Automatic cable peeling system apparatus equipped with cable sheath recovery box

A system device and recovery box technology, applied in the direction of dismantling/armored cable equipment, etc., can solve the problems of high repair cost, high labor intensity of workers, pollution of the environment, etc., to facilitate stripping with a knife, improve stripping efficiency, and quickly The effect of stripping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

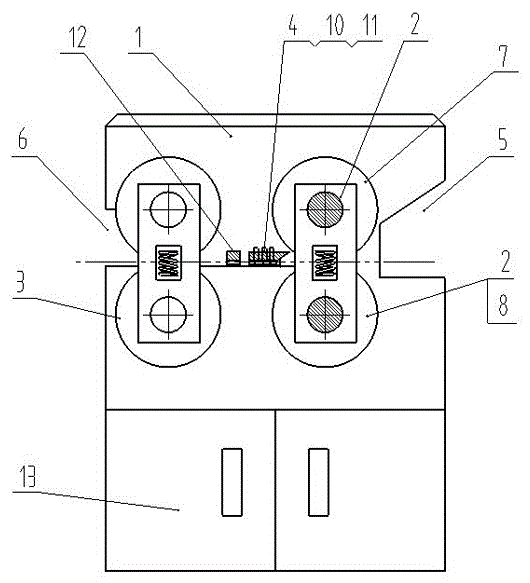

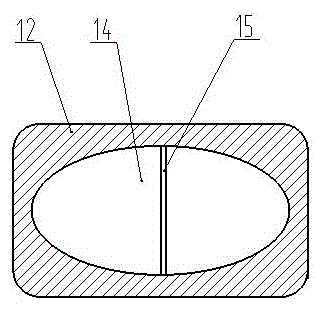

[0015] like figure 1 A cable automatic stripping system device with a wire sheath recovery box shown, including a box body 1, an incoming wire roller assembly 2, an outgoing wire roller assembly 3 and a wire stripping knife assembly 4, is characterized in that the incoming wire The roller assembly 2 is arranged at the inlet 5 of the box body 1, the outlet roller assembly 3 is arranged at the outlet 6 of the box body 1, and the stripping knife assembly 4 is arranged at the inlet roller Between the assembly 2 and the outlet roller assembly 3, the inlet roller assembly 2 includes an upper inlet roller 7 and a lower inlet roller 8, and the upper inlet roller 7 and the lower inlet roller (8 ) with a heating device 9 inside. A wire sheath separation device 12 is arranged behind the wire stripping knife assembly 4 , and a wire sheath recovery box 13 is arranged in the box body 1 below the separation device 12 .

[0016] A heating device 9 is installed in the wire inlet roller assem...

Embodiment 2

[0018] like figure 1 Shown is an automatic cable stripping system with a wire sheath recovery box. On the basis of Embodiment 1, the incoming wire roller assembly 2 and the outgoing wire roller assembly 3 rotate synchronously.

Embodiment 3

[0020] like figure 1 Shown is an automatic cable stripping system device with a wire sheath recovery box. On the basis of Example 1, the heating device (9) is a silicon carbide rod.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com