Carbon steel impeller assembling and welding device, and method

A welding device and impeller technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of low efficiency of manual welding of blades, waste of manpower, material resources and costs, affecting the quality of impellers, etc., to achieve excellent machining performance, reduce Processing difficulty and cost, stable and reliable effect of disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

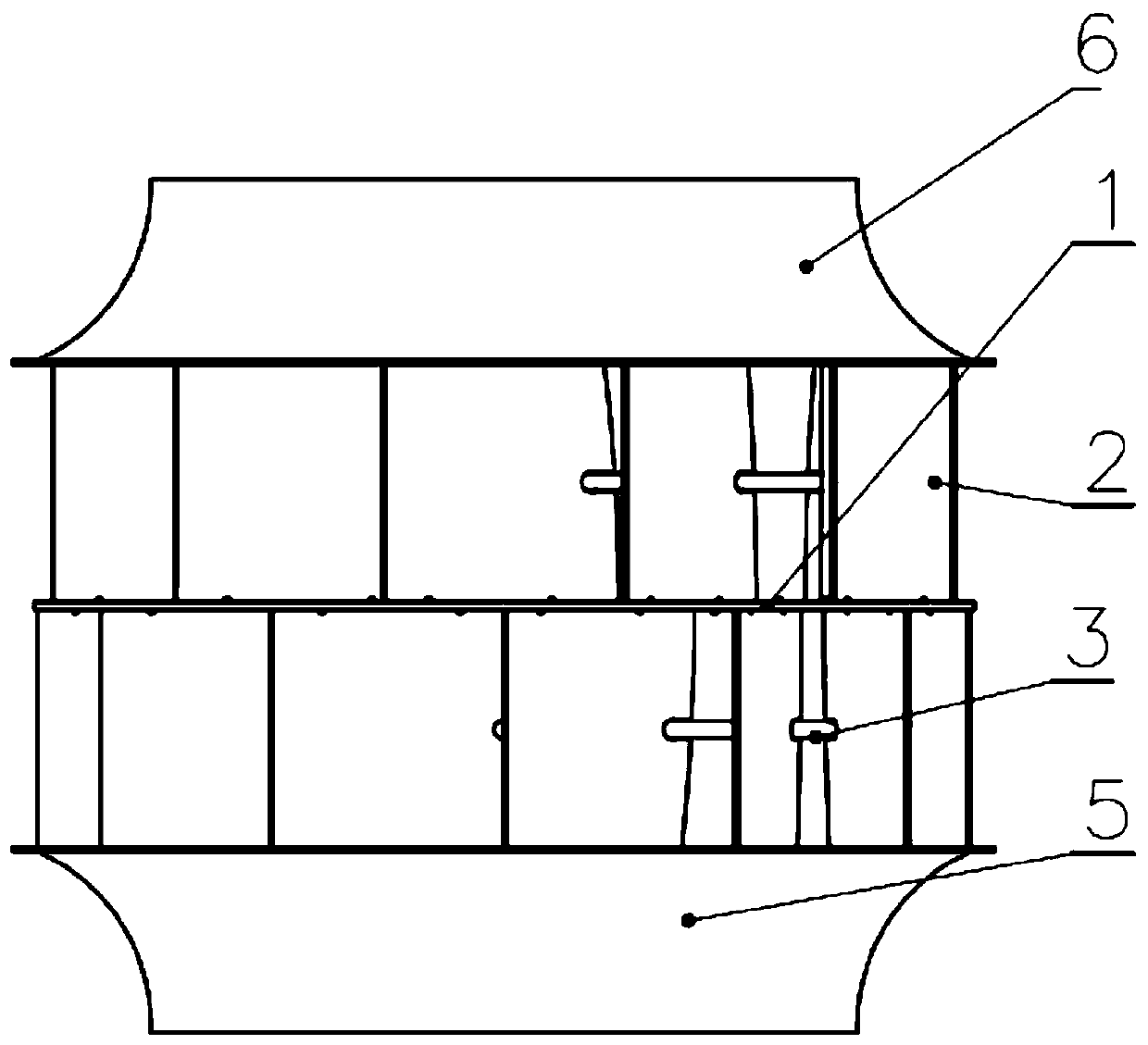

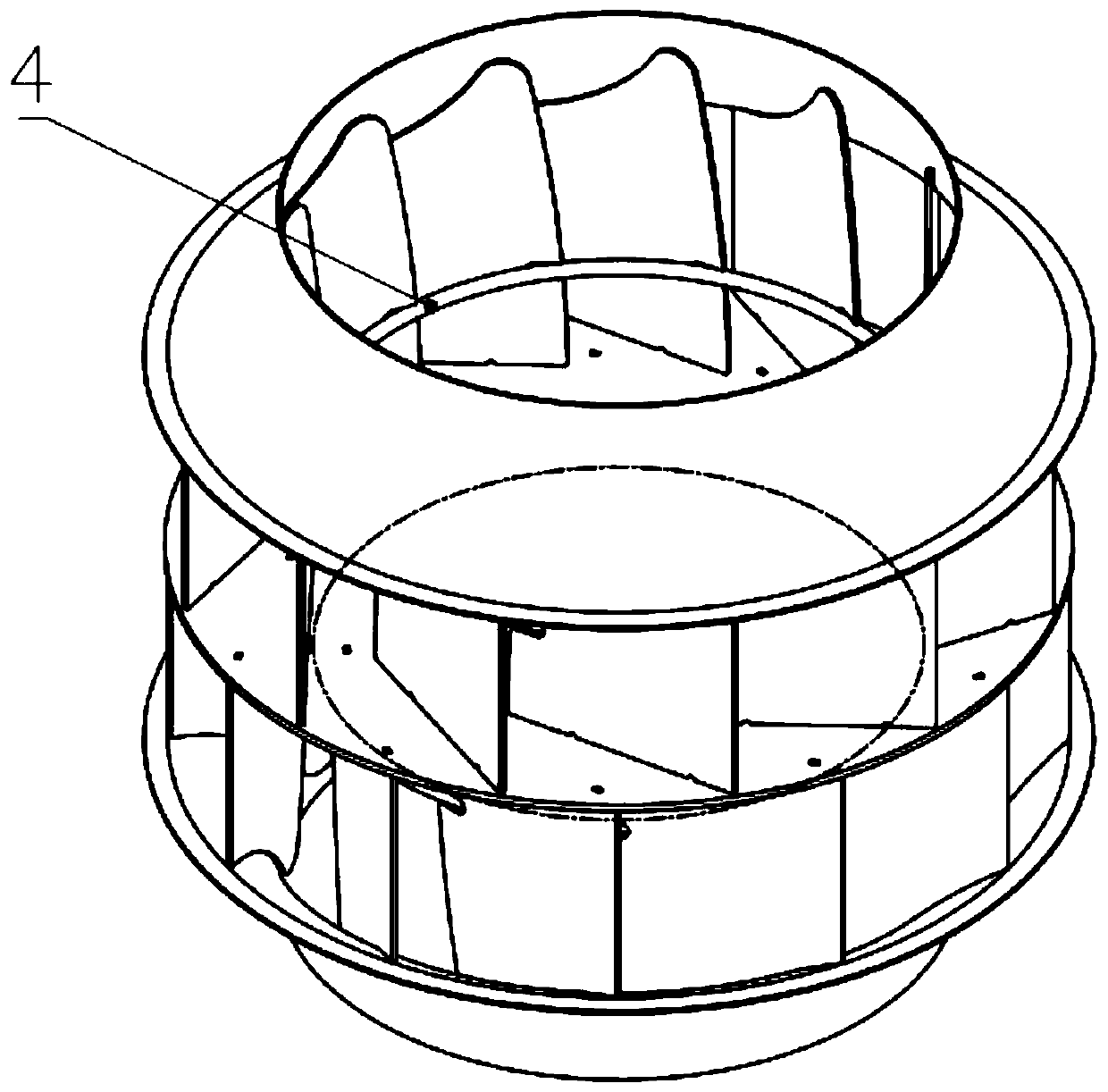

