Cable stripping device and stripping method

A wire stripping device and wire stripper technology, which is applied in the direction of cable installation device, cable installation, dismantling/armored cable equipment, etc., can solve the problem of cutting one's own hand or other parts, difficulty in grasping the cutting force, Damage to cables and other problems, achieve the effect of rapid stripping, improve construction quality, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to better understand the technical solutions of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

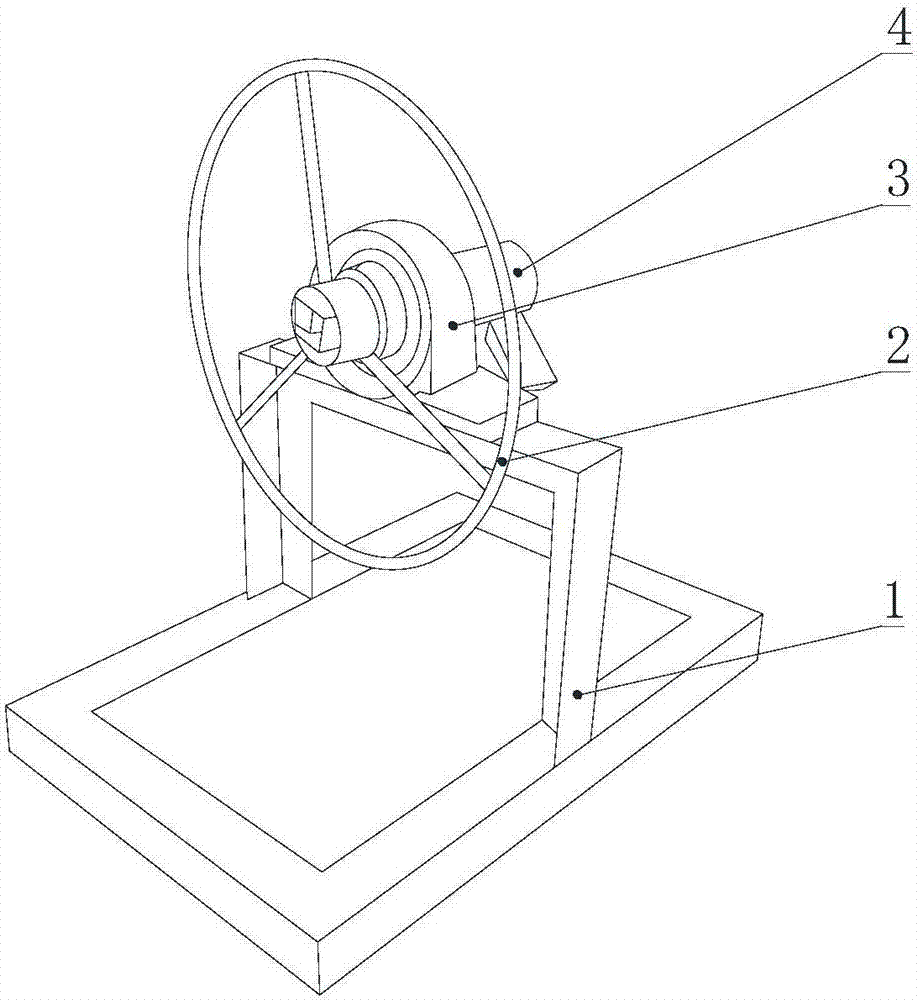

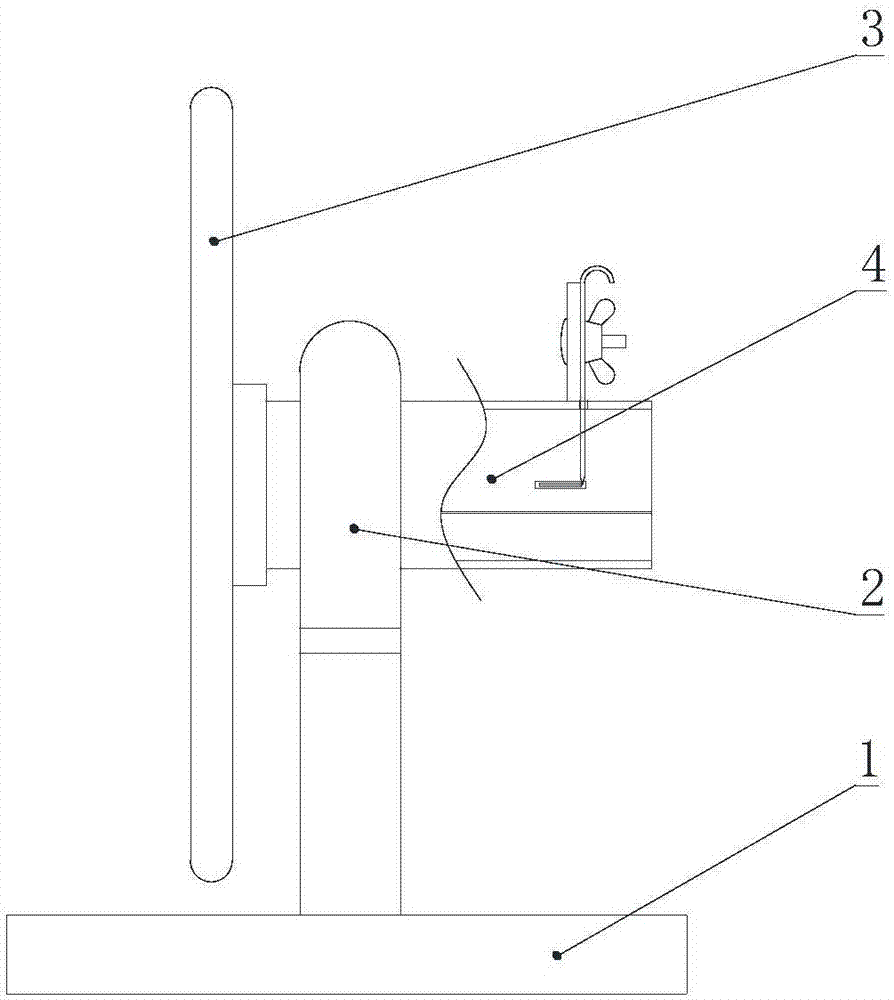

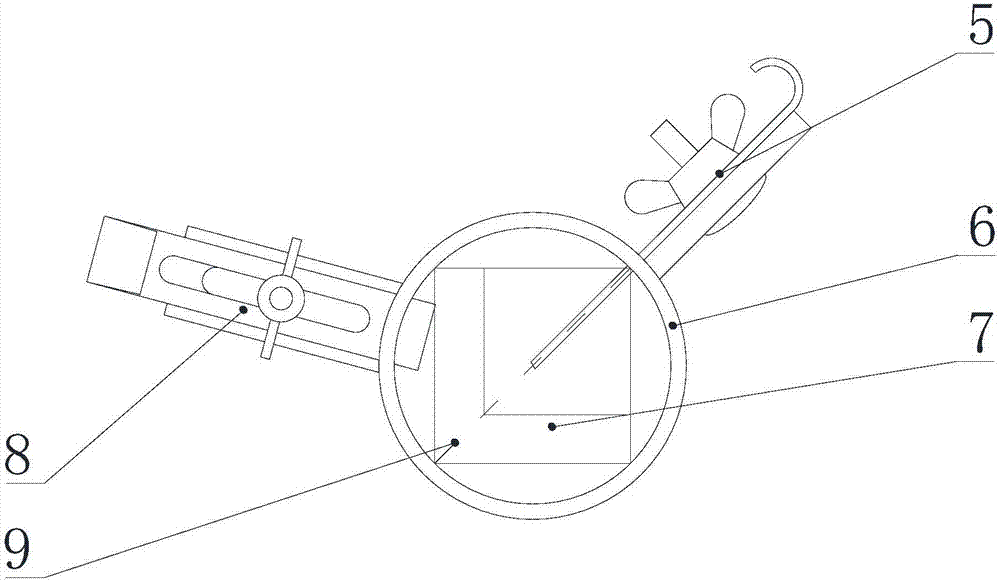

[0034] Such as Figure 1-2 As shown, a wire stripping device 4 includes a base 1, a support base 3, a turntable 2 and a wire stripper 4. The base 1 adopts a frame structure, which can be specifically designed with an iron frame, and a rectangular iron angle steel is used to weld a The bottom plate is provided with a door-shaped frame on the two sides parallel to each other on the bottom plate. The top of the base 1 is fixed with a support seat 3. Specifically, a support seat 3 is provided on the top of the door-shaped frame. The support seat 3 is Mounted bearings. The bearing with seat is used, which is convenient to purchase and can meet the rigidity requirement of the wire stripper 4 . Such as image 3 As shown, the support base 3 is provided with a vertical an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com