Fluid catalytic cracking gas-oil separating and stripping device and method thereof

A technology of fluidized catalytic cracking and stripping, which is applied in the direction of catalytic cracking, separation methods, chemical instruments and methods, etc. It can solve the problems of long residence time, thermal cracking reaction, increasing the difficulty of stripping in the stripping section, etc., and achieve sufficient steam Lifting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

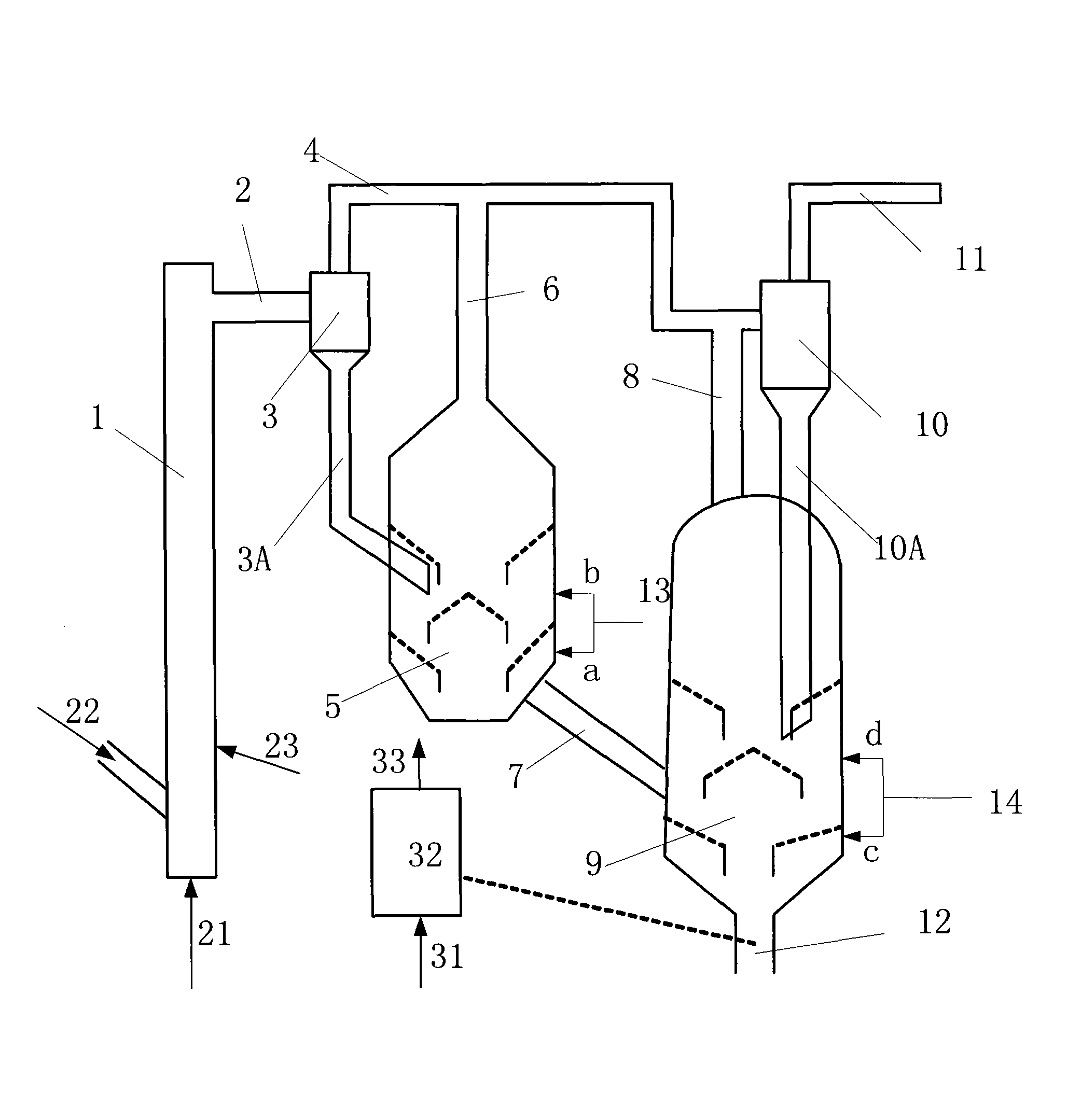

[0030] The method provided by the present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited thereby. The present invention is not limited to two-stage cyclone separation and two-stage stripping, and can also increase one or more stages by similar connection mode after two-stage cyclone separation and two-stage stripping, and the riser reactor of illustration can be It can be coaxial or non-coaxial.

[0031] Accompanying drawing is the equipment and method flow schematic diagram of the present invention.

[0032] The fluidized catalytic cracking oil and gas separation and stripping equipment provided by the present invention comprise a primary cyclone separator 3, a first stripper 5, a secondary cyclone separator 10 and a second stripper 9, wherein each stage of cyclone separator is A plurality of cyclone separators are provided, each cyclone separator is provided with an inlet, a gas phase outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com