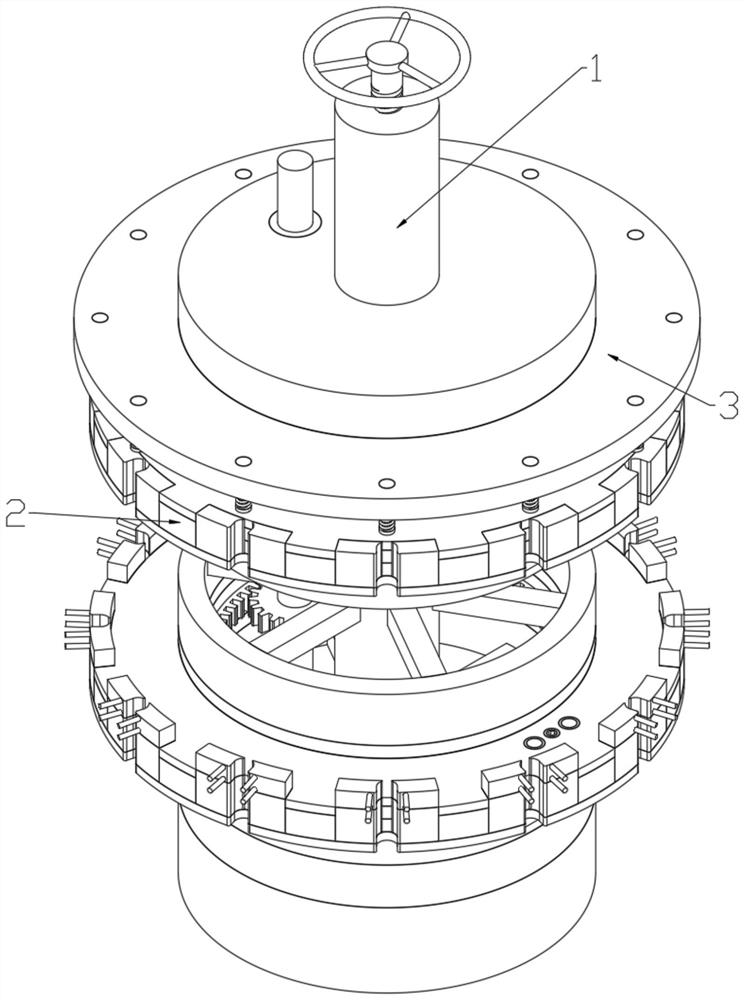

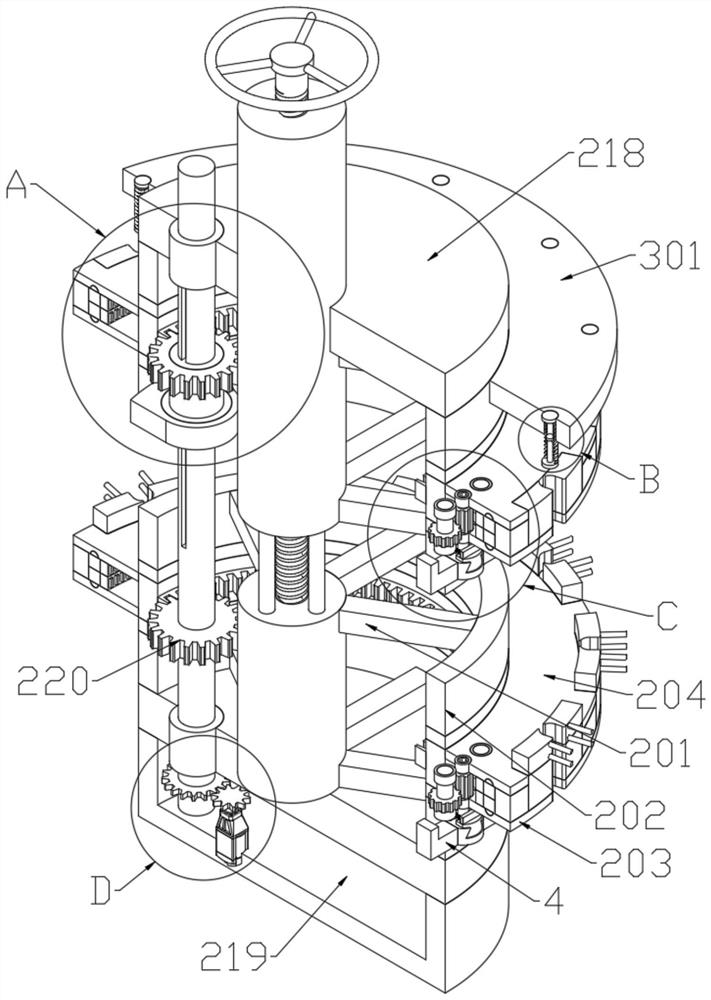

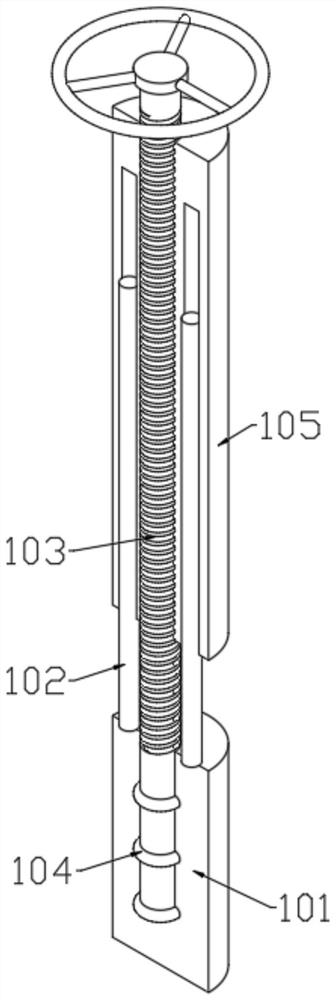

A sealing test device and a sealing test system for a turntable bearing

ActiveCN109612656BImprove reliabilityIncrease the areaMeasurement of fluid loss/gain rateMaterials scienceFace seal

