Gear bearing machine

A bending machine and gear technology, applied in the field of bending machines, can solve the problems of uneven heating, poor processing quality, and affecting the appearance of electric boilers, etc., and achieve the effect of fast bending and guaranteed bending effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

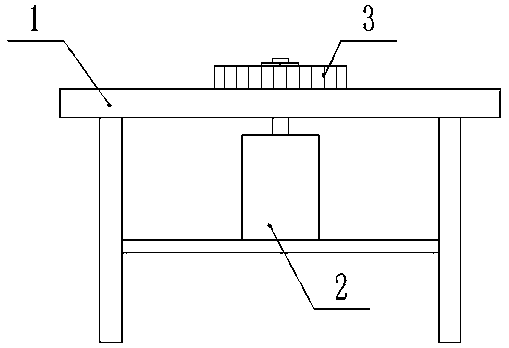

[0017] Such as Figure 1 to Figure 3 Shown: a gear bending machine, including: a platform 1, a motor 2, a driving gear 3, a driven gear 4 and a driven control assembly 5; a motor 2 is arranged under the platform 1, and the output shaft of the motor 2 is vertical It is arranged straight and the output shaft of the motor 2 passes through the platform 1 and can rotate relative to the platform 1. The output shaft of the motor 2 is fixed with a driving gear 3, and the platform 1 is provided with a chute 6. The driven gear 4 and the driving gear 3 meshes and the driven gear 4 can slide along the chute 6, a driven control assembly 5 for fastening the driven gear 4 is arranged between the driven gear 4 and the chute 6, and the driven gear 4 and the driving gear The distance between the 3 meshing teeth is max. 3mm.

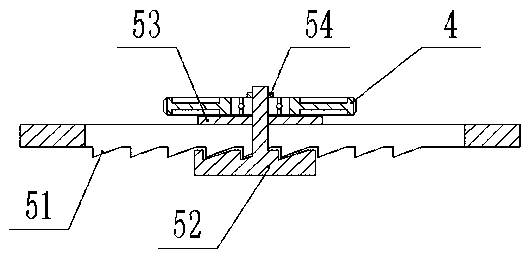

[0018] The driven control assembly 5 includes: a fixed tooth 51, a driven tooth 52, a gasket 53 and a fastening nut 54; The fixed tooth 51 is a plurality of protruding t...

Embodiment 2

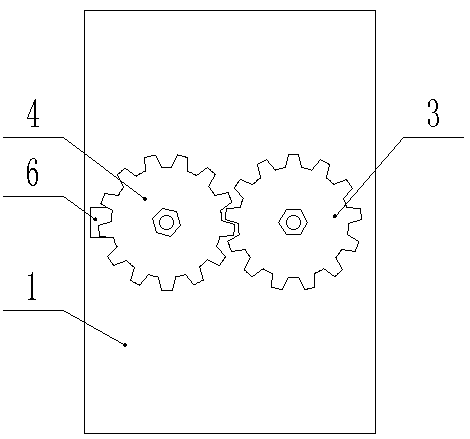

[0021] Such as figure 1 , figure 2 , Figure 4 and Figure 5 Shown: a gear bending machine, including: a platform 1, a motor 2, a driving gear 3, a driven gear 4 and a driven control assembly 5; a motor 2 is arranged under the platform 1, and the output shaft of the motor 2 is vertical It is arranged straight and the output shaft of the motor 2 passes through the platform 1 and can rotate relative to the platform 1. The output shaft of the motor 2 is fixed with a driving gear 3, and the platform 1 is provided with a chute 6. The driven gear 4 and the driving gear 3 meshes and the driven gear 4 can slide along the chute 6, a driven control assembly 5 for fastening the driven gear 4 is arranged between the driven gear 4 and the chute 6, and the driven gear 4 and the driving gear The distance between the 3 meshing teeth is max. 3mm.

[0022] The shape and structure of the driving gear 3 and the driven gear 4 are consistent, and the driving gear 3 includes: a tooth bracket, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com