Water chilling unit ejector performance simulation test system and test method

A simulation test and chiller technology, which is applied in the testing of machines/structural components, instruments, measuring devices, etc., can solve problems such as insufficient oil return capacity, waste of after-sales costs, and fluctuations in ejection performance, so as to reduce testing costs and eliminate The effect of high volatility and guaranteed reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing.

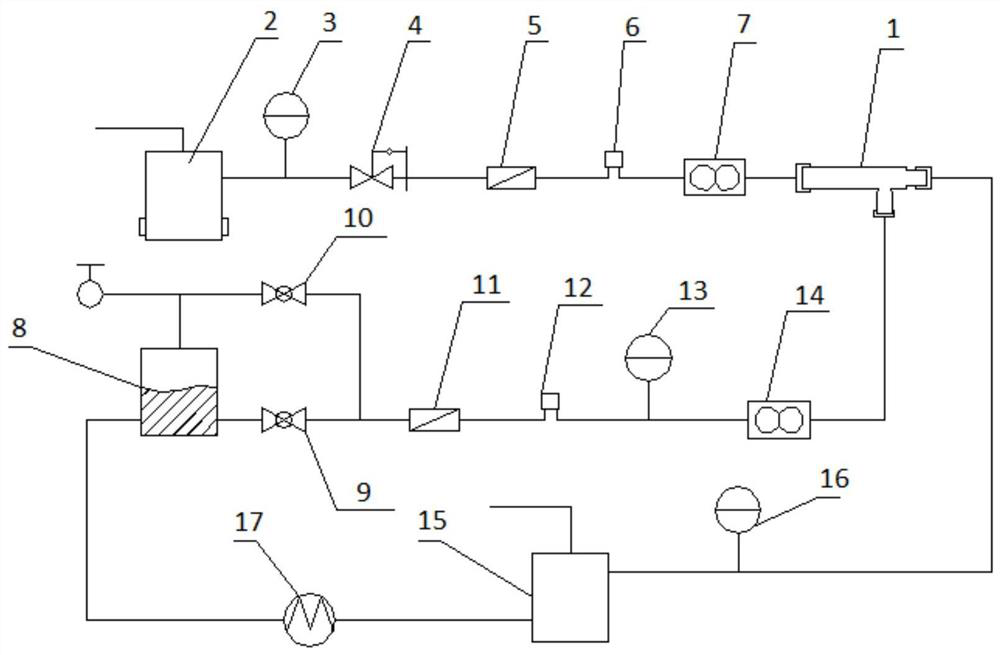

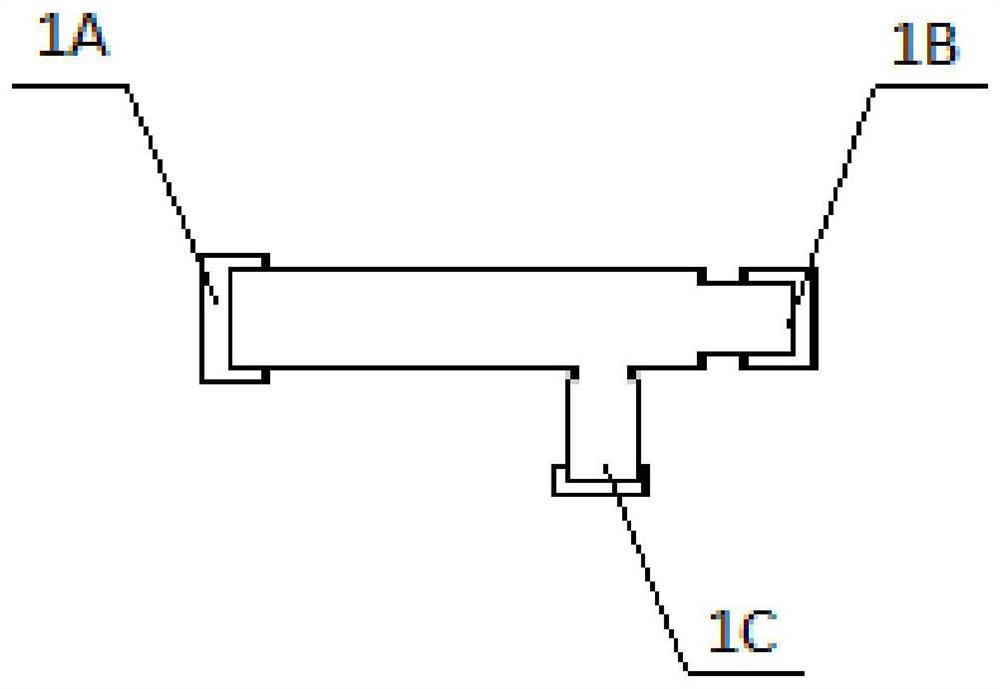

[0030] figure 1 It is a structural schematic diagram of the test system of the present application. Such as figure 1 As shown, the test system includes an injector 1 to be tested, a jet flow