The invention provides a seal testing device and system for a rotary disc bearing. The seal testing device comprises an outer ring sealing cap used for being connected with the end surface of one side, backing on the sealing ring, of the outer ring of the bearing in a sealing mode, and further comprises an inner ring sealing cap used for being connected with the end surface of an inner ring of thebearing in a sealing mode; after the outer ring sealing cap and the inner ring sealing cap are connected with the bearing, and a sealing inner cavity is enclosed by the outer ring sealing cap and theinner ring sealing cap and the bearing; a gas charging connector used for being connected with a high-pressure gas source and charging compressed gas into the sealing inner cavity is arranged on oneof the outer ring sealing cap and the inner ring sealing cap, a pressure detecting device used for communicating with the sealing inner cavity is further arranged on one of the outer ring sealing capand the inner ring sealing cap, and the pressure detecting device judges the sealing property of the bearing by detecting whether the pressure in the sealing inner cavity changes or not. According tothe sealing testing device and system for the rotary disc bearing, the rotary disc bearing does not need to be subjected to installation detection, and the problem that the seal testing efficiency islow due to installation and dismantling is solved.

Owner:LUOYANG BEARING RES INST CO LTD

Sealing performance detection test bench for integrated fire hydrant water pressure monitoring instrument

PendingCN109374228ASimple structureEasy to testMeasurement of fluid loss/gain rateEngineeringTest bench

The invention discloses a sealing performance detection test bench for an integrated fire hydrant water pressure monitoring instrument. The test bench comprises a bracket, a water pump, a pressure pump, a support member, a cover plate, a fastener and two sealing rings. The support member is installed at the bracket and is provided with a first receiving groove and a water outlet hole communicatedwith the first receiving groove and the water pump; and the water pump and the pressure pump are communicated. A second receiving groove and a water inlet hole re formed in the cover plate; the secondreceiving groove matches the first receiving groove; the water inlet hole is communicated with the second receiving groove and the pressure pump; the fastener is used for connection of the cover plate with the support member; and the two sealing rings are installed at the two sides of a flange of an integrated fire hydrant water pressure monitoring instrument.

Owner:HEFEI KDLIAN SAFETY TECHNOLOGY CO LTD +2

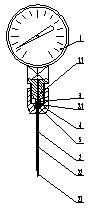

Pipe inner cavity pressure detector of evaporator

InactiveCN102829934ASimple structureEasy to manufactureMeasurement of fluid loss/gain rateCavity pressureEngineering

The invention discloses a pipe inner cavity pressure detector of an evaporator. The pipe inner cavity pressure detector comprises a pressure meter, a seal pad, a needle head, a connection sleeve and a pipe cap, wherein the pipe cap is connected with an opening of a pipe of an inner cavity of the evaporator and is a rubber piece which forms a seal space with the pipe of the evaporator; the seal pad, the needle head and the seal pad are arranged between a joint of the pressure meter and the end surface of an inner hole of the connection sleeve, and the connection sleeve is in threaded matching with the joint of the pressure meter, so that the seal connection between the needle head, the joint of the pressure meter and the connection sleeve is realized. When the pipe inner cavity pressure detector is used, firstly the pipe cap is in sealed connection with the opening of the pipe of the inner cavity of the evaporator, air is filled in the seal space of the inner cavity of the evaporator to enable the seal space to be of the certain pressure, pressure preservation is kept for a while, a needle tip and a needle pipe are punctured into the pipe cap of the opening of the pipe of the inner cavity of the evaporator, and a pressure change situation of the inner cavity of the evaporator can be observed from the pressure meter, so that the seal performance of the inner cavity of the evaporator is judged. The whole detection operation is very quick, and the pipe inner cavity pressure detector is suitable for detecting the seal performance of the inner cavity during large-batch production of the evaporator.

Owner:JIANGSU XINCHENG ELECTRICAL APPLIANCE GENERAL FACTORY

A cable stuffing box leak detection device

The invention provides a sealing detection device of a cable gland, and the device comprises a manual pressurization pump, a water injection pipe, a first cup-shaped pipe joint nut, a second cup-shaped pipe joint nut as well as a first rear baffle ring, a combined sealing ring and a second rear baffle ring which are located between the first cup-shaped pipe joint nut and the second cup-shaped pipe joint nut, wherein the left end of the first cup-shaped pipe joint nut is connected to the first rear baffle ring and compresses the combined sealing ring; the left end of the combined sealing ring is connected to the second rear baffle ring; the first cup-shaped pipe joint nut, the first rear baffle ring, the combined sealing ring, the second rear baffle ring and the second cup-shaped pipe joint nut wrap a cable inside; a front clamping buckle and a rear clamping buckle which are connected through buckling and threaded connection sleeve the outer layer; a sealed water injection cabin is formed between a sleeve and the cable, and the sleeve is formed by the front clamping buckle and the rear clamping buckle; and the manual pressurization pump communicates with the water inject cabin by the water injection pipe. The device provided by the invention can simulate cable gland states under different depth conditions, can detect sealing performance of a sealing material of the cable gland and has the advantages of high control precision, small and compact appearance and convenient operation.

