Stamping device with die inner side pushing and bending structure

A technology of stamping device and die base, which is applied in the field of stamping dies, can solve the problems of affecting the feeding of the material belt and the lifting of the mold material belt, so as to achieve the effect of rapid material removal and improvement of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

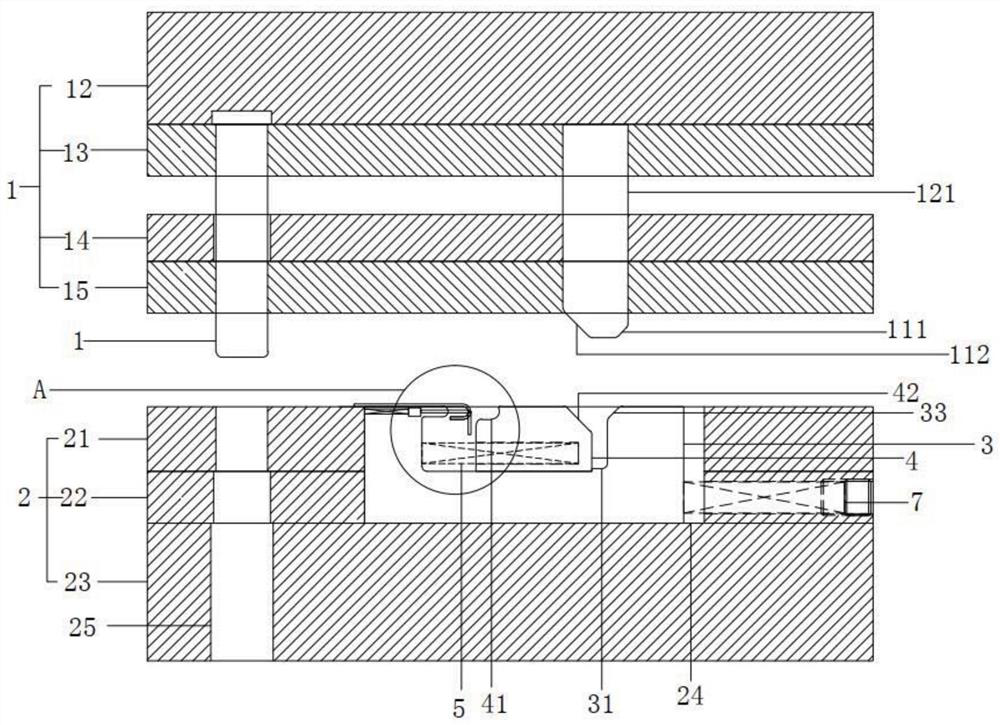

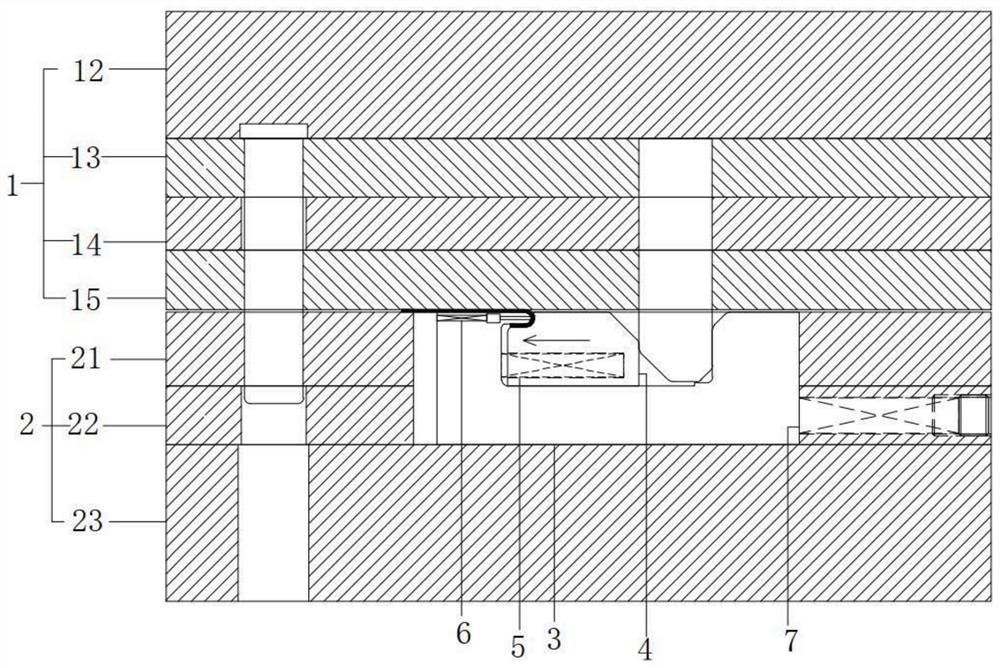

[0024] see Figure 1 to Figure 3 , the figure shows a stamping device with a mold-inside push-bending structure provided by Embodiment 1 of the present invention, which mainly includes:

