Variable-spray whole-torrential flow showerhead

A technology of full-jet flow and sprinkler head, which is applied in spraying devices, spraying devices with movable outlets, gardening, etc. It can solve the problems of small water jet flow rate and variable spraying of nozzles, and achieve uniform spraying, simple product structure and reliable operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

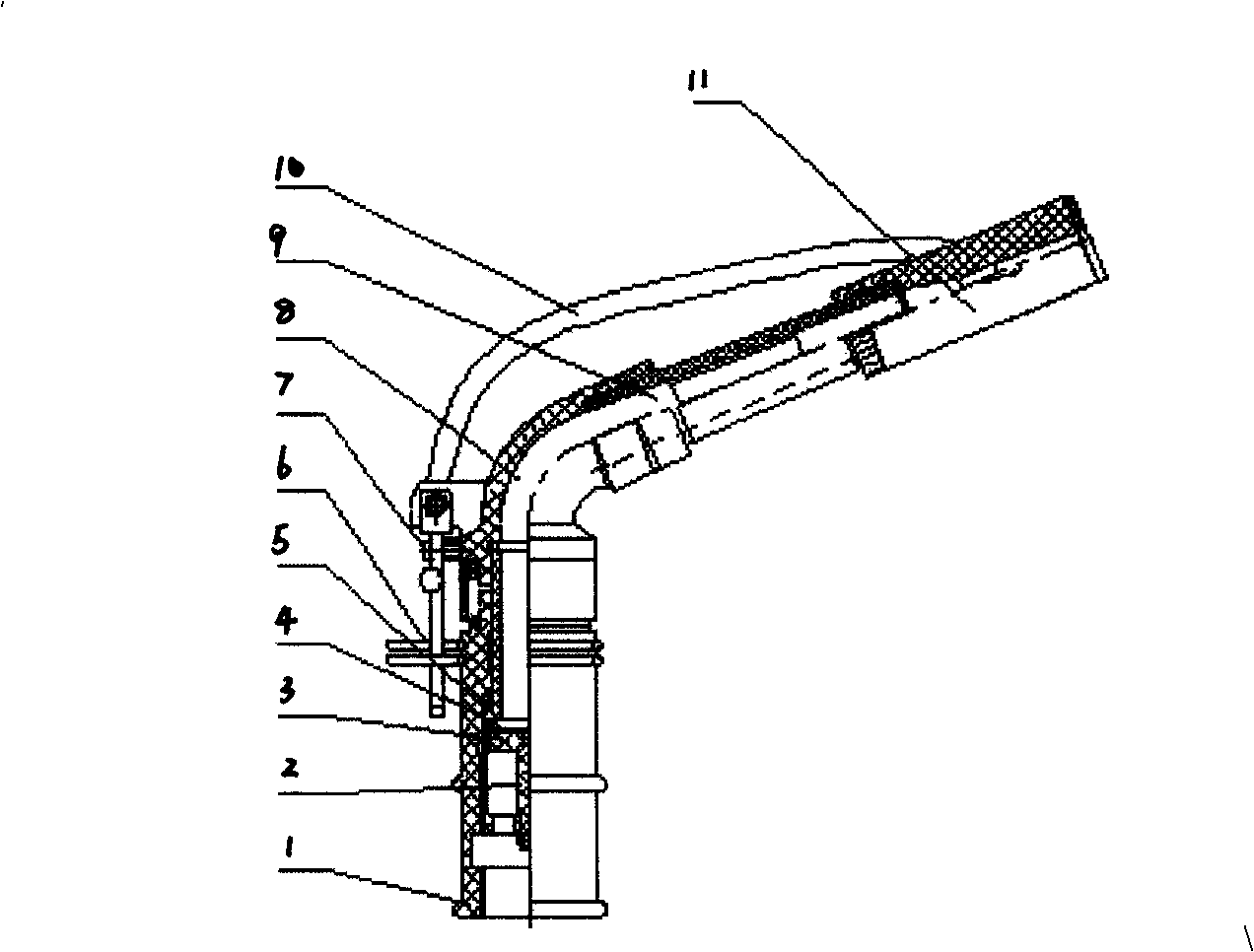

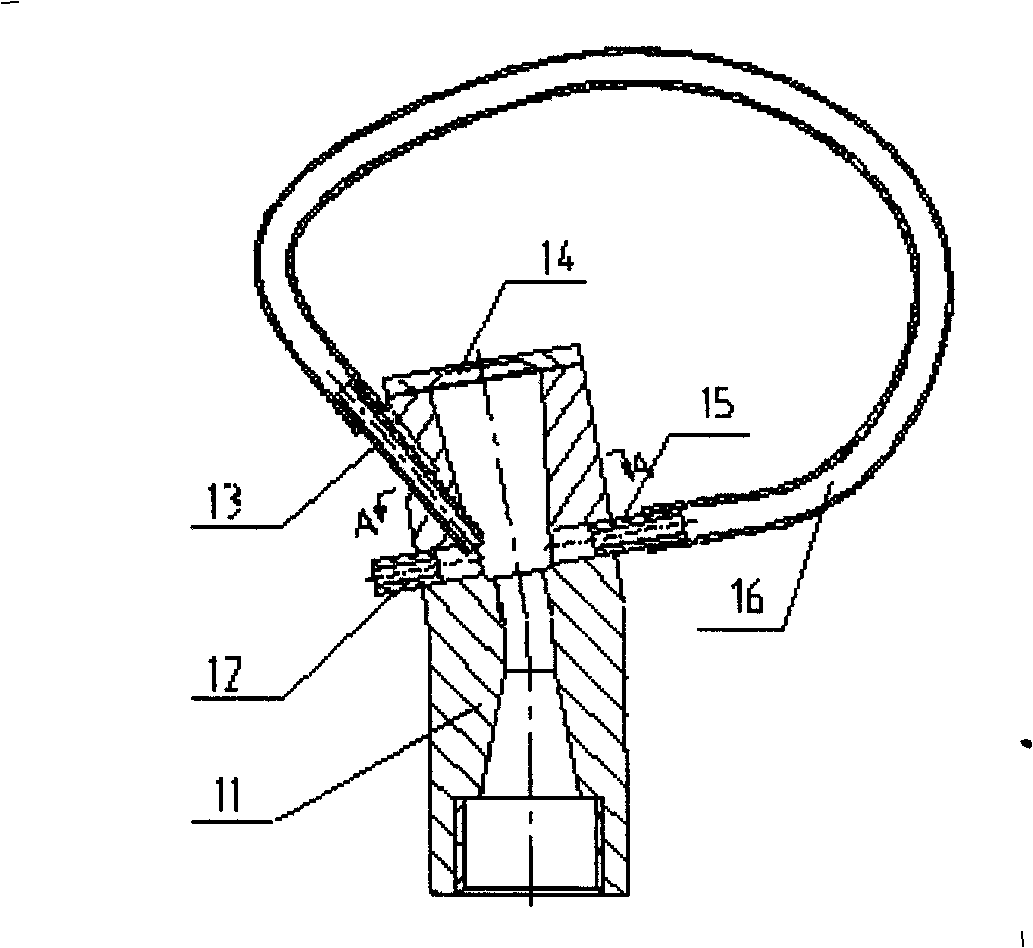

[0016] Such as figure 1 , 2 As shown, the present invention includes a flow path composed of a static piece (3), a moving piece (4), a hollow shaft (5), a spray body (8), a nozzle pipe (9), a swivel connection seat (1), a support Rod (2), limit ring (6), reversing mechanism (7), reverse plastic