Owner:NAVAL UNIV OF ENG PLA

A full-sea depth simulation test system for a seawater hydraulically adjustable ballast device

ActiveCN110553866BThe test phenomenon is obviousJudgment of tightnessDetection of fluid at leakage pointMeasurement of fluid loss/gain rateWater sourceBallast

The invention discloses a full-sea-depth working condition simulation test system of a seawater hydraulic adjustable ballast device, and belonging to the related field of submersibles; the test systemcomprises a control valve group, three hand pumps, a three-plunger pump station and an open type water tank, wherein the control valve group is formed by integrating a plurality of valves; the control valve group comprises a plurality of stop valves, a port I and a port II are formed in the integrated control valve group; the port I is connected with the open type water tank; the port II is connected with an outlet of the three-plunger pump station; the three hand pumps are respectively a first hand pump, a second hand pump and a third pressure pump; each stop valve is controlled to be openedand closed through the first hand pump and the second hand pump, the three-plunger pump station and the third hand pump are adopted to simulate the marine environment, the first hand pump and the second hand pump are adopted to simulate a hydraulic source, and the open type water tank is adopted to simulate the ballast water tank and provide a water source for the three-plunger pump station. According to the system, various experimental data can be conveniently obtained, and reliable guidance is provided for the actual seawater hydraulic adjustable ballast device to work under the sea.

Owner:HUAZHONG UNIV OF SCI & TECH

Top cover sorting device for food processing

The invention discloses a top cover sorting device for food processing. The device comprises an operation table and a top cover, a thin film is arranged in the top cover, a separating plate is fixed to the operation table, an electric telescopic rod is fixed to the outer wall of the top of the separating plate, a wing plate is fixed to the outer wall of the top end of the electric telescopic rod, a plurality of glands distributed at equal intervals are arranged on the outer wall of the bottom of the wing plate, sealing covers are arranged on the outer walls of the tops of the glands, sealing rings are clamped to the outer walls of the bottoms of the glands, a conveying groove is formed in the outer wall of the top of the operation table, a conveyor belt is slidably arranged on the inner wall of the bottom of the conveying groove, and a gas detector is fixed to the outer wall of one side of the operation table. According to the device, the gas detector detects the pressure of gas in a gas-inlet pipe and detects the volume of the gas filled into the gas detector through a gas guide pipe, and the sealing performance of the top cover is determined according to the change condition of the gas pressure in the gas-inlet pipe and the volume number of the gas received by the gas detector through the gas guide pipe.

