Stainless steel pipe machining process

A technology of stainless steel pipe and processing technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problem of low automation of stainless steel pipe bending, and achieve the effect of ensuring the bending effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

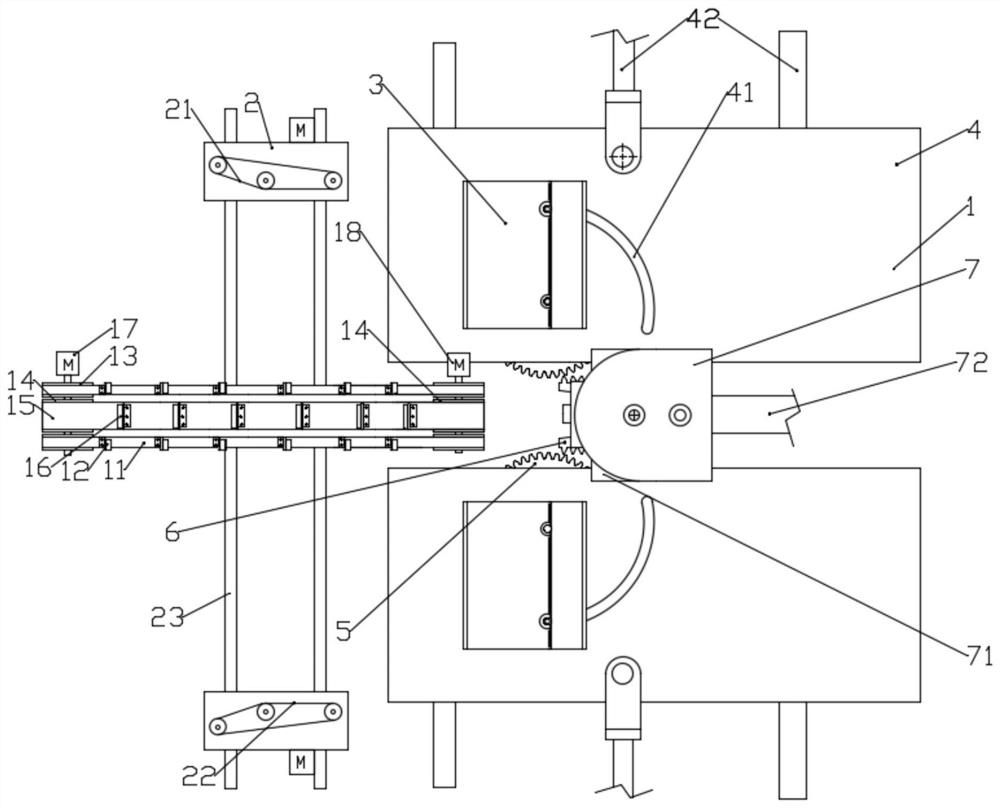

[0043] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0044] This embodiment discloses a processing technology for stainless steel pipes: follow the steps below:

