Knitting tool holder

A tool and support technology, used in warp knitting, knitting, textiles and papermaking, etc., can solve the problems of quality improvement and large wall thickness of knitting tool supports, and achieve the effect of improving stability and simplifying installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

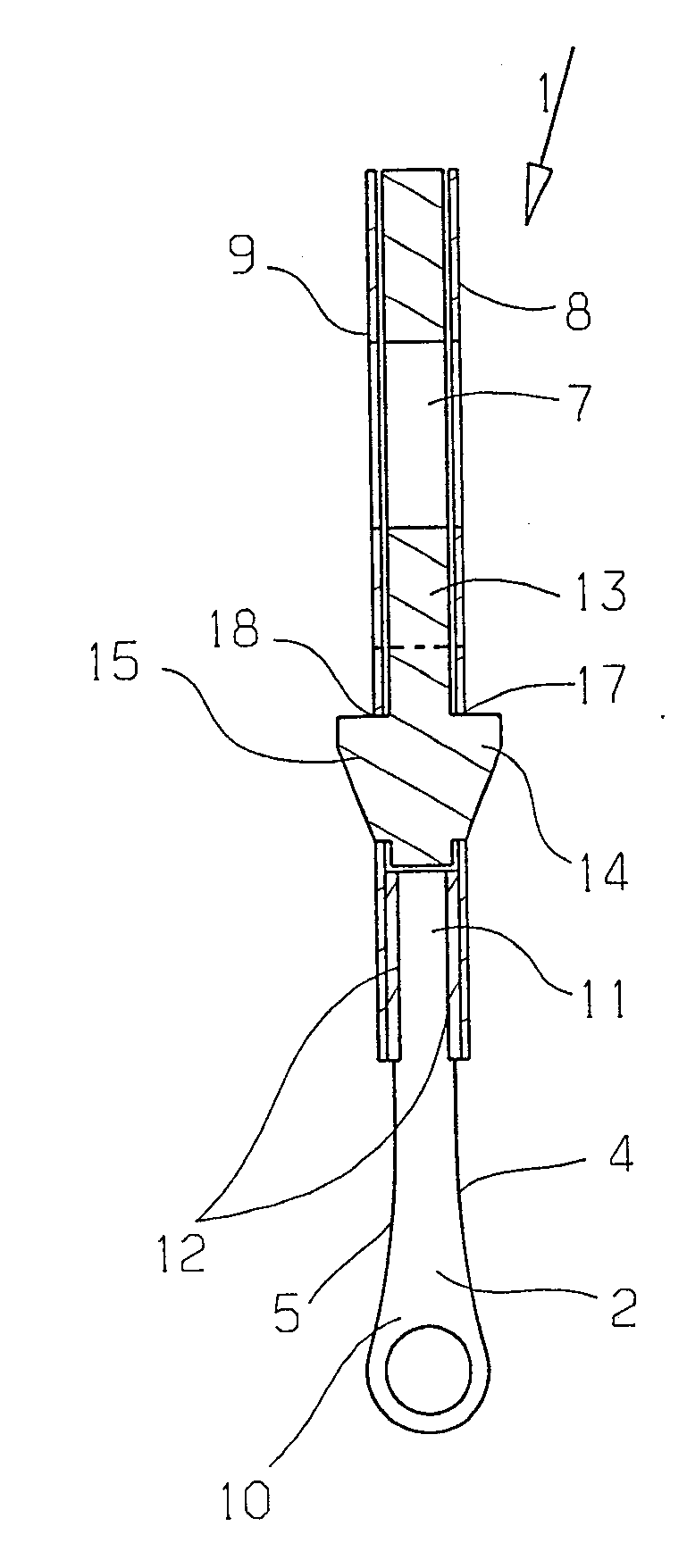

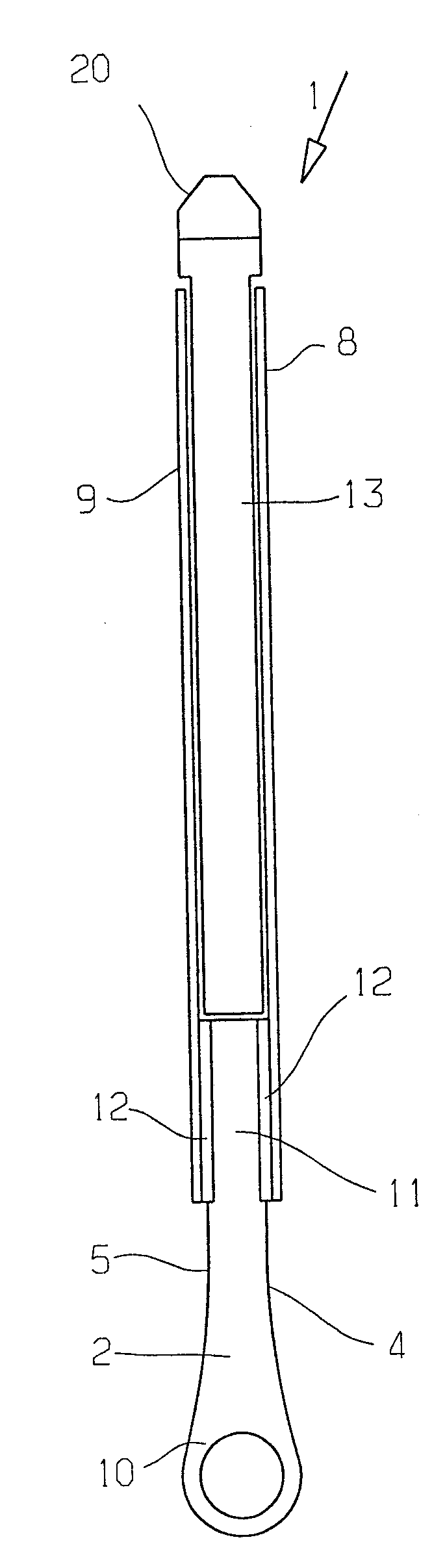

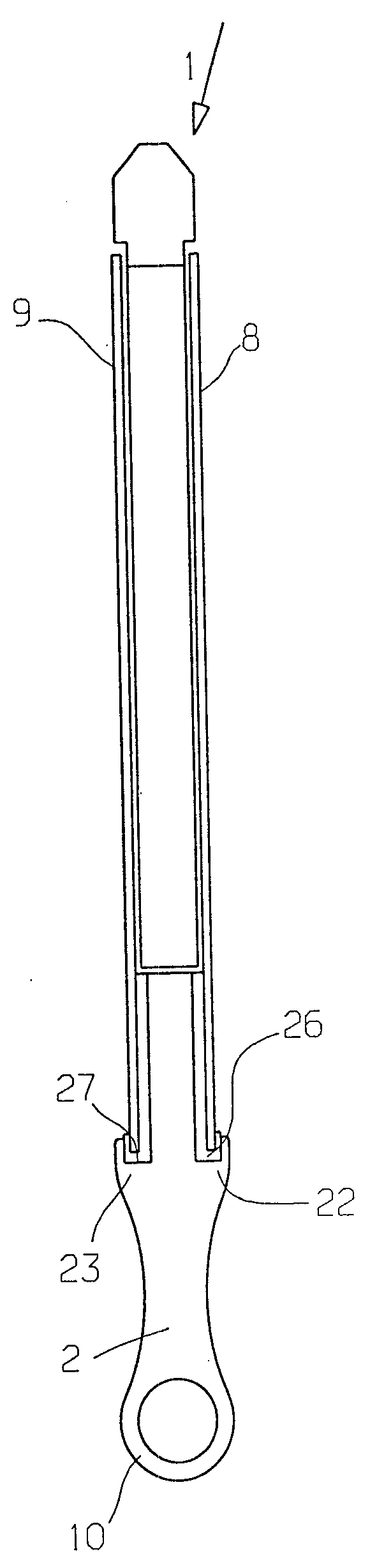

[0033] figure 1 A weaving tool holder 1 is shown with a plurality of weaving tools 2 which are arranged next to each other at a predetermined distance 3 from one another. Knitting Tool 2 in figure 1 Only the narrow side 4 is visible in . when will be in figure 1 If the narrow side 4 visible in is assigned to the front side, then the corresponding narrow side 5 is located on the rear side. The narrow sides 4, 5 point in opposite directions.

[0034] Depend on figure 2 and 3 It can be seen that the knitting tool 2 here in the form of an eye needle is of planar design. They can be stamped, for example, from sheet metal of corresponding thickness.

[0035] The weaving tool holder has two eyes 6 , 7 through which screws can be guided, and the weaving tool holder 1 can be screwed to a weaving tool bar, not shown in detail. The braiding tool holder 1 has a width of, for example, 1 or 2 inches. Since the eyes 6 , 7 can be arranged relatively far apart from one another, the k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com