Owner:杭州儒可贸易有限公司

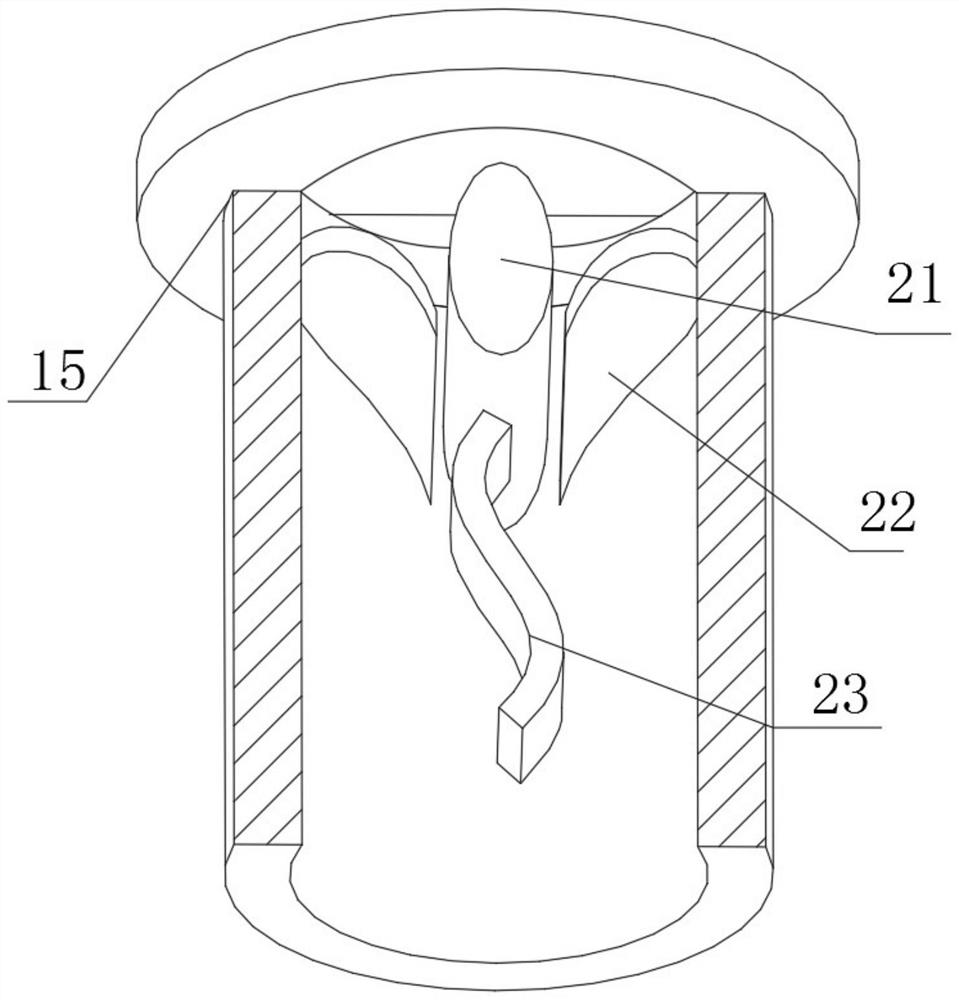

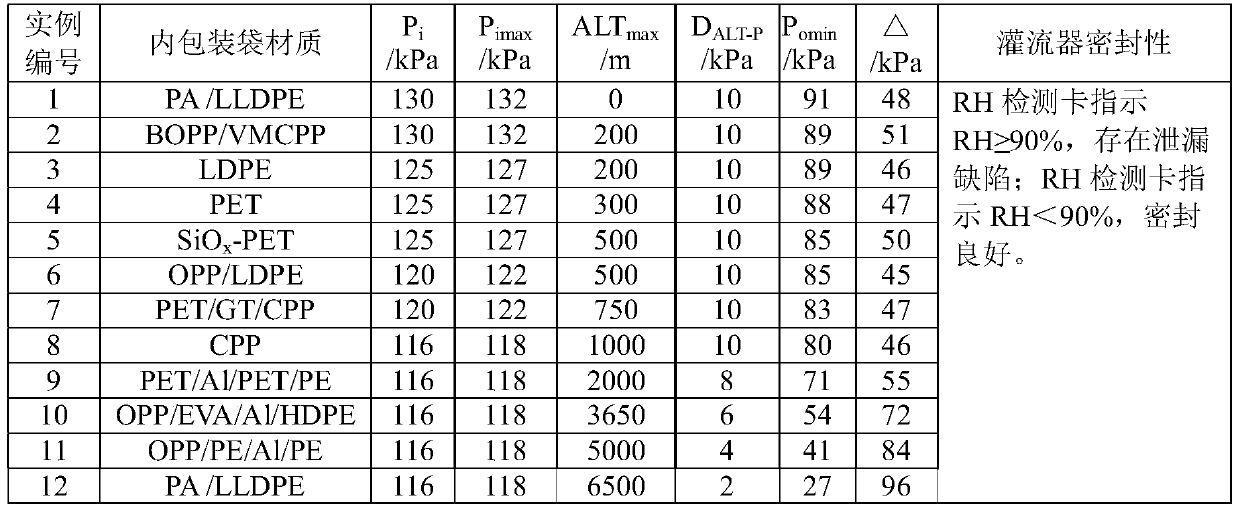

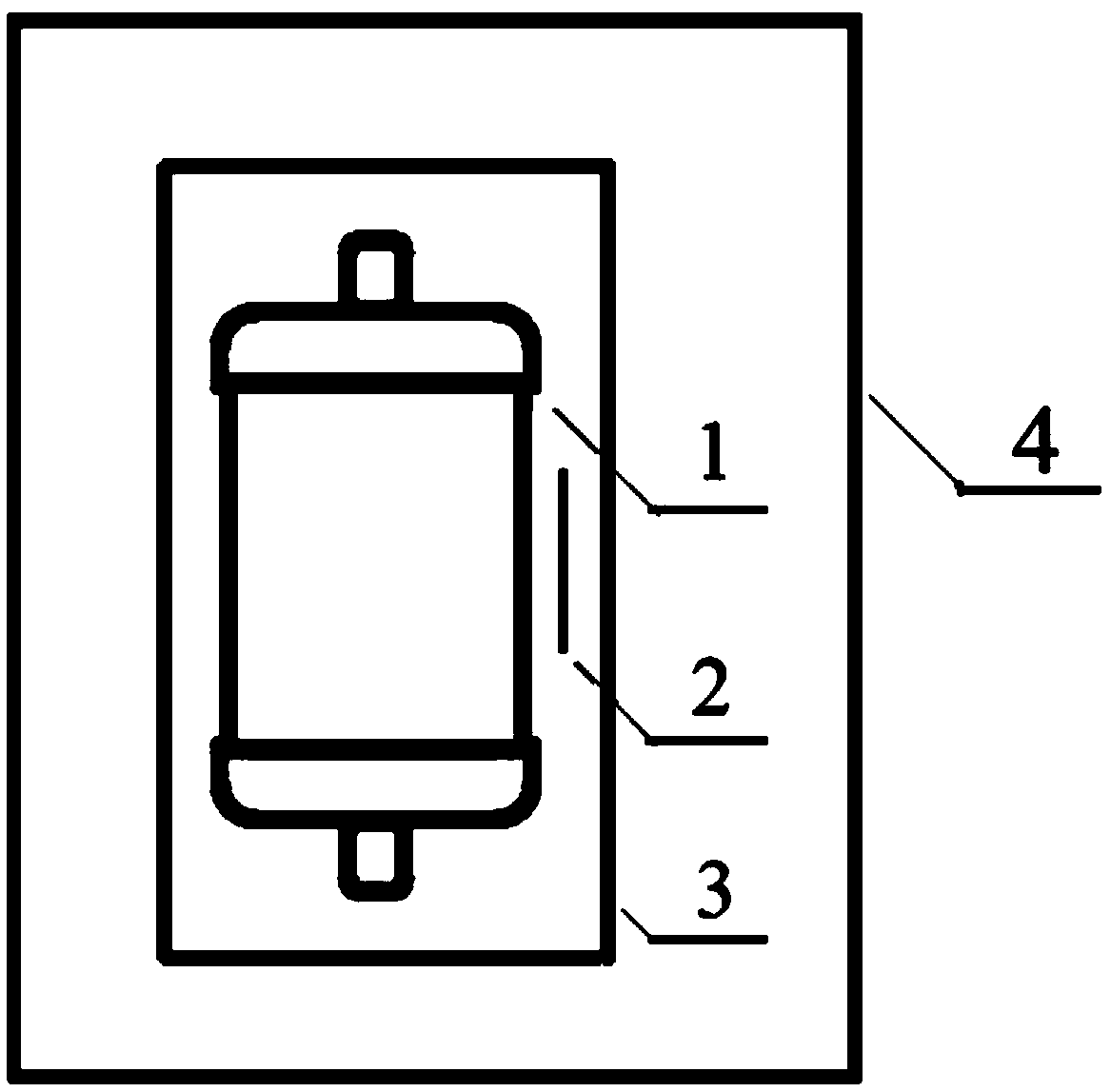

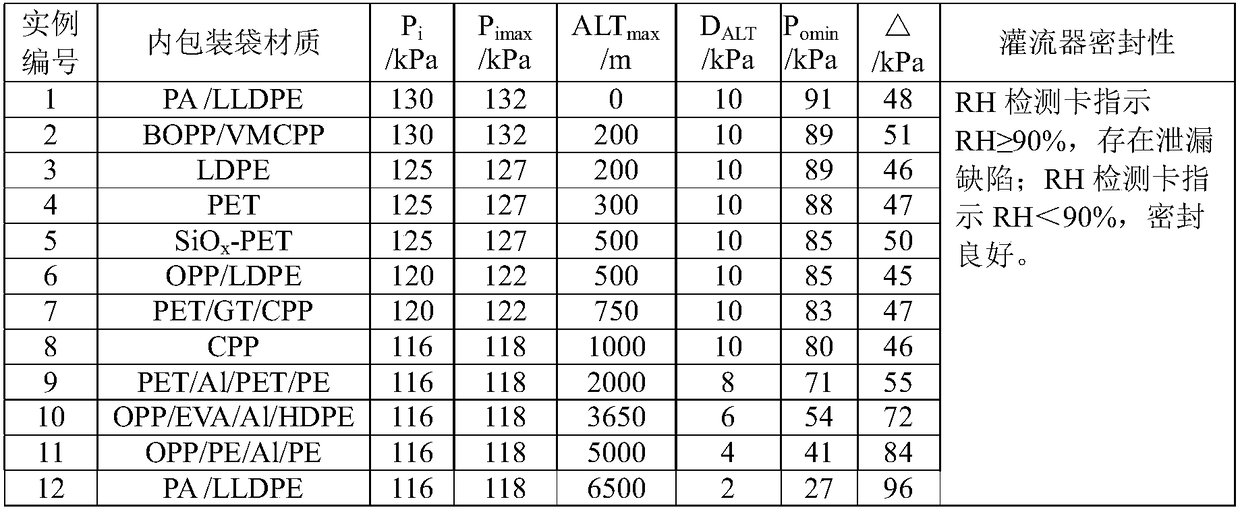

A sealing detection device for a hemoperfusion device

ActiveCN108645570BJudgment of tightnessEasy to judgeFluid-tightness measurement using fluid/vacuumHematological testHemoperfusion

The invention provides a seal detection device of a blood perfusion device. The seal detection device of a blood perfusion device includes an inner packaging bag and a humidity card, wherein a blood perfusion device is arranged in the inner packaging bag, and the inner packaging bag is filled with positive pressure gas; the humidity card is embedded into the surface of the inner packaging bag or arranged in the inner packaging bag for detecting the humidity in the inner packaging bag.; the positive pressure inflation pressure in the inner package bag is 116 kPa to 130 kPa; and the inner package bag is subjected to an internal pressure of 132 kPa or more. The seal detection device of a blood perfusion device can conveniently determine the sealing property of the blood perfusion device, andcan conveniently and accurately determine whether the internal packaging bag is perfect and has no leakage.

Owner:JIANGSU UNIV OF TECH +1

Seal testing device and system for rotary disc bearing

ActiveCN109612656AImprove reliabilityIncrease the areaMeasurement of fluid loss/gain rateTest efficiencyEngineering

The invention provides a seal testing device and system for a rotary disc bearing. The seal testing device comprises an outer ring sealing cap used for being connected with the end surface of one side, backing on the sealing ring, of the outer ring of the bearing in a sealing mode, and further comprises an inner ring sealing cap used for being connected with the end surface of an inner ring of thebearing in a sealing mode; after the outer ring sealing cap and the inner ring sealing cap are connected with the bearing, and a sealing inner cavity is enclosed by the outer ring sealing cap and theinner ring sealing cap and the bearing; a gas charging connector used for being connected with a high-pressure gas source and charging compressed gas into the sealing inner cavity is arranged on oneof the outer ring sealing cap and the inner ring sealing cap, a pressure detecting device used for communicating with the sealing inner cavity is further arranged on one of the outer ring sealing capand the inner ring sealing cap, and the pressure detecting device judges the sealing property of the bearing by detecting whether the pressure in the sealing inner cavity changes or not. According tothe sealing testing device and system for the rotary disc bearing, the rotary disc bearing does not need to be subjected to installation detection, and the problem that the seal testing efficiency islow due to installation and dismantling is solved.

