Kettle tightness detection device and detection method employing same

A detection device, a gas-gas technology, which is used in fluid tightness testing, measuring devices, and liquid/vacuum tightness measurement. , to achieve the effect of fast response, simple structure and improved sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

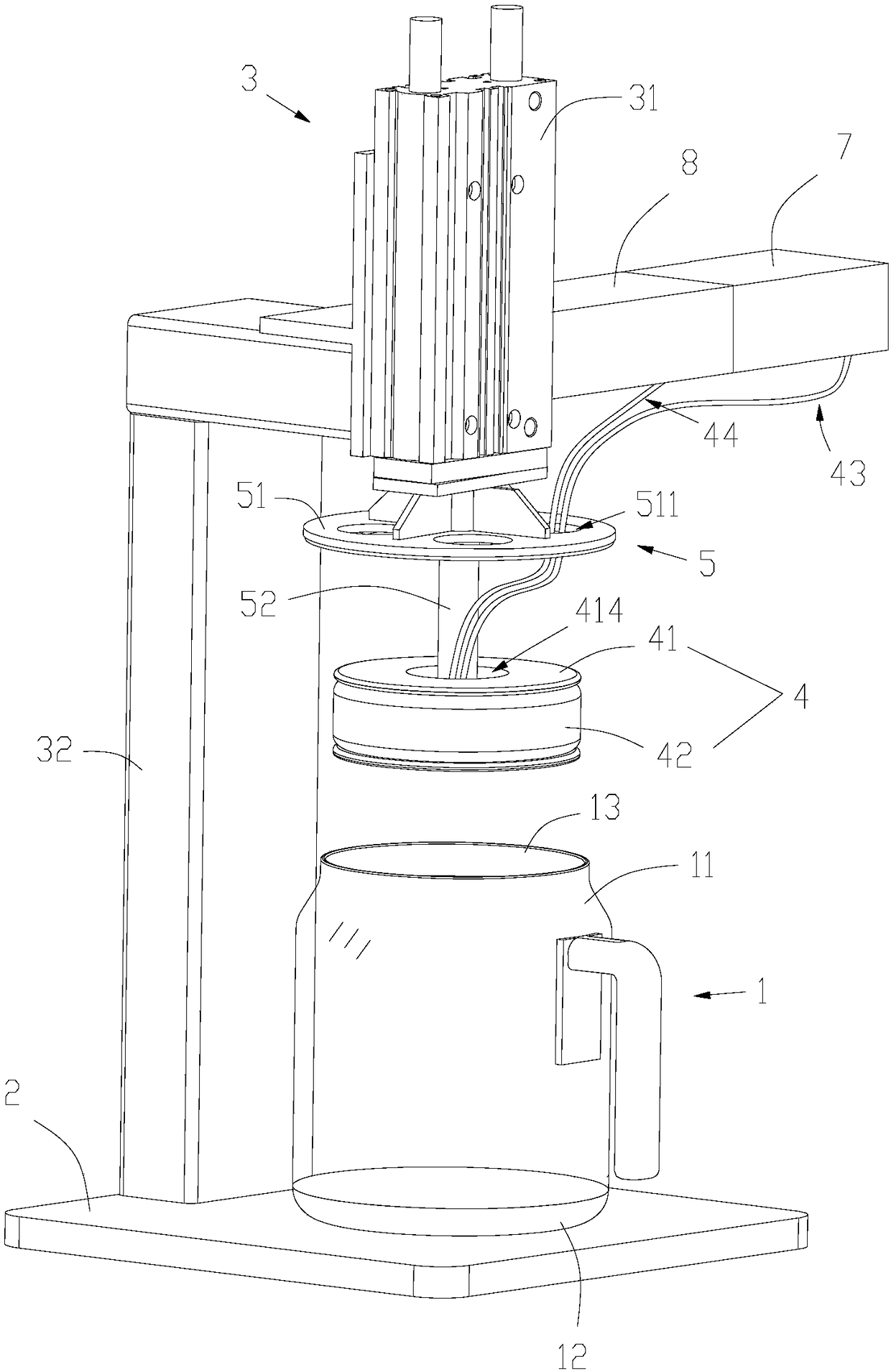

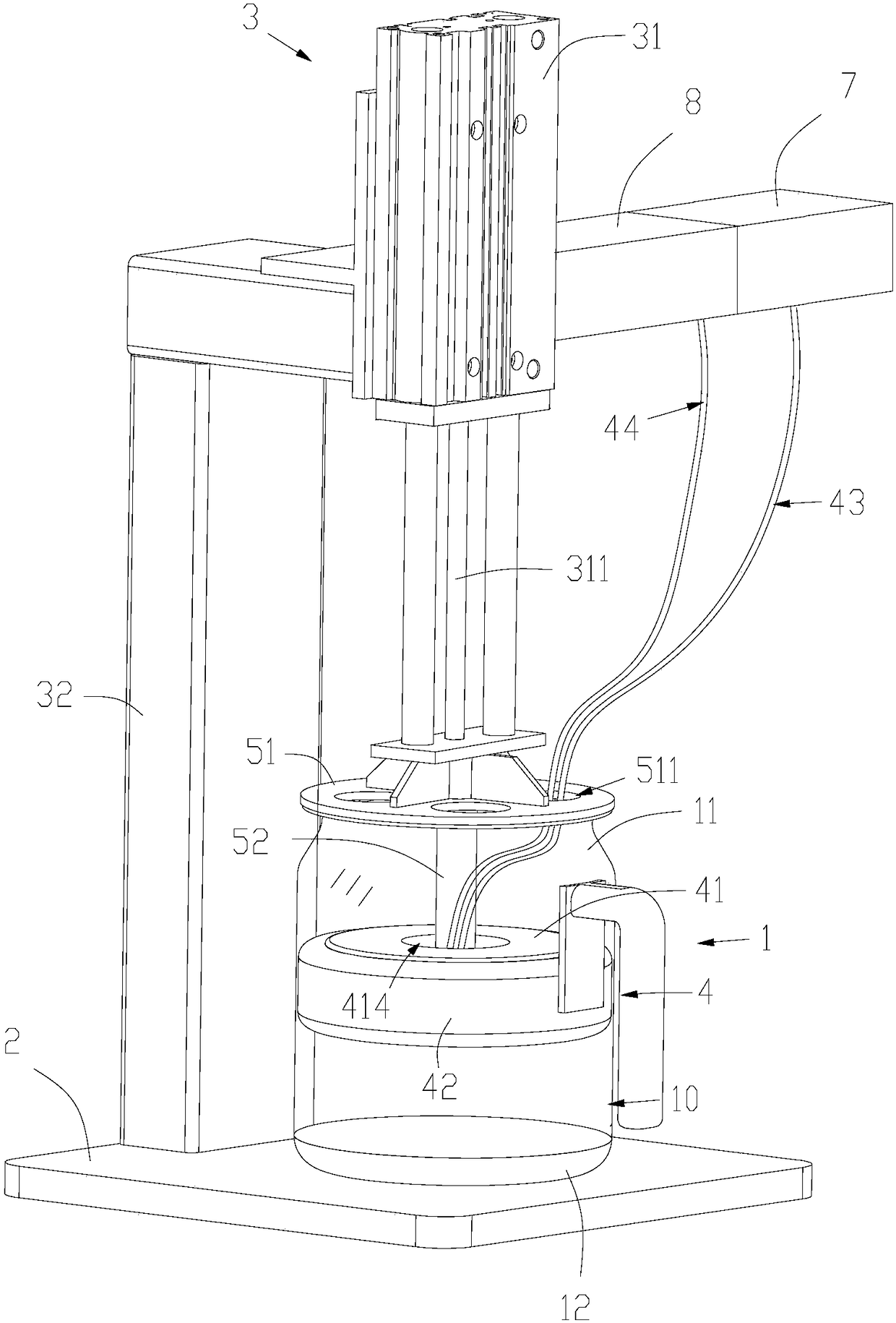

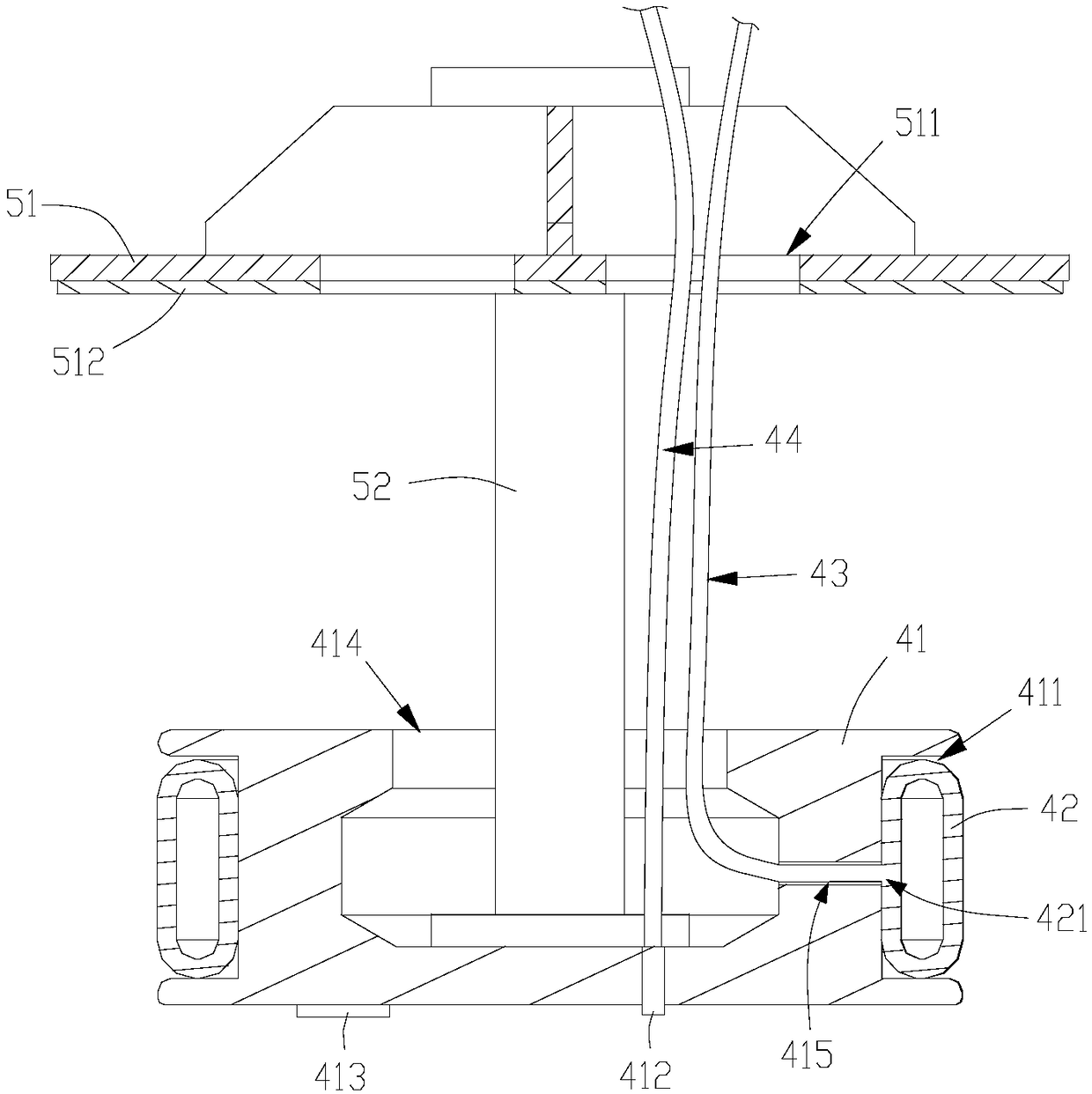

[0026] see figure 1 , the present embodiment provides a kettle body air tightness detection device, the involved kettle body 1 includes a kettle body 11 and a kettle bottom 12, the kettle bottom 12 is fixedly connected to the lower end of the kettle body 11, and the upper end of the kettle body 11 is opened There is a spout 