Electric wire breaking device for carbon-fiber composite-core wire

A composite core, carbon fiber technology, applied in the installation of overhead lines/cable equipment, electrical components, cables, etc., can solve the problems of low work efficiency, poor cutting effect, large labor consumption, etc., to achieve fast wire breakage and save money Good manpower and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

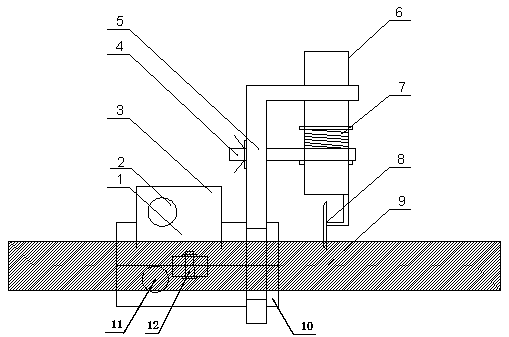

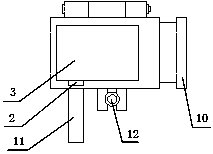

[0032] Embodiment: a carbon fiber composite core wire electric wire breaker, see Fig. 1 to Fig. 6, including wire clamping device 1, rotating fixing bracket 5, feed adjustment device 4 and electric saw 6; wire clamping device 1 such as figure 2 As shown, it is a bearing bush type structure, it is divided into two halves, which can be opened and closed, and the front end is provided with a circular groove slide rail 10, which clamps the wire 9 and then is clamped by adjusting bolts 12, through the liner of different wall thicknesses 11 can realize the clamping of wires of different cross-sections; the chainsaw 6 is powered by the battery 3, and the battery 3 and the switch 2 are integrated on the wire clamping device 1; image 3 As shown, its lower ring can be opened and closed to snap into the circular groove track 10 of the wire clamping device 1, and the electric saw 6 can be snapped into the upper opening. During the wire stripping process, the rotating fixing device can fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com