Bending method for manufacturing and processing electric power cabinet

A technology of electrical cabinets and electric power, which is applied in the field of manufacturing and processing of electrical cabinets, can solve problems such as poor bending effects, reduced production efficiency, and poor adjustment of profile bending angles, so as to achieve guaranteed results, increase yield, Effects that improve performance and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

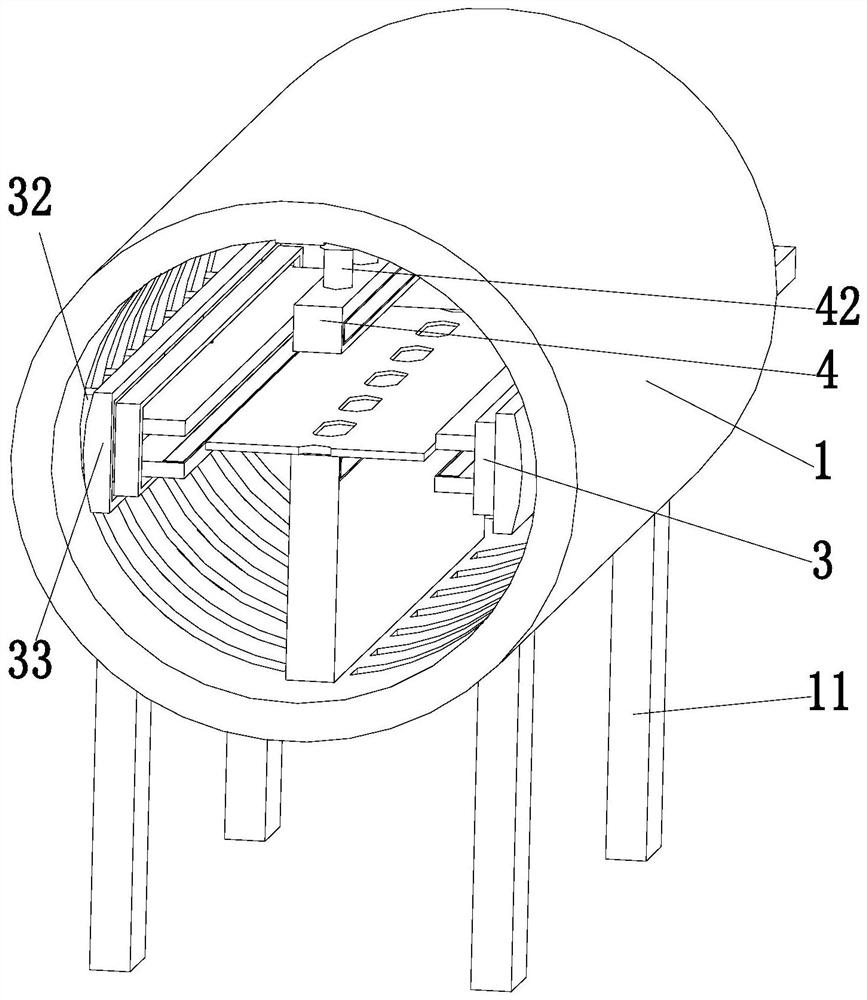

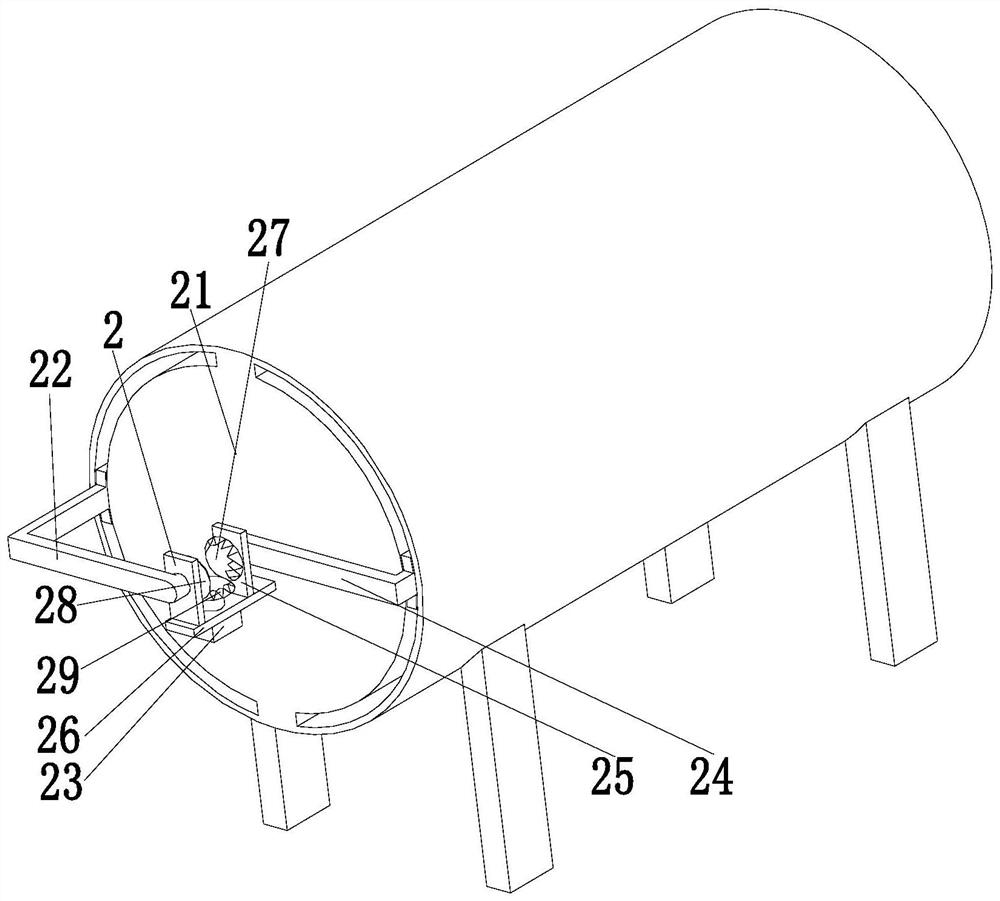

[0034] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

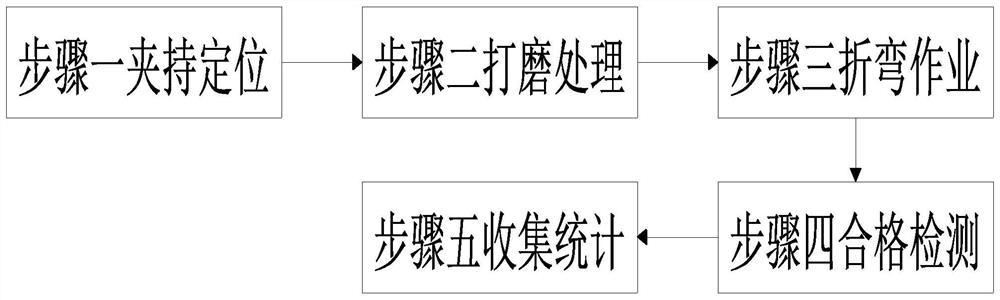

[0035] Such as Figure 1 to Figure 9 As shown, a method for manufacturing and processing a power electric cabinet is characterized in that it mainly includes the following manufacturing steps:

[0036] Step 1, clamping and positioning, manually clamping and positioning the profiles that need to be bent after the stamping is completed;

[0037] Step 2, grinding treatment, manually use a grinding pen to grind the profile clamped and positioned in step 1, and remove the profile after grinding;

[0038] Step 3, bending operation, place the profile polished in step 2 to the bending equipment for bending operation;

[0039] Step 4, qualified inspection, manually inspect the bending effect of the bent profile in step 3, mark the qualified bent profile, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com