Method and device for heating a connection element

A technology for connecting elements and components, applied in the field of heating connecting elements, can solve the problems of unutilized output of heat energy, circuit damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

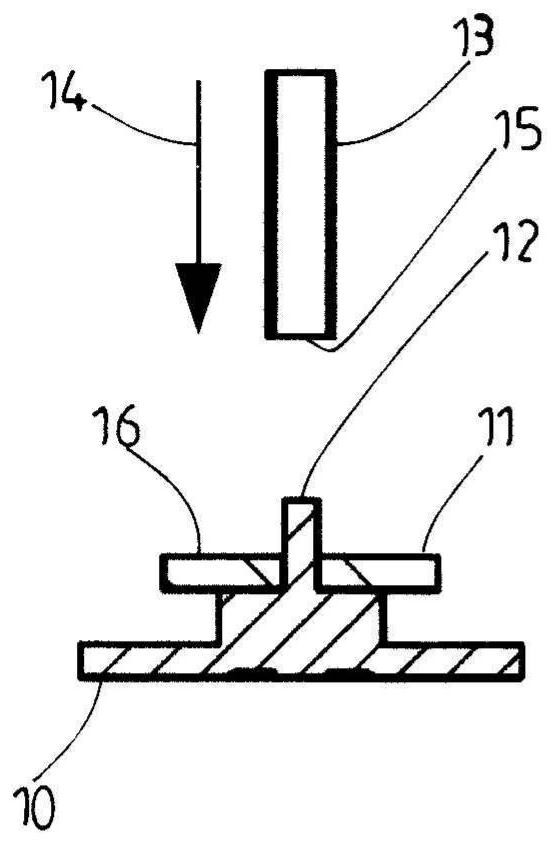

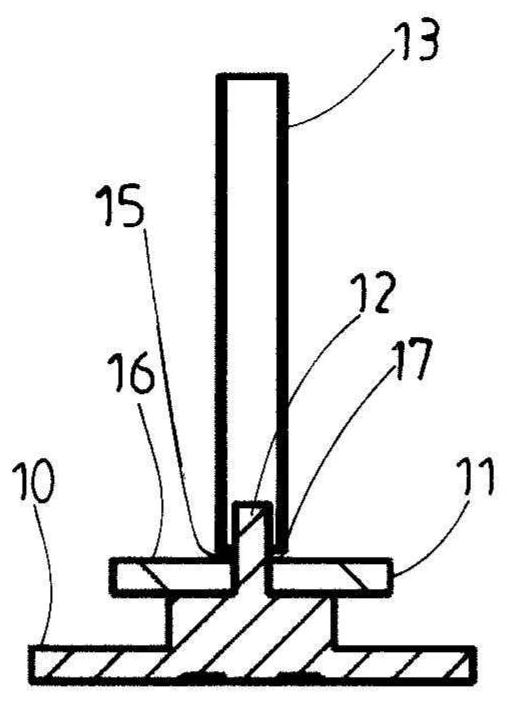

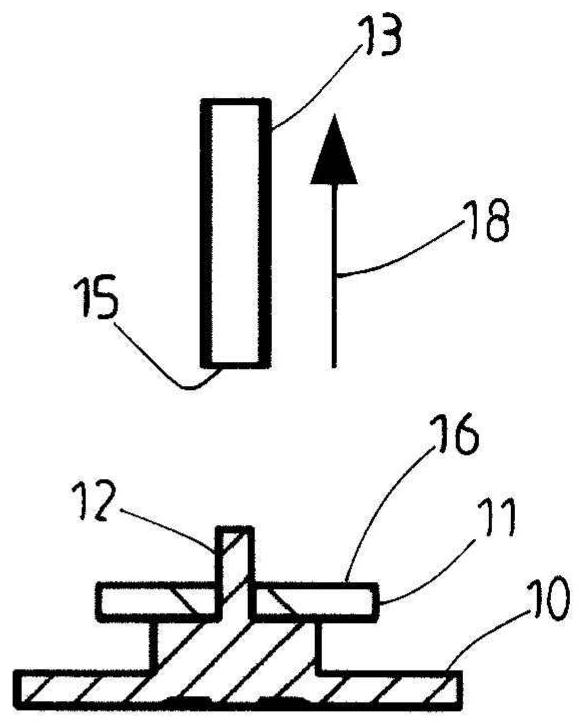

[0030] In order to connect the first part 10 with the second part 11 (also called joint partner), it is known to first heat the connecting element 12 (also called pin or rivet) by applying a heat medium or hot air ( Figure 1a , 1b, 1c). In this example representing prior art, the connecting element 12 is an integral part of the first part 10 and is guided through an opening in the second part 11 . Here, the substantially tubular nozzle 13 is first guided in the direction of the arrow 14 over the connecting element 12 ( Figure 1a , 1b ). For the sake of clarity, only a strongly schematic part of the nozzle 13 is shown here. It goes without saying that connecting elements 12 can also be supplied to the nozzle.

[0031] The hot air to be guided through the nozzles 13 is generated by a not shown hot air generator. In this case, air is first supplied to the hot air generator and subsequently heated to the desired temperature. The hot air is guided through the nozzles 13 dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com