part, a jet flow part to be tested and a control part (not shown), wherein the injector 1 to be tested includes an introduction tube 1A, an outlet tube 1B and a jet tube 1C( figure 2 ), the part of the drawing jet and the part of the drawn jet are connected to the introduction pipe 1A and the jet pipe 1C of the injector 1 to be tested through, for example, a cylinder.

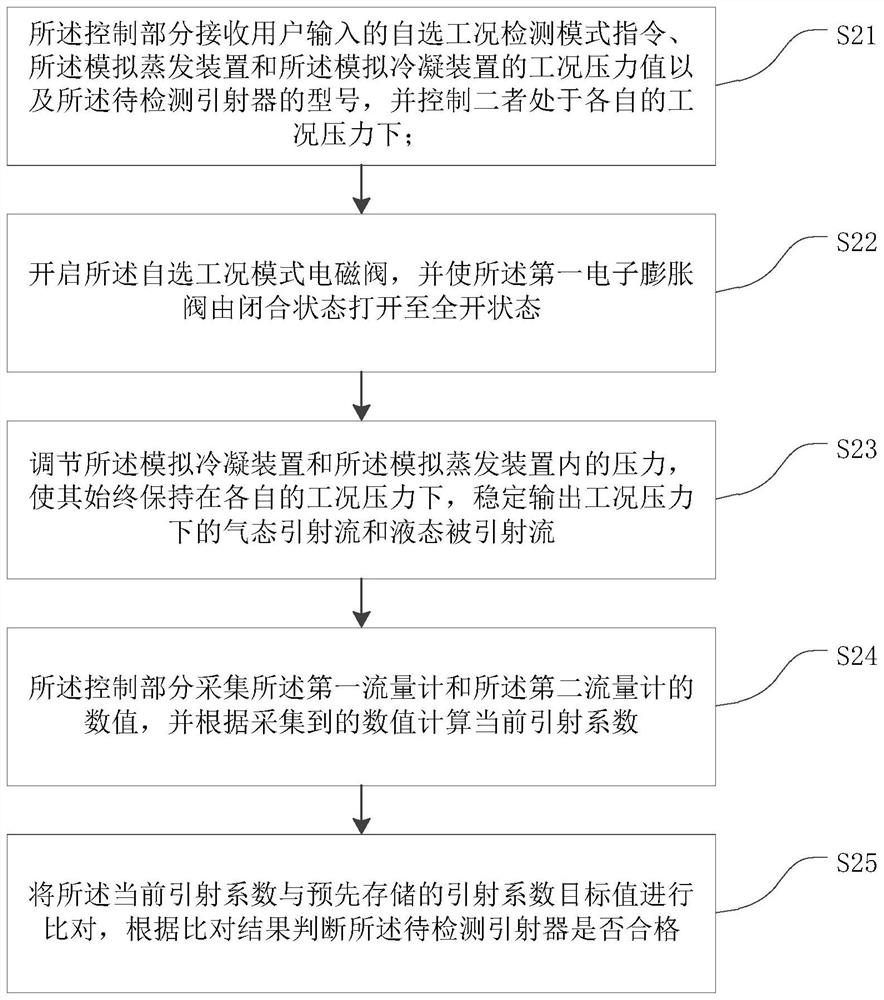

[0031] Specifically, the jet flow part includes a simulated condensing device 2 and a first pressure sensor 3 and a first electronic pressure regulating valve which are sequentially arranged on the pipeline connecting the simulated condensing device 2 and the introduction pipe 1A of the injector 1 to be tested. 4. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com