Directly operable clutch with vented geometry

A technology of clutch and clutch disc, applied in the direction of clutch, friction clutch, mechanical drive clutch, etc., to achieve the effect of increased cooling performance, simplified manufacturing and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

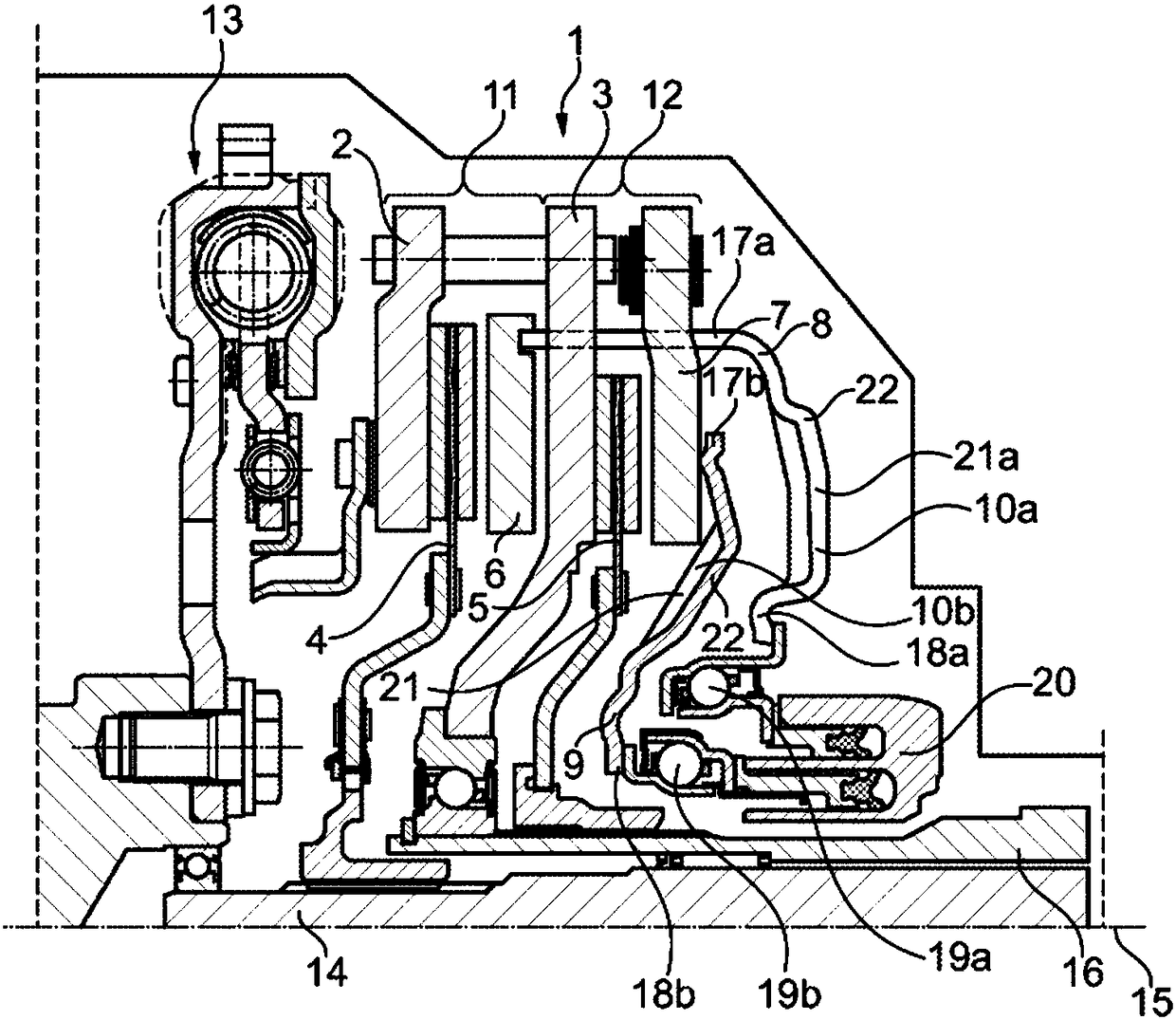

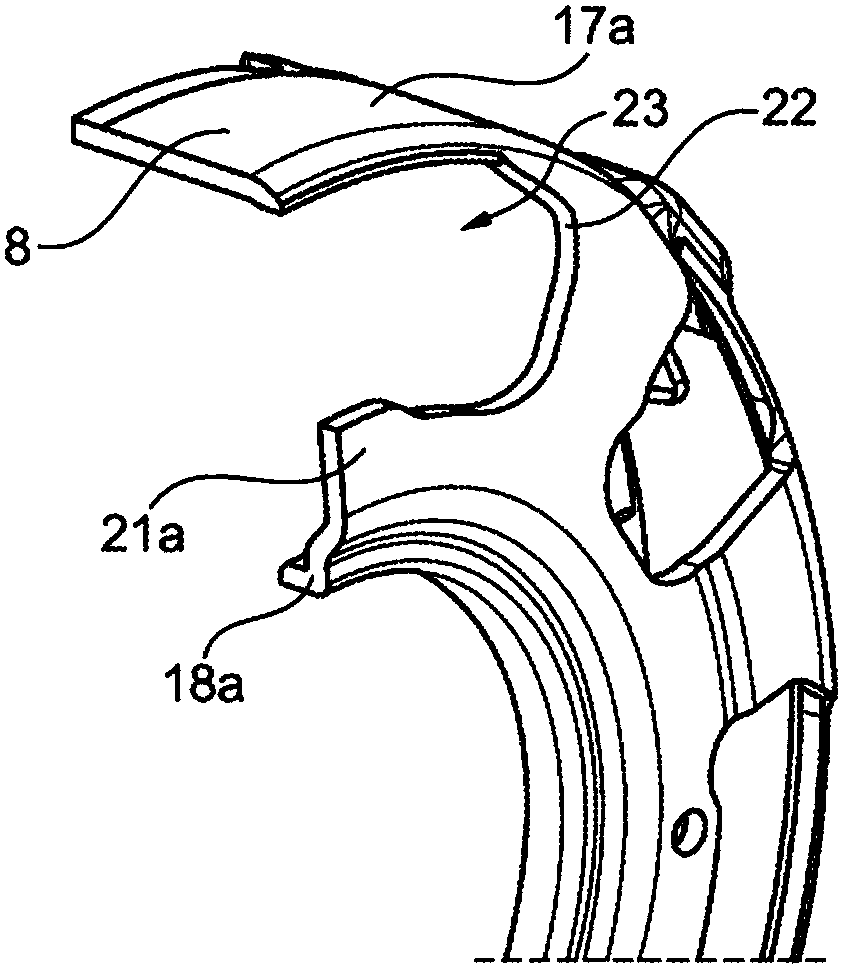

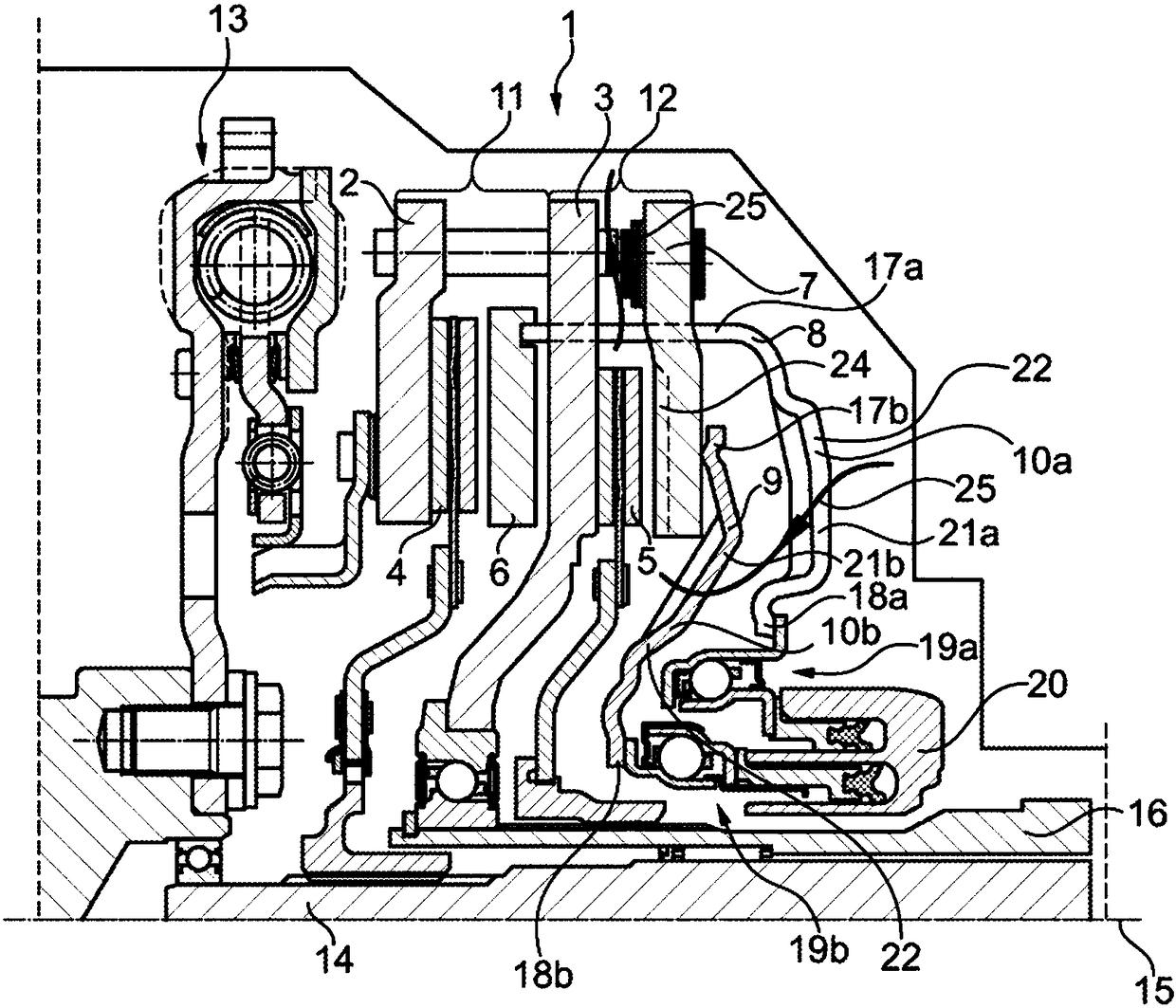

[0029] exist figure 1A first embodiment of a friction clutch 1 (also referred to as friction coupling) according to the invention can be seen in FIG. The friction clutch 1 is designed for a drive train of a motor vehicle, such as a Passenger cars, trucks, buses or agricultural trucks. The friction clutch 1 is designed here as a dry friction clutch 1 , as an alternative thereto, it can also be designed as a wet friction clutch 1 . The friction clutch 1 is also designed and used as a double clutch, as is basically known from DE 10 2011 013 475 A1. The disclosure content of DE 10 2011 013 475 A1 is therefore incorporated here.

[0030] The friction clutch 1 basically has pressure plates 6 , 7 which can be moved back and forth relative to the counter pressure plates 2 , 3 and the clutch plates 4 , 5 in order to engage and disengage the clutch 1 . Furthermore, the friction clutch 1 also has actuating elements 8 , 9 which influence the displacement position of the pressure plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com