Non-woven cloth hot-sticking forming equipment and non-woven cloth hot-sticking forming process

A technology of non-woven fabrics and forming equipment, which is applied in the field of non-woven fabric thermal bonding forming equipment and technology, which can solve the problems of material hanging on the wall, no stripping mechanism, and limited use of heat dissipation structure, and achieve powerful functions and design Reasonable and ingenious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

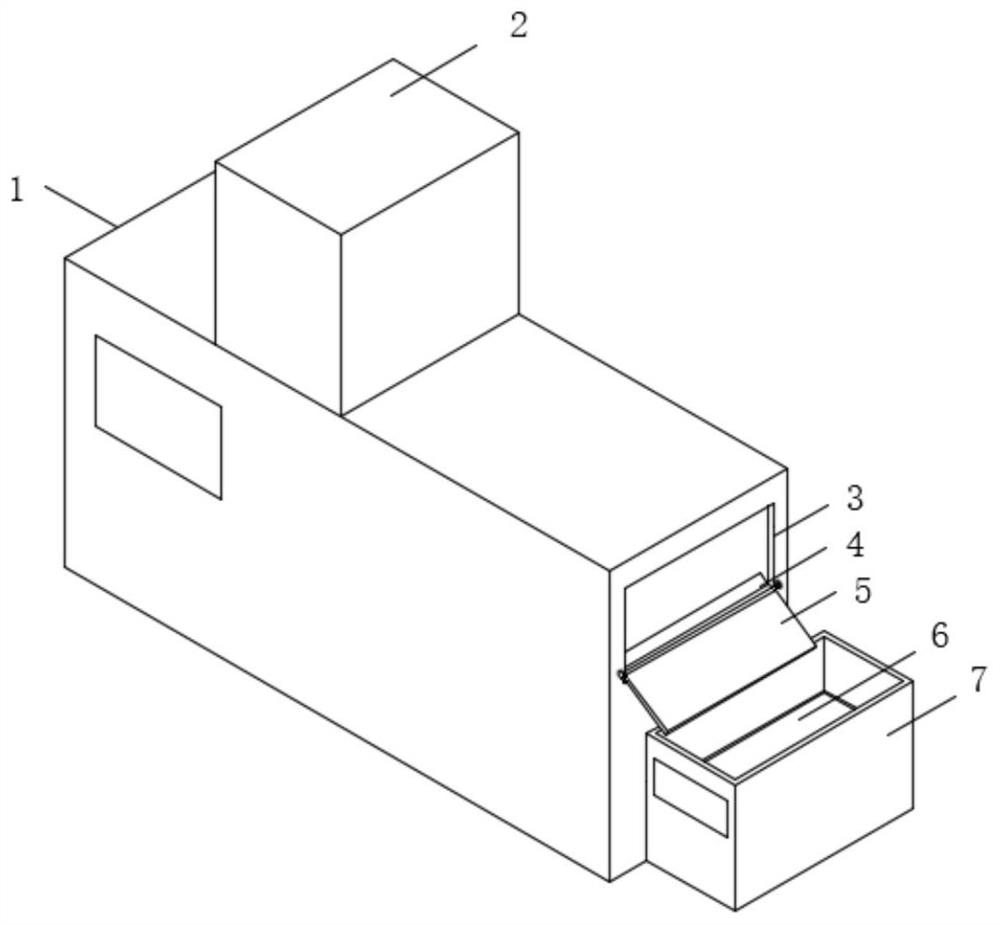

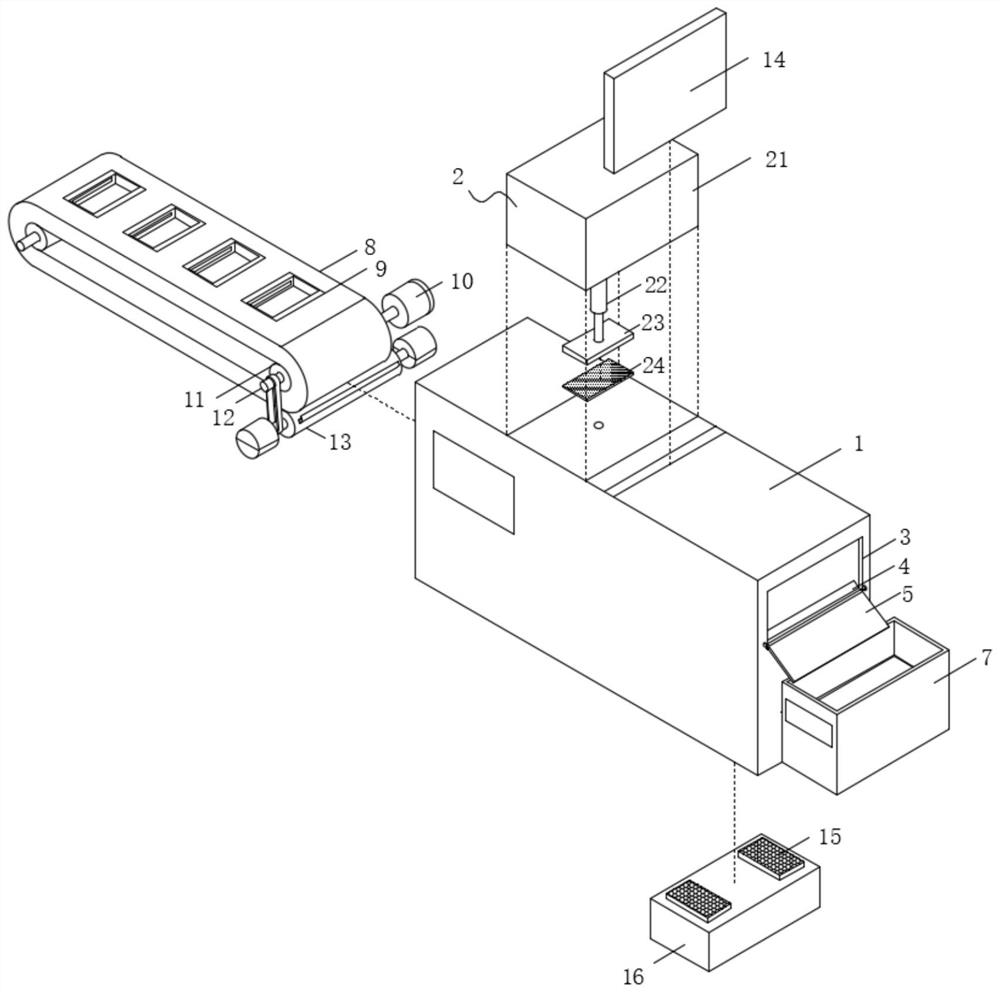

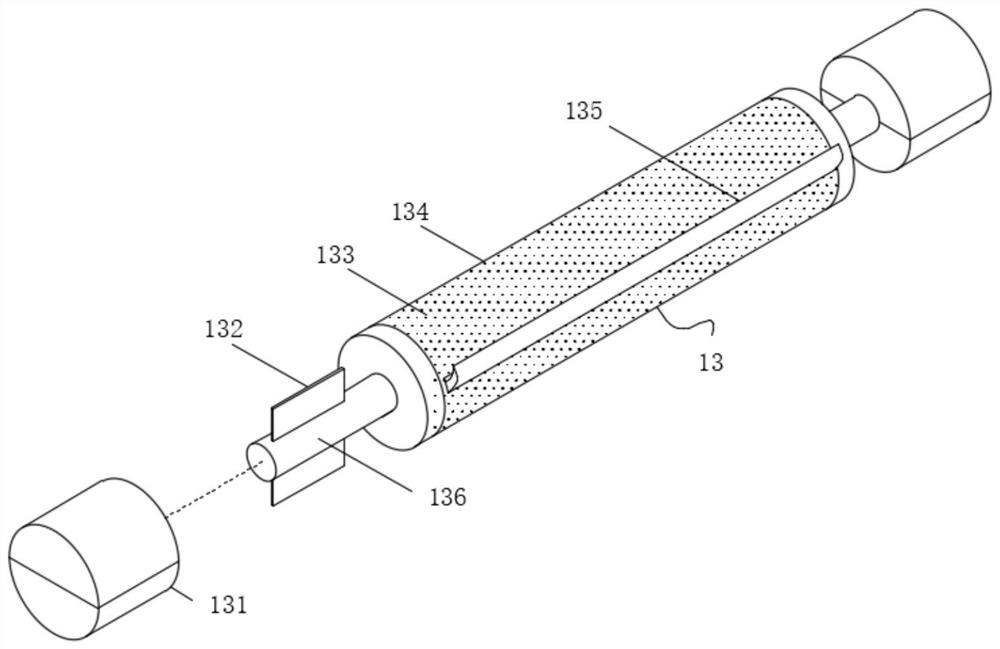

[0038] see Figure 1-7 , the present invention provides a technical solution: a non-woven fabric thermal bonding forming equipment, including a casing 1, an outlet groove 3 is provided on one side of the casing 1, and an inner inner flap 4 of the outlet groove 3, On one side of the outer wall of the casing 1, a position close to the outlet groove 3 is installed with a feed plate 5 through a mounting bracket, and a storage box 7 is fixedly installed on one side of the casing 1, and the storage box 7 A weighing plate 6 is arranged inside, and a driving motor 10 is fixedly installed on one side of the outer wall of the casing 1, and one end of the output shaft of the driving motor 10 is fixedly installed with a driving roller 11 through a mounting shaft 12, and the driving roller 11 The outside is provided with a conveying steel belt 8, and the interior of the conveying steel belt 8 is inlaid with an inner forming mechanism 9, which is used for hot-bonding molding of materials; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com