A cable stuffing box leak detection device

A technology for leak detection and cable stuffing, which is applied in fluid tightness testing, measuring devices, liquid tightness measurement using liquid/vacuum, etc. It can solve the problems of cable stuffing box tightness detection, leakage, lack, etc.

Active Publication Date: 2019-01-22

NAVAL UNIV OF ENG PLA

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, at present, due to the lack of corresponding testing tools, in practice, seldom carry out the sealing test of the cable stuffing box according to the above requirements, resulting in frequent leakage in this part

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

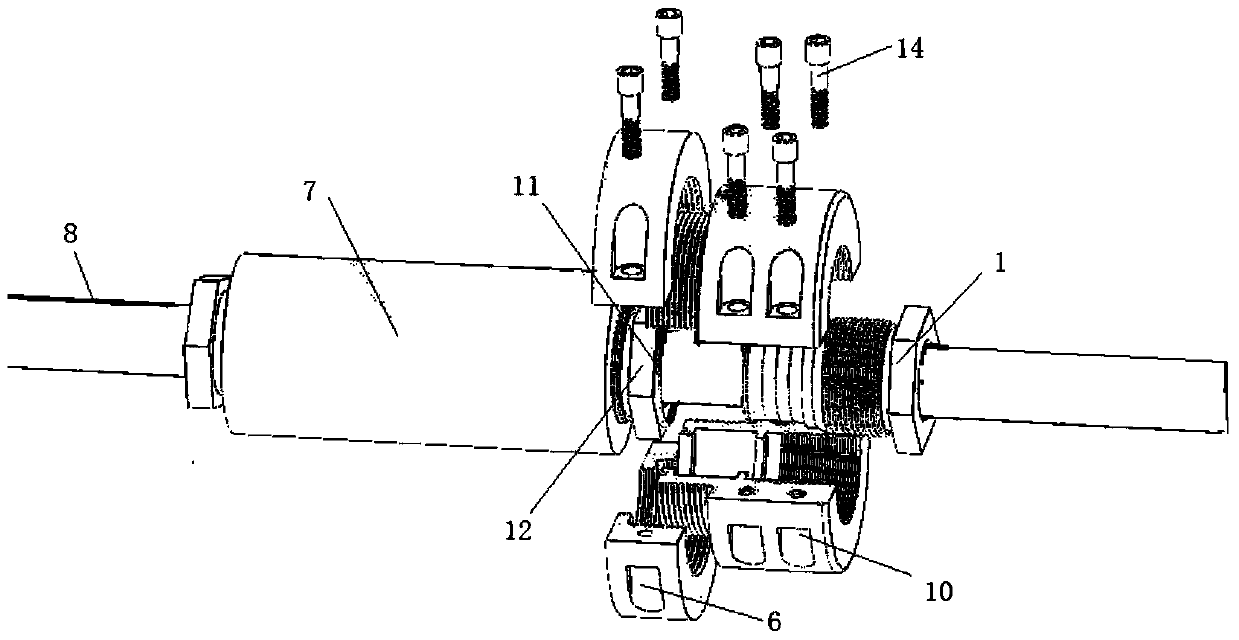

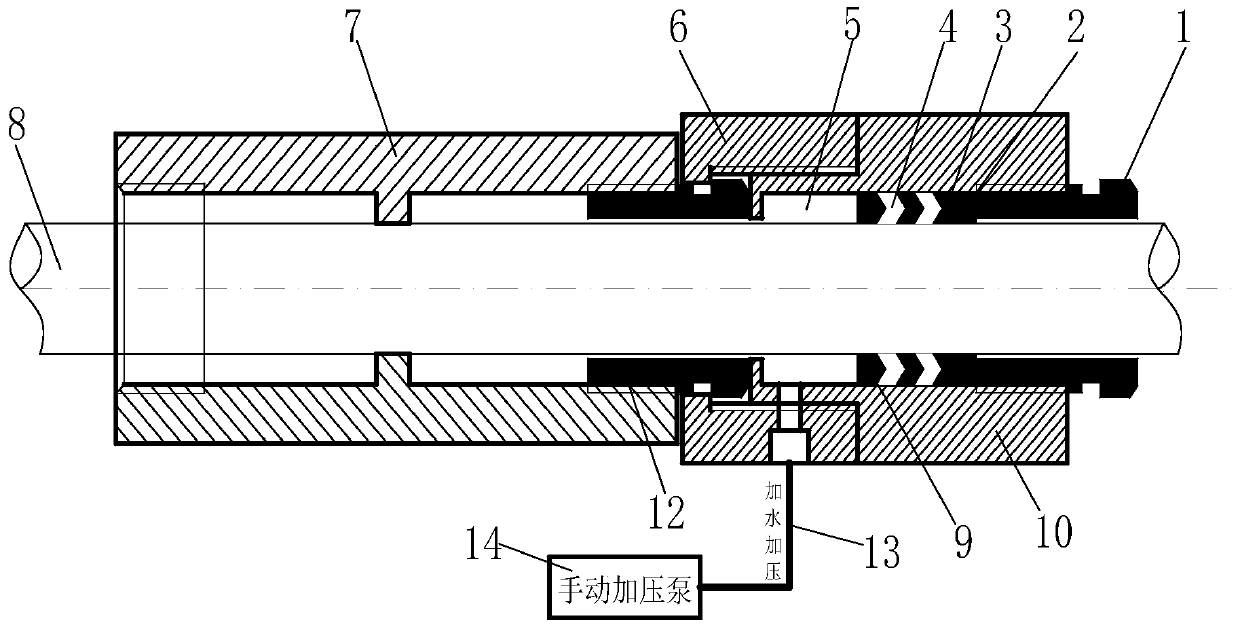

The invention provides a sealing detection device of a cable gland, and the device comprises a manual pressurization pump, a water injection pipe, a first cup-shaped pipe joint nut, a second cup-shaped pipe joint nut as well as a first rear baffle ring, a combined sealing ring and a second rear baffle ring which are located between the first cup-shaped pipe joint nut and the second cup-shaped pipe joint nut, wherein the left end of the first cup-shaped pipe joint nut is connected to the first rear baffle ring and compresses the combined sealing ring; the left end of the combined sealing ring is connected to the second rear baffle ring; the first cup-shaped pipe joint nut, the first rear baffle ring, the combined sealing ring, the second rear baffle ring and the second cup-shaped pipe joint nut wrap a cable inside; a front clamping buckle and a rear clamping buckle which are connected through buckling and threaded connection sleeve the outer layer; a