Hose coupler for seabed flexible hose

A technology of hose joints and hoses, which is applied in the direction of pipes/pipe joints/fittings, hose connection devices, mechanical equipment, etc., and can solve the problem of complex connections between joints and pipelines that cannot meet the requirements of high-pressure sealing connections of large-diameter marine hoses and other issues to achieve the effect of improving the overall sealing effect, reasonable sealing structure, and avoiding the overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

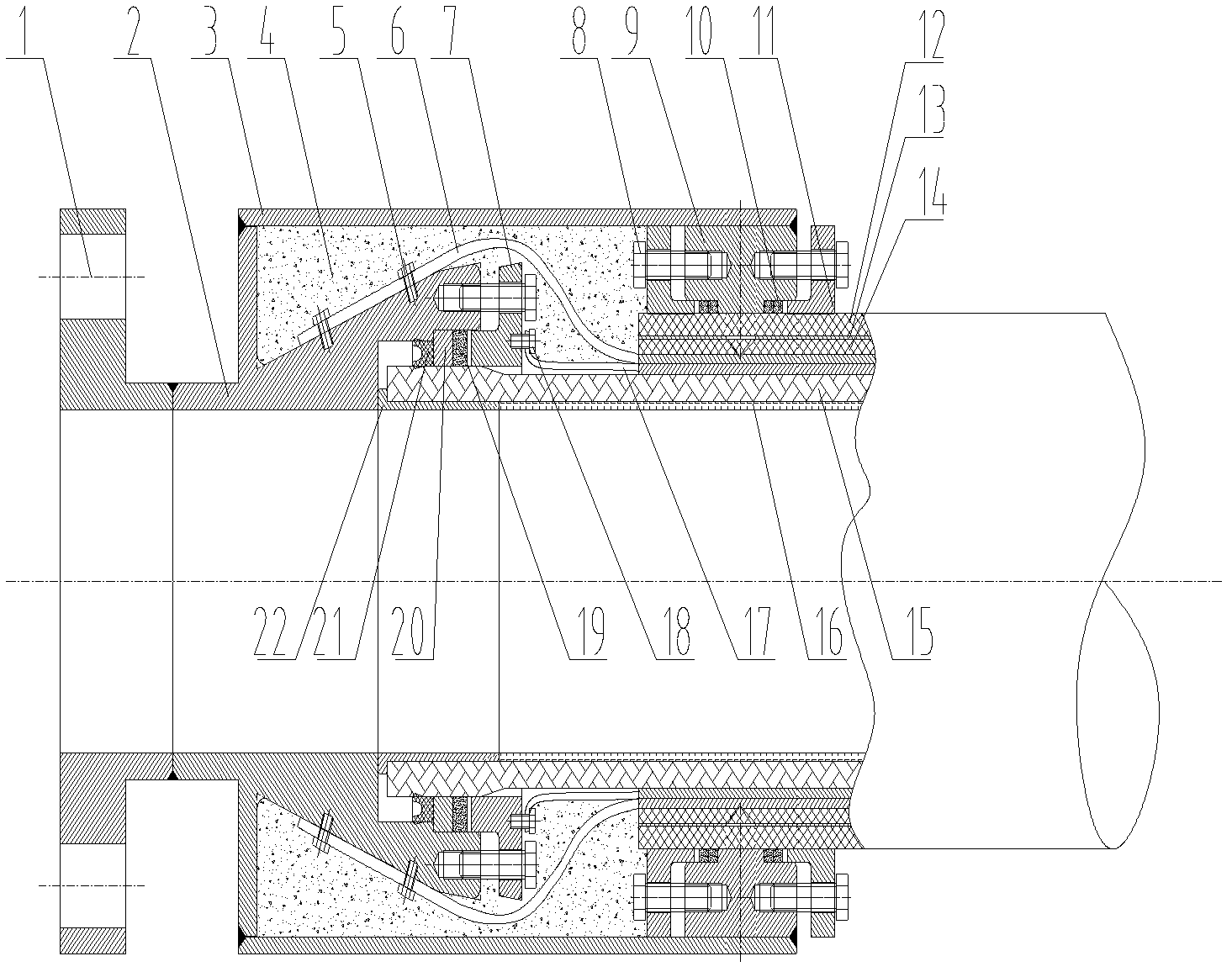

[0009] 1. Treatment of the connection end of the seabed flexible hose: cut off the end of the interlocking skeleton layer 16 so as to put the joint core 22 into it. The polymer coatings 12, 14, the hose steel tape layer 13 are cut off from the hose ends.

[0010] 2. Installation at the end of the hose joint: install the sealing flange 11, the rubber seal 10, and the end of the joint 9 into the end of the hose in sequence, and then tighten the high-strength screws 8 on both sides to fix the position.

[0011] 3. Installation of the front end of the hose joint: install the sealing flange 7, the rubber seal 19, the metal pressure ring 20, the Y-shaped sealing ring 21, the joint core 22, and the joint front end 2 into the end of the hose in sequence, and insert the joint core The sub 22 is pressed into the hose polymer wrap 15 and then held in place by tightening high strength screws. At the same time, the joint flange 7 and the joint front end 2 are connected together by welding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com