Owner:LUOYANG BEARING RES INST CO LTD

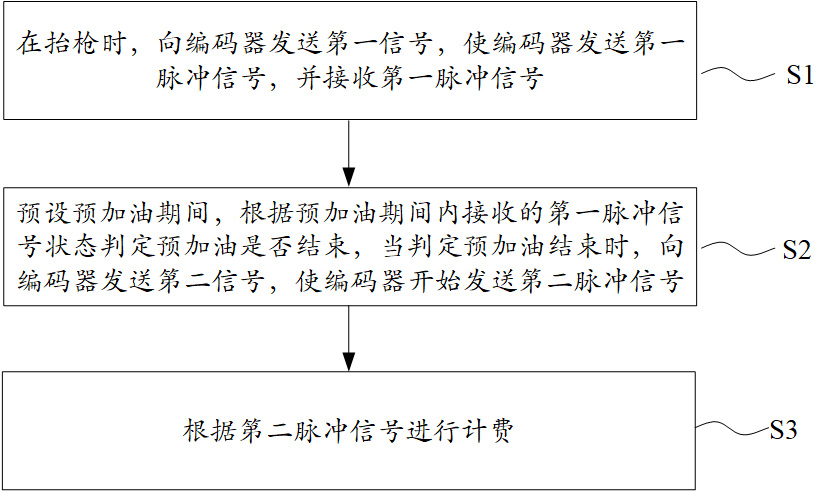

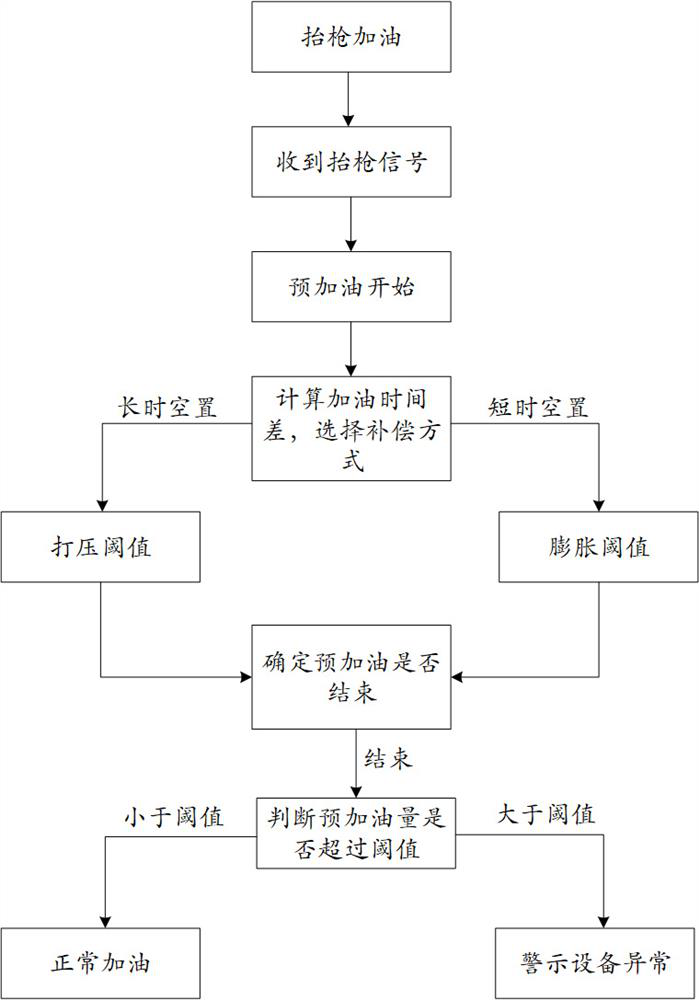

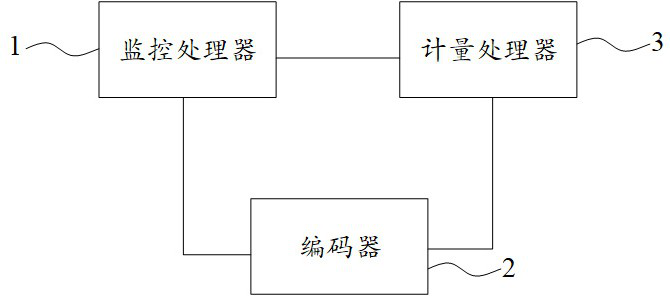

A method and system for preventing the gun from being lifted and judging the sealing state of the refueling device

ActiveCN112938883BJudgment of tightnessJudging whether the sealing of the refueling device is normalLiquid transferring devicesControl theoryReliability engineering

The present invention relates to a method for preventing words from lifting a gun and judging the sealing state of a refueling device. The first step is to send a first signal to an encoder when the gun is lifted, so that the encoder sends a first pulse signal and receives the first pulse signal; The second step is to preset the pre-fueling period, and judge whether the pre-fueling is over according to the state of the first pulse signal received during the pre-fueling period. When it is judged that the pre-fueling is over, send a second signal to the encoder to make the encoder start sending The second pulse signal; the third step is to perform billing according to the second pulse signal; wherein, according to the state of the first pulse signal received during the pre-fuel period, determining whether the pre-fuel is over includes, if the first pulse signal is not received, Then it is judged as the end of pre-fueling, if the received first pulse signal changes from presence to non-existence, then it is judged as the end of pre-fueling, the present invention can prevent the occurrence of the problem of raising the gun and jumping characters and determine the sealing state of the refueling device.

