Gas leakage detection method for engine cylinder

A technology of engine cylinder and detection method, which is applied in the direction of using liquid/vacuum degree for liquid tightness measurement, etc., can solve problems such as difficult to find leakage and air leakage, and achieve the effect of reducing maintenance cost, reducing maintenance time, and avoiding replacement of normal components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

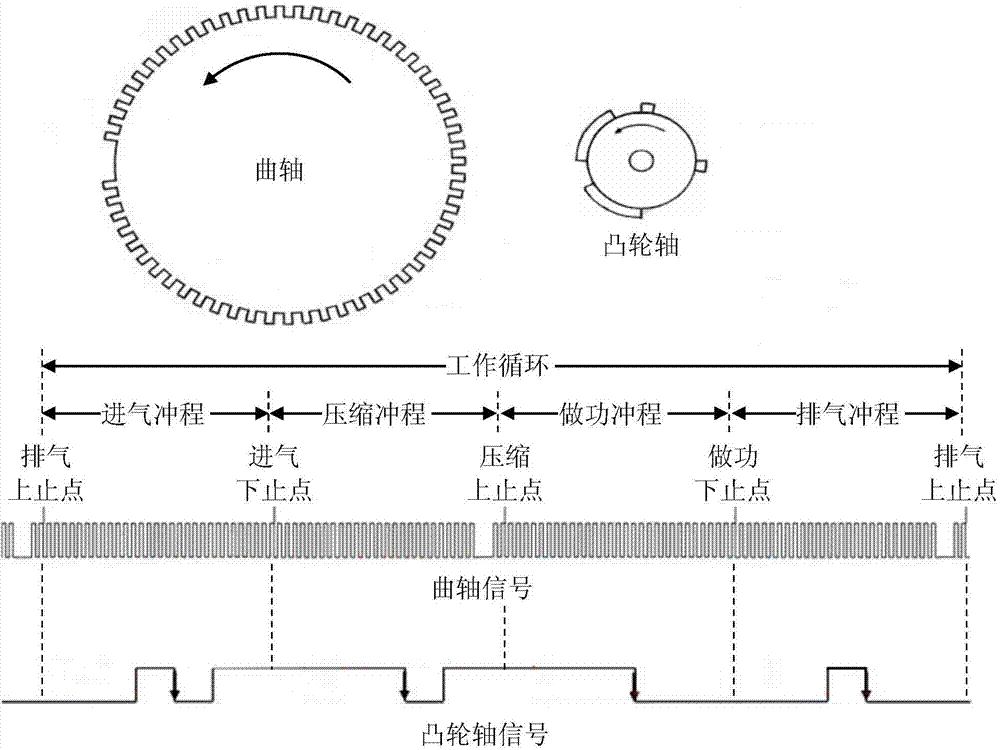

[0010] see figure 1 , each working cycle of a four-stroke engine commonly used in motor vehicles consists of an intake stroke, a compression stroke, a power stroke and an exhaust stroke.

[0011] During the intake stroke, the intake valve opens and the exhaust valve closes, fuel and air are injected into the cylinder through the intake valve to form a combustible mixture.

[0012] During the compression stroke, both the intake and exhaust valves are closed, and the combustible mixture is compressed by the piston to increase the pressure and temperature in the cylinder.

[0013] In the power stroke, both the intake valve and the exhaust valve are closed, and the combustible mixture is ignited by the spark plug (gasoline engine) or ignites by itself (diesel engine) to release heat energy, which makes the pressure and temperature in the cylinder further rise sharply and pushes the piston to move. output mechanical energy.

[0014] During the exhaust stroke, the intake valve clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com