Plastic inspection well leakage test device and detection method

A technology for plastic inspection wells and test devices, which is applied in the direction of using liquid/vacuum degree for liquid tightness measurement, and by measuring the acceleration and deceleration rate of fluids, etc. Simple and reliable, low cost, convenient and simple to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

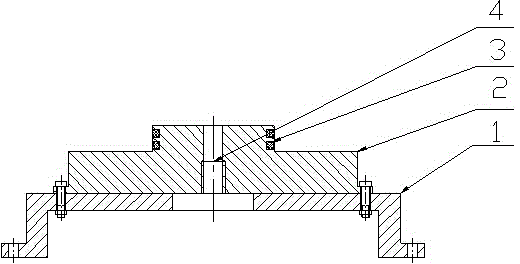

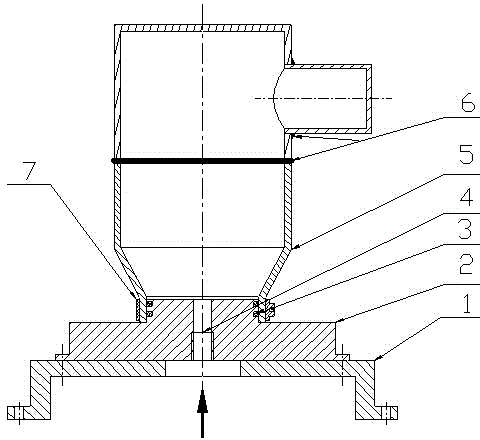

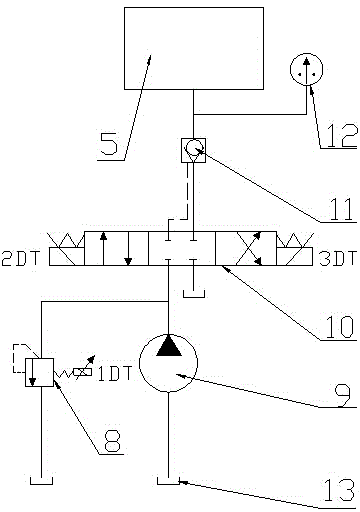

[0021] Embodiment 1: as Figure 1-3 As shown, a plastic inspection well sealing test device and detection method, including machine base 1, workbench 2, sealing ring 3, water injection hole 4, plastic inspection well 5, locking hoop 7; The bolts are fixed on the foundation, the workbench 2 is installed on the machine base 1 through bolts, the sealing ring 3 is installed on the workbench 2, the workbench 2 is provided with a water injection hole 4, and the plastic inspection well 5 is installed on the The upper part of the workbench 2 and the middle part of the plastic inspection well 5 are provided with a welding seam 6 .

[0022] The detection method of the plastic inspection well sealing test device is to first place the prepared plastic inspection well 5 on the workbench 2 with the well head facing down, and lock and fix the plastic inspection well 5 on the workbench 2 with the locking hoop 7, and then Fill the plastic inspection well 5 with pressurized water through the w...

Embodiment 2

[0023] Embodiment 2: as Figure 1-2 As shown, a plastic inspection well sealing test device and detection method, including machine base 1, workbench 2, sealing ring 3, water injection hole 4, plastic inspection well 5, locking hoop 7; The bolts are fixed on the foundation, the workbench 2 is installed on the machine base 1 through bolts, the sealing ring 3 is installed on the workbench 2, the workbench 2 is provided with a water injection hole 4, and the plastic inspection well 5 is installed on the The upper part of the workbench 2 and the middle part of the plastic inspection well 5 are provided with a welding seam 6 .

[0024] The detection method of the plastic inspection well sealing test device is to first place the prepared plastic inspection well 5 on the workbench 2 with the well head facing down, and lock and fix the plastic inspection well 5 on the workbench 2 with the locking hoop 7, and then Fill the plastic inspection well 5 with pressurized water through the w...

Embodiment 3

[0025] Embodiment 3: as Figure 1-2 As shown, a plastic inspection well sealing test device and detection method, including machine base 1, workbench 2, sealing ring 3, water injection hole 4, plastic inspection well 5, locking hoop 7; The bolts are fixed on the foundation, the workbench 2 is installed on the machine base 1 through bolts, the sealing ring 3 is installed on the workbench 2, the workbench 2 is provided with a water injection hole 4, and the plastic inspection well 5 is installed on the The upper part of the workbench 2 and the middle part of the plastic inspection well 5 are provided with a welding seam 6 .

[0026] The detection method of the plastic inspection well sealing test device is to first place the prepared plastic inspection well 5 on the workbench 2 with the well head facing down, and lock and fix the plastic inspection well 5 on the workbench 2 with the locking hoop 7, and then Fill the plastic inspection well 5 with pressurized water through the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com