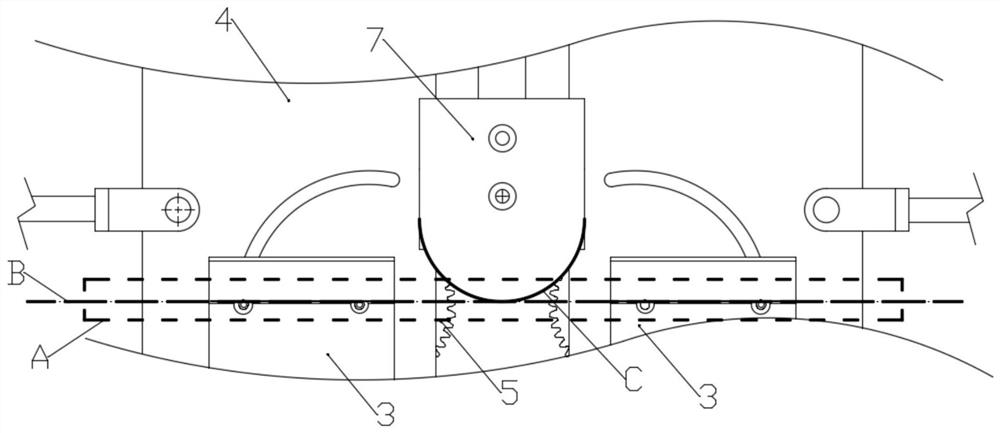

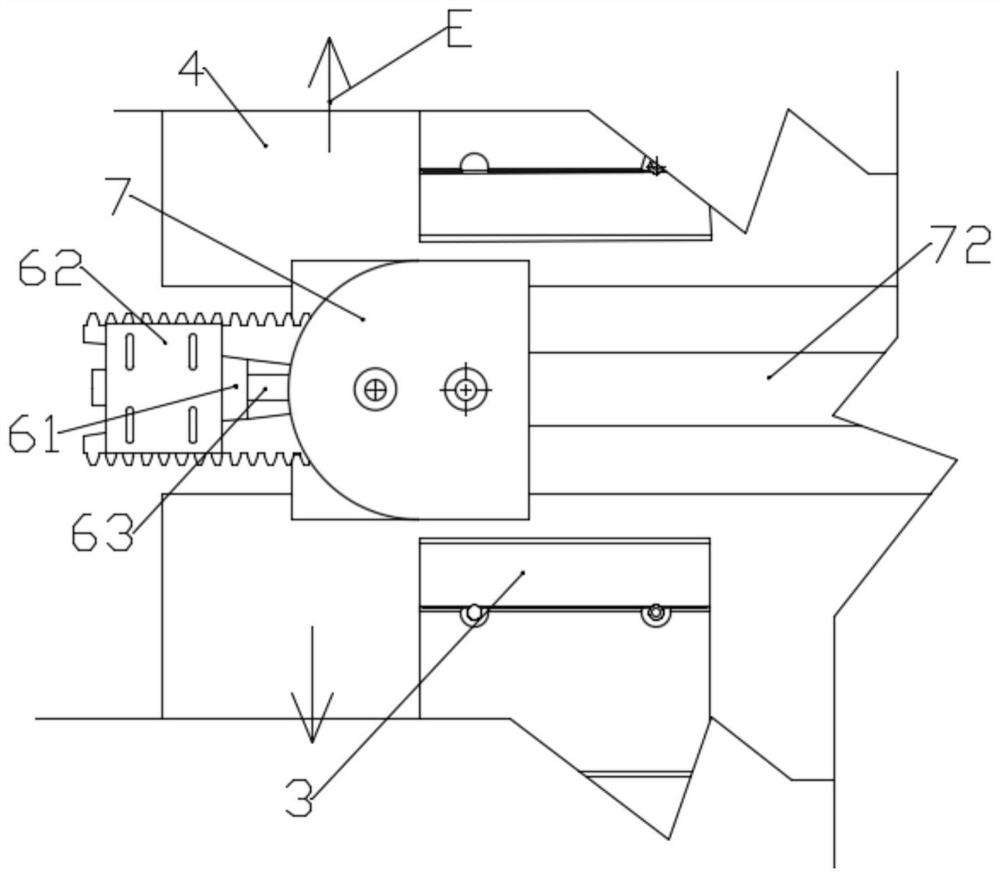

[0045] Step 1: Measure the outer diameter of the stainless steel pipe, select and install the outer bending part 3, bending head 7 and gear 5 according to the outer diameter of the stainless steel pipe, and adjust the wedge rack 6 to be normal to the two gears 5 Engagement width; there are two outer bending parts 3, and the outer bending parts 3 are provided with bending grooves 32;

[0046] The feeding device adopted in step 1 comprises an outer synchronous belt 11 and an inner synchronous belt 15 arranged in parallel, and there are two outer synchronous belts 11, and two outer synchro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com