Copper alloy strip with high intensity, high conductivity and high bending performance and preparation method thereof

A copper alloy strip, high-strength technology, applied in the direction of metal rolling, can solve the problems of poor strength of electronic copper strip, low softening temperature, coarse grain structure, etc., to achieve refined structure of finished products, shorten production process, crystal The effect of particle size reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

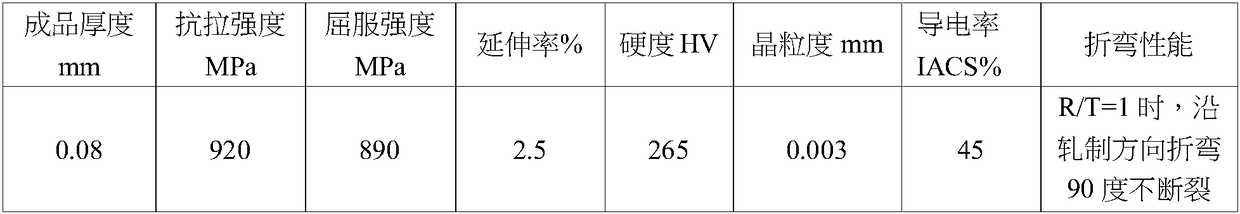

[0074] The thickness of the finished product is 0.08mm, requiring tensile strength ≥ 900MPa, electrical conductivity ≥ 40%, elongation ≥ 1%, grain size ≤ 0.005mm, high-strength, non-brittle when bent at 90 degrees when R / T = 1, Production process of copper alloy strip with high conductivity and high bending performance:

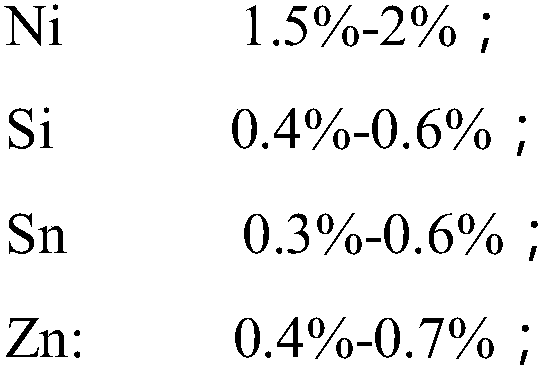

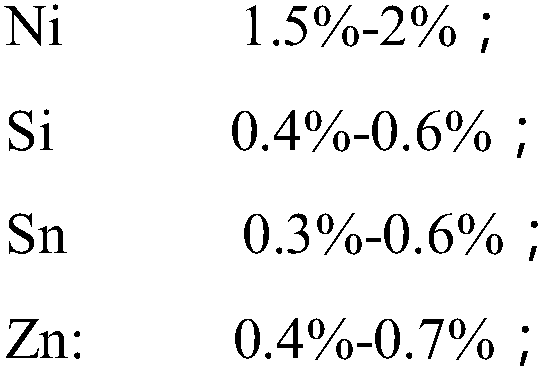

[0075] In step a, during semi-continuous casting, the alloy composition is strictly controlled at Ni: 1.5%, Si: 0.5%, Sn: 0.4%, Zn: 0.6%, Fe≤0.02%, Mg≤0.01%, and the balance is Cu and unavoidable impurities, the casting temperature is 1250°C, and the pull-stop-reverse process is adopted, and the size of the slab obtained by casting is 200mm in thickness and 650mm in width;

[0076] In step b, the billet is annealed at high temperature, the annealing temperature is 900°C, and the holding time is 5h;

[0077] Step c, after the billet is annealed, hot rolling is carried out, and the billet is rolled from a thickness of 200mm to 16mm;

[0078] Step d, the bille...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com