Airtight valve airtightness detection platform

A technology of air tightness detection and closed valve, which is applied in the direction of using liquid/vacuum degree for liquid tightness measurement, by measuring the acceleration and deceleration rate of fluid, etc. It is difficult to effectively guarantee the quality and performance, so as to achieve the effect of good detection effect, convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

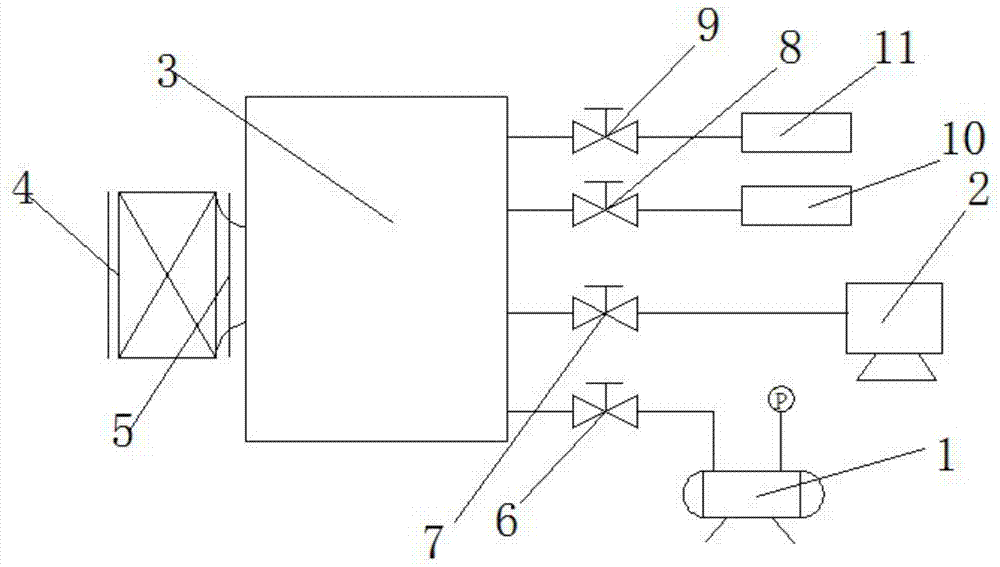

[0018] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0019] Airtightness testing platform for airtight valves, including air compressor 1, vacuum pump 2, static pressure box 3, airtight valve 4 and variable diameter pipe 5, one side of the static pressure box 3 is equipped with variable diameter pipe 5, and the static pressure The other side of box 3 is installed ball valve one 6, ball valve two 7, ball valve three 8, ball valve four 9 in sequence, wherein the volume of static pressure box 3 is 4m 3 , the material of the static pressure box 3 is a steel plate, the thickness of the steel plate is 4mm, the end of the reducing pipe 5 is equipped with a closed valve 4, and the end of the ball valve-6 is equipped with an air compressor 1, A vacuum pump 2 is installed at th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com