Milky white PE (polyethylene) label film and production method thereof

A label and milky white technology, applied in the field of milky white PE label film and its production, can solve the problems of PE label film stiffness, poor yellowing resistance, difficulty in meeting printing and use requirements, etc., to meet printing and use requirements, without Surface precipitation, the effect of solving wrinkles and film surface wrinkles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

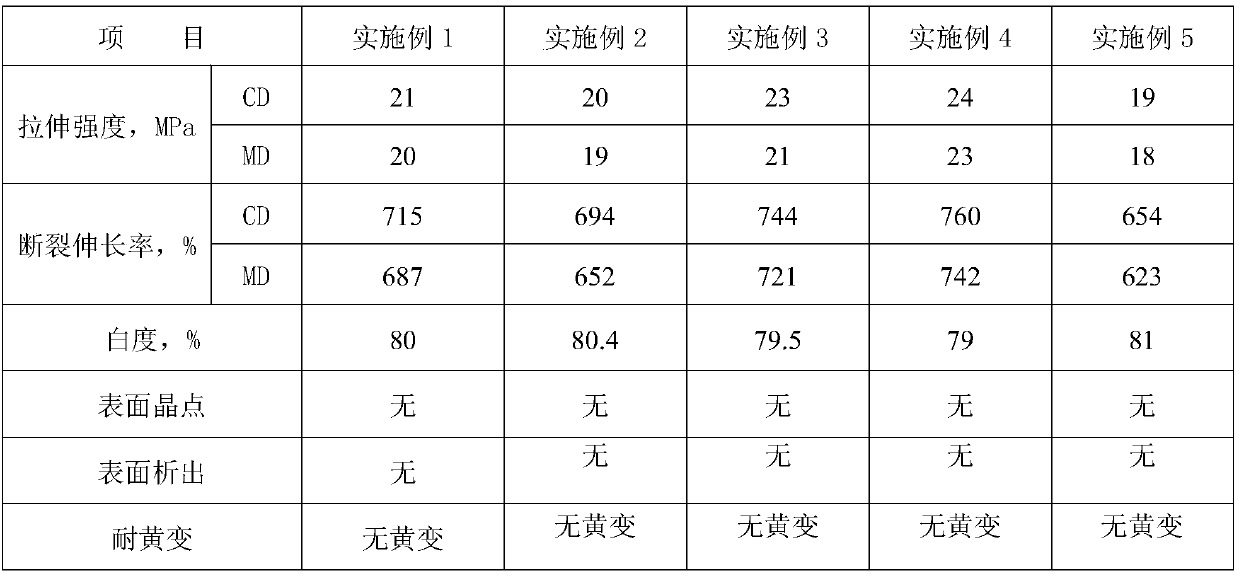

Examples

Embodiment 1

[0036] The production method of described milky white PE label film is as follows:

[0037] In step 1, the raw materials of the outer film layer, the middle film layer and the inner film layer are subjected to dust removal treatment.

[0038] Step 2, put the raw materials of the outer film layer, middle film layer and inner film layer into the corresponding suction area of the multi-layer co-extrusion film blowing machine according to the above-mentioned component ratio requirements, and transport them to the hopper of the extruder under vacuum negative pressure, through The corresponding barrel of the extruder is plasticized into a melt, and when the melt is extruded by the extruder, it is filtered through a filter to reach the die head; the outer film layer and the inner film layer respectively include 69.5wt% LDPE, 30wt% cast Grade HDPE contains 0.5wt% PPA, and the intermediate film layer includes 45wt% blown film grade HDPE, 36.5wt% LDPE, 18wt% white masterbatch and 0.5w...

Embodiment 2

[0050] The production method of described milky white PE label film is as follows:

[0051] In step 1, the raw materials of the outer film layer, the middle film layer and the inner film layer are subjected to dust removal treatment.

[0052] Step 2, put the raw materials of the outer film layer, middle film layer and inner film layer into the corresponding suction area of the multi-layer co-extrusion film blowing machine according to the above-mentioned component ratio requirements, and transport them to the hopper of the extruder under vacuum negative pressure, through The corresponding barrel of the extruder is plasticized into a melt, and when the melt is extruded by the extruder, it is filtered through a filter to reach the die head; the outer film layer and the inner film layer respectively include 68.5wt% LDPE, 31wt% cast Grade HDPE and 0.5wt% PPA, the intermediate film layer includes 44wt% blown film grade HDPE, 37.5wt% LDPE, 18.3wt% white masterbatch and 0.2wt% PPA....

Embodiment 3

[0060] The production method of described milky white PE label film is as follows:

[0061] In step 1, the raw materials of the outer film layer, the middle film layer and the inner film layer are subjected to dust removal treatment.

[0062] Step 2, put the raw materials of the outer film layer, middle film layer and inner film layer into the corresponding suction area of the multi-layer co-extrusion film blowing machine according to the above-mentioned component ratio requirements, and transport them to the hopper of the extruder under vacuum negative pressure, through The corresponding barrel of the extruder is plasticized into a melt, and when the melt is extruded by the extruder, it is filtered through a filter to reach the die head; the outer film layer and the inner film layer respectively include 70.5wt% LDPE, 29wt% cast Grade HDPE and 0.5wt% PPA, the intermediate film layer includes 46wt% blown film grade HDPE, 35.5wt% LDPE, 17.7wt% white masterbatch and 0.8wt% PPA....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com