Rolling type insulated wire bending device

A technology of insulated wires and bending devices, which is applied in the field of bending machines, can solve problems such as time-consuming and labor-intensive, substandard bending angles, hidden dangers caused by safe and stable operation of transformers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

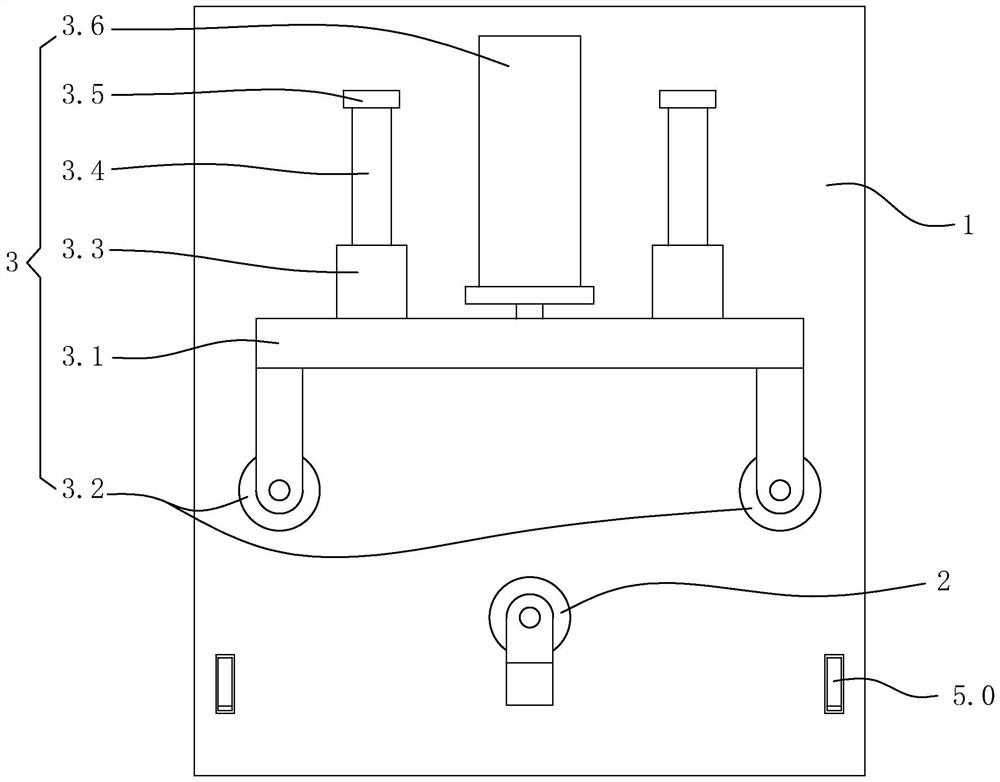

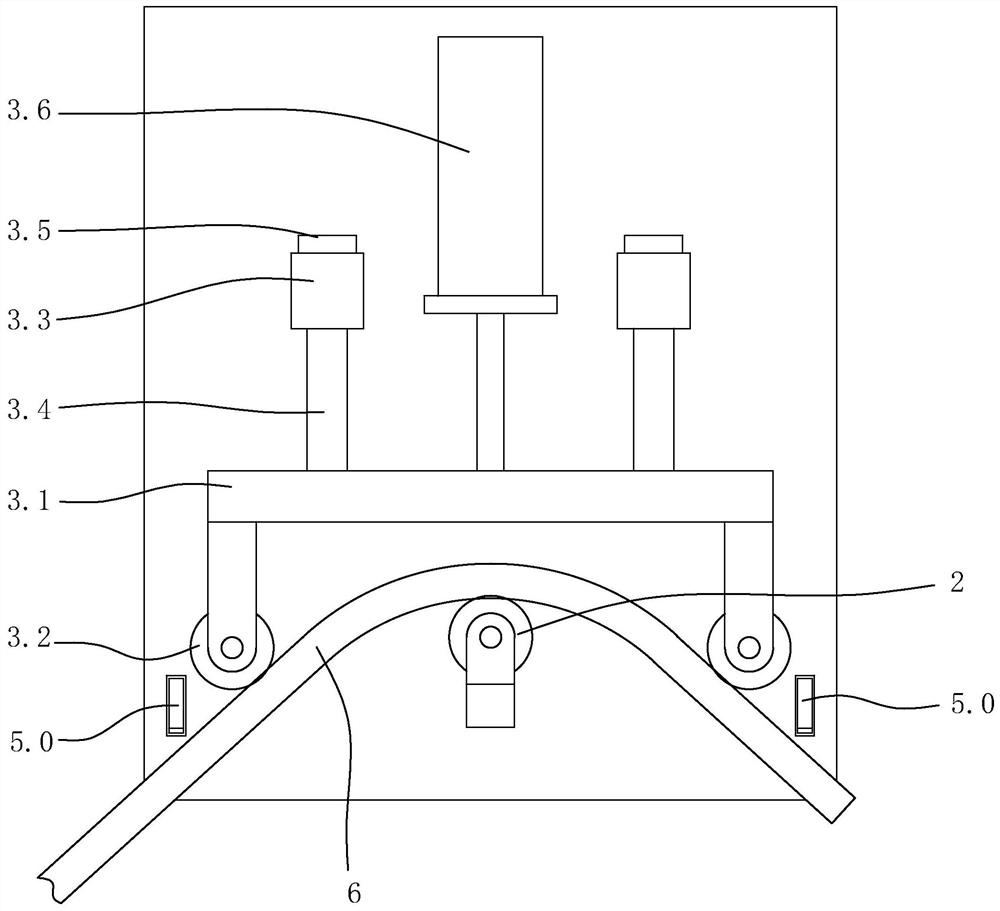

[0038] Specific embodiment one: as figure 1 As shown, a rolling type insulated wire bending device includes a frame, a fixed roller 2 and a wire bending mechanism 3 . The frame includes a workbench 1. In this embodiment, the workbench is distributed horizontally, and supporting feet are provided below the workbench. The