Battery cover plate leak detection method

A battery cover, leak detection technology, applied in the direction of detecting the appearance of fluid at the leak point, using liquid/vacuum degree for liquid tightness measurement, etc., can solve the problem of neglecting detection evaluation and control, detection process lag, detection cost Advanced problems, to achieve the effect of simple test method, prevention of leakage hazards, and accurate test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

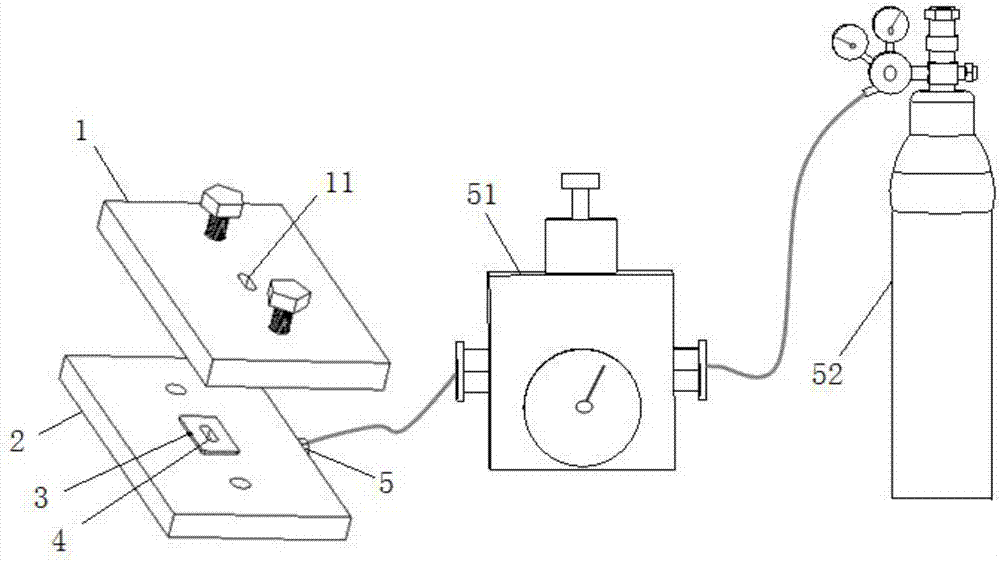

[0023] refer to figure 1 As shown, this embodiment is a battery cover leak detection device, including an upper pressing plate 1, and a lower pressing plate 2 corresponding to the upper pressing plate 1; Viton gaskets with high temperature resistance, corrosion resistance and excellent elasticity are used. The elastic washer 3 is provided with a hollow cavity 4 , and the component under test (not shown in the figure) of the battery cover is clamped in the hollow cavity 4 . An opening 11 corresponding to the hollow space 4 is vertically penetrated in the upper platen 1 , the upper platen 1 is detachably fixed to the lower platen 2 by screws, and the elastic gasket 3 is sealed in the upper platen 1 and the lower platen 2 . The lower platen 2 is provided with an air inlet 5, and the air inlet 5 is externally connected with an air pressure regulating valve 51, and the air pressure regulating valve 51 is connected with a nitrogen tank 52. The interior of the air inlet 5 communica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com