Owner:BEIJING TOCEL ELECTRONICS

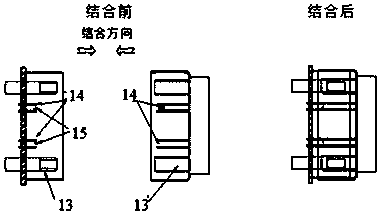

Automobile fuel tank pressure testing device

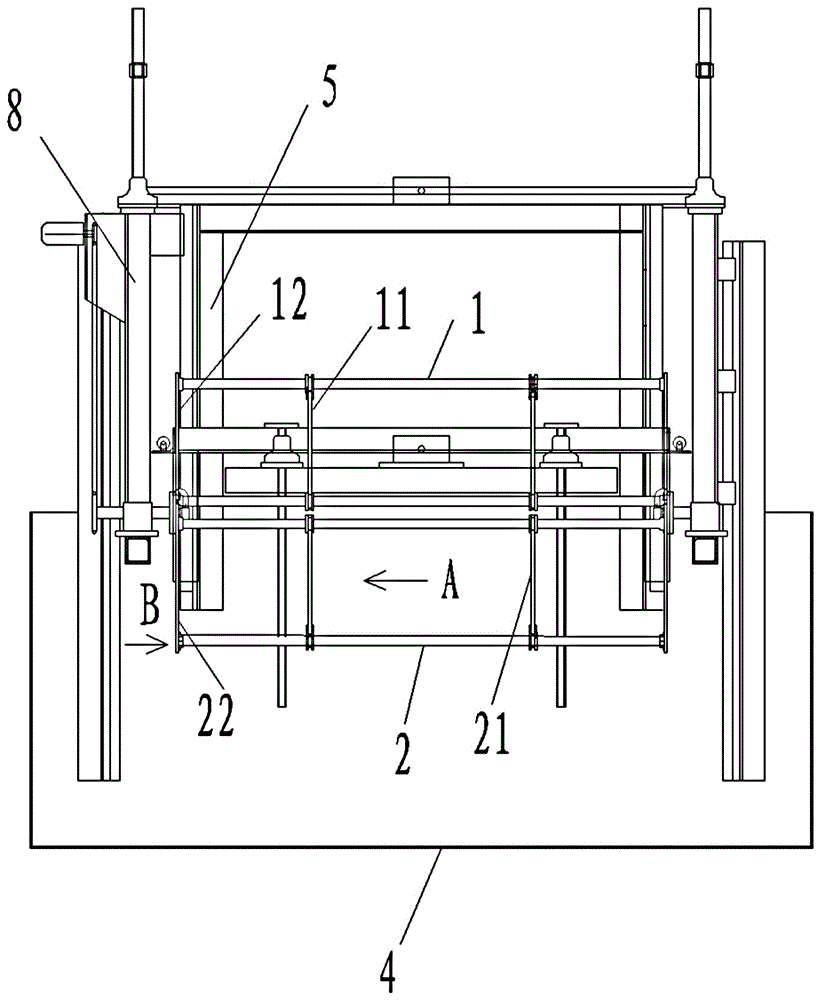

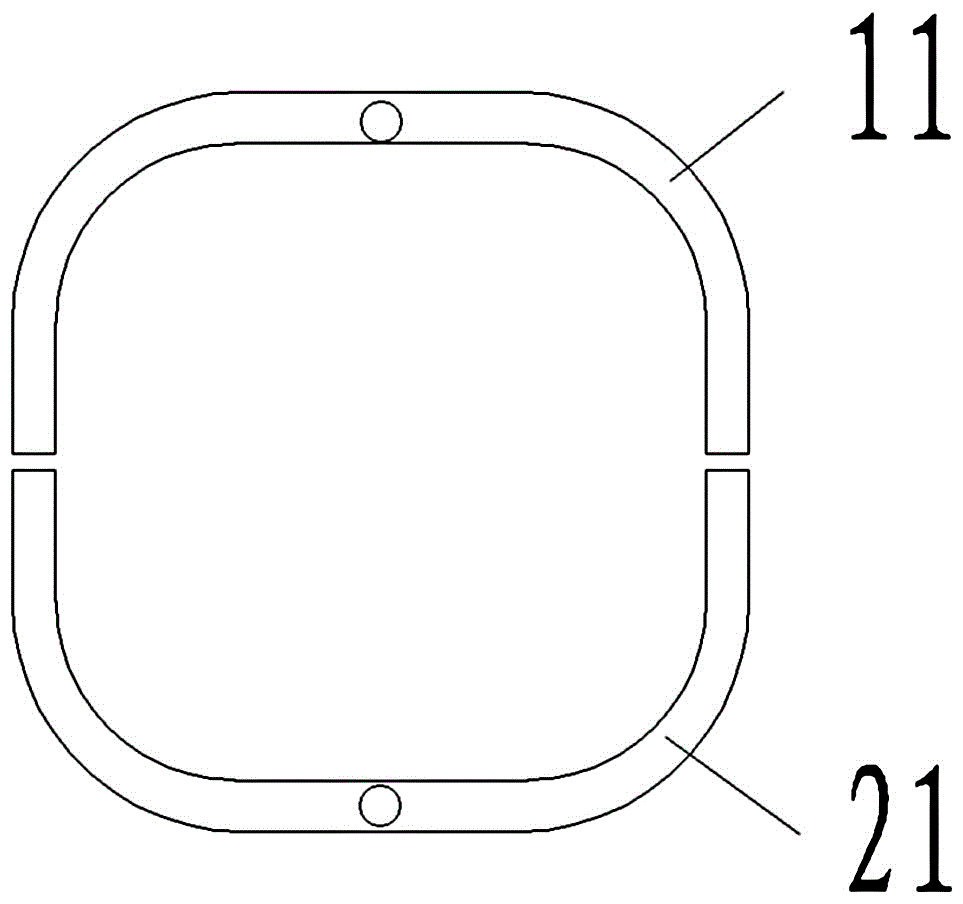

ActiveCN106546388AJudgment of tightnessLeakage checkMeasurement of fluid loss/gain rateInternal combustion piston enginesTest efficiencyFixed frame

The invention discloses an automobile fuel tank pressure testing device, which comprises an upper cage frame, a lower cage frame, a water tank used for accommodating the upper cage frame and the lower cage frame, an upper cage frame lifting mechanism and a lower cage frame lifting mechanism, and is characterized in that the upper cage frame and the lower cage frame can mutually engaged so as to form clamping for a fuel tank; the upper cage frame lifting mechanism comprises a fixed frame arranged at the rear side of the water tank, the top part of the fixed frame is provided with an upper lifting motor, the upper lifting motor is connected to an upper lifting arm through a first lead screw lifting mechanism, the upper lifting arm is connected with the upper cage frame, and the upper lifting arm and the upper cage frame are of a separable structure; the lower cage frame lifting mechanism comprises a lower lifting motor arranged on the fixed frame, the lower lifting motor is connected to a lower lifting arm through a second lead screw lifting mechanism, and the lower lifting arm is connected with the lower cage frame; and the upper cage frame and the lower cage frame clamp and tightly hold the fuel tank and immerse the fuel tank into the water tank so as to perform a water pressure test on the fuel tank, and the sealing performance of the fuel tank is judged. The automobile fuel tank pressure testing device is simple and convenient to operate, and improves the test efficiency.