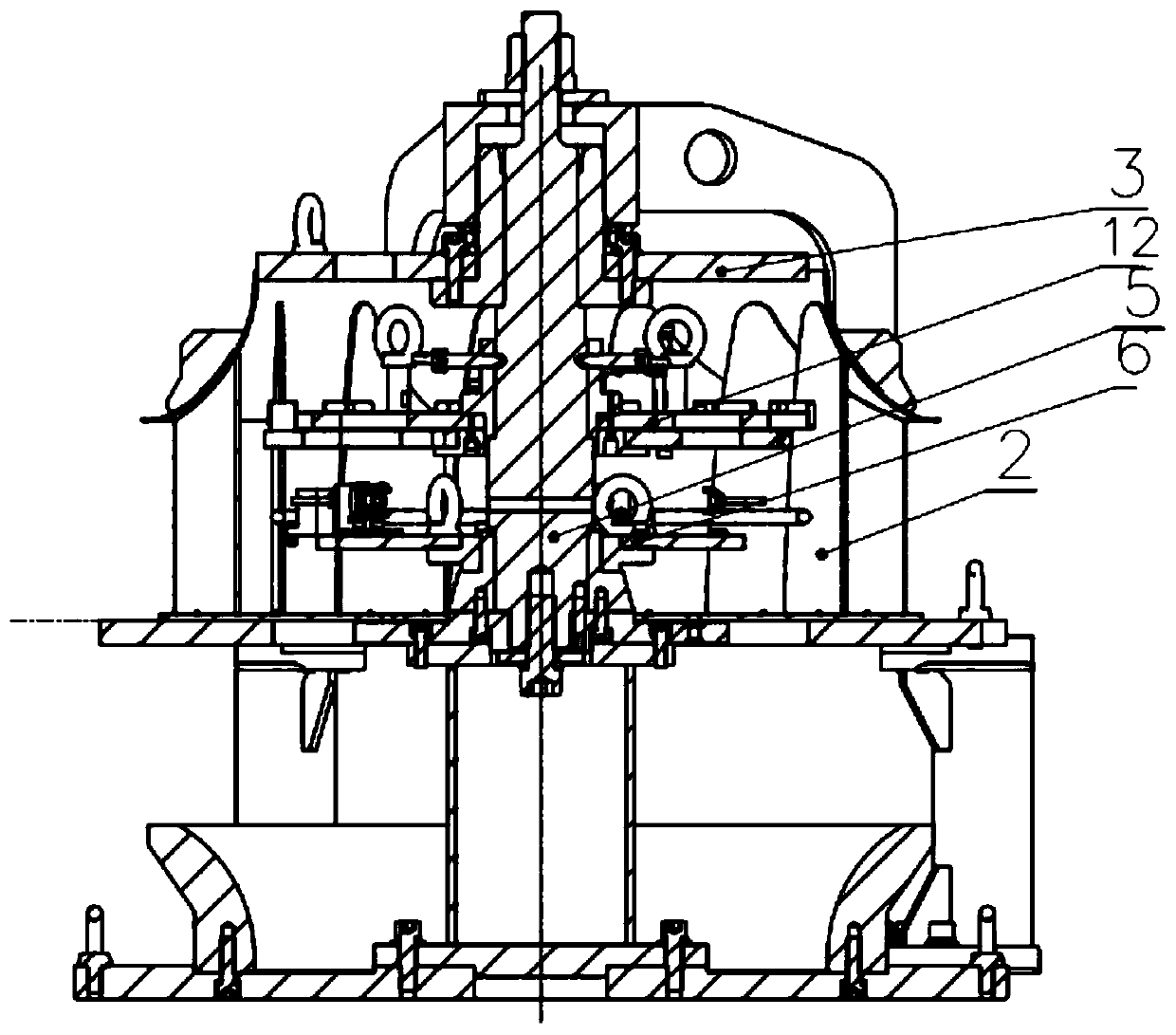

[0036] see Figure 1-16 , in an embodiment of the present invention, a carbon steel impeller assembly and welding device, including a main body assembly 7, a central shaft 8, a central support ring 9, a pressure plate 10, a cone centering assembly 11, an impeller orientation assembly assembly 12, and a main body reverse assembly 13 and the impeller orientation group reverse assembly 14; the main body assembly 7 includes a bottom plate 15, a tray 16, a supporting plate 17, a lower column 18 and a spacer 19; the bottom plate 15 and the supporting plate 17 are distributed through several arrays The column 18 is connected, a tray 16 is provided between the bottom plate 15 and the supporting plate 17, and a spacer 19 is provided on the lower end of the tray 17; the central shaft 8 includes a central support 20, a positioning plate 21, and a diamond pin 22 , screw rod 23, connecting shaft 24; the upper end of the center support 20 is provided with a positioning plate 21, and the dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com