fixed roller is arranged on the workbench, and the rotating shaft of the fixed roller is vertically distributed. The fixed roller is located above the workbench.

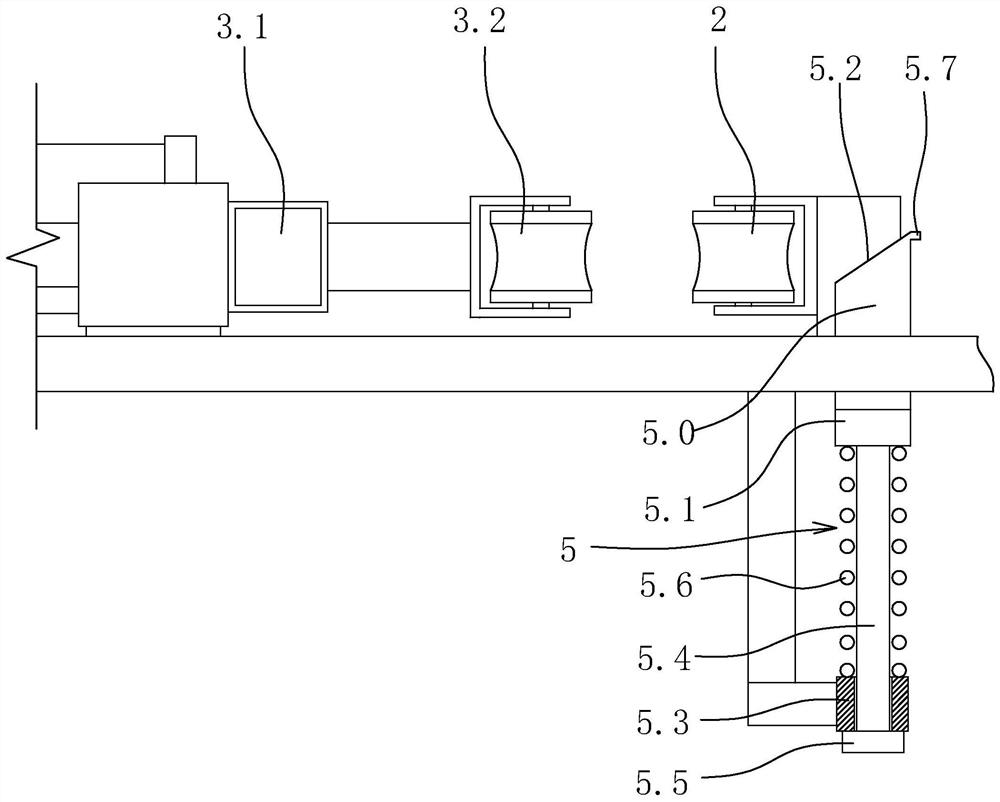

[0039] The wire bending mechanism 3 includes a translation support 3.1, a horizontal guide sleeve 3.3 fixed on the workbench, a horizontal guide rod 3.4 arranged on the translation support and slidingly matched with the horizontal guide sleeve, and a horizontal guide rod 3.4 arranged on the workbench for pushing the translation support. Jack 3.6 and two moving rollers 3.2 that are arranged side by side on the translation support. The rotating shaft of the moving roller is parallel to the rotating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com