Owner:BENGBU TONGDA AUTO PARTS

Device for detecting mould impermeability

InactiveCN101514936BAvoid the disadvantage of burstingImprove efficiencyMeasurement of fluid loss/gain rateWater sourceEngineering

The invention discloses a device for detecting mould impermeability, belonging to the technical field of mould. The device comprises a tank body which is communicated with a water inlet pipe, an air inlet pipe and a water and air outlet pipe. The water inlet pipe is connected with a water source. The water and air outlet pipe is connected with the mould. The air inlet pipe is connected with an air source. The device drives water into the mould by compressed air, thereby overcoming the disadvantage that the drive pressure of a water pump is too high as well as the disadvantage of the low efficiency of manual pressurizing.

Owner:QINGDAO HISENSE MOLD

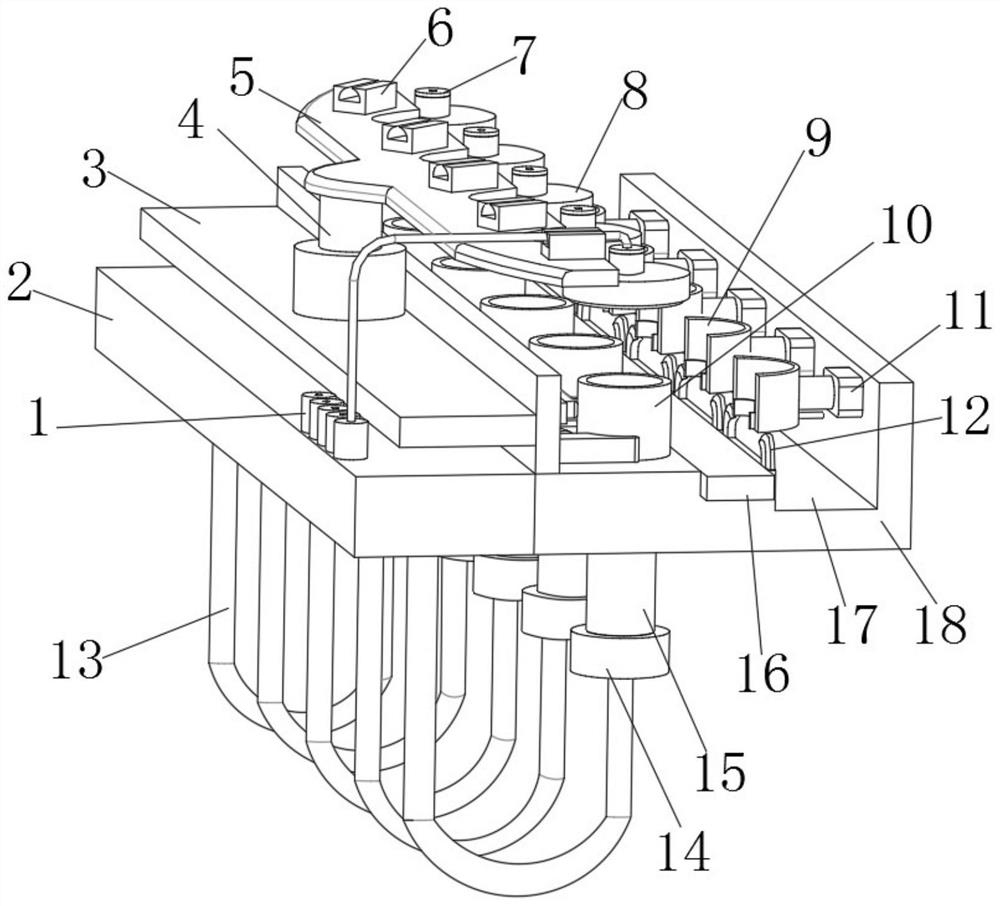

Automatic assembling and testing equipment for insulin syringe

PendingCN114199465AJudgment of tightnessDetection of fluid at leakage pointMetal-working hand toolsBiomedical engineeringInsulin humulin

The invention discloses automatic assembling and testing equipment for insulin syringes, particularly relates to the technical field of syringe production, and aims to solve the problems that when the insulin syringes are automatically assembled, a testing device needs to be arranged to detect the sealing performance of the syringes, and blank pipes and piston shafts of different sizes need to be automatically assembled and tested. Comprising a fixing mechanism, the fixing mechanism comprises a fixed column and a movable column, a clamping mechanism is installed on the outer ring of the fixing mechanism, the clamping mechanism comprises a plurality of first clamping blocks which are annularly distributed in two layers, and a second clamping block is installed at the top end of the first clamping block on the bottom layer; a plurality of first springs are annularly distributed on the outer side of the clamping mechanism, piston shafts and empty cylinders of different sizes can be assembled through the device by adjusting the distance between a movable column and a fixed column and the distance between symmetrical first clamping blocks, and the sealing performance of an injector is judged by observing the compression degree of the first springs.

Owner:深圳市优界科技有限公司

Seal detection device of blood perfusion device

ActiveCN108645570AJudgment of tightnessEasy to judgeFluid-tightness measurement using fluid/vacuumInternal pressurePositive pressure

The invention provides a seal detection device of a blood perfusion device. The seal detection device of a blood perfusion device includes an inner packaging bag and a humidity card, wherein a blood perfusion device is arranged in the inner packaging bag, and the inner packaging bag is filled with positive pressure gas; the humidity card is embedded into the surface of the inner packaging bag or arranged in the inner packaging bag for detecting the humidity in the inner packaging bag.; the positive pressure inflation pressure in the inner package bag is 116 kPa to 130 kPa; and the inner package bag is subjected to an internal pressure of 132 kPa or more. The seal detection device of a blood perfusion device can conveniently determine the sealing property of the blood perfusion device, andcan conveniently and accurately determine whether the internal packaging bag is perfect and has no leakage.

Owner:JIANGSU UNIV OF TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com