pipe (10), jet element body (11) and other parts, wherein the jet element body (11) is connected by the signal water connector (13 ), the signal water inlet nozzle (15), the reverse gas supply nozzle (12), the outlet cover plate (14), and the guide pipe (16). The reverse plastic pipe (10) is connected with the reverse air supply nozzle (12), and the working state of the nozzle includes three states of direct injection, stepping and reverse.

[0017] The working process is as follows:

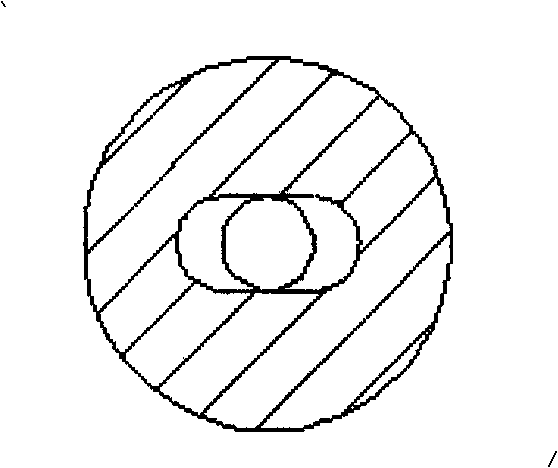

[0018] Direct state: such as Figure 6 As shown, the water jet passes through the inclination angle (17) of the jet element body, and the driving force on the nozzle overcomes the friction force of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com