A test device for connector insertion force

A test device and plug-in force technology, applied in the detection field, can solve the problems of strong work, poor test stability, and low manual test efficiency, and achieve high test accuracy, high work efficiency, and meet the needs of mass production testing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

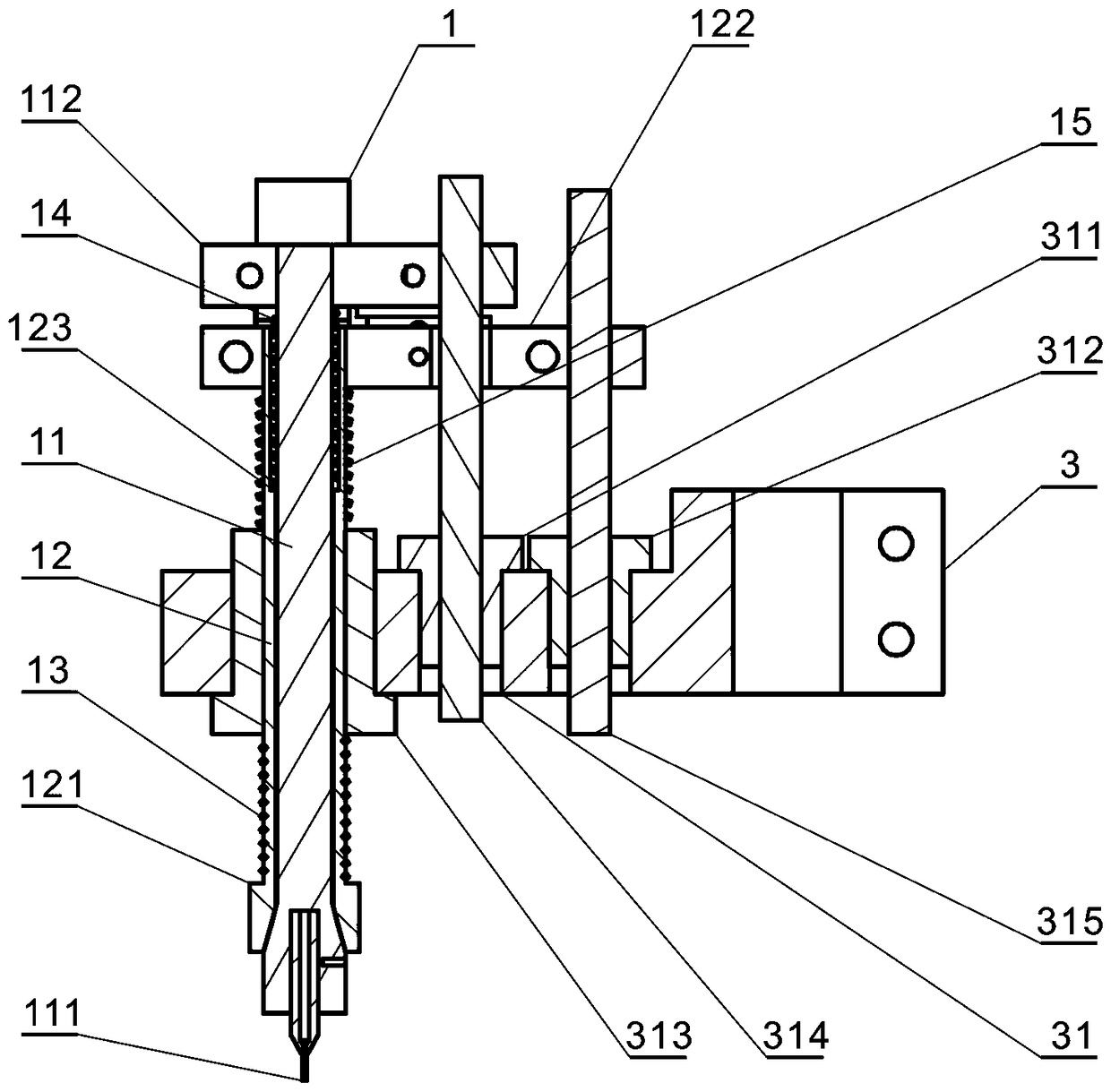

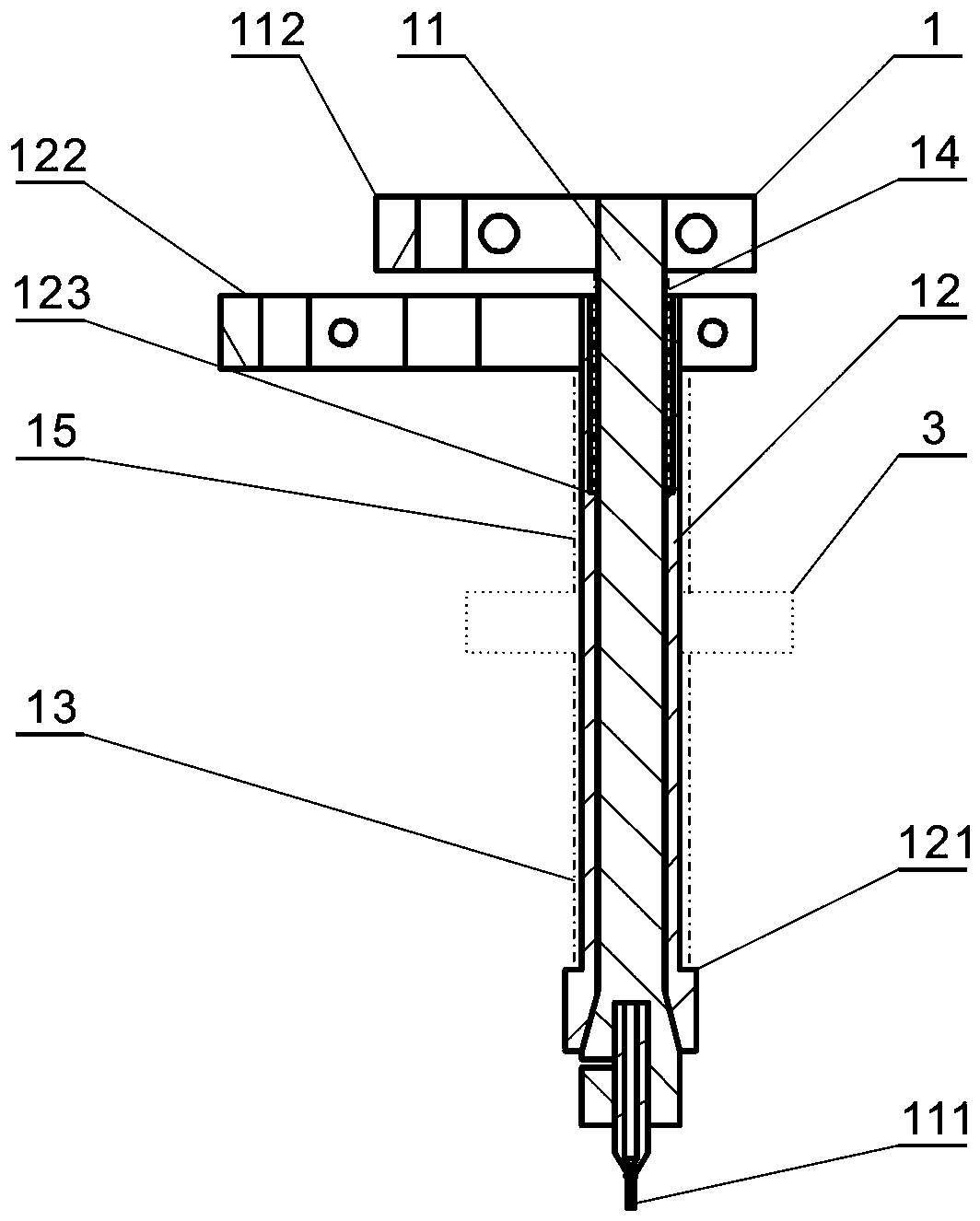

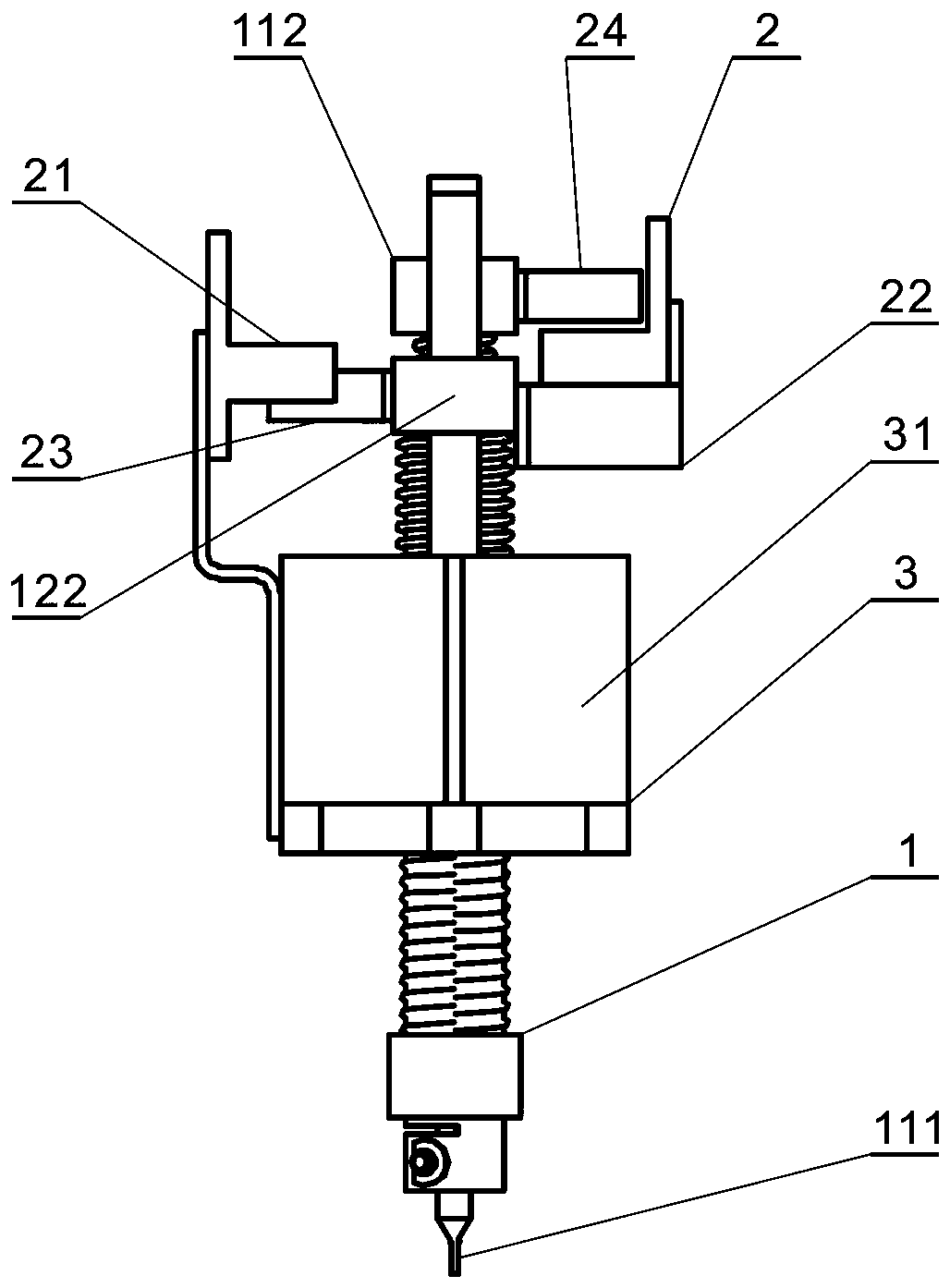

[0013] refer to figure 1 , figure 2 , image 3 , the present invention includes a docking assembly 1, a detection assembly 2 and a floating worktable 3. The docking assembly 1 is composed of a docking rod 11, a linear guide sleeve 12, a first spring 13, a second spring 14 and a balance spring 15. The docking rod 11 The bottom end of the linear guide sleeve 12 is provided with a docking member 111, the top end is provided with a docking rod holder 112, the outer side of the linear guide sleeve 12 is provided with a first spring seat 121, the inner wall is provided with a second spring seat 123, and the top end is provided with a guide sleeve holder 122. And the docking rod 11 is arranged in the linear guide bush 12, the first spring 13 and the balance spring 15 are arranged between the first spring seat 121 of the linear guide bush 12 and the guide bush holder 122, and the second spring 14 is arranged in the docking rod 11 between the docking rod holder 112 of the linear gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com