Rapid and efficient hardware plate bending system

A fast and flat technology, applied in metal processing equipment, feeding devices, positioning devices, etc., can solve problems such as inability to fix metal sheets, complex bending device structure, and affect the bending effect, etc., to achieve bending efficiency and fast , high bending efficiency, and the effect of saving bending time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

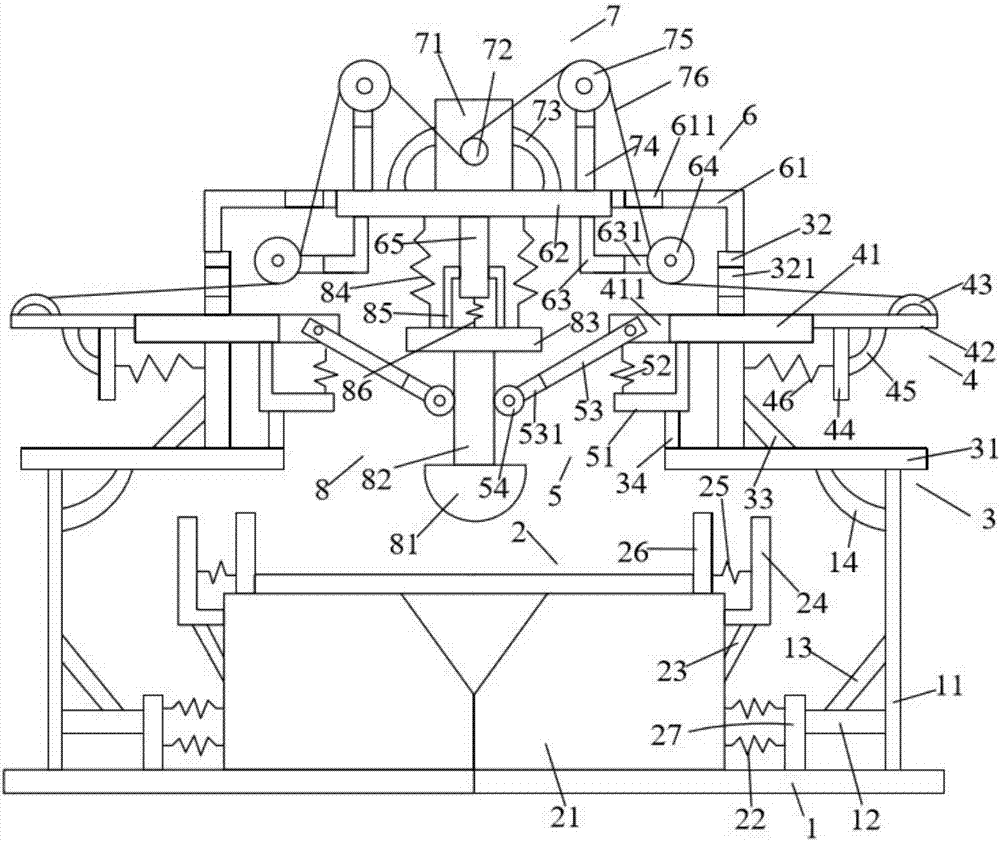

[0018] The following will make a clear and complete description of the rapid and efficient bending system for hardware plates of the present invention in conjunction with the accompanying drawings.

[0019] Such as figure 1As shown, the rapid and efficient bending system for hardware plates of the present invention includes a base plate 1, a support and fixing device 2 above the base plate 1, a bracket device 3 located on the left and right sides above the support and fixing device 2, and is arranged on the The abutment device 4 on the support device 3, the roller device 5 arranged on the abutment device 4, the horizontal plate device 6 above the support device 3, the motor device arranged on the horizontal plate device 6 7 and a pressing device 8 located below the horizontal plate device 6 .

[0020] Such as figure 1 As shown, the base plate 1 is rectangular parallelepiped and placed horizontally, the base plate 1 is provided with first support rods 11 on the left and right...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com