Preparation method of curved glass

A technology of curved glass and glass, applied in glass manufacturing equipment, glass molding, glass re-molding, etc., can solve the problems of low production efficiency and poor quality, and achieve the goal of avoiding direct contact, improving quality, and ensuring bending effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of the present invention will be introduced in detail below in conjunction with the accompanying drawings and embodiments

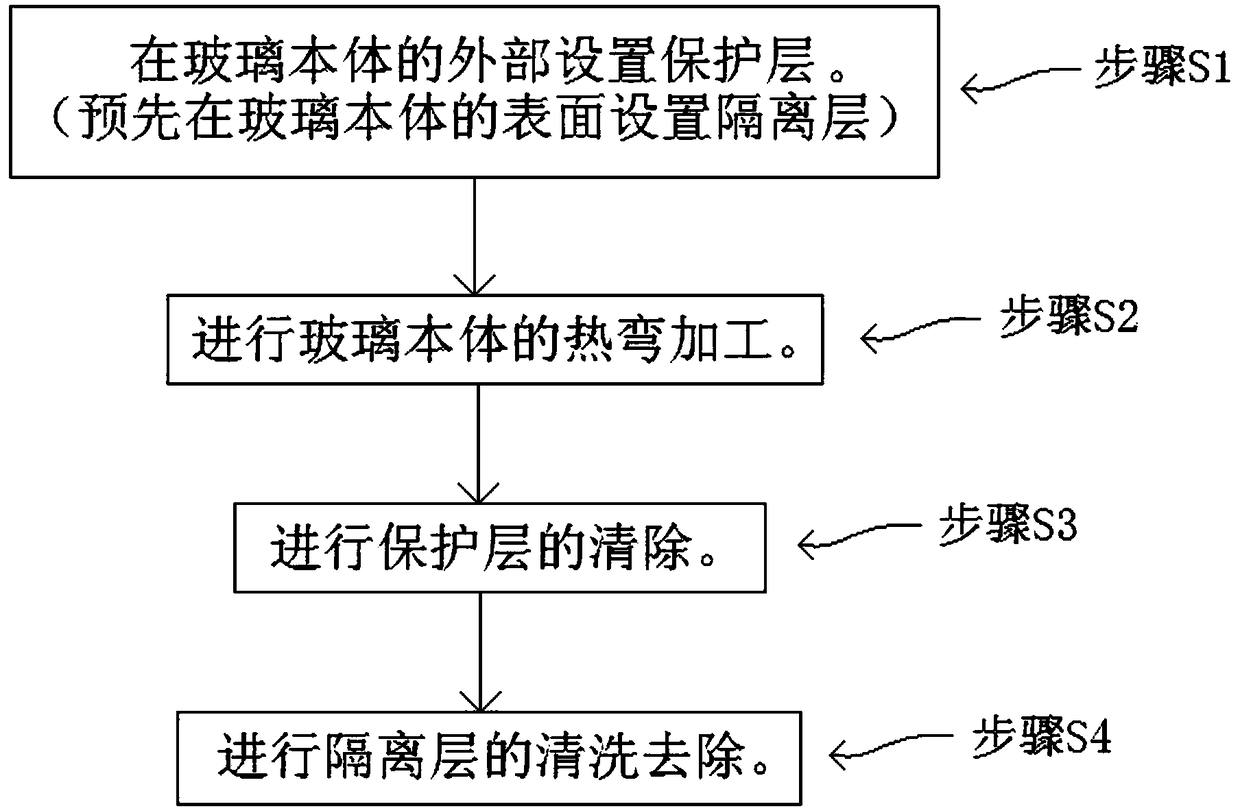

[0024] combine figure 1 with figure 2 As shown, Gorilla Glass 3 glass with a thickness of 0.6mm is selected as the glass body from Corning Corporation, and the method for preparing curved glass of the present invention is introduced in detail. The specific operation steps are as follows:

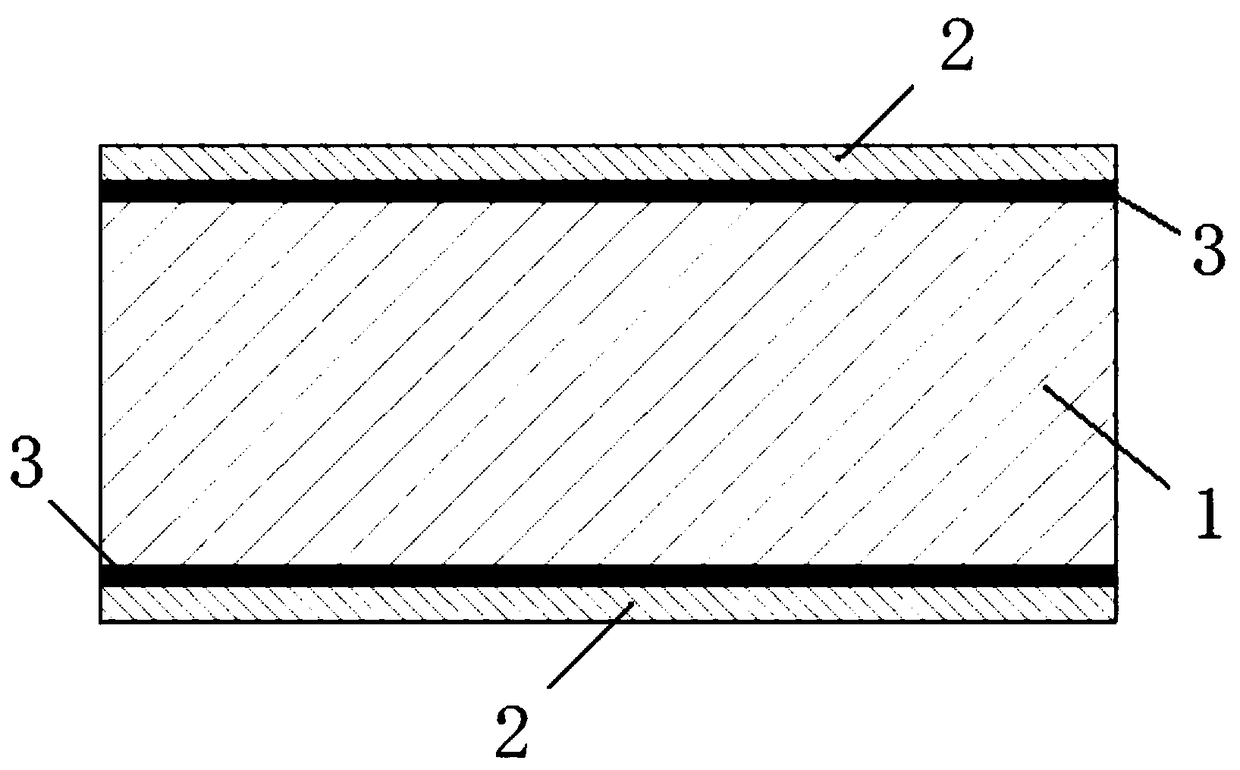

[0025] Step S1, setting a protective layer on the outside of the glass body. A sheet material having a thermal bending performance similar to that of the glass body 1 and having a certain thickness is selected as the protective layer 2 , and the sheet material is laid flat on the surface of the glass body 1 .

[0026] Preferably, in this embodiment, according to the selected mold and the pre-statistical analysis of the depth of hot bending defects, Corning's Gorilla Glass 3 with a thickness of 0.2 mm is selected as the protective layer. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com