sealed water injection cabin is formed between a sleeve and the cable, and the sleeve is formed by the front clamping buckle and the rear clamping buckle; and the manual pressurization pump communicates with the water inject cabin by the water injection pipe. The device provided by the invention can simulate cable gland states under different depth conditions, can detect sealing performance of a sealing material of the cable gland and has the advantages of high control precision, small and compact appearance and convenient operation.

Description

technical field The invention relates to the technical field of marine cable stuffing boxes, in particular to a cable stuffing box leak detection device. Background technique A large number of watertight cable stuffing boxes exist in ships, such as cable stuffing boxes for submersibles to wear pressure hulls, or cable stuffing boxes for surface ships to wear various pressure bulkheads. According to the requirements of the ship cable sealing process, the test of the sealing of the cable stuffing box on the pressure-resistant shell lasts for 5 minutes with the corresponding required water pressure to observe whether there is any water leakage, and it is required that when the sealing packing is changed on the ship, the simulation test should be carried out again. However, at present, due to the lack of corresponding testing tools, the sealing test of the cable stuffing box is seldom carried out according to the above requirements in practice, resulting in frequent leakage in ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01M3/28

CPCG01M3/2838

Inventor 刘伯运陈如木邱金水刘燕红后伟任广鲁陈功

Owner NAVAL UNIV OF ENG PLA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com