[0025] The upper die mechanism 1, the upper die mechanism 1 also includes an upper die base 12, an upper splint 13, a stop plate 14 and an upper stripping plate 15, the upper splint 13 is fixedly installed on the upper die base 12, and the stop plate 14 is arranged on the upper splint Below 13, the upper stripping plate is fixedly installed on the stop plate 14, and the stop plate and the stripping plate are fixed with screws to form the unloading part. The upper die mechanism 1 is provided with a punch 11, and the bottom of the punch 11 has a first a slope 111 and a second slope 112;

[0026] Lower mold mechanism 2, lower mold mechanism 2 also comprises lower formwork 21, lower backing plate 22 and lower mold base 23, lower backing plate 22 is fixedly connected on the lower mold base 23, lo...

Embodiment 2

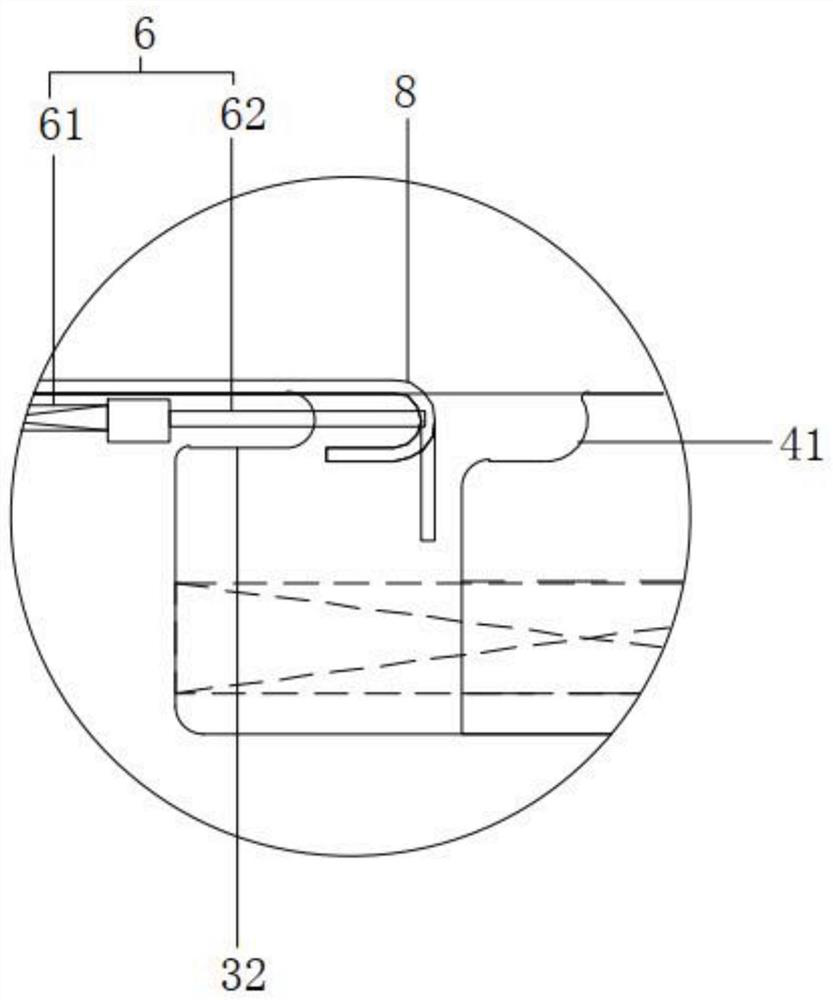

[0033] see Figure 1 to Figure 3 , the figure shows a stamping device with a mold-inside push-bending structure provided by Embodiment 2 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: the first A slide block 3 is provided with an installation cavity, and the thimble assembly 6 is arranged in the installation cavity. The thimble assembly 6 includes a third elastic member 61 and a thimble 62. One end of the third elastic member 61 is connected to the cavity wall of the installation cavity. The third elastic The other end of the component 61 is connected to a thimble 62 , and the protruding corner 32 has a through hole for the thimble to enter and exit. Through the setting of the above structure, rapid material removal can be realized and the production efficiency can be improved.

Embodiment 3

[0035] see Figure 1 to Figure 3 , the figure shows a stamping device with a mold-inside push-bending structure provided by Embodiment 3 of the present invention. This embodiment further makes the following technical solutions as improvements on the basis of the above-mentioned embodiments: The mold base 12 is provided with an inner guide post 121 , and the lower die mechanism 2 is provided with a guide hole 25 matching the inner guide post 121 . Through the setting of the above structure, the precision of mold clamping can be improved, and the quality of product production can be improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com