13, and the detection device includes a frame 32, a base 2, a drive assembly 3 and a detection assembly 4, and the detection assembly 4 is installed on the frame 32.

[0027] see figure 1 and figure 2 , the pot body 1 is placed on the base 2 with the spout 13 facing upwards, the driving assembly 3 includes a driving cylinder 31, the driving cylinder 31 is arranged above the base 2 through a frame 32, and the extension of the piston rod 311 is The outgoing direction is toward the lower side, and the detection assembly 4 is installed on the lower end of the piston rod 311. The detection assembly 4 can move up and down relative to the kettle body 1 through ...

Embodiment 2

[0036] see Figure 4 , the difference between the present embodiment and the first embodiment lies in the difference in the arrangement of the base 2, the detection device of the present embodiment also includes a conveying mechanism 6, and the conveying mechanism 6 is provided with a plurality of bases 2 along its conveying direction, each base 2 are placed with pots 1, and the conveying mechanism 6 sequentially transports the pots 1 to be detected on each base 2 to the bottom of the detection assembly 4 for detection of sealing performance. Preferably, the drive assembly 3 and Multiple groups of detection components 4 can be arranged accordingly, so that multiple pot bodies 1 can be detected at one time. The arrangement of the conveying mechanism 6 can improve the degree of automation of the detection